Effect of Si3N4 substrate surface roughness on the wear resistance of diamond film prepared by HFCVD

-

摘要:

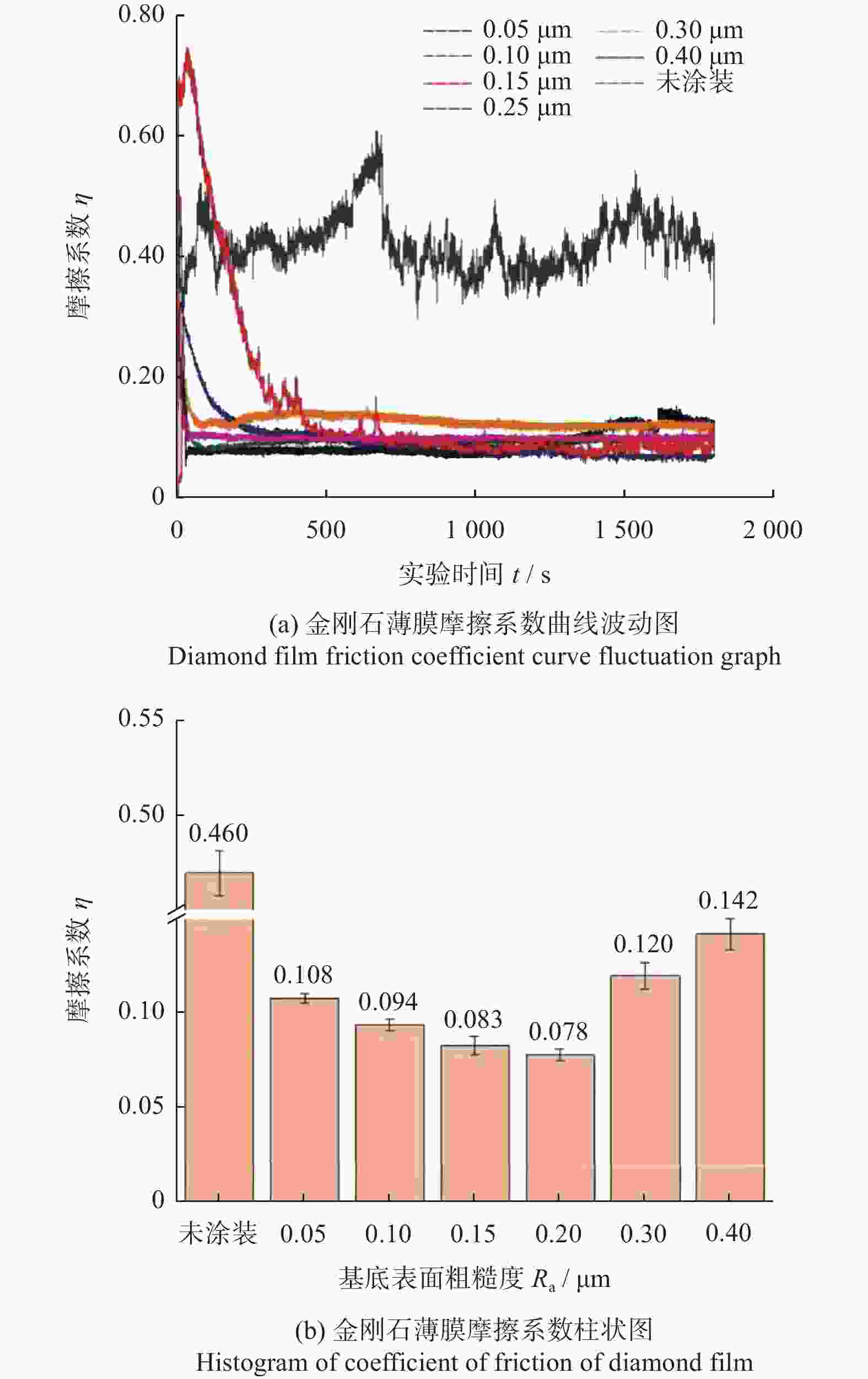

采用热丝化学气相沉积法(hot filament chemical vapour deposition,HFCVD)在不同表面粗糙度的Si3N4基底表面制备金刚石薄膜,并对薄膜的特性进行检测与分析。利用场发射电子扫描显微镜、原子力显微镜检测植晶后的Si3N4基底表面以及制备的金刚石薄膜表面形貌;利用多功能摩擦磨损实验机、探针式轮廓仪,在干摩擦条件下,测试金刚石薄膜的摩擦系数及磨损率。综合基底粗糙度对植晶质量的影响、金刚石薄膜表面形貌与摩擦磨损检测实验结果,确定了Si3N4基底表面粗糙度对金刚石薄膜耐磨性的影响。结果表明:基底表面粗糙度会影响植晶的均匀性及致密性,进而影响金刚石颗粒在基底表面的生长,同时基底的表面形貌也会复映在金刚石薄膜表面。表面粗糙度为0.15 μm和0.20 μm的基底所制备的金刚石薄膜拥有较好的耐磨性,可得到最低的磨损率1.75 × 10−7 mm3/(m·N)和最低的摩擦系数0.078。

Abstract:[OBJECTIVES] Silicon nitride engineering ceramic materials are widely used in microelectronics and wear-resistant components due to their excellent physicochemical properties and mechanical stability under severe working conditions. However, silicon nitride ceramics suffer from brittleness, poor plastic deformation, and a tendency for brittle fracture, which limits their reliability in components for reducing wear and enhancing resistance. With the development of CVD technology, diamond-coated silicon nitride materials show great potential for wide application. Research indicates that the substrate surface roughness affects the properties of diamond films. In this study, diamond films were prepared by HFCVD with silicon nitride ceramic substrates of varying roughness to investigate the effect of substrate surface roughness on the tribological properties of diamond films.

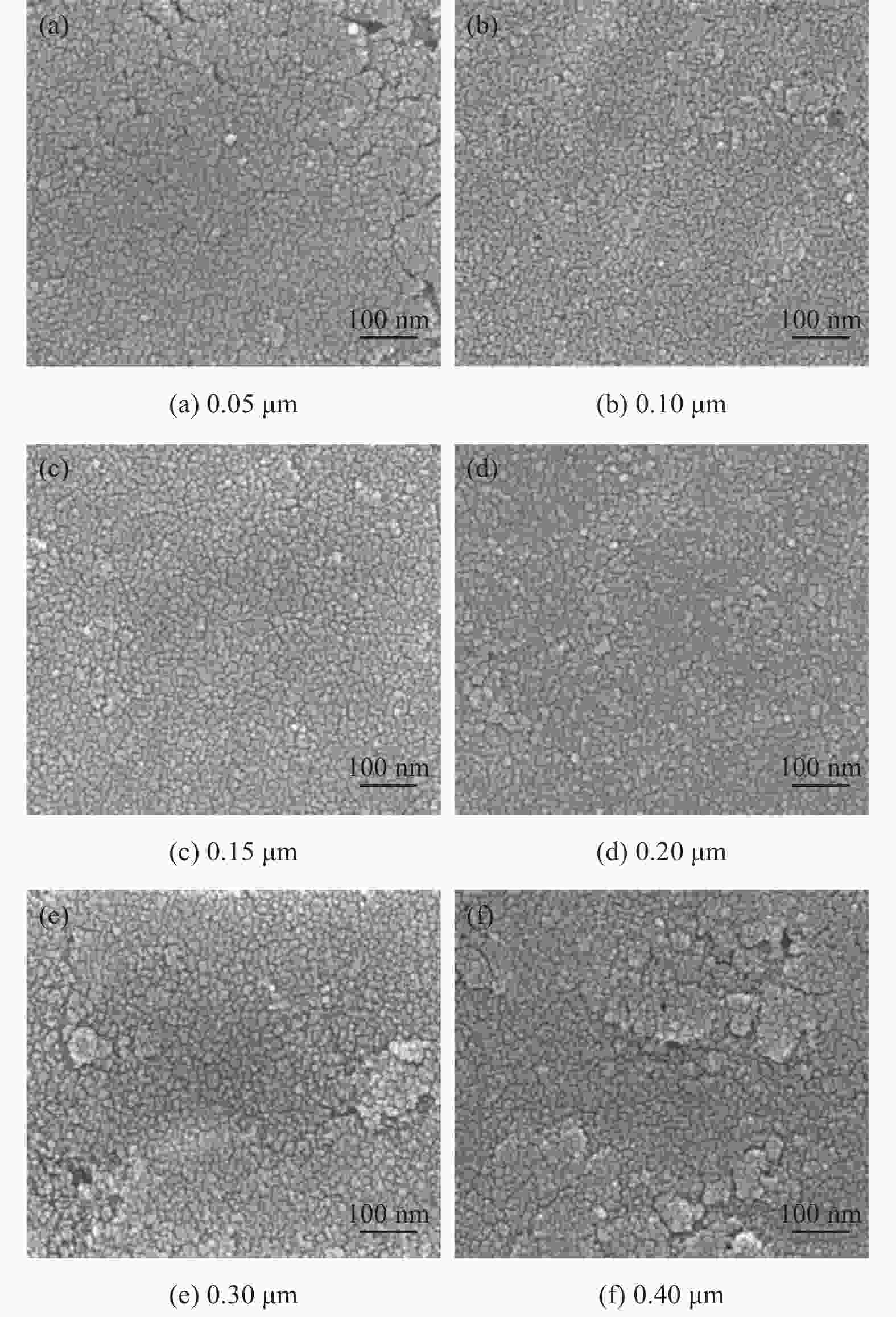

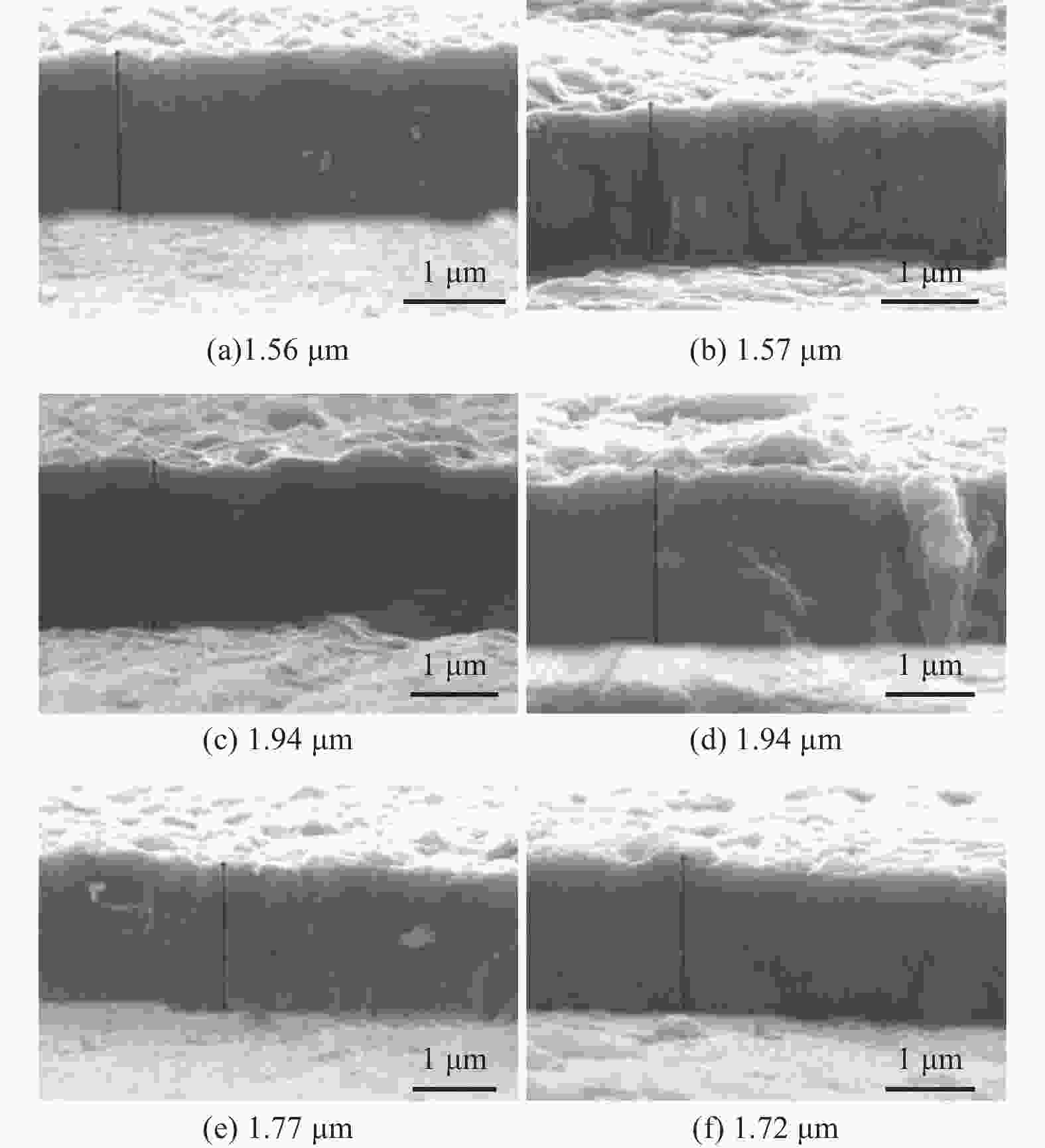

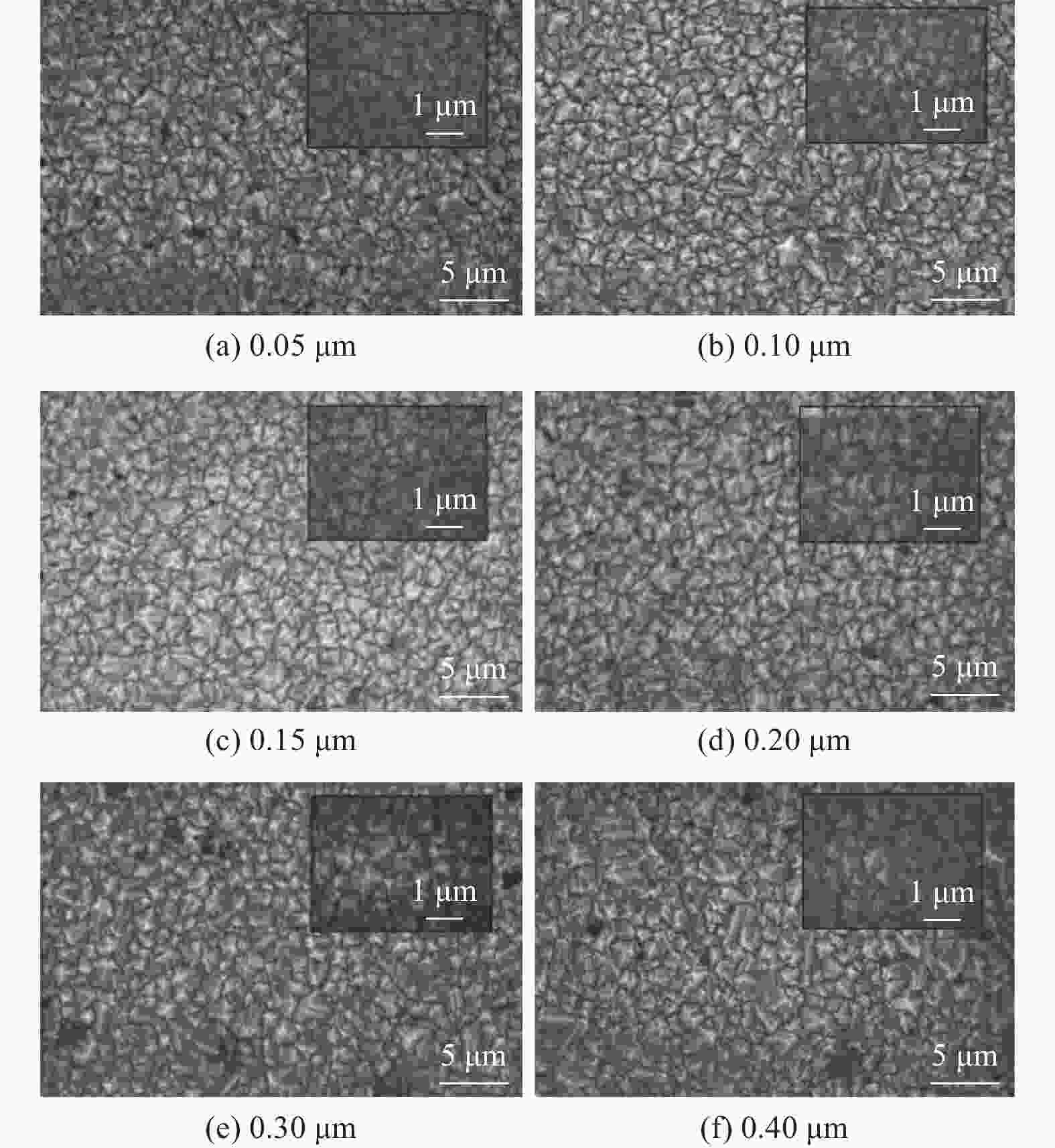

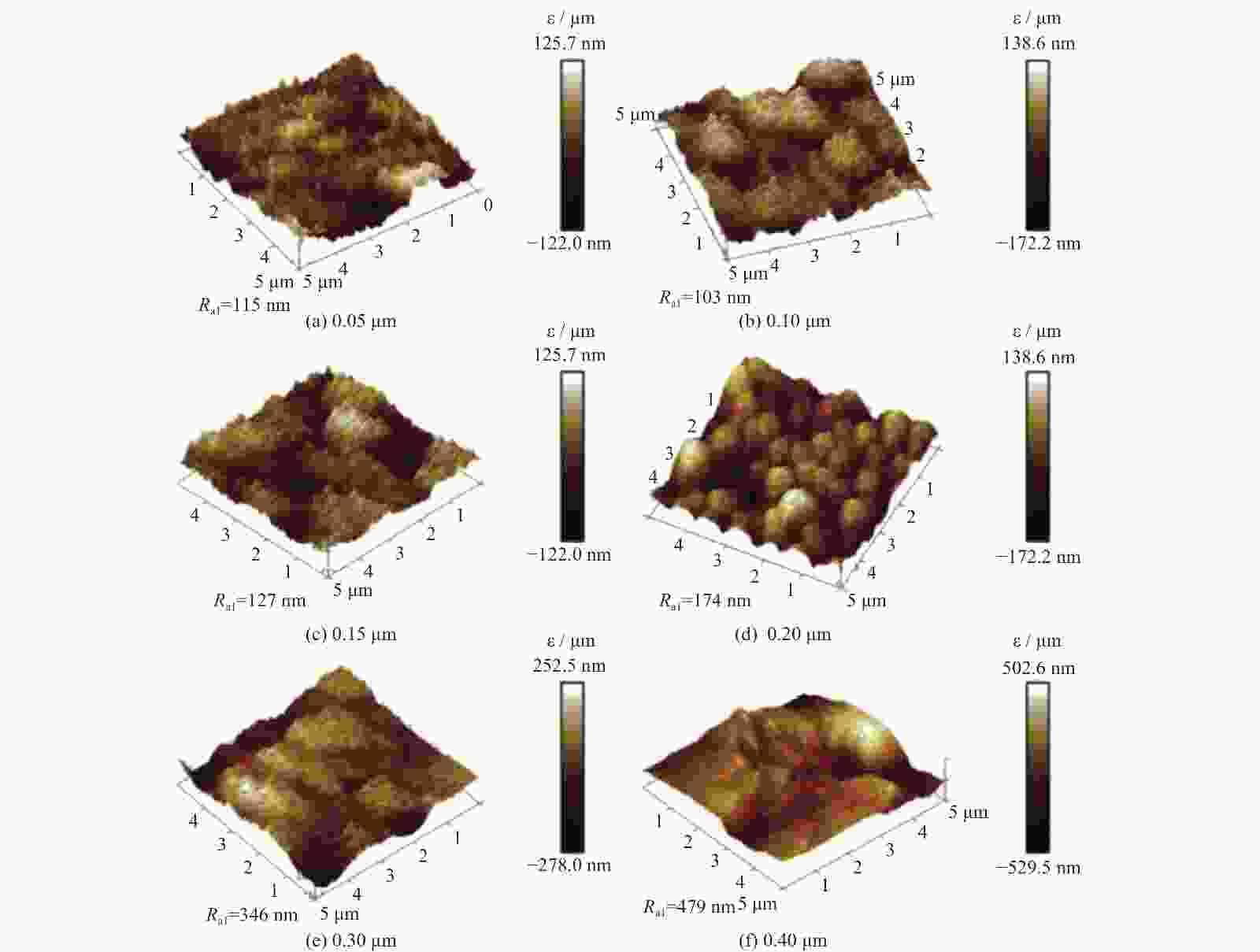

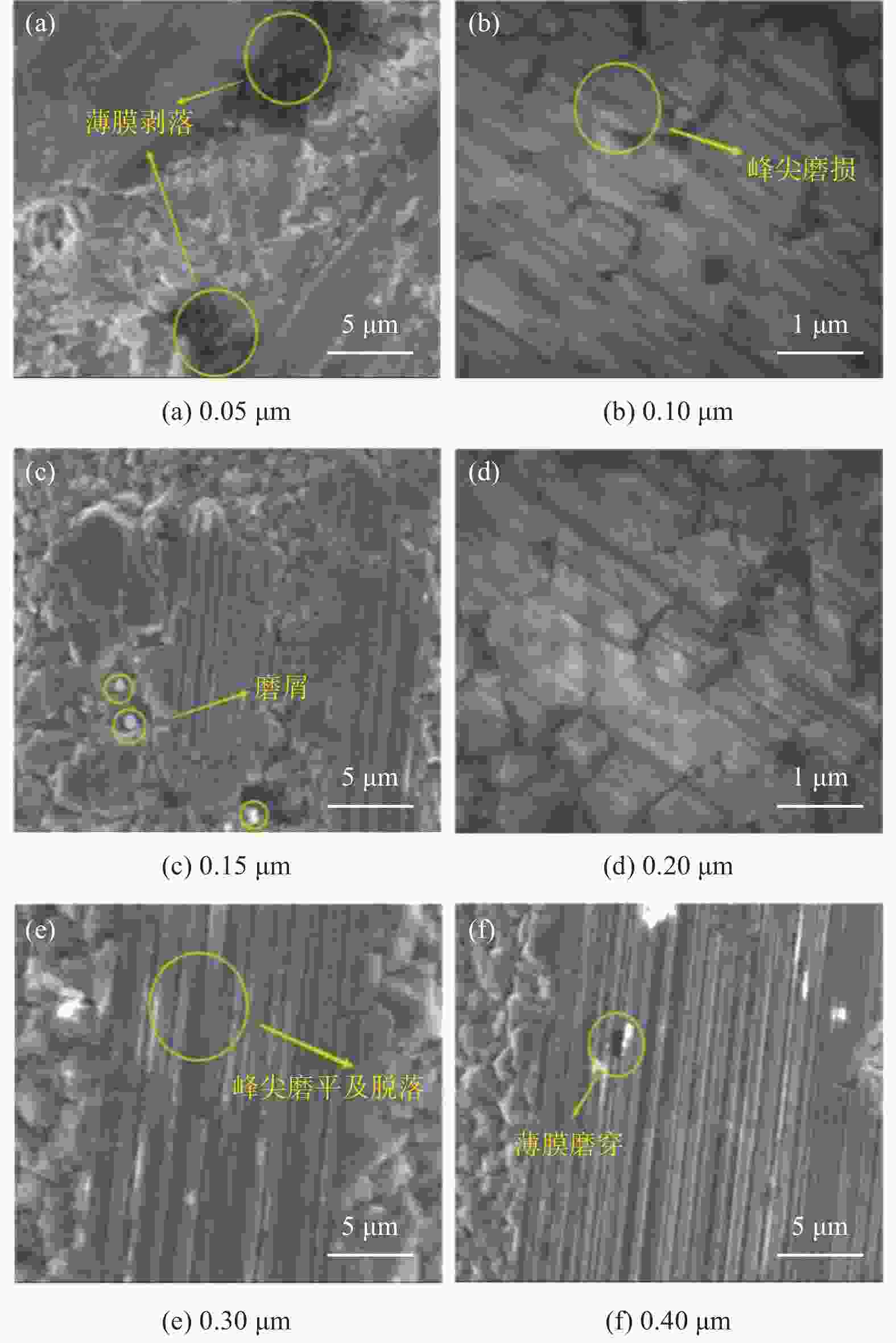

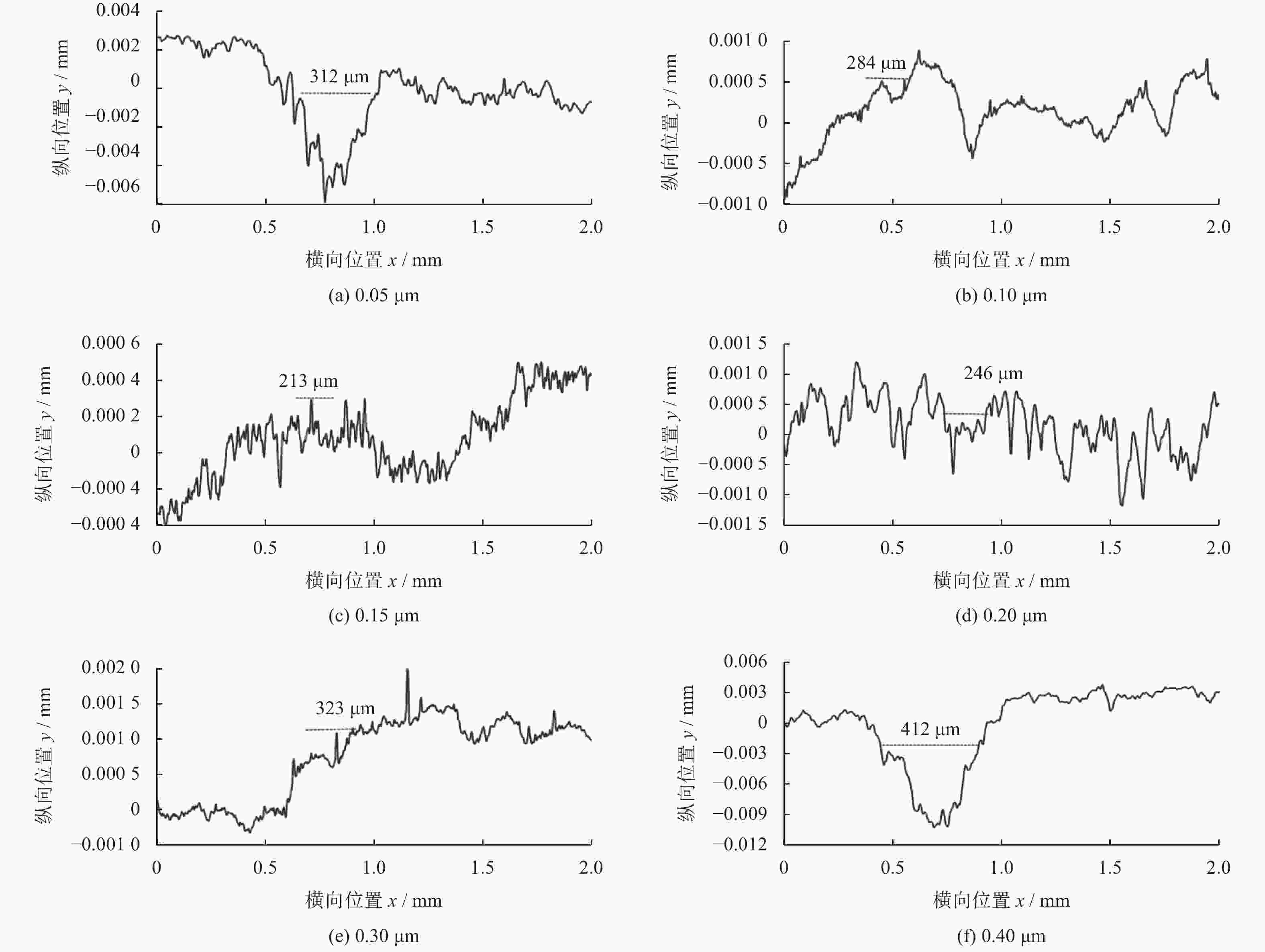

[METHODS] The silicon nitride ceramic substrates were ground to various surface roughness levels using diamond grinding pastes of different grain sizes. After pretreatment by ultrasonic cleaning, a diamond suspension was used for crystal seeding on the surface to increase the nucleation density of diamonds. Thin film deposition was then carried out on the surface of the processed silicon nitride ceramic substrate using parameters of 1% methane concentration, 1KPa chamber pressure, and a substrate temperature of 2500±10 ℃. This process yielded micrometer-scale diamond thin films (MCD) on the surface of the silicon nitride ceramic substrate with different surface roughness. The surface morphology was characterized using a scanning electron microscope and an atomic force microscope. The quality and rate of grain growth in the diamond films on substrates of different roughness were analyzed to assess the influence of surface roughness on film growth. The physical phase composition of diamond films on substrates with varying roughness was characterized by Raman spectrometer. The bond strength between the diamond films and the silicon nitride ceramic substrates with different roughness was characterized by using an Anton Paar scratch meter microscopic combination viewer (MCT3) and an ultra-deep field microscope. The critical loads Lc1 and Lc2—corresponding to the onset of semicircular cracks within the film scratches and the appearance of adhesion failure-type debris at the scratch edges, respectively—were determined through acoustic emission, load-friction curves, and examination of the scratch surface morphology. This analysis also explored the fracture mechanisms of the films and the effect of substrate surface roughness on the film-substrate bonding strength. Tribological properties of the diamond films were investigated using a "ball-on-disk" reciprocating friction and wear tester, with silicon nitride ceramic balls as the counter-body. Scanning electron microscope (SEM), probe-type surface profiler (PSP) and super depth-of-field microscope (DFM) were used to examine the diamond films after abrasion.

[RESULTS] The results showed that: (1) diamond films exhibited the highest growth rate of 0.647 μm/h on substrates with surface roughness of 0.15 μm and 0.20 μm. The density and dimensional homogeneity of diamond grains decreased with the increase of substrate surface roughness due to the influence of the quality of crystallization, and the surface roughness of the diamond films increased with the grain sizes and the substrate roughness. The content of diamond phases in the films gradually increased and the content of trans-polyacetylene and graphite gradually decreased with the increase of substrate surface roughness, particularly notable on substrates with 0.30 μm roughness, where diamond films showed the highest diamond phase content and the least graphite phase, impurities, and grain defects. (2) Diamond films on the substrate with surface roughness of 0.20 μm could withstand the highest load, with critical loads Lc1 and Lc2 being 9.4 N and 11.9 N, respectively.(3) The friction coefficient of diamond film correlated with the roughness of the substrate, the size of the grains and the content of the impurities, with the lowest coefficient of 0.078 observed on substrates with 0.20 μm roughness. The wear rate of diamond films aligned with that of the counter-abrasive, with insufficient film-substrate bonding leading to film detachment and increased wear. High-quality grains and strong film-substrate bonding yielded low wear rates for both diamond films and counter-abrasives, with the lowest wear rate on substrates with 0.20 μm roughness being 1.75x10-7mm3/(m N).

[CONCLUSION] This study shows that the tribological properties of diamond films initially improve and then decline with increasing substrate surface roughness. Notably, micrometer-scale diamond films grown on substrates with a surface roughness of 0.10 to 0.20 μm exhibit superior growth quality and tribological performance.

-

[1] 廖圣俊. 基片用氮化硅陶瓷材料的制备及性能研究 [D]. 淄博: 山东理工大学, 2021.LIAO Shengjun, Preparation and properties of silicon nitride ceramic materials for substrate [D]. Zibo: Shandong University of Technology, 2021. [2] 王宜豹, 邱慧敏, 张妹, 等. 多层金刚石薄膜制备工艺和应力分析研究 [J]. 山东科学,2020,33(1):61-67. doi: 10.3976/j.issn.1002-4026.2020.01.009WANG Yibao, QIU Huimin, ZHANG Mei, et al. Research on the preparation technology and stress analysis of multilayer diamond films [J]. Shangdong Science,2020,33(1):61-67. doi: 10.3976/j.issn.1002-4026.2020.01.009 [3] 陆峰, 查丽琼, 刘鲁生, 等. 基于硬脆材料加工的金刚石涂层硬质合金刀具制备及切削性能研究 [J]. 稀有金属与硬质合金,2018,46(4):78-82, 86.LU Feng, CHA Liqiong, LIU Lusheng, et al. Research on preparation and cutting performance of diamond coated cemented carbide tools used in hard brittle material machining [J]. Rare Metal sand Cemented Carbides,2018,46(4):78-82, 86. [4] 张珂, 姜云浩, 陆峰, 等. 氮化硅表面生长金刚石薄膜及其摩擦磨损性能研究 [J]. 沈阳建筑大学学报(自然科学版),2017,33(4):688-698.ZHANG Ke, JIANG Yunhao, LU Feng, et al. Preparation and tribology property of diamond film on silicon nitride [J]. Joural of Shenyang Jianzhu University (Natural Science),2017,33(4):688-698. [5] 文怀兴, 孙建建, 陈威. 氮化硅陶瓷轴承润滑技术的研究现状与发展趋势 [J]. 材料导报,2015,29(17):6-14.WEN Huaixing, SUN Jianjian, CHEN Wei. Review on research status and development trend on silicon nitride ceramic bearings [J]. Materials Reports,2015,29(17):6-14. [6] 杨思远, 邬奕欣, 吴小倩, 等. 类金刚石薄膜应用与制备技术发展现状 [J]. 黑龙江科学,2021,15(16):20-21, 24. doi: 10.3969/j.issn.1674-8646.2021.16.006YANG Siyuan, WU Yixin, WU Xiaoqian, et al. Development of diamond-like film application and preparation technology [J]. Heilongjiang Science,2021,15(16):20-21, 24. doi: 10.3969/j.issn.1674-8646.2021.16.006 [7] 张东灿. 金刚石薄膜和类金刚石薄膜摩擦学性能试验及其应用研究 [D]. 上海: 上海交通大学, 2010.ZHANG Dongcan. Study on the tribological properties and applications of diamond-like carbon films [D]. Shanghai: Shanghai Jiaotong University, 2010. [8] LINNIK S A, GAYDAYCHUK A V. Synthesis of multilayer polycrystalline diamond films using bias induced secondary nucleation [J]. Materials Letters,2015,139:389-392. doi: 10.1016/j.matlet.20l4.10.142 [9] LIU J, HEI L F, CHEN G C, et al. Influence of seeding pre-treatments on mechanical properties of ultrananocrystalline diamond films on silicon and Si3N4 substrates [J]. Thin Solid Films,2014,556:385-389. doi: 10.1016/j.tsf.2014.01.065 [10] MARTINHO R P, SILVA F J G, BAPTISTA A P M. Wear behaviour of uncoated and diamond coated Si3N4 tools under severe turning conditions [J]. Wear,2007,263(7/8/9/10/11/12):1417-1422. doi: 10.1016/j.wear.2007.01.048 [11] BELMONTE M, SILVA V A, FERNANDES A J, et al. Surface pretreatments of silicon nitride for CVD diamond deposition [J]. Journal of the American Ceramic Society,2003,86(5):749-754. doi: 10.1111/j.1151-2916.2003.tb03369.x [12] ABREU C S, AMARAL M, FERNANDES A J S, et al. Friction and wear performance of HFCVD nanocrystalline diamond coated silicon nitride ceramics [J]. Diamond and Related Materials,2006,15(4/5/6/7/8):739-744. doi: 10.1016/j.diamond.2005.10.042 [13] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics,1953,24(8):981-988. doi: 10.1063/1.1721448 [14] 刘伟, 满卫东, 吕继磊, 等. 植晶工艺对金刚石涂层硬质合金刀具切削性能的影响 [J]. 硬质合金,2017,34(3):167-173.LIU Wei, MAN Weidong, LYU Jilei, et al. Effect of seeding process on machinability of diamond coated cemented carbide cutting tools [J]. Cemented Carbide,2017,34(3):167-173. [15] KUZIN V V, FEDOROV S Y, GRIGOR’EV S N. Correlation of diamond grinding regimes with Si3N4-ceramic surface quality [J]. Refractories and Industrial Ceramics,2017,58(1):78-81. doi: 10.1007/s11148-017-0058-3 [16] 王贺, 沈建辉, 闫广宇, 等. 甲烷浓度对碳化硅基底金刚石薄膜摩擦性能影响 [J]. 人工晶体学报,2021,50(11):2067-2074.WANG He, SHEN Jianhui, YAN Guangyu, et al. Tribological properties of SiC-based diamond films synthesized using different methane concentrations [J]. Journal of Synthetic Crystals,2021,50(11):2067-2074. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS