| [1] |

SCOTT D. A bit of history: Overcoming early setbacks, PDC bits now drill 90%-plus of worldwide footage [J]. Drilling Contractor,2015,71(4):60-68.

|

| [2] |

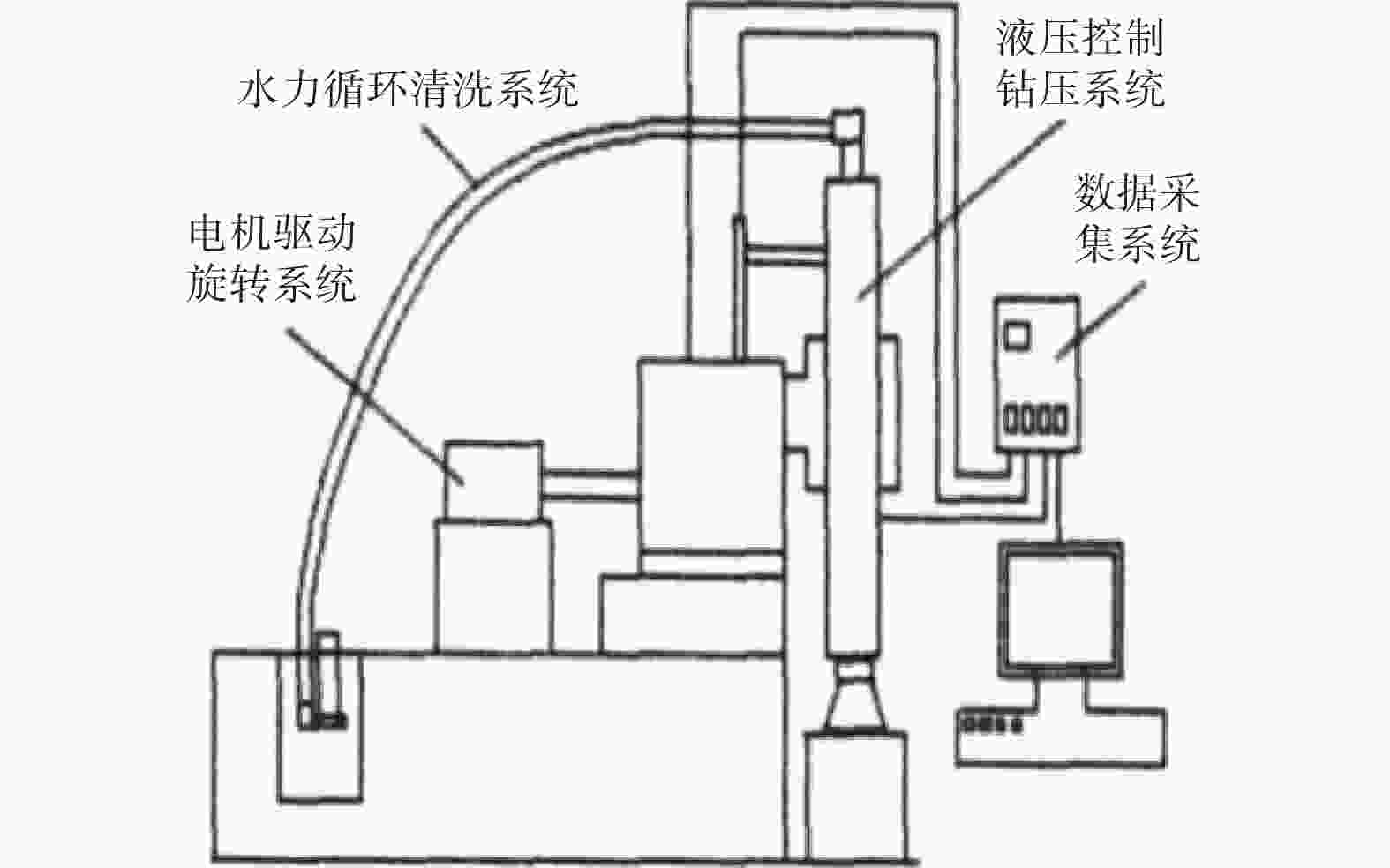

赵昌盛. 刀具破岩机理试验装置设计与仿真研究 [D]. 成都: 西南交通大学, 2016.ZHAO Changsheng. Experimental device design and simulation study on rock breaking mechanism of cutting tools [D]. Chengdu: Southwest Jiaotong University, 2016.

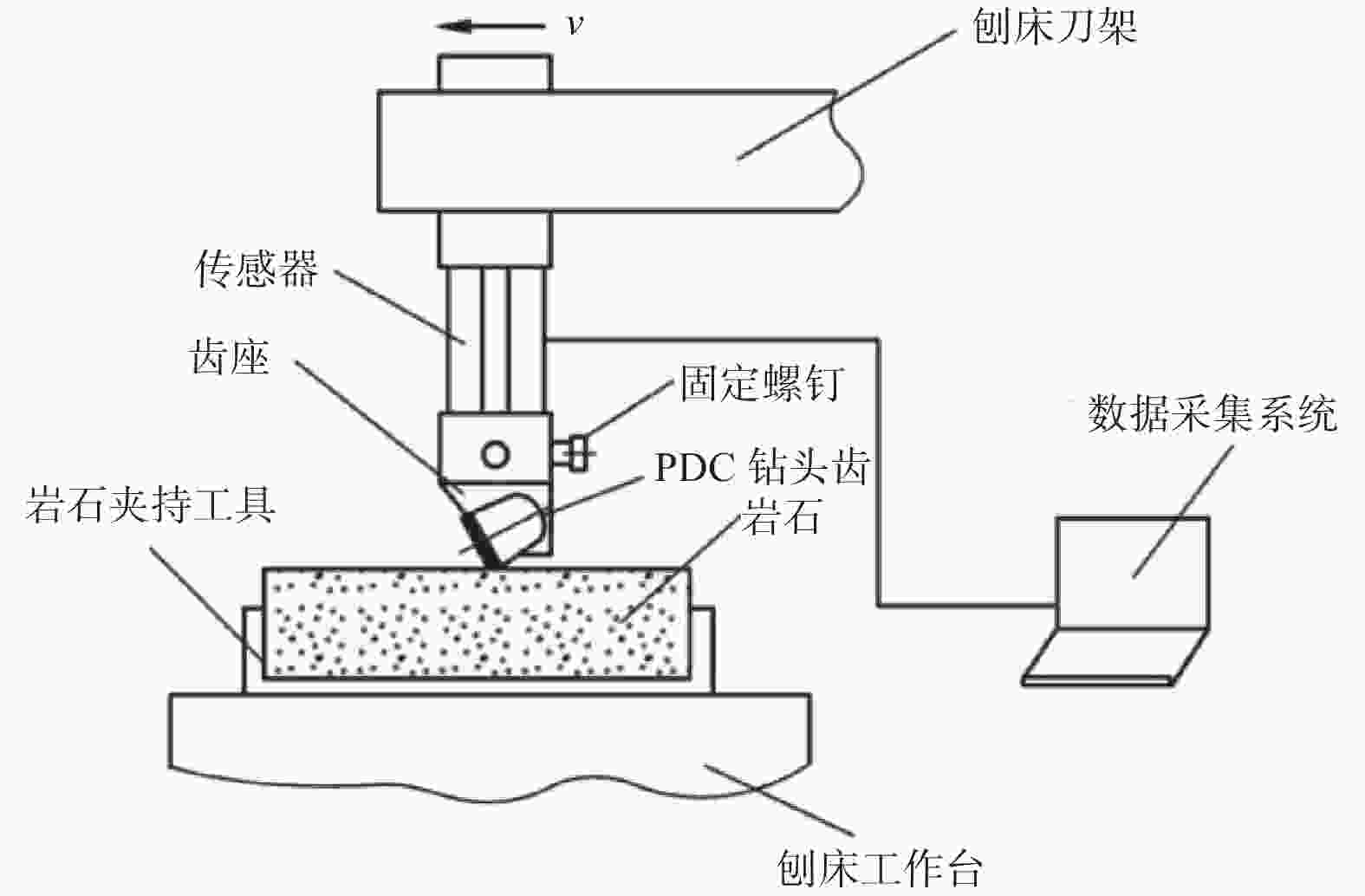

|

| [3] |

龚秋明, 何冠文, 赵晓豹, 等. 掘进机刀盘滚刀间距对北山花岗岩破岩效率的影响实验研究 [J]. 岩土工程学报,2015,37(1):54-60.GONG Qiuming, HE Guanwen, ZHAO Xiaobao, et al. Influence of different cutter spacings on rock fragmentation efficiency of Beishan granite by TBM [J]. Chinese Journal of Geotechnical Engineering,2015,37(1):54-60.

|

| [4] |

邵方源, 刘志强. 排齿间距对镶齿滚刀破岩效果影响试验研究 [J]. 中国煤炭,2016,42(7):59-62.SHAO Fangyuan, LIU Zhiqiang. Experimental study on the effect of tooth row space of inserted tooth hob on rock breaking [J]. Coal Science and Technology Magazine,2016,42(7):59-62.

|

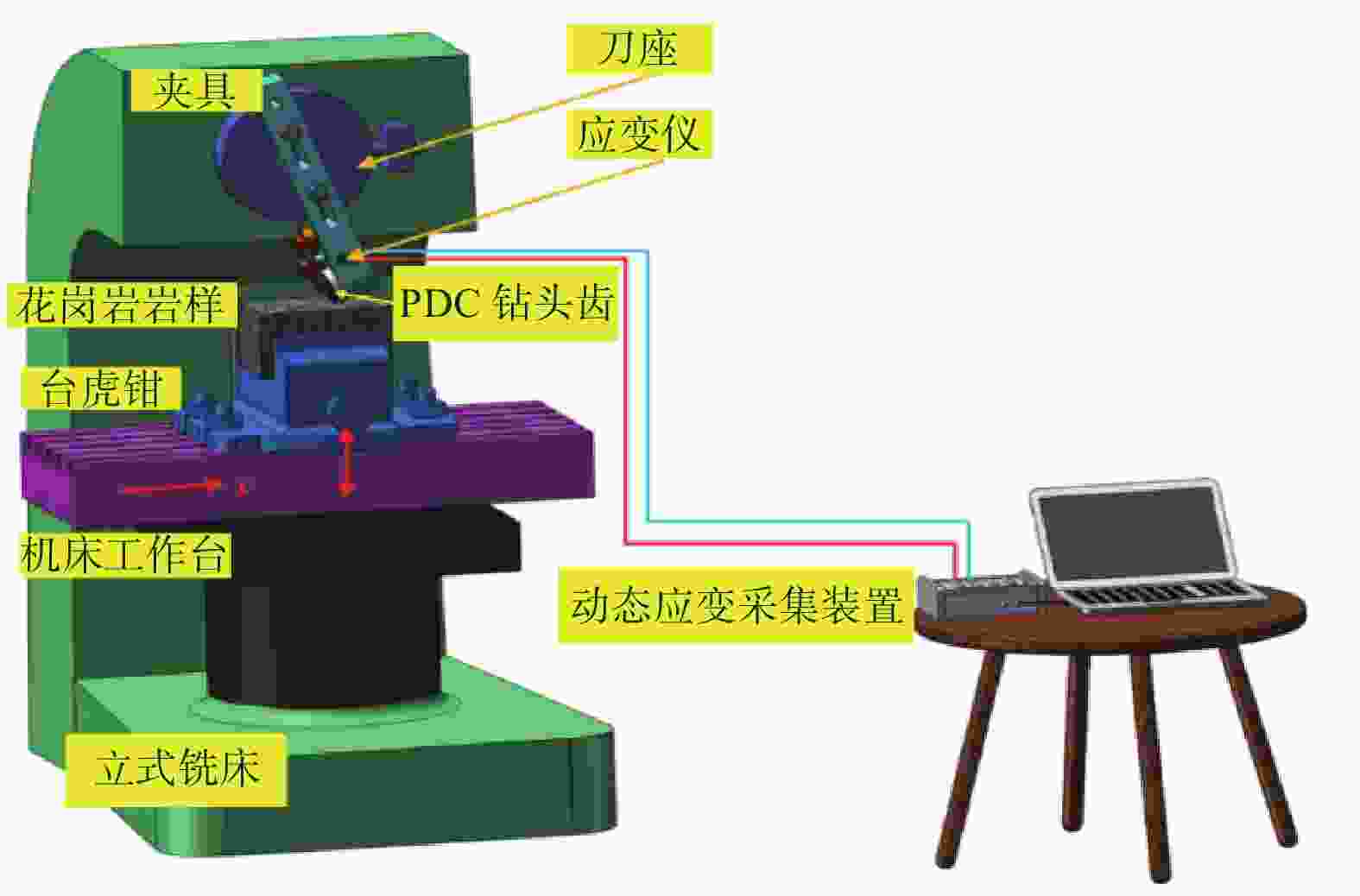

| [5] |

CHE D, ZHANG W, EHMANN K. Chip formation and force responses in linear rock cutting: An experimental study [J]. Journal of Manufacturing Science and Engineering,2017,139(1):011011. doi: 10.1115/1.4033905

|

| [6] |

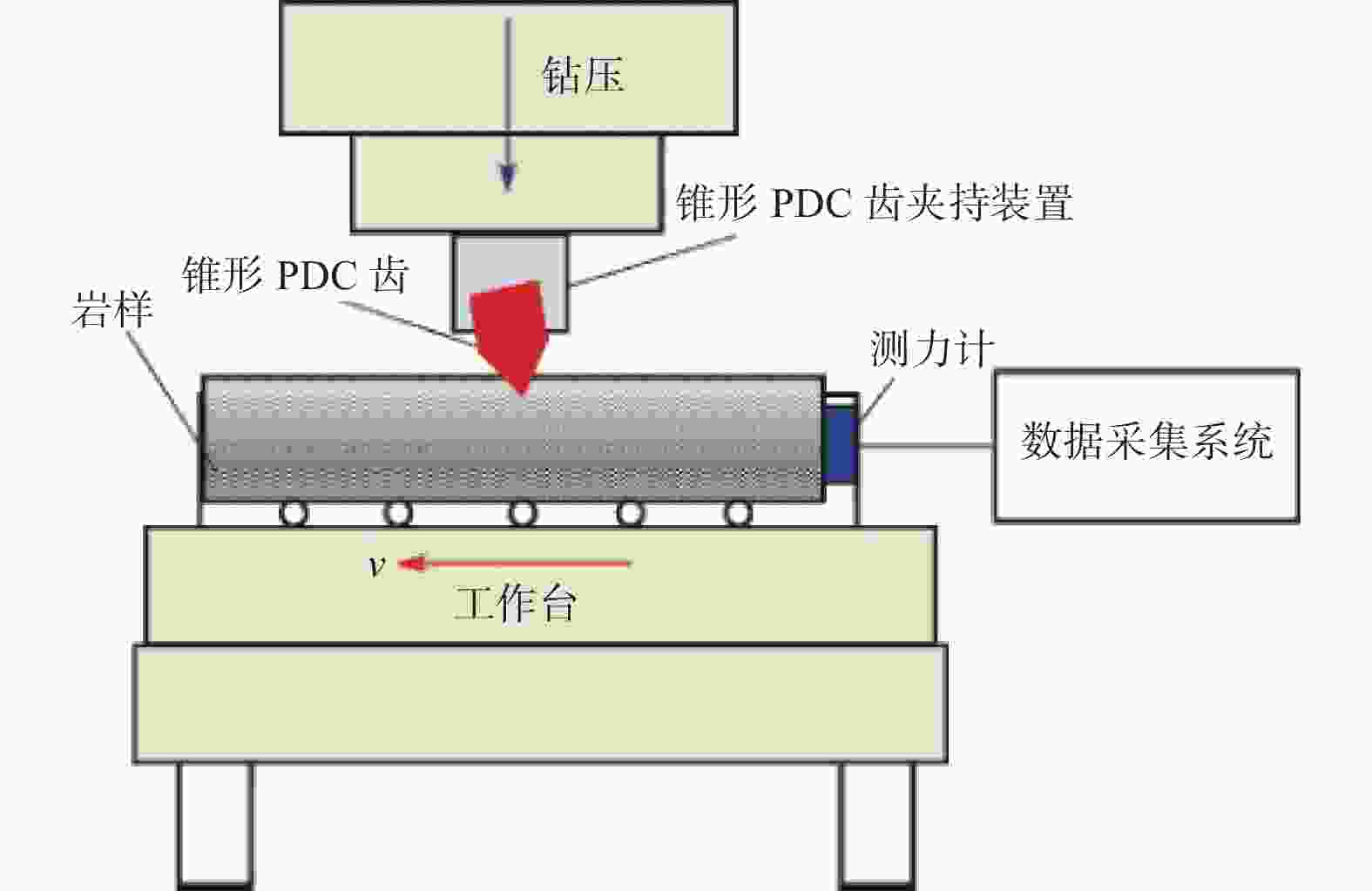

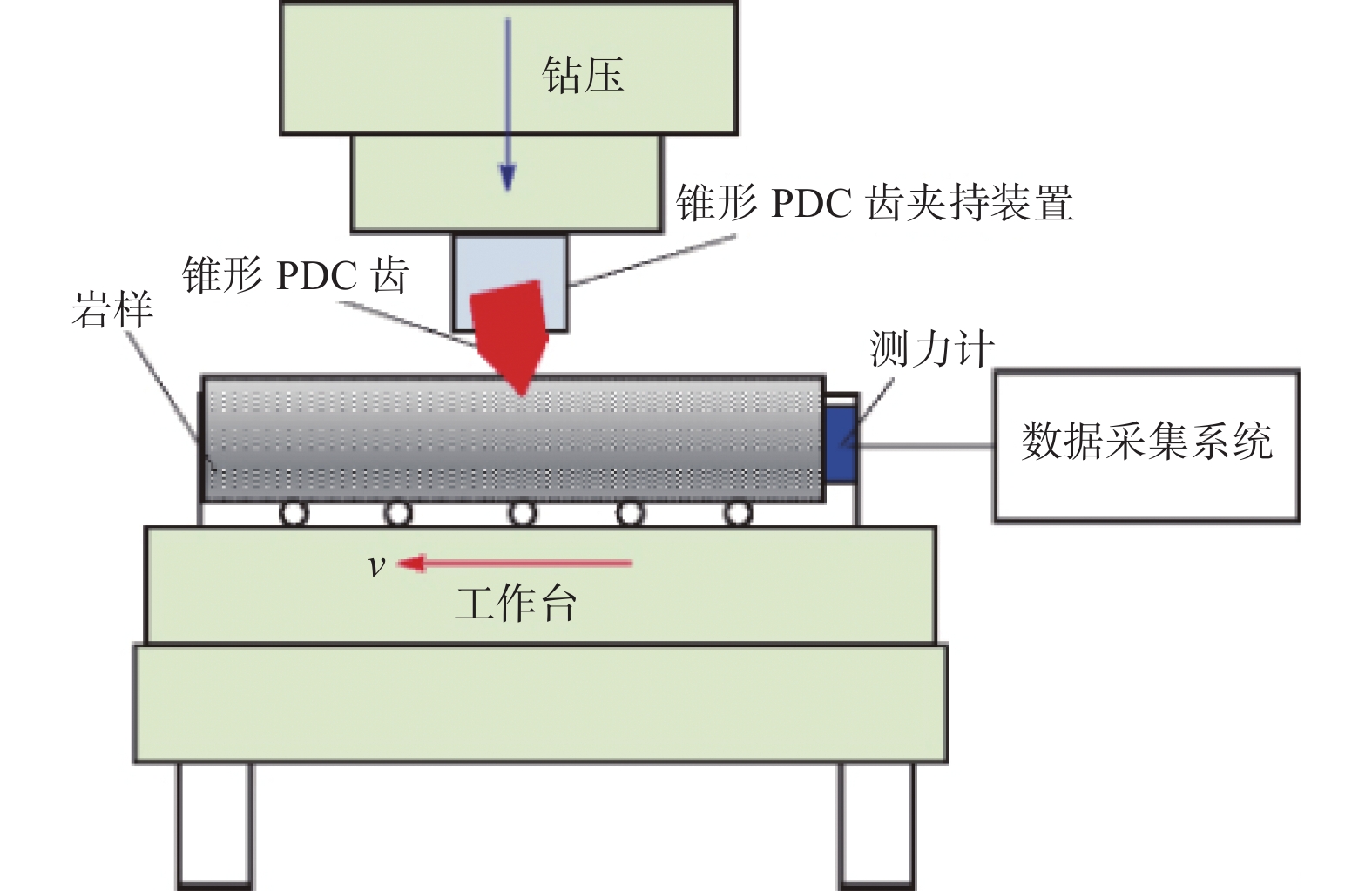

邹德永, 郭玉龙, 赵建, 等. 锥形PDC单齿破岩试验研究 [J]. 石油钻探技术, 2015, 43 (1): 122-125.ZOU Deyong, GUO Yulong, ZHAO Jian, et al. Experimental study on rock breaking of conical PDC cutter [J]. Petroleum Drilling Techniques, 2015, 43(1): 122-125.

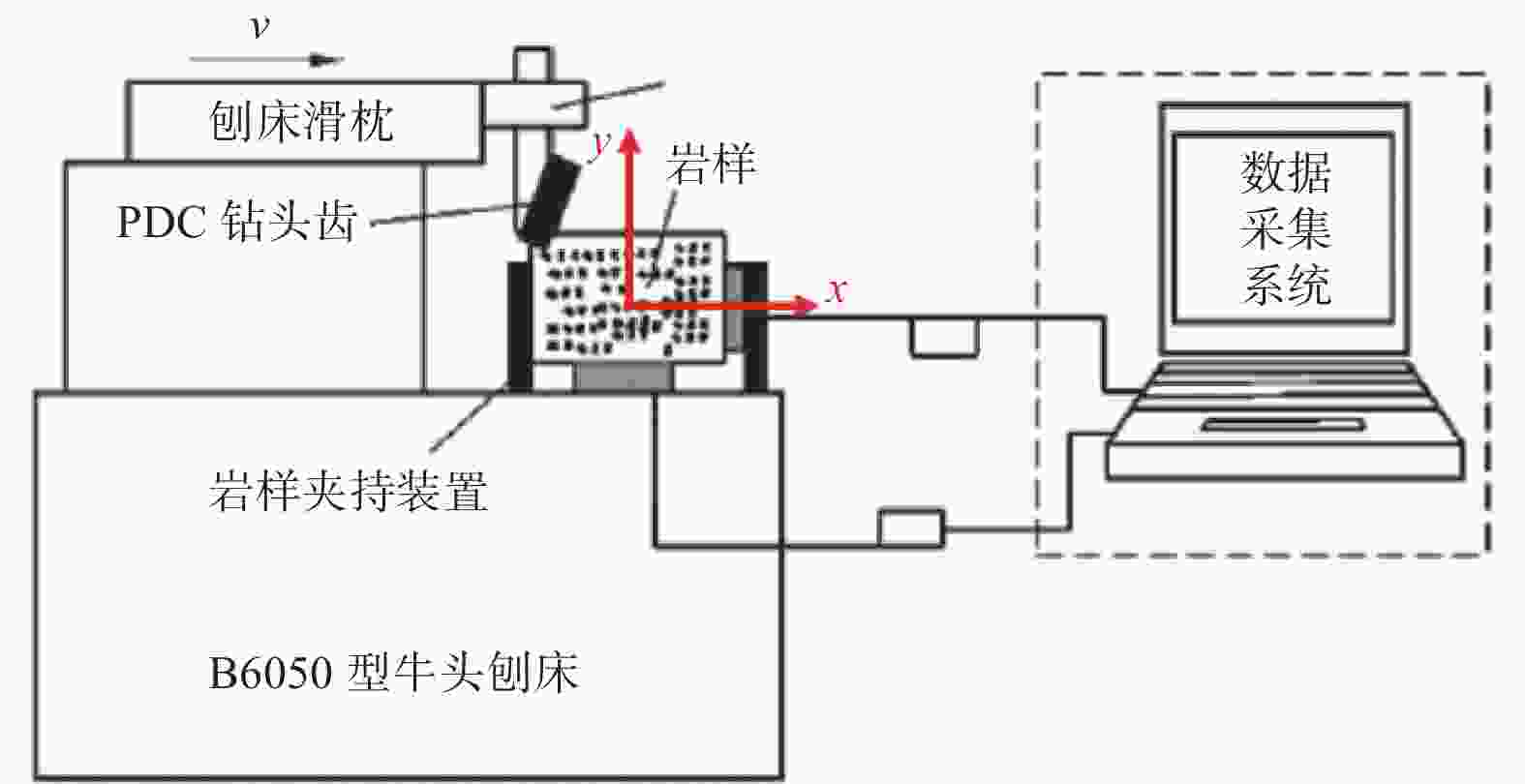

|

| [7] |

孙源秀, 邹德永, 徐城凯, 等. 锥形聚晶金刚石复合片钻头(PDC)齿与常规PDC齿破岩效果对比试验 [J]. 科学技术与工程. 2015, 15(36): 159-162.SUN Yuanxiu, ZOU Deyong, XU Chengkai, et al. Contrast experiment on conical PDC cutter and conventional PDC cutter [J]. Science Technology and Engineering, 2015, 15(36): 159-162.

|

| [8] |

孙源秀, 邹德永, 侯绪田, 等. 锥形PDC齿犁切破岩受力试验研究 [J]. 石油机械. 2014, 42 (9): 23-26.SUN Yuanxiu, ZOU Deyong, HOU Xutian, et al. Test of force of conical PDC cutter during rock plow-breaking [J]. China Petroleum Machinery, 2014, 42(9): 23-26.

|

| [9] |

姜鑫, 邹德永, 王家骏, 等. PDC 切削齿冲击载荷预测模型的试验研究 [J]. 石油机械,2014,42(4):1-3. doi: 10.3969/j.issn.1001-4578.2014.04.001JIANG Xin, ZOU Deyong, WANG Jiajun, et al. Experimental study of the prediction model for impact load on PDC cutters [J]. China Petroleum Machinery,2014,42(4):1-3. doi: 10.3969/j.issn.1001-4578.2014.04.001

|

| [10] |

XIONG C, HUANG Z, YANG R, et al. Comparative analysis cutting characteristics of stinger PDC cutter and conventional PDC cutter [J]. Journal of Petroleum Science and Engineering,2020,189:106792. doi: 10.1016/j.petrol.2019.106792

|

| [11] |

CHENG Z, SHENG M, LI G, et al. Imaging the formation process of cuttings: characteristics of cuttings and mechanical specific energy in single PDC cutter tests [J]. Journal of Petroleum Science and Engineering,2018,171:854-862. doi: 10.1016/j.petrol.2018.07.083

|

| [12] |

杨迎新, 胡浩然, 黄奎林, 等. 环脊式 PDC 钻头破岩机理实验研究 [J]. 地下空间与工程学报,2019,15(5):1451-1460.YANG Yingxin, HU Haoran, HUANG Kuilin, et al. Experimental research on the rock-breaking mechanism of annular-ridge PDC bit [J]. Chinese Journal of Underground Space and Engineering,2019,15(5):1451-1460.

|

| [13] |

CHE D, HAN P, PENG B, et al. Finite element study on chip formation and force response in two-dimensional orthogonal cutting of rock: International manufacturing science and engineering conference [C]. Detroit: ASME, 2014.

|

| [14] |

韩艳浓, 陈军海, 孙连环, 等. 一种确定岩石抗压强度的新技术: 刻划测试 [J]. 科学技术与工程,2015,15(9):151-155.HAN Yannong, CHEN Junhai, SUN Lianhuan, et al. A new technique for determining strength of rocks: Scratch test [J]. Science Technology and Engineering,2015,15(9):151-155.

|

| [15] |

陈军海, 王怡, 韩艳浓, 等. 一种利用岩石强度刻划试验确定岩石PDC钻头可钻性级值的方法 [J]. 中国石油大学学报(自然科学版), 2017, 41 (2): 94-99.CHEN Junhai, WANG Yi, HAN Yannong, et al. A new method for assessing rock′s drillability for PDC bits via a scratch testing [J]. Journal of China University of Petroleum (Edition of Natural Science), 2017, 41(2): 94-99.

|

| [16] |

CRANE D, ZHANG Y, DOUGLAS C, et al. Innovative PDC cutter with elongated ridge combines shear and crush action to improve PDC bit performance: SPE middle east oil & gas show and conference [C]. Manama: OnePetro, 2017.

|

| [17] |

梁尔国, 李子丰, 邹德永. PDC 钻头综合受力模型的试验研究 [J]. 岩土力学,2009,30(4):938-942.LIANG Erguo, LI Zifeng, ZOU Deyong. Experimental research on integrated mechanical model of PDC bit [J]. Rock and Soil Mechanics,2009,30(4):938-942.

|

| [18] |

马清明, 王瑞和. PDC 切削齿破岩受力的试验研究 [J]. 中国石油大学学报(自然科学版),2006,30(2):45-47.MA Qingming, WANG Ruihe. Experimental study on force of PDC cutter breaking rock [J]. Journal of China University of Petroleum (Edition of Natural Science),2006,30(2):45-47.

|

| [19] |

邹德永, 张将海, 王瑞和. PDC 钻头力学模型的试验研究 [J]. 石油钻探技术,2005,33(2):41-43.ZOU Deyong, ZHANG Jianghai, WANG Ruihe. The experiment study on mechanical model of PDC bits [J]. Petroleum Drilling Techniques,2005,33(2):41-43.

|

| [20] |

梁尔国, 李子丰, 邹德永. PDC 切削齿受力的试验研究 [J]. 石油机械,2009,37(11):12-15.LIANG Erguo, LI Zifeng, ZOU Deyong. Experimental study of forces on PDC cutter [J]. China Petroleum Machinery,2009,37(11):12-15.

|

| [21] |

邹德永, 王瑞和. PDC 钻头的岩石研磨性试验研究 [J]. 石油大学学报(自然科学版),2003,27(2):41-43.ZOU Deyong, WANG Ruihe. Experimental study of rock abrasiveness of PDC drill bits [J]. Journal of China University of Petroleum (Edition of Natural Science),2003,27(2):41-43.

|

| [22] |

全国磨料磨具专业化技术委员会. 人造金刚石烧结体磨耗比测定方法: JB/T3235-1999 [S]. 北京: 国家机械工业局, 1999: 05.National Abrasives Specialized Technical Committee. Method for determining the abrasion ratio of synthetic diamond sintered bodies: JB/T3235-1999 [S]. Beijing: State Bureau of Machine Building Industry, 1999: 05.

|

| [23] |

赵云良, 赵爽之, 闫森. 金刚石烧结体(PCD与PDC)的发展概况(四) [J]. 超硬材料工程, 2014, 26: 48-51.ZHAO Yunliang, ZHAO Shuangzhi, YAN Sen. The development of sintered polycrystalline diamond compact (PCD & PDC)(four) [J] Superhard Material Engineering, 2014, 26: 48-51.

|

| [24] |

DURRAND C J, SKEEM M R, HALL D R. Thick PDC, shaped cutters for geothermal drilling: A fixed cutter solution for a roller cone drilling environment: 44th U. S. rock mechanics symposium and 5th U. S.-Canada rock mechanics symposium [C]. Salt Lake City: OnePetro, 2010.

|

| [25] |

SANTANA R, SKOFF G, KROUGH B, et al. Development, testing, and deployment of a new hyperbolic diamond element bit in DJ basin of Colorado: Abu Dhabi international petroleum exhibition & conference [C]. Abu Dhabi: OnePetro, 2019.

|

| [26] |

IZBINSKI K, CARDOE J, BOMIDI J. Increased ROP by 18% in Norway and in other applications through optimizing cutter geometry from laboratory tests, numerical models and field tests: SPE/IADC international drilling conference and exhibition 2019 [C]. The Hague: SPE, 2019.

|

| [27] |

RAHMANI R, PASTUSEK P, YUN G, et al. Investigation of geometry and loading effects on PDC cutter structural integrity in hard rocks: SPE/IADC drilling conference and exhibition [C]. Galveston: SPE, 2020.

|

| [28] |

HAWKINS S, BRACKIN V, AMERI M T. Rolling depth-of-cut control improves tool-face control and overall ROP during steerable motor applications: SPE/IADC drilling conference and exhibition [C]. Galveston: SPE, 2020.

|

| [29] |

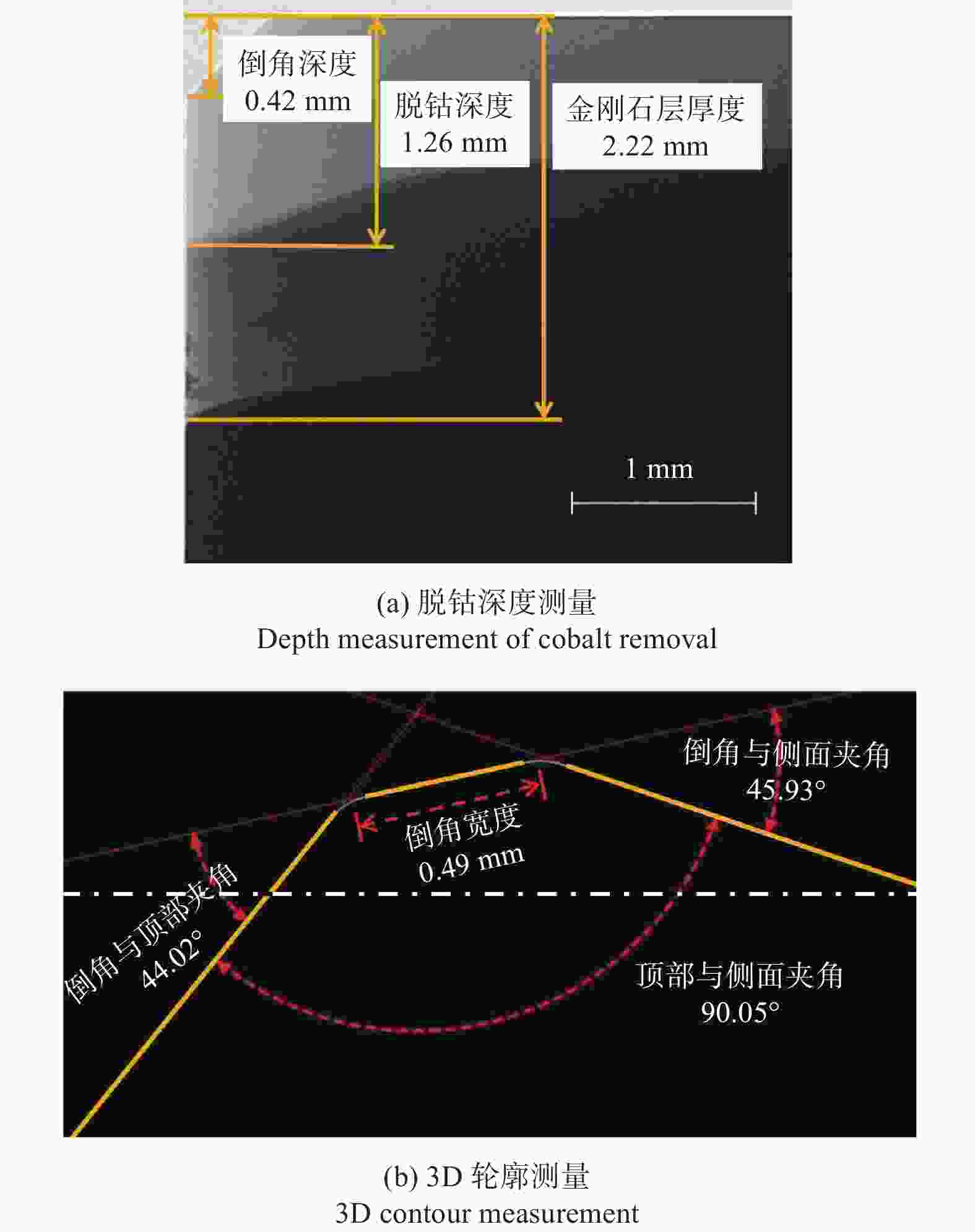

SHAO F, LIU W, GAO D. Effects of the chamfer and materials on performance of PDC cutters [J]. Journal of Petroleum Science and Engineering,2021,205:108887. doi: 10.1016/j.petrol.2021.108887

|

| [30] |

PLEMONS B, DOUGLAS C, SHEN Y, et al. New cutter technology for faster drilling in hard/abrasive formations: SPE International Oil and Gas Conference and Exhibition in China [C]. Beijing: SPE, 2010.

|

| [31] |

赵东鹏, 马姗姗, 牛同健, 等. 硬质岩层钻探用曲面聚晶金刚石复合片的性能表征 [J]. 金刚石与磨料磨具工程,2016,36(6):83-86.ZHAO Dongpeng, MA Shanshan, NIU Tongjian, et al. Characterization of polycrystalline diamond compact with non-planar surfaces for drilling hard-formation [J]. Diamond & Abrasives Engineering,2016,36(6):83-86.

|

| [32] |

王滨, 邹德永, 林森, 等. 锥形PDC齿耐磨性能试验研究 [J]. 石油机械,2015,43(7):23-26.WANG Bin, ZOU Deyong, LIN Sen, et al. Wear resistance test of conical PDC cutter [J]. China Petroleum Machinery,2015,43(7):23-26.

|

| [33] |

LYONS N, IZBINSKI K, PAULI A, et al. Footage in STACK lateral of Oklahoma increased by 185% through new non-planar PDC cutter geometry development and implementation: SPE/IADC Drilling Conference and Exhibition [C]. Fort Worth: SPE, 2018.

|

| [34] |

CURRY D A, LOURENÇO A M, LEDGERWOOD III L W, et al. The effect of borehole pressure on the drilling process in salt [J]. SPE Drilling & Completion,2017,32(1):25-41.

|

| [35] |

RAFATIAN N, MISKA S, LEDGERWOOD L W W, et al. Experimental study of MSE of a single PDC cutter interacting with rock under simulated pressurized conditions [J]. SPE Drilling & Completion,2010,25(1):10-18.

|

| [36] |

RAJABOV V, MISKA S, MORTIMER L, et al. The effects of back rake and side rake angles on mechanical specific energy of single PDC cutters with selected rocks at varying depth of cuts and confining pressures: SPE/IADC drilling conference and exhibition [C]. San Diego: SPE, 2012.

|

| [37] |

AKBARI B, MISKA S Z. Modern experimental design techniques reveal the significance of depth of cut in PDC cutter performance [J]. Journal of Energy Resources Technology, 2016, 139(2): 4034291.

|

| [38] |

未九森, 邵方源, 谭紫阳 , 等. PDC切削齿直径对切削力的影响规律研究 [J]. 石油机械,2023,51(4):8-15.WEI Jiusen, SHAO Fangyuan, TAN Ziyang, et al. Influence of PDC cutter diameter on cutting force [J]. China Petroleum Machinery,2023,51(4):8-15.

|

| [39] |

邹德永, 蔡环. 布齿参数对 PDC 钻头破岩效率影响的试验 [J]. 中国石油大学学报(自然科学版),2009,33(5):76-79.ZOU Deyong, CAI Huan. Experiment on effect of cutter parameters of PDC bit on rate of penetration [J]. Journal of China University of Petroleum (Edition of Natural Science),2009,33(5):76-79.

|

| [40] |

于鹏. 适应硬地层的犁削型 PDC 钻头研究 [D]. 青岛: 中国石油大学 (华东), 2013.YU Peng. Research on plow type PDC drill bit adapted to hard formation [D]. Qingdao: China University of Petroleum (East China), 2013.

|

| [41] |

杨顺辉. 锥形PDC齿钻头的研制及室内试验评价 [J]. 石油机械,2015,43(2):14-17.YANG Shunhui. Development and laboratory tests evaluation of PDC bit with conical cutter [J]. China Petroleum Machinery,2015,43(2):14-17.

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS