Performance of thermal field-assisted precision lapping for single crystal sapphire wafers

-

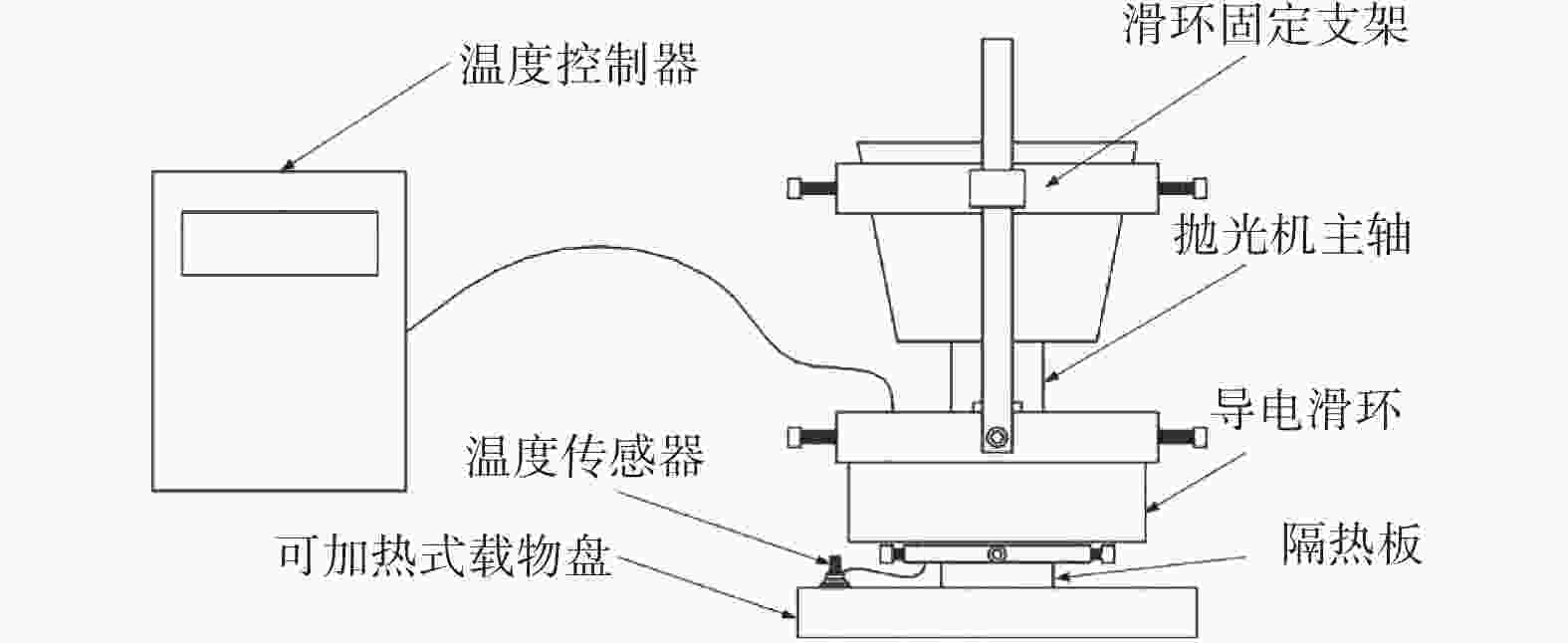

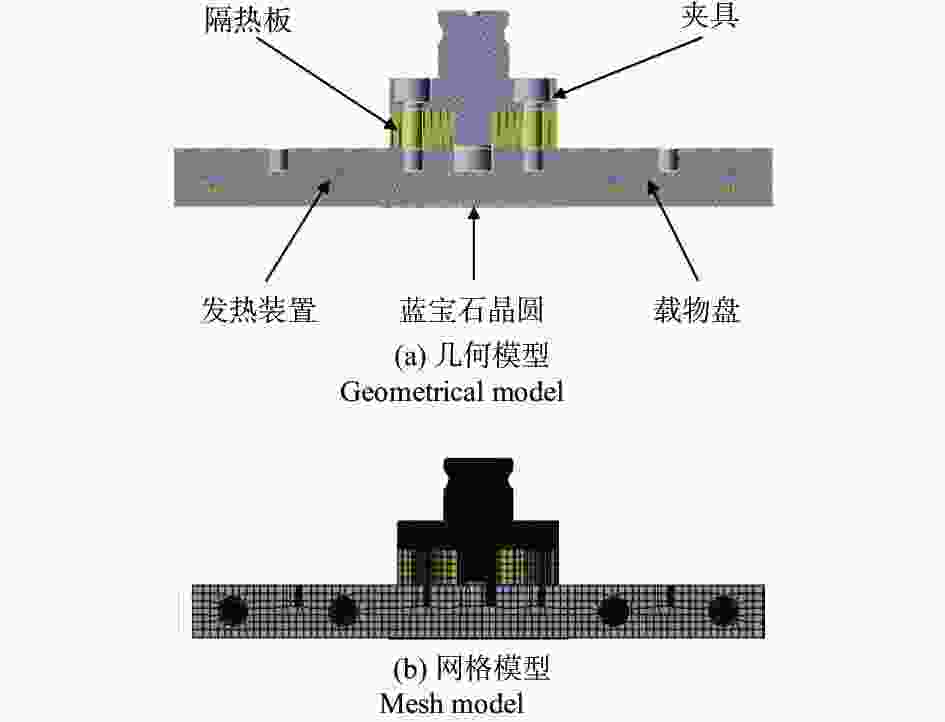

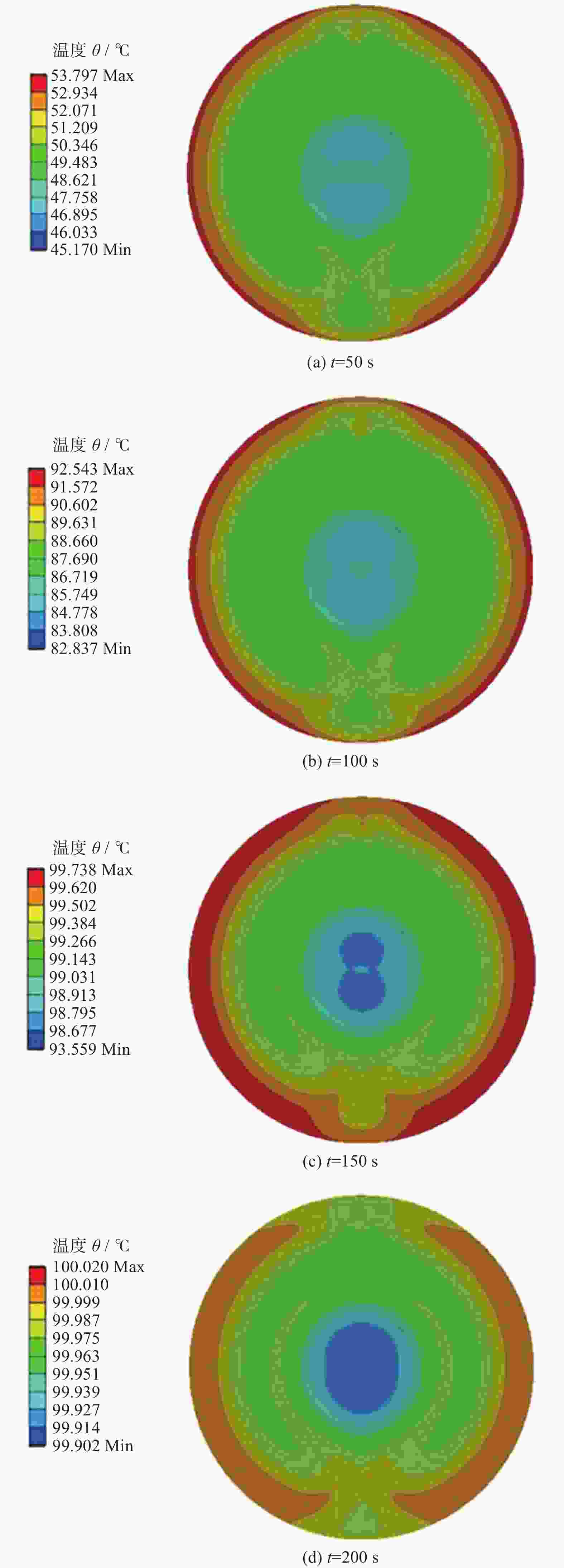

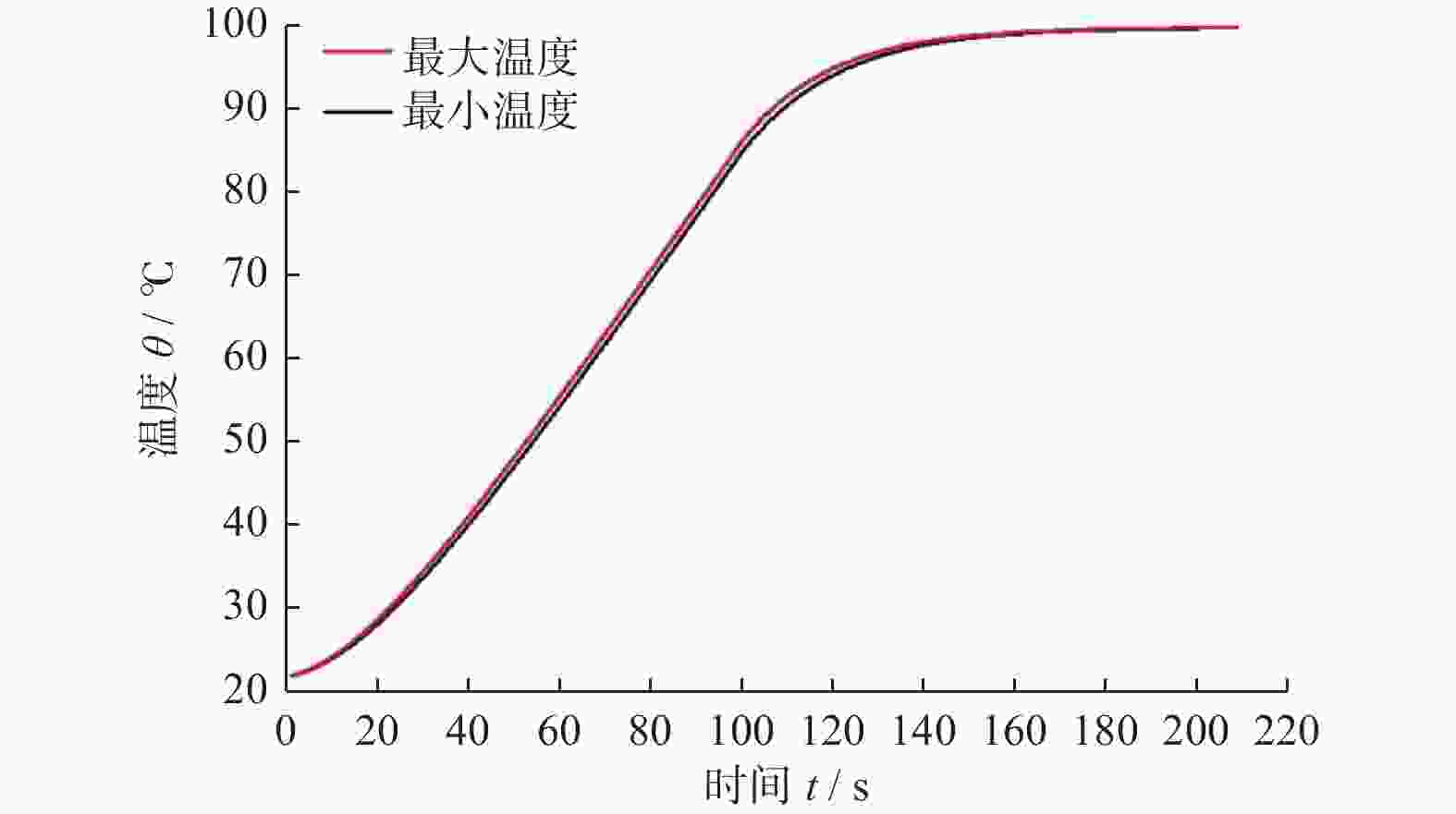

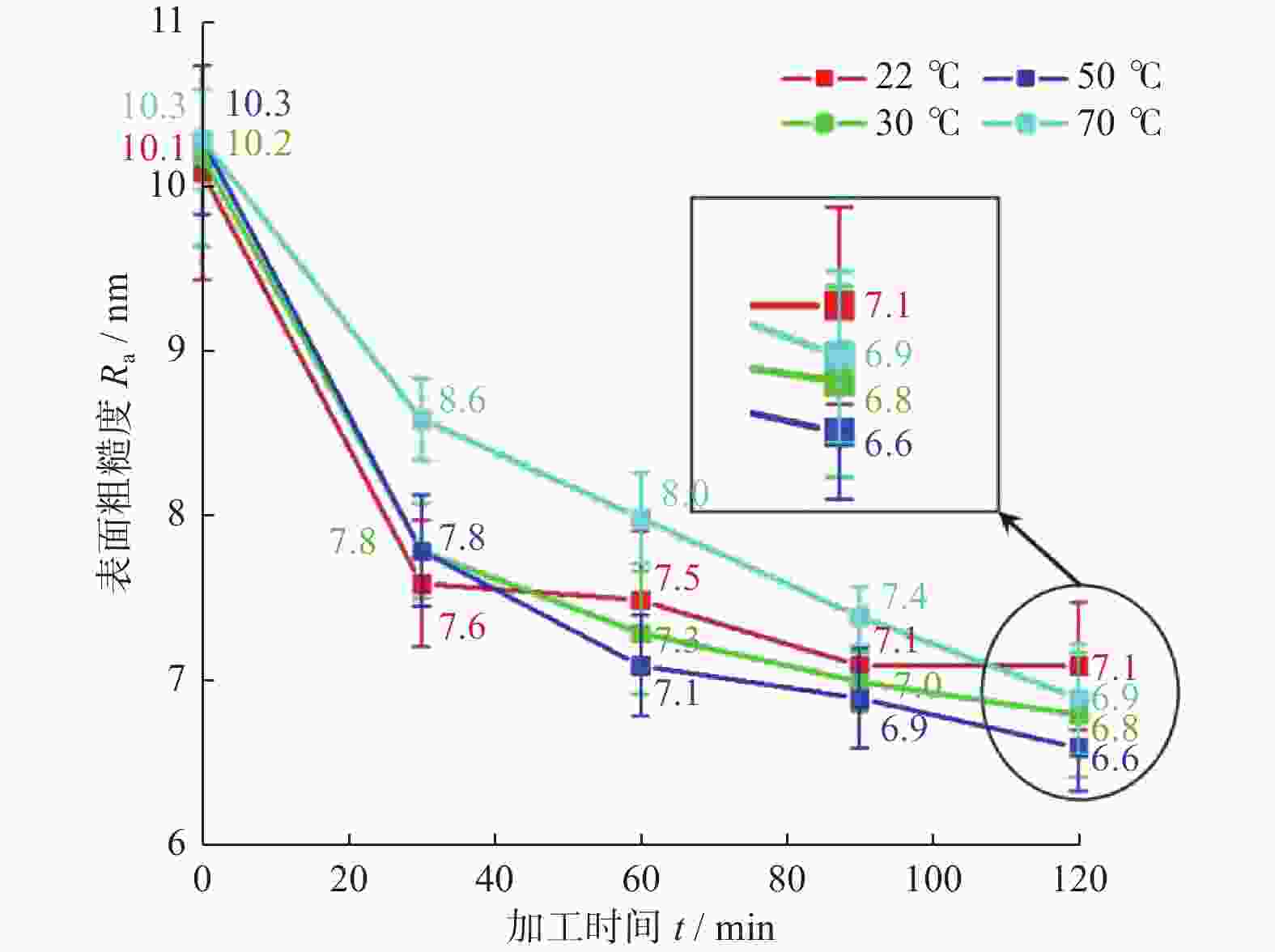

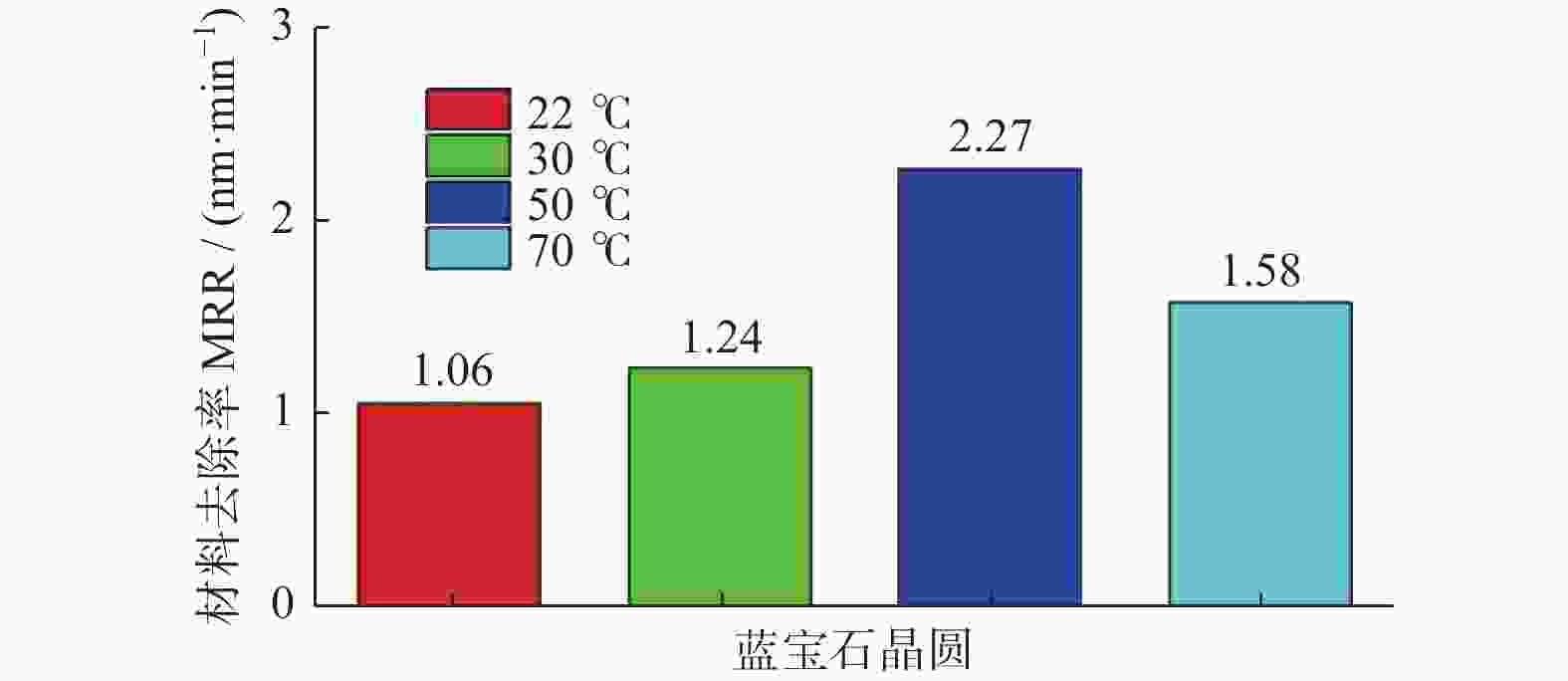

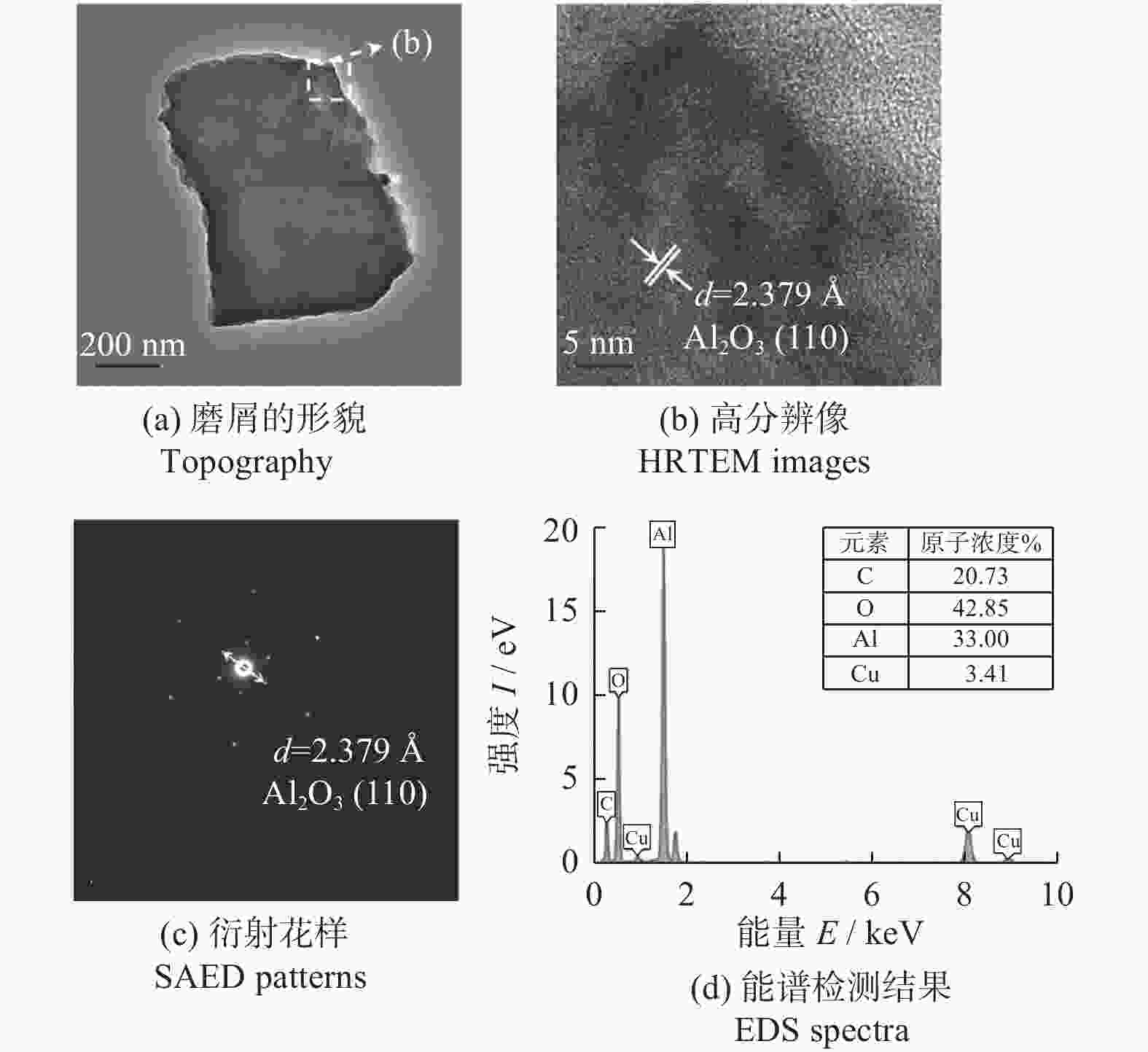

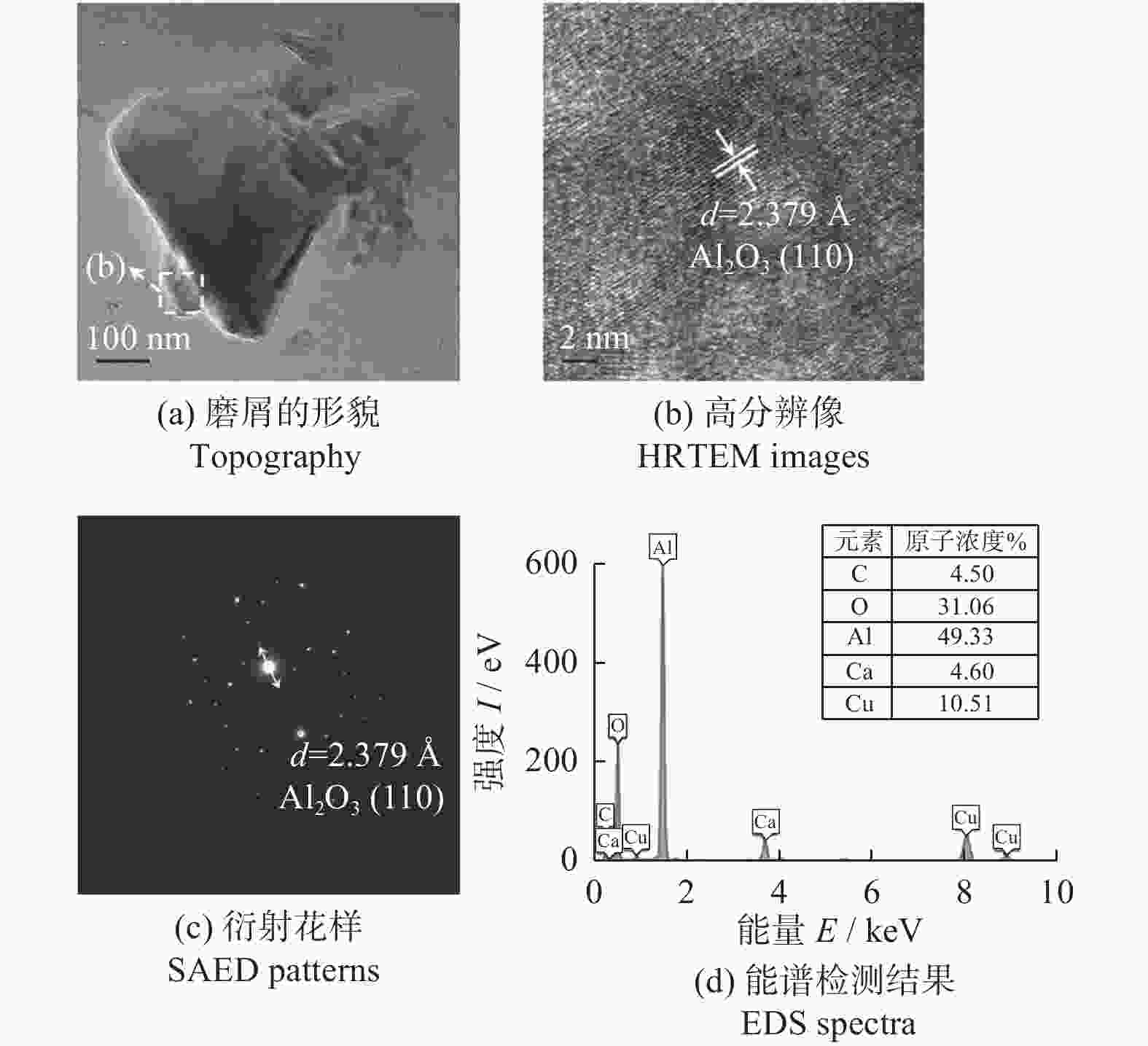

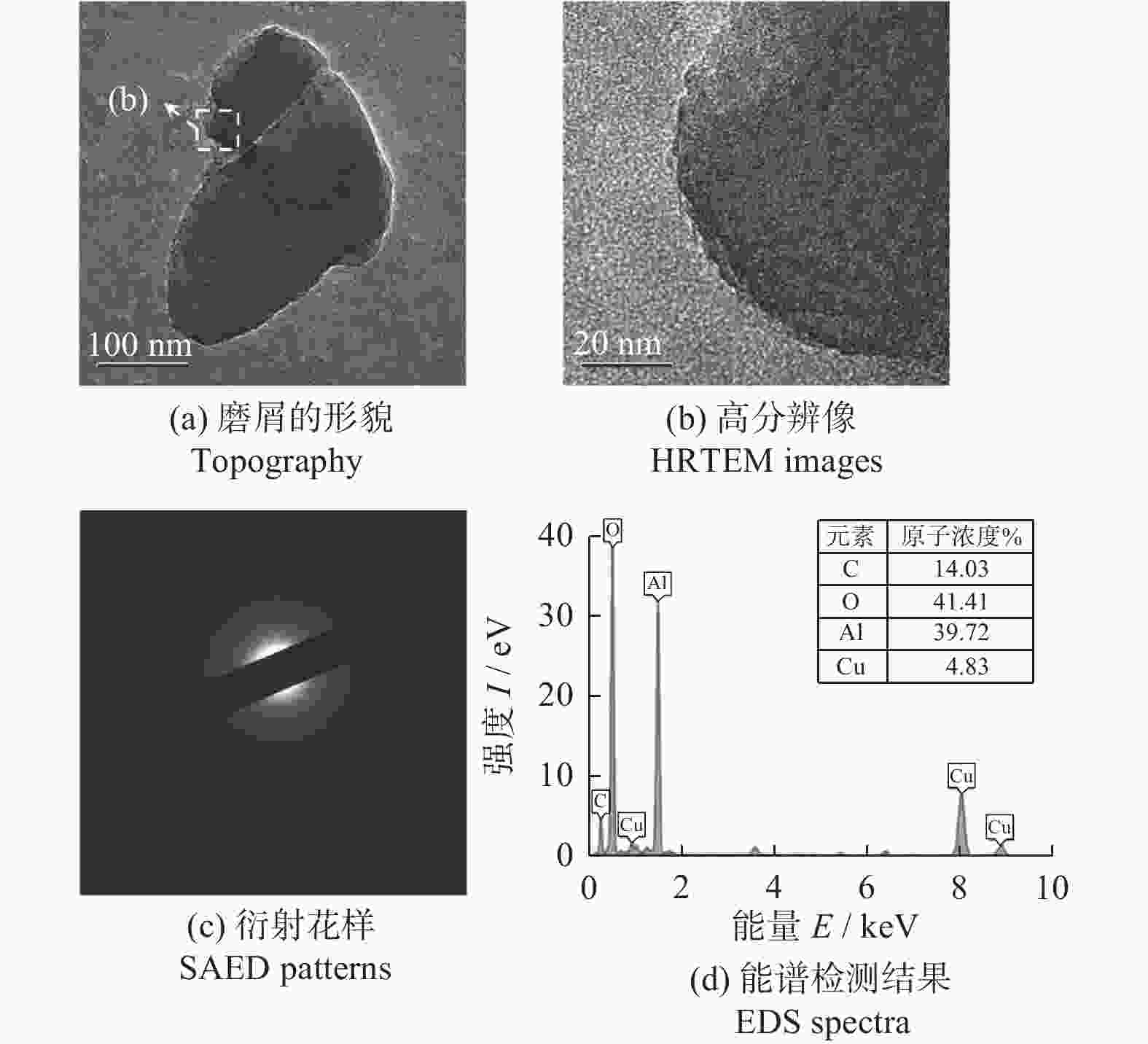

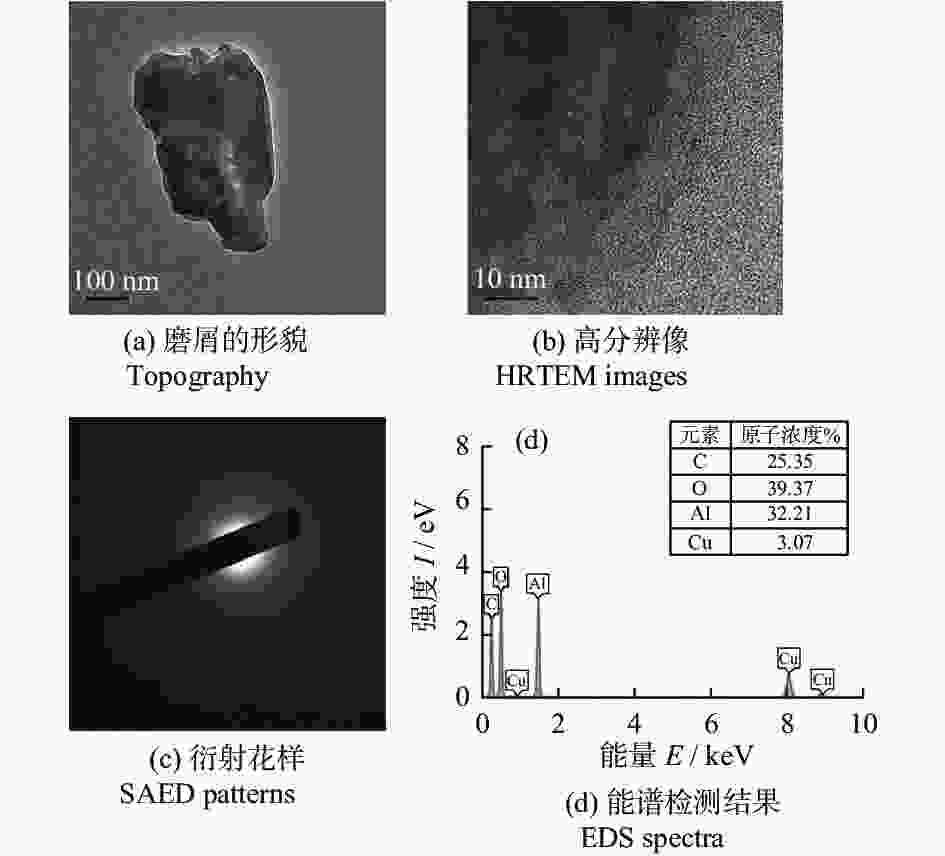

摘要: 针对传统蓝宝石晶圆精磨加工表面质量差、效率低下的难题,提出热场辅助蓝宝石晶圆加工技术,研究热场辅助对蓝宝石晶圆精研加工性能的影响。通过自行设计的热场辅助装置控制加工区温度,基于半固结柔性磨具,在不同加工区温度条件下对蓝宝石晶圆进行精研加工,对比分析加工区温度对其加工性能的影响,并深入探讨材料去除机理。仿真结果表明,自行设计的热场辅助装置可使精研加工区迅速达到设定温度,且整个过程中晶圆的温度差<1.3 ℃。与室温下的加工结果相比,当加工区温度控制在50.0 ℃时,蓝宝石晶圆的表面粗糙度下降了6%,材料去除率提高了近114.2%。磨屑检测结果表明,提高加工区温度后,晶圆表面材料在去除过程中发生晶态结构转变,提高了蓝宝石加工过程中的水合反应速率,从而提高了材料去除率。热场辅助蓝宝石晶圆精研加工可同时获得较高的表面质量和加工效率,具有广阔的应用前景。Abstract: To address the issues of poor surface quality and low efficiency in conventional sapphire wafer lapping processing, a thermal field-assisted processing technology was proposed. The influence of thermal field-assistance on sapphire wafer lapping performance was investigated. While controlling the temperature of the processing area with a self-designed thermal field-assisted device, the lapping tests of sapphire wafers were performed under different processing area temperatures using a semi-fixed flexible machining tool. The effect of processing area temperature on lapping performance was thoroughly examined, along with the material removal mechanism. The simulation results show that the processing area can be quickly heated by a self-designed thermal field-assisted device, and the temperature difference between different areas of the wafer is less than 1.3℃. When the processing area temperature was controlled at 50℃, the surface roughness of sapphire wafers decreased by 6%, and the material removal rate (MRR) improved by nearly 114.2% compared to room temperature. The wear debris test results show that with the increase in processing area temperature during the removal process, the crystal structure of the wafer surface material changed, leading to an improved hydration reaction rate during processing and resulting in a high MRR. Thermal field-assisted precision lapping of sapphire wafers can achieve high surface quality while also increasing processing efficiency, which has a wide range of applications.

-

Key words:

- sapphire wafer /

- thermal field-assisted /

- precision lapping /

- surface roughness /

- removal mechanism

-

表 1 材料性能参数

Table 1. Parameters of material property

材料 密度ρ/

(kg·m−3)弹性模量E/ (N·m−2) 泊松比μ 比热容C/ (J·kg−1·K−1) 热导率 λ/ (W·m−1·K−1) 蓝宝石 3 975 3.8 × 1011 0.29 782 24.00 镍铬合金 8 400 2.1 × 1011 0.25 460 15.00 云母 2 450 2.1 × 106 0.18 2 422 0.43 304 7 900 1.9 × 1011 0.30 480 16.20 1Cr13 7 750 2.2 × 1011 0.30 473 25.10 表 2 单晶蓝宝石晶圆精研加工工艺参数

Table 2. Precision lapping process parameters of single crystal sapphire wafer

加工参数 条件 载物盘转速 v/( r·min−1) 60 磨具转速 f /( r·min−1) 120 工作压力F/Pa 5 冷却液 去离子水 加工时间 t/ min 120 加工温度 θ/ ℃ 22,30,50,70 冷却液温度 θ1 / ℃ 22,30,50,70 -

[1] LI Z, DENG Z, HU Y. Effects of polishing parameters on surface quality in sapphire double-sided CMP [J]. Ceramics International,2020,46(9):13356-13364. doi: 10.1016/j.ceramint.2020.02.116 [2] LYE C S M, WANG Z, LAM Y C. Multi-Foci division of nonlinear energy absorption on ultrashort pulse laser singulation of sapphire wafers [J]. Micromachines,2021,12(11):1328. doi: 10.3390/mi12111328 [3] ZHANG Z, LIU J, HU W, et al. Chemical mechanical polishing for sapphire wafers using a developed slurry [J]. Journal of Manufacturing Processes,2021,62:762-771. doi: 10.1016/j.jmapro.2021.01.004 [4] BHATTACHARYA M, DEY A, MUKHOPADHYAY A K. Influence of loading rate on nanohardness of sapphire [J]. Ceramics International,2016,42(12):13378-13386. doi: 10.1016/j.ceramint.2016.05.091 [5] SHI X, PAN G, ZHOU Y, et al. A study of chemical products formed on sapphire (0001) during chemical-mechanical polishing [J]. Surface and Coatings Technology,2015,270:206-220. doi: 10.1016/j.surfcoat.2015.02.053 [6] 万林林, 戴鹏, 刘志坚, 等. 蓝宝石超精密研磨加工研究进展 [J]. 兵器材料科学与工程,2018,41(1):115-123. doi: 10.14024/j.cnki.1004-244x.20180102.004WAN Linlin, DAI Peng, LIU Zhijian, et al. Research progress in ultra-precision lapping process of sapphire [J]. Ordnance Material Science and Engineering,2018,41(1):115-123. doi: 10.14024/j.cnki.1004-244x.20180102.004 [7] 杨建东, 朱艳秋, 任长根, 等. 机械密封研磨磨具均匀磨损探讨 [J]. 农业机械学报,1998(1):109-113. doi: 10.3969/j.issn.1000-1298.1998.01.023YANG Jiandong, ZHU Yanqiu, REN Changgen, et al. Probing lapping tool well-distributed wear in lapping mechanical seals [J]. Transactions of the Chinese Society for Agricultural Machinery,1998(1):109-113. doi: 10.3969/j.issn.1000-1298.1998.01.023 [8] 杨建东, 田春林, 金海峰. 固着磨料研磨对工件表面残余应力的影响 [J]. 中国表面工程,2002(4):37-38. doi: 10.3321/j.issn:1007-9289.2002.04.008YANG Jiandong, TIAN Chunlin, JIN Haifeng. Effect of solid abrasive lapping on residual surface stress [J]. China Surface Engineering,2002(4):37-38. doi: 10.3321/j.issn:1007-9289.2002.04.008 [9] 朱永伟, 付杰, 居志兰, 等. 材料特性对亲水性固结磨料研磨垫加工性能的影响 [J]. 纳米技术与精密工程,2013,11(1):51-56. doi: 10.13494/j.npe.2013.010ZHU Yongwei, FU Jie, JU Zhilan, et al. Influence of material characteristics on machining performance of hydrophilic fixed abrasive pad [J]. Nanotechnology and Precision Engineering,2013,11(1):51-56. doi: 10.13494/j.npe.2013.010 [10] 林智富, 高尚, 康仁科, 等. 固结金刚石研磨盘加工蓝宝石基片的磨削性能研究 [J]. 人工晶体学报,2016,45(5):1317-1322. doi: 10.3969/j.issn.1000-985X.2016.05.030LIN Zhifu, GAO Shang, KANG Renke, et al. Research on grinding performance of fixed-abrasive diamond lapping plates for sapphire substrates [J]. Journal of Synthetic Crystals,2016,45(5):1317-1322. doi: 10.3969/j.issn.1000-985X.2016.05.030 [11] 臧江龙. 单晶蓝宝石基片固结磨料机械化学抛光技术 [D]. 大连: 大连理工大学, 2013.ZANG Jianglong. Fixed abrasive mechanical chemical polishing of single crystal sapphire substrate [D]. Dalian: Dalian University of Technology, 2013. [12] LU J, LUO Q, XU X, et al. Removal mechanism of 4H- and 6H-SiC substrates (0001 and 0001) in mechanical planarization machining [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2019,233(1):69-76. doi: 10.1177/0954405417718595 [13] GIORDANO F R, FOX W P, HORTON S B. A first course in mathematical modeling [M]. Stamford: Cengage Learning, 2013. [14] LI J, WANG Z P, LIU W X, et al. Numerical simulation of tire steady-state temperature field based on ANSYS workbench [J]. Key Engineering Materials,2012,501:382-387. doi: 10.4028/www.scientific.net/KEM.501.382 [15] WANG X, LEI H, CHEN R. CMP behavior of alumina/metatitanic acid core-shell abrasives on sapphire substrates [J]. Precision Engineering,2017,50:263-268. doi: 10.1016/j.precisioneng.2017.05.013 [16] XIE W, ZHANG Z, LIAO L, et al. Green chemical mechanical polishing of sapphire wafers using a novel slurry [J]. Nanoscale,2020,12(44):22518-22526. doi: 10.1039/D0NR04705H [17] 赵之琳, 李薇薇, 钱佳, 等. 不同粒径纳米二氧化硅磨料对蓝宝石CMP去除机制的影响 [J]. 电镀与涂饰,2021,40(9):720-725. doi: 10.19289/j.1004-227x.2021.09.013ZHAO Zhilin, LI Weiwei, QIAN Jia, et al. Removal mechanism of sapphire during CMP using nano-silica abrasives with different sizes [J]. Electroplating & Finishing,2021,40(9):720-725. doi: 10.19289/j.1004-227x.2021.09.013 [18] XU Y, ZHAO G, WANG Q, et al. Synthesis of Al2O3/SiO2 core-shell composite abrasives toward ultrasmooth and high-efficiency polishing for sapphire wafers [J/OL]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering,(2022-11-19) [2022-09-21].https://journals.sagepub.com/doi/10.1177/09544089221124226 [19] 冯军. 水合辅助超声磨料流抛光蓝宝石微腔体技术研究 [D]. 长春: 吉林大学, 2019.FENG Jun. Hydration-assisted ultrasonic abrasive flow polishing technology on sapphire microcavity [D]. Changchun: Jilin University, 2019. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS