Effect of Y2O3 on properties of iron-based diamond tools

-

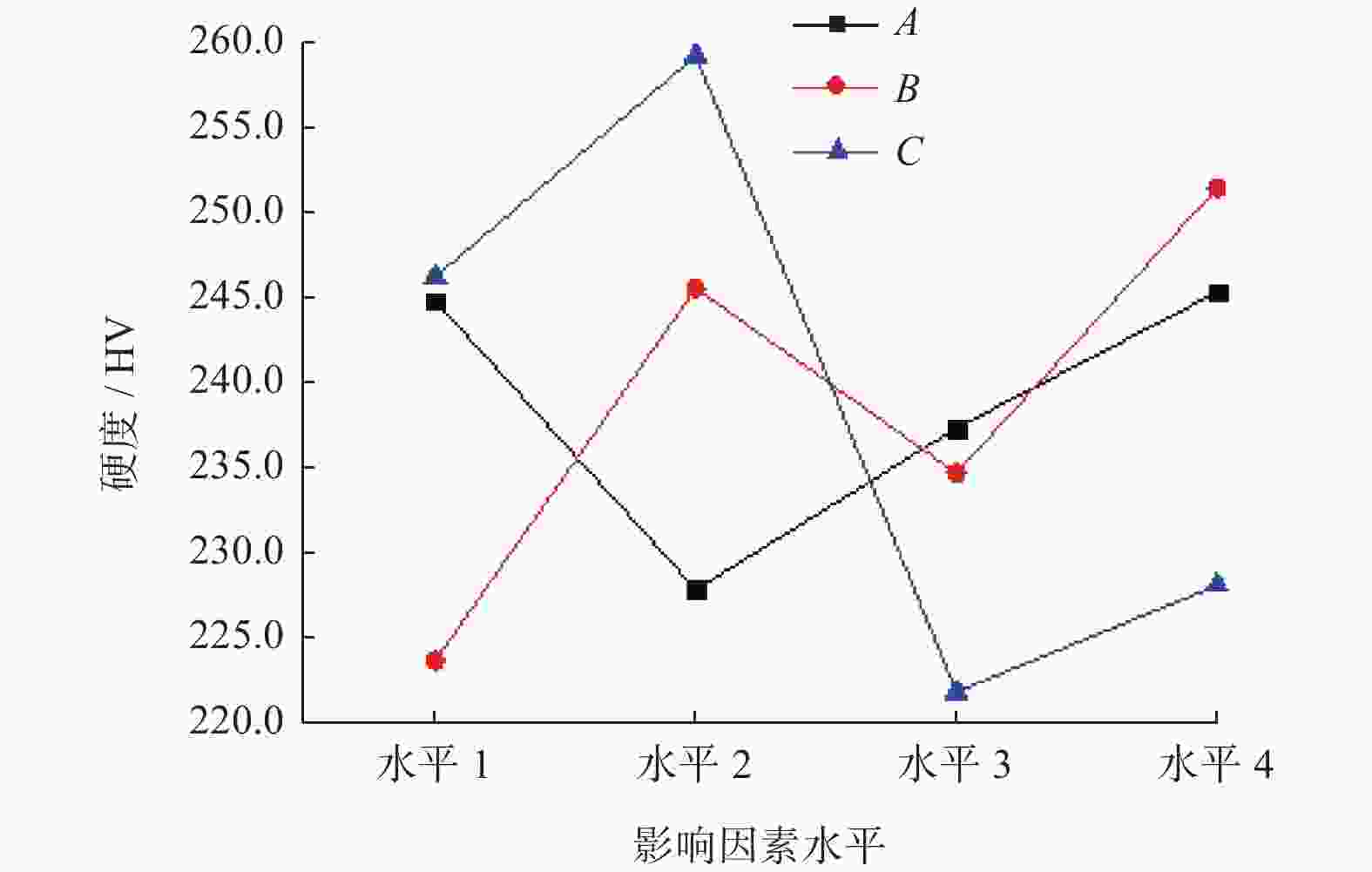

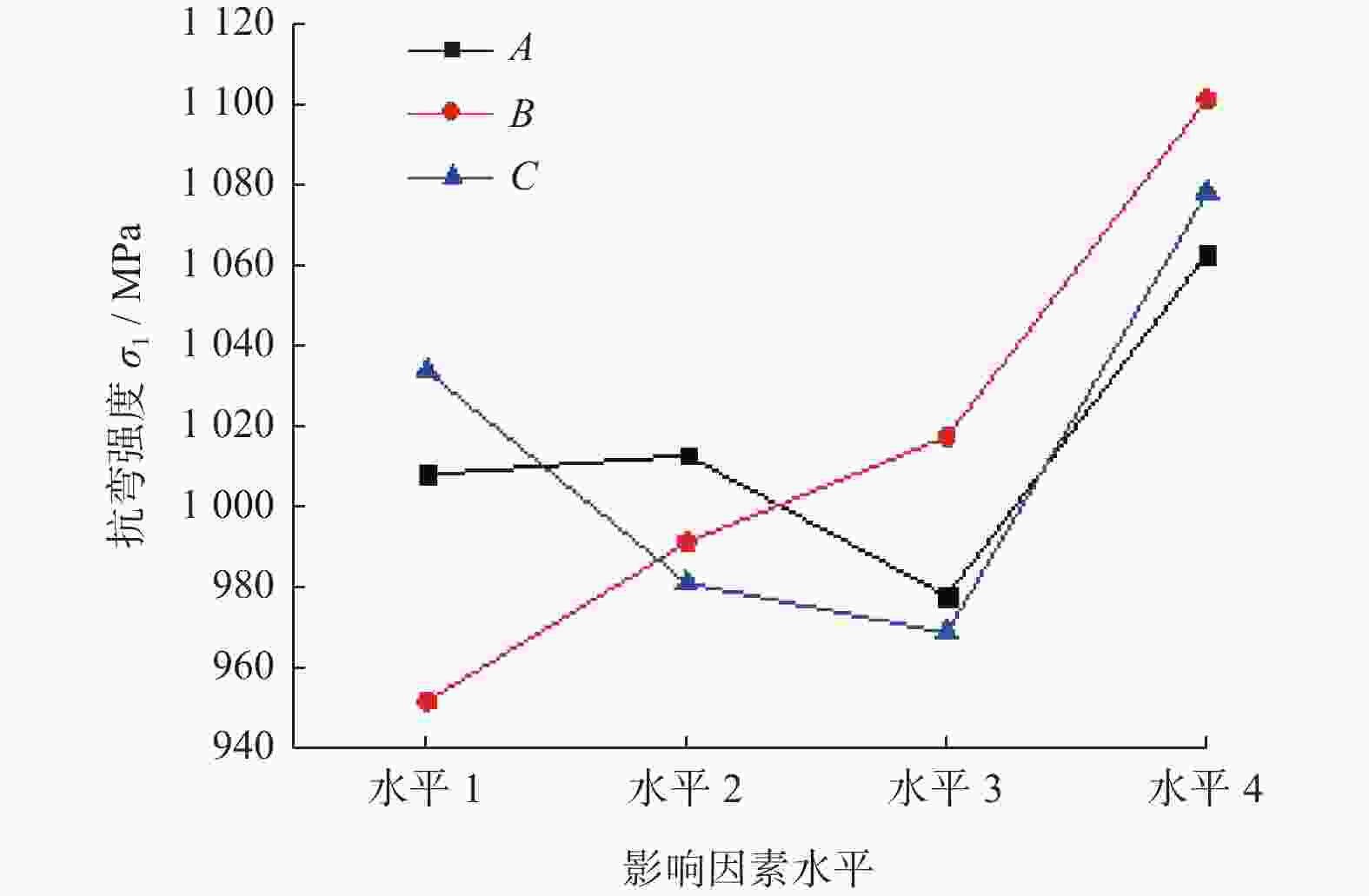

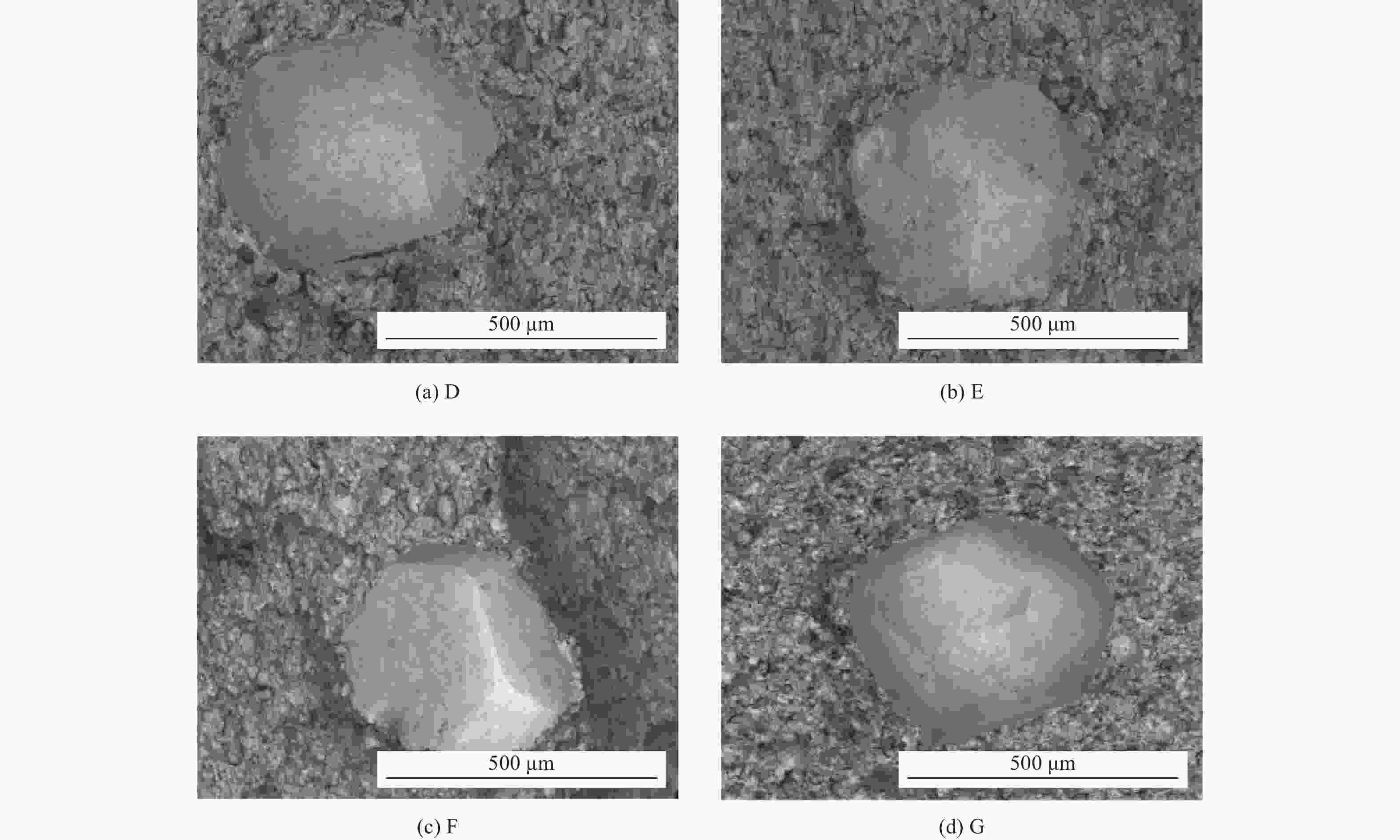

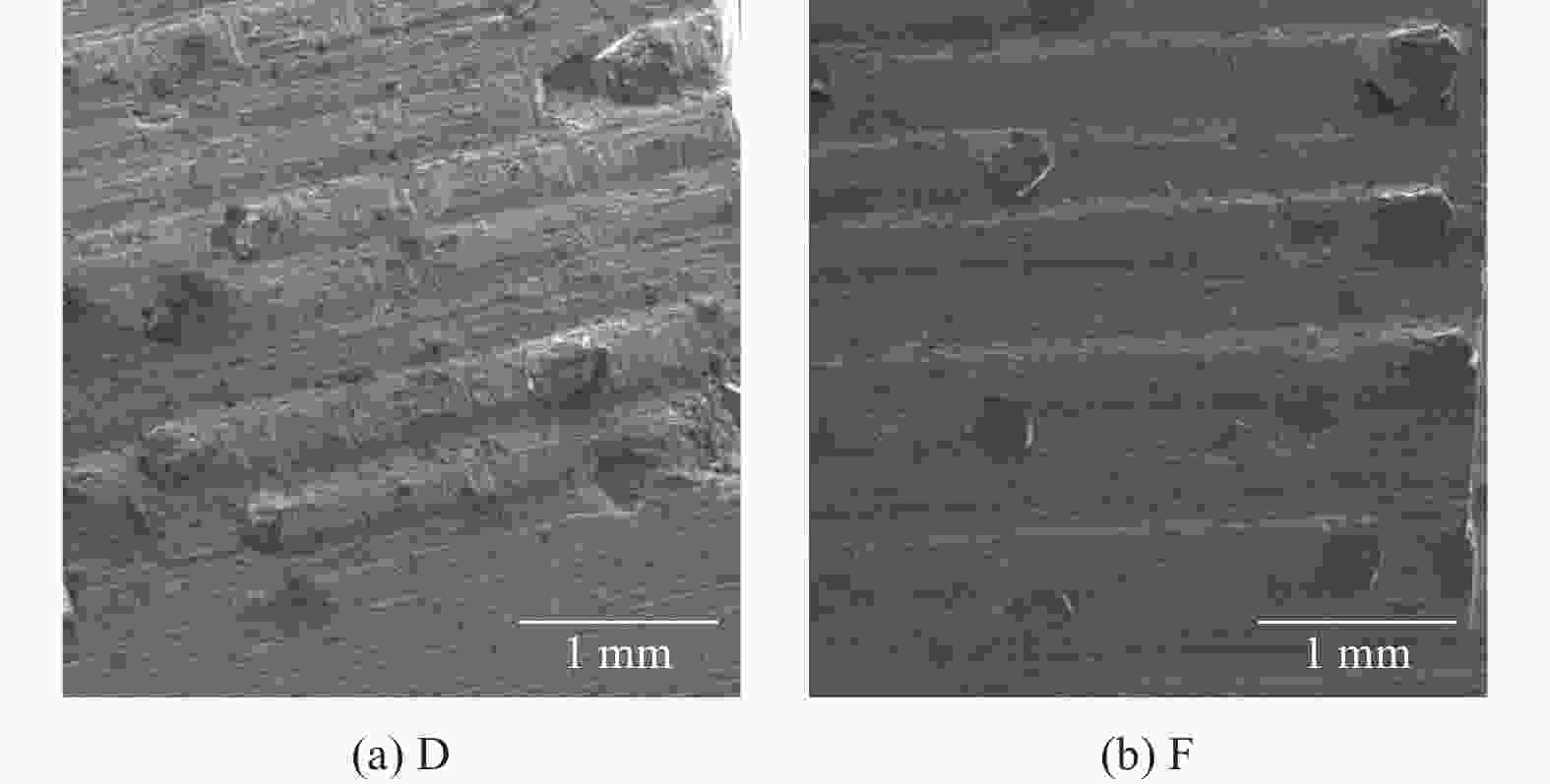

摘要: 采用正交试验方法研究热压压力、烧结温度和Y2O3含量等3个因素对铁基胎体硬度、致密度、抗弯强度和断口微观形貌等的影响,并获得较优的烧结工艺参数。在此基础上,制备含Y2O3的铁基金刚石工具,并对其断口形貌、耐磨性和锋利度等进行检测及分析。结果表明:含Y2O3的铁基结合剂胎体,其相对密度和硬度的影响因素次序为Y2O3含量>烧结温度>热压压力,抗弯强度的影响因素次序为烧结温度>Y2O3含量>热压压力;且Y2O3能促进铁基金刚石胎体组织的致密化,降低其烧结温度。在烧结温度为780 ℃、热压压力为51 kN的较优烧结工艺下,适量的Y2O3能使金刚石工具的孔隙率减小、黏结状况改善,并增强黏结剂对金刚石磨粒的把持能力。Abstract:

The effects of hot pressing pressure, sintering temperature and Y2O3 content on the hardness, the density, the flexural strength and the fracture morphology of the iron-based matrix were studied by orthogonal test, and the better sintering process parameters were obtained. On this basis, the iron-based diamond tool containing Y2O3 was prepared, and its fracture morphology, wear resistance and sharpness were detected and analyzed. The results show that the order of factors affecting the relative density and the hardness of the iron-based binder matrix containing Y2O3 is Y2O3 content, followed by the sintering temperature and the hot pressing pressure, and the influencing factor order of the flexural strength is sintering temperature, Y2O3 content and hot pressing pressure. Y2O3 can promote the densification of iron-based diamond matrix structure and reduces its sintering temperature. Under the better sintering process with sintering temperature of 780 ℃ and hot pressing pressure of 51 kN, an appropriate amount of Y2O3 can reduce the porosity of diamond tools, improve the bonding condition, and enhance the holding ability of binder to diamond abrasive particles. -

Key words:

- diamond tool /

- Y2O3 /

- mechanical property /

- sharpness

-

表 1 铁基胎体配方表(质量分数)

Table 1. Formula of iron-based matrix (mass fraction)

配方编号 CuSn15

ω2 / %FeCu30

ω3 / %FeCu40Ni12Sn7Co10

ω4 / %Y2O3

ω1 / %D 27.00 63.00 10.00 0 E 26.93 62.84 9.98 0.25 F 26.87 62.68 9.95 0.50 G 26.80 62.52 9.93 0.75 表 2 正交试验的因素和水平

Table 2. Factors and levels of orthogonal test

水平 因素 热压压力

F / kN

A烧结温度

θ / ℃

BY2O3质量分数

ω1 / %

C1 43 760 0 2 47 780 0.25 3 51 800 0.50 4 55 820 0.75 表 3 胎体烧结试样正交试验方案及性能检测结果

Table 3. Orthogonal test scheme and performance test results of matrix sintered samples

试验编号 A B C 相对密度 R1 硬度 / HV 抗弯强度 σ1 / MPa 1# 1 1 1 0.950 4 225.48 934 2# 1 2 2 0.949 1 283.00 1 003 3# 1 3 3 0.947 9 230.48 930 4# 1 4 4 0.993 8 241.00 1 163 5# 2 1 2 0.935 6 230.00 896 6# 2 2 1 0.954 2 246.03 999 7# 2 3 4 0.989 1 221.00 1 058 8# 2 4 3 0.960 8 215.00 1 096 9# 3 1 3 0.946 5 209.73 913 10# 3 2 4 0.984 8 220.93 1 027 11# 3 3 1 0.957 7 241.48 1 013 12# 3 4 2 0.948 5 277.90 957 13# 4 1 4 0.973 3 230.13 1 062 14# 4 2 3 0.952 4 232.80 934 15# 4 3 2 0.959 6 246.50 1 066 16# 4 4 1 0.967 0 272.50 1 186 表 4 正交试验结果的极差分析结果

Table 4. Range analysis results of orthogonal test results

水平 相对密度 R1 硬度 / HV 抗弯强度 σ1 / MPa A B C A B C A B C 1 0.960 3 0.951 5 0.957 3 244.99 223.83 246.37 1008 951 1033 2 0.959 9 0.960 1 0.948 2 228.01 245.69 259.35 1013 991 981 3 0.959 4 0.963 6 0.951 9 237.51 234.86 222.00 978 1017 969 4 0.963 1 0.967 5 0.985 3 245.48 251.60 228.26 1062 1101 1078 极差值 0.003 7 0.016 1 0.037 0 17.48 27.77 37.35 84 150 109 表 5 金刚石胎体/工具试样性能测试结果

Table 5. Performance test results of diamond matrix/tool samples

编号 C 胎体 金刚石工具 抗弯强度损失率

η / %相对密度

R1硬度 / HV 抗弯

强度

σ1 / MPa相对密度

R2硬度

/ HV抗弯

强度

σ2 / MPaD 0 0.955 0 220.50 1 050.35 0.984 9 239.78 755.38 28.80 E 0.25 0.952 8 201.00 1 022.25 0.978 3 247.53 651.25 36.29 F 0.50 0.956 1 210.00 998.00 0.987 0 245.00 899.00 9.91 G 0.75 0.984 8 220.93 1 027.00 0.994 9 242.00 791.75 22.90 表 6 金刚石工具试样耐磨性测试结果

Table 6. Wear resistance test results of diamond tool samples

试样编号 C 工具试样损耗的

质量

m1 / g砂轮损耗的

质量

m2 / g磨耗比

RD 0 0.11 13.50 0.008 1 E 0.25 0.27 11.80 0.022 9 F 0.50 0.25 22.90 0.010 9 G 0.75 0.30 21.80 0.013 8 -

[1] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展 [J]. 金刚石与磨料磨具工程,2019,39(2):37-45.WU Yanping, YAN Qingzhi. Research progress of metal bonded diamond tools [J]. Diamond & Abrasives Engineering,2019,39(2):37-45. [2] 侯明, 郭胜惠, 高冀芸, 等. 预合金结合剂成分及烧结工艺对金刚石工具性能的影响 [J]. 材料导报,2019,33(7):2403-2407. doi: 10.11896/cldb.18050079HOU Ming, GUO Shenghui, GAO Jiyun, et al. Effects of pre-alloyed binder composition and sintering process on the properties of diamond tools [J]. Material Guide,2019,33(7):2403-2407. doi: 10.11896/cldb.18050079 [3] LOGINOV P, ZHASSAY U A, BYCHKOVA M Y, et al. Chromium-doped Fe-Co-Ni binders for diamond cutting tools: The features of the structure, mechanical properties, and adhesion to diamond [J]. International Journal of Refractory Metals and Hard Materials,2020,92(16):105289. [4] 林涛, 余雄健, 邵慧萍, 等. 铁基超细预合金粉对花岗岩切割锯片锋利度的影响 [J]. 功能材料,2015,46(21):27-30. doi: 10.3969/j.issn.1001-9731.2015.21.006LIN Tao, YU Xiongjian, SHAO Huiping, et al. Effect of iron-based ultra-fine pre-alloyed powder on the sharpness of granite cutting saw blade [J]. Functional Materials,2015,46(21):27-30. doi: 10.3969/j.issn.1001-9731.2015.21.006 [5] 王昆昆, 罗铁钢, 董应虎, 等. Y2O3对Ti-6Al-4V合金显微组织及力学性能的影响 [J]. 粉末冶金工业,2020,30(4):26-31.WANG Kunkun, LUO Tiegang, DONG Yinghu, et al. Effect of Y2O3 on microstructure and mechanical properties of Ti-6Al-4V alloy [J]. Powder Metallurgy Industry,2020,30(4):26-31. [6] 吴颖. 新型金刚石工具铜基结合剂及其性能的研究 [D]. 重庆: 重庆大学, 2014.WU Ying. Study on a new copper based binder for diamond tools and its properties [D]. Chongqing: Chongqing University, 2014. [7] 刘英, 张永安, 王卫, 等. 稀土Y对Ni-Fe-Co-Cu合金微观组织和高温氧化性能的影响 [J]. 稀有金属,2020(1):9-17. doi: 10.13373/j.cnki.cjrm.xy18040044LIU Ying, ZHANG Yong'an, WANG Wei, et al. Effect of rare earth Y on microstructure and high temperature oxidation properties of Ni–Fe–Co–Cu alloy [J]. Rare Metals,2020(1):9-17. doi: 10.13373/j.cnki.cjrm.xy18040044 [8] LI Y, SUN H, YANG K, et al. Effect of Y doping and vacuum hot-press sintering on microstructure and mechanical properties of TiAl-based alloys [J]. Rare Metal Materials and Engineering,2019,48(6):1756-1761. [9] 叶纪超. 稀土氧化钇对金刚石钻头胎体性能的影响 [D]. 北京: 中国地质大学, 2019.YE Jichao. Effect of rare earth yttrium oxide on properties of diamond bit matrix [D]. Beijing: China University of Geosciences, 2019. [10] 郭森林. 稀土氧化物及V2O5对Co-Cu-Sn基CBN工具胎体性能的影响 [D]. 郑州: 河南工业大学, 2012.GUO Senlin. Effects of rare earth oxides and V2O5 on the properties of Co-Cu-Sn based CBN tool matrix [D]. Zhengzhou: Henan University of Technology, 2012. [11] 国家标准局. 致密烧结金属材料与硬质合金密度测定方法GB/T 3850—2015 [S]. 北京: 中国标准出版社, 2015.National Bureau of Standards. Dense sintered metal materials and cemented carbides—Determination of density: GB/T 3850—2015 [S] Beijing: China Standards Press, 2015. [12] DAI Q L, LUO C B, XU X P, et al. Effects of rare earth and sintering temperature on the transverse rupture strength of Fe-based diamond composites [J]. Journal of Materials Processing Technology,2002,129(1/2/3):427-430. doi: 10.1016/S0924-0136(02)00593-9 [13] 朱振东, 张作栋, 栗晓龙, 等. 结合剂强度和不同镀层对金刚石工具出刃高度的影响 [J]. 金刚石与磨料磨具工程,2021,41(4):53-57.ZHU Zhendong, ZHANG Zuodong, LI Xiaolong, et al. Effects of bond strength and different coatings on the cutting edge height of diamond tools [J]. Diamond & Abrasives Engineering,2021,41(4):53-57. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS