Optimizing process parameters of ultrasonic vibration assisted grinding CFRP based on response surface method

-

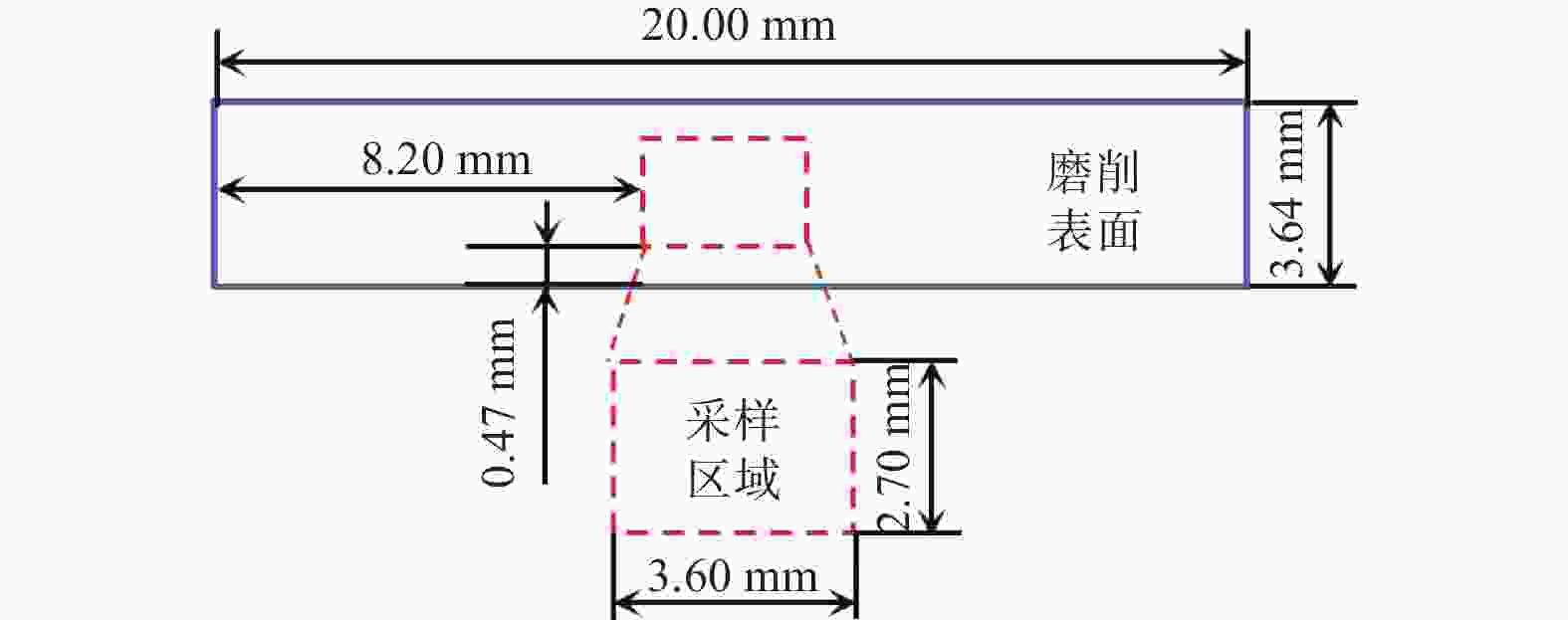

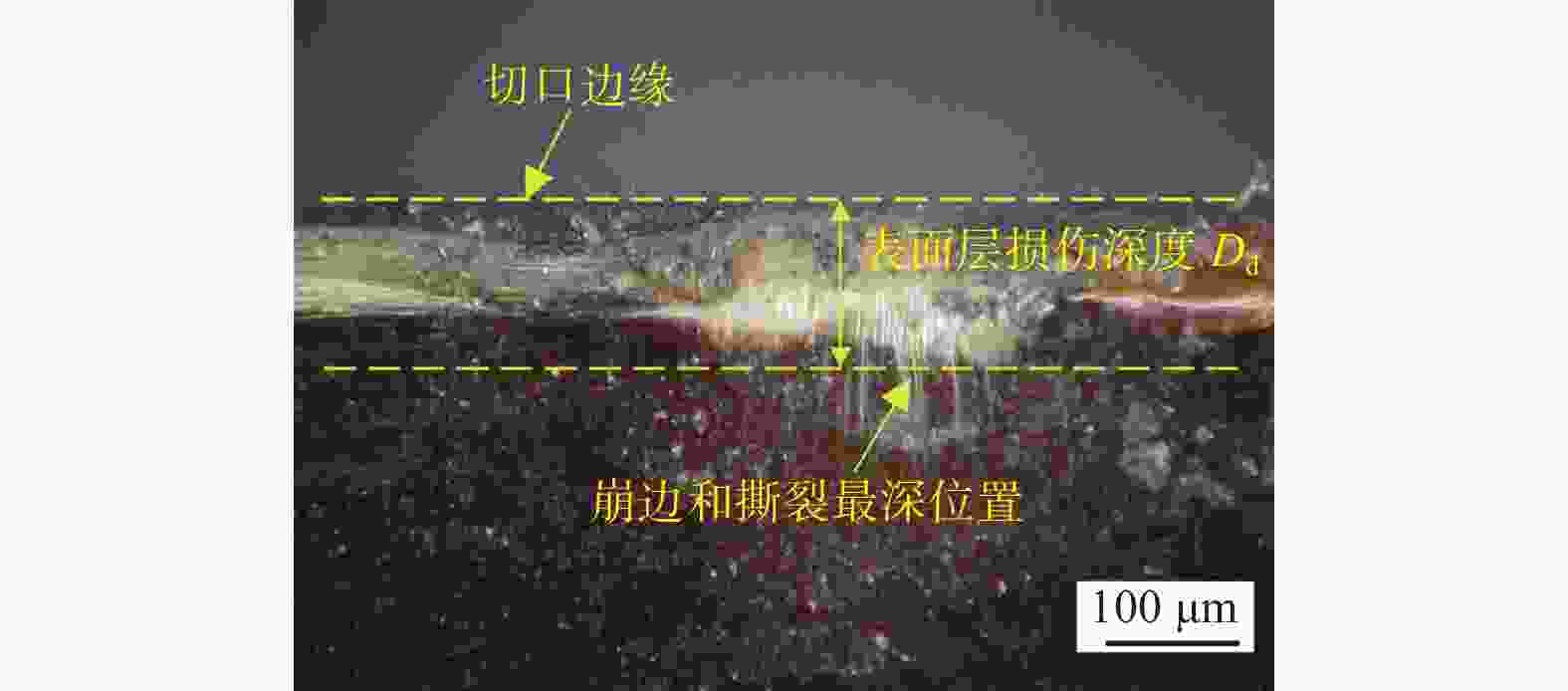

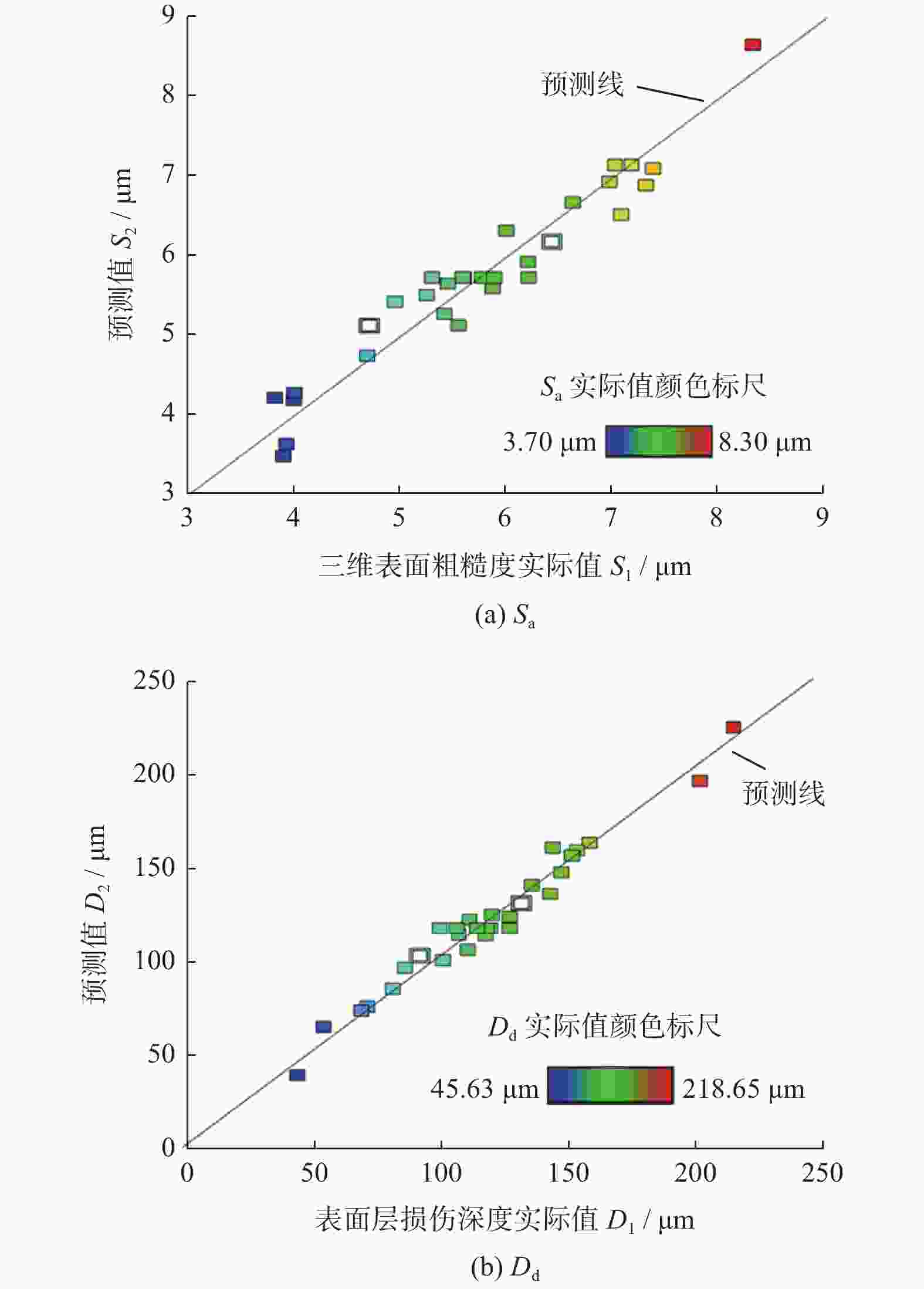

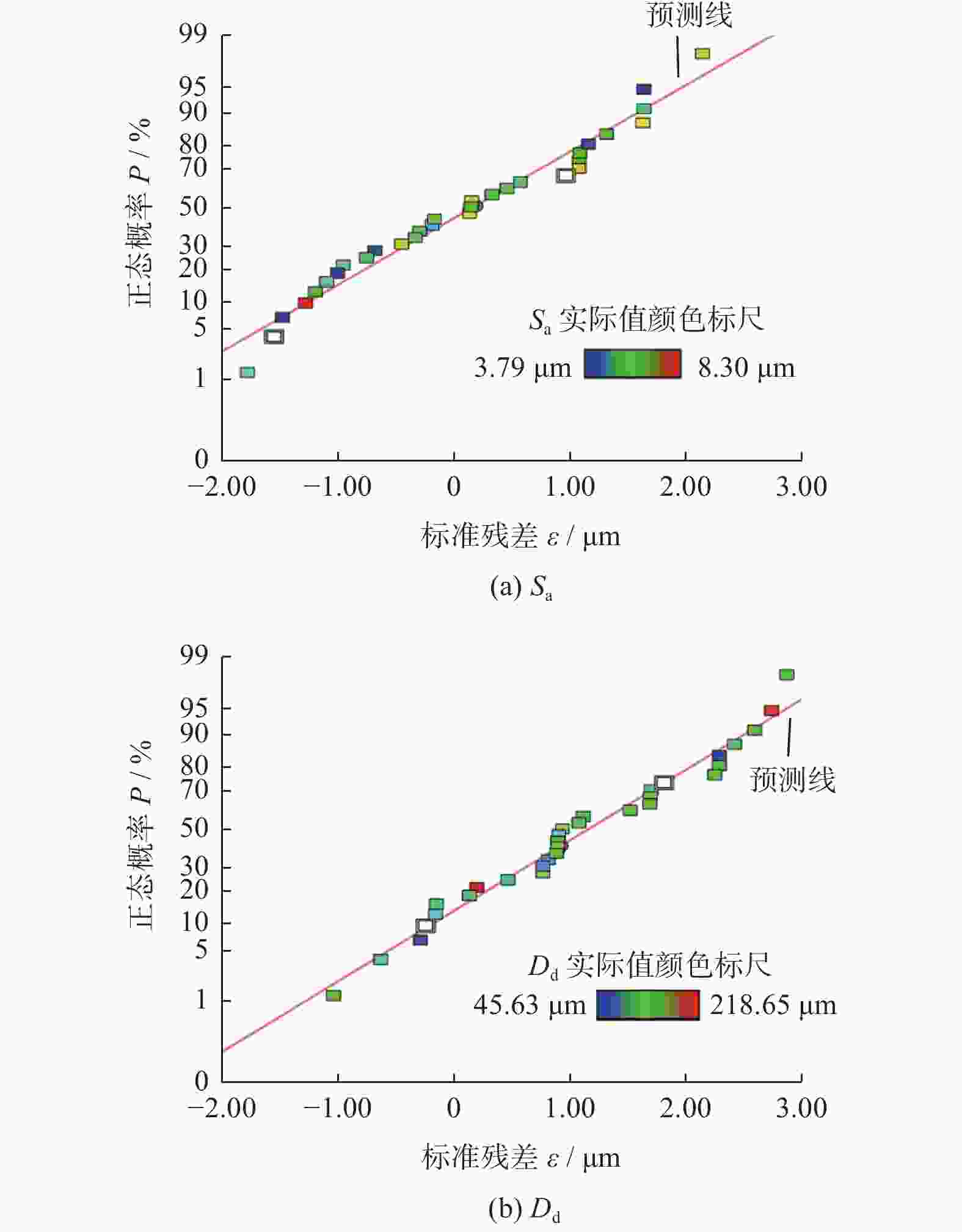

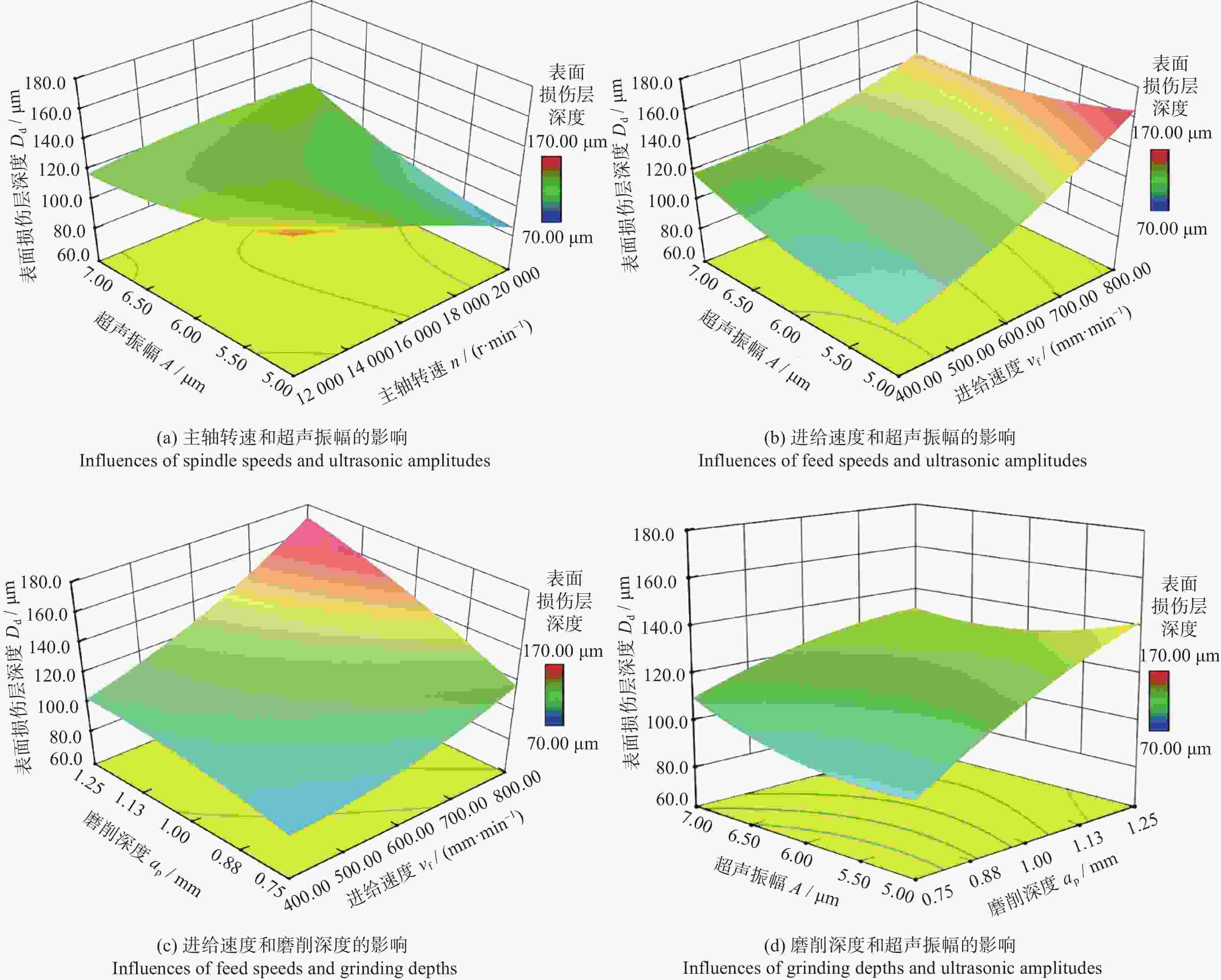

摘要: 针对CFRP加工表面高质量和高效率相矛盾的问题,利用响应曲面法建立三维表面粗糙度Sa和表面损伤层深度Dd的二阶回归模型,并采用遗传算法进行多目标优化,获得小的Sa、Dd和最大的材料去除率VMRR。结果表明:Sa和Dd的回归模型显著、可靠性好,其中进给速度vf对Sa和Dd的影响最显著,磨削深度ap、主轴转速n和超声振幅A的影响次之。响应曲面分析结果显示:n−A、vf−ap以及vf−A之间的交互作用对Sa影响显著;n−A、vf−A、vf−ap以及ap−A之间的交互作用对Dd影响显著。在Sa、Dd和VMRR权重占比分别为1/5、1/5和3/5的条件下,与中心点结果相比,优化后的Sa降低了11.01%,Dd降低了10.08%,VMRR提高了62.02%。且在优化工艺参数下的Sa和Dd的试验值与预测值的相对误差绝对值分别为8.25%和9.41%,表明预测模型准确性较高,可用于CRFP超声振动磨削的工艺参数优化和预测。Abstract: To solve the contradiction between high quality and high efficiency of CFRP machining surface, the quadratic regression models of 3D surface roughness Sa and surface damage layer depth Dd were established by using the response surface method, and the genetic algorithm was used for multi-objective optimization to obtain small Sa, Dd and maximum material removal rate VMRR. The results show that the regression models of Sa and Dd are explicit and reliable, and the feed speed vf has the most significant influence on Sa and Dd, followed by the grinding depth ap, the spindle speed n and the ultrasonic amplitude A. The results of response surface analysis show that the interactions of n and A, vf and ap, vf and A have significant effects on Sa. The interactions of n and A, vf and A, vf and ap, ap and A have significant effects on Dd. When the weight ratios of Sa, Dd and VMRR are 1/5, 1/5 and 3/5 respectively, compared with the central point results, the optimized Sa decreases by 11.01%, Dd decreases by 10.08%, and VMRR increases by 62.02%. The absolute values of the relative errors between the experimental and the predicted values of Sa and Dd under the optimized process parameters are 8.25% and 9.41% respectively, indicating that the prediction model has high accuracy and can be used for the optimization and prediction of the process parameters of CRFP ultrasonic vibration grinding.

-

表 1 试验因素水平

Table 1. Experiment factors and levels

编码水平 因素 主轴转速

n / (r·min−1)进给速度

vf / (mm·min−1)磨削深度

ap / mm超声振幅

A / μm−2 8 000 200.00 0.50 4.00 −1 12 000 400.00 0.75 5.00 0 16 000 600.00 1.00 6.00 1 20 000 800.00 1.25 7.00 2 24 000 1 000.00 1.50 8.00 表 2 因素设计及测试结果

Table 2. Factor design and test results

序号

m磨削参数 响应结果 n vf ap A Sa / μm σSa / μm Dd / μm σDd / μm 1 0 0 −2 0 4.66 0.25 55.96 11.38 2 1 −1 −1 −1 3.87 0.20 45.63 8.81 3 1 −1 1 −1 3.79 0.15 73.36 12.46 4 0 0 0 −2 6.60 0.29 138.66 22.58 5 0 0 0 0 5.28 0.26 108.70 8.42 6 1 1 1 −1 7.06 0.33 156.59 18.68 7 −1 1 −1 −1 7.29 0.31 161.52 21.05 8 0 0 2 0 6.95 0.26 145.89 13.02 9 0 0 0 0 5.58 0.26 117.15 8.42 10 −1 −1 1 1 4.68 0.18 94.18 15.88 11 −1 1 −1 1 5.42 0.35 113.89 12.05 12 −1 1 1 1 7.36 0.29 154.54 19.43 13 −1 1 1 −1 8.30 0.41 218.65 23.68 14 −1 −1 −1 −1 4.93 0.19 103.44 9.17 15 0 0 0 0 5.81 0.26 122.11 8.42 16 0 0 0 0 5.75 0.26 120.65 8.42 17 0 −2 0 0 3.90 0.25 88.28 10.28 18 −1 −1 1 −1 5.85 0.18 122.77 14.93 19 −1 −1 −1 1 5.39 0.27 113.24 21.26 20 0 0 0 0 6.19 0.26 129.91 8.42 21 0 0 0 2 7.16 0.31 150.27 15.91 22 0 2 0 0 5.98 0.23 205.31 21.82 23 −2 0 0 0 6.40 0.21 134.49 20.19 24 0 0 0 0 5.56 0.26 116.85 8.42 25 1 −1 1 1 6.18 0.34 129.84 23.63 26 1 1 1 1 7.00 0.33 147.00 15.71 27 1 1 −1 −1 3.97 0.17 83.42 9.08 28 2 0 0 0 3.98 0.22 70.96 12.72 29 0 0 0 0 5.86 0.26 102.11 8.42 30 1 1 −1 1 5.52 0.18 120.22 14.63 31 1 −1 −1 1 5.23 0.28 109.73 17.03 表 3 Sa的方差分析

Table 3. Variance analysis of Sa

项目 平方和 自由度 均方值 F值 P值 备注 模型 37.89 14 2.71 15.78 < 0.000 1 非常显著 n 5.46 1 5.46 31.83 < 0.000 1 3 vf 10.87 1 10.87 63.38 < 0.000 1 1 ap 7.21 1 7.21 42.07 < 0.000 1 2 A 0.34 1 0.34 1.96 0.180 6 4 n−vf 0.58 1 0.58 3.38 0.084 6 n−ap 0.32 1 0.32 1.90 0.187 6 n−A 4.78 1 4.78 27.85 < 0.000 1 vf−ap 2.57 1 2.57 14.99 0.001 4 vf−A 1.19 1 1.19 6.93 0.018 1 ap−A 0.10 1 0.10 0.59 0.453 3 n2 0.45 1 0.45 2.63 0.124 5 vf2 1.02 1 1.02 5.92 0.027 1 ap2 0.02 1 0.02 0.13 0.722 7 A2 2.51 1 2.51 14.64 0.001 5 残差 2.74 16 0.17 失拟项 2.26 10 0.23 2.77 0.112 3 不显著 纯误差 0.49 6 0.08 总和 40.64 30 R2=0.932 5 表 4 Dd的方差分析

Table 4. Variance analysis of Dd

项目 平方和 自由度 均方值 F值 P值 备注 模型 41 019.85 14 2 929.99 32.58 <0.000 1 非常显著 n 4 916.29 1 4 916.29 54.67 <0.000 1 3 vf 14 885.82 1 14 885.82 165.52 <0.000 1 1 ap 7 550.43 1 7 550.43 83.96 < 0.000 1 2 A 68.33 1 68.33 0.76 0.396 3 4 n−vf 274.71 1 274.71 3.05 0.099 7 n−ap 154.60 1 154.60 1.72 0.208 3 n−A 4 842.00 1 4 842.00 53.84 < 0.0001 vf−ap 1 399.13 1 1 399.13 15.56 0.001 2 vf−A 2 169.56 1 2 169.56 24.12 0.000 2 ap−A 741.04 1 741.04 8.24 0.011 1 n2 422.38 1 422.38 4.70 0.045 7 vf2 1 471.65 1 1 471.65 16.36 0.000 9 ap2 527.39 1 527.39 5.86 0.027 7 A2 1 242.08 1 1 242.08 13.81 0.001 9 残差 1 438.94 16 89.93 失拟项 942.49 10 94.25 1.14 0.456 3 不显著 纯误差 496.46 6 82.74 总和 42 458.79 30 R2=0.966 1 表 5 不同权重占比下的优化结果

Table 5. Optimized results under different weight ratios

组号 权重因素 优化结果 参数 结果 ${W_{{S_{\rm{a}}}}} $ ${W_{{D_{\rm{d}}}}} $ ${W_{{V_{{\rm{MRR}}}}}} $ n

(r·min−1)vf

(mm·min−1)ap

mmA

μmSa

μmDd

μmVMRR

(mm3·min−1)1 1/3 1/3 1/3 23 693 882.36 0.90 4.41 3.34 81.21 2 902.41 2 3/5 1/5 1/5 23 864 999.98 0.72 4.69 1.93 68.59 2 630.45 3 1/5 3/5 1/5 23 602 714.27 0.97 4.05 3.50 52.18 2 512.22 4 1/5 1/5 3/5 23 999 745.94 1.30 4.49 5.09 105.01 3 538.53 中心点 — — — 16 000 600.00 1.00 6.00 5.72 116.78 2 184.00 表 6 Sa和Dd试验值与预测值对比

Table 6. Comparison of Sa and Dd test values with predicted values

项目 三维表面粗糙度

Sa /μm表面层损伤深度

Dd /μm试验值 4.67 95.13 预测值 5.09 105.01 相对误差绝对值 8.25% 9.41% -

[1] DONG S, LIAO W, ZHENG K, et al. Investigation on exit burr in robotic rotary ultrasonic drilling of CFRP/aluminum stacks [J]. International Journal of Mechanical Sciences,2019,151:868-876. doi: 10.1016/j.ijmecsci.2018.12.039 [2] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战 [J]. 复合材料学报,2020,37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry deve-lopment [J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706. [3] 胡记强, 王兵, 张涵其, 等. 热塑性复合材料构件的制备及其在航空航天领域的应用 [J]. 宇航总体技术,2020,4(4):61-70.HU Jiqiang, WANG Bing, ZHANG Hanqi, et al. Fabrication of thermoplastic composite components and their application in aerospace [J]. Astronautical Systems Engineering Technology,2020,4(4):61-70. [4] GAUGEL S, SRIPATHY P, HAEGER A, et al. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP) [J]. Composite Structures,2016,155:173-183. doi: 10.1016/j.compstruct.2016.08.004 [5] WANG X, KWON P, STURTEVANT C, et al. Comparative tool wear study based on drilling experiments on CFRP/Ti stack and its individual layers [J]. Wear,2014,317(1/2):265-276. doi: 10.1016/j.wear.2014.05.007 [6] 郭留雨. 含分层缺陷复合材料格栅加筋结构压缩力学性能分析 [D]. 哈尔滨: 哈尔滨理工大学, 2019.GUO Liuyu. The effects of delamination defici-encies on compressive mechanical properties of reinforced composite skin structures [D]. Harbin: Harbin University of Science and Technology, 2019. [7] XU W, ZHANG L, WU Y. Effect of tool vibration on chip formation and cutting forces in the machining of fiber-reinforced polymer composites [J]. Machining Science and Technology,2016,20(2):312-329. doi: 10.1080/10910344.2016.1168930 [8] ASMAEL M, SAFAEI B, ZEESHAN Q, et al. Ultrasonic machining of carbon fiber-reinforced plastic composites: A review [J]. The Inter-national Journal of Advanced Manufacturing Technology,2021,113:3079-3120. doi: 10.1007/s00170-021-06722-2 [9] 胡安东. 超声振动辅助铣磨CFRP试验研究 [D]. 南京: 南京航空航天大学, 2016.HU Andong. Study on ultrasonic vibration assisted grinding of CFRP [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. [10] WANG H, HU Y, CONG W, et al. A novel investigation on horizontal and 3D elliptical ultrasonic vibrations in rotary ultrasonic surface machining of carbon fiber reinforced plastic composites [J]. Journal of Manufacturing Processes,2020,52:12-25. doi: 10.1016/j.jmapro.2020.01.027 [11] WANG H, Ning F, HU Y, et al. Edge trimming of CFRP composites using rotary ultrasonic machining: Effects of ultrasonic vibration: ASME 2018 13th international manufacturing science and engineering conference [C]. New York: ASME, 2018. [12] LI Y, REN C, WANG H, et al. Edge surface grinding of CFRP composites using rotary ultrasonic machining: Comparison of two mach-ining methods [J]. The International Journal of Advanced Manufacturing Technology,2019,100:3237-3248. doi: 10.1007/s00170-018-2901-1 [13] CHEN X, WANG H, HU Y, et al. Rotary ultrasonic machining of CFRP composites: Effects of machining variables on workpiece delamination: ASME 2019 14th international manufacturing science and engineering conference [C]. Pennsylvania: ASME, 2019. [14] LIU J, ZHANG D, QIN L, et al. Feasibility study of the rotary ultrasonic elliptical machining of carbon fiber reinforced plastics (CFRP) [J]. International Journal of Machine Tools and Manufacture,2012,53(1):141-150. doi: 10.1016/j.ijmachtools.2011.10.007 [15] WANG H, NING F, HU Y, et al. Surface grinding of CFRP composites using rotary ultrasonic machining: A comparison of workpiece machining orientations. [J]. The International Journal of Advanced Manufacturing Technology,2018,95:2917-2930. doi: 10.1007/s00170-017-1401-z [16] 何宝凤, 魏翠娥, 刘柄显, 等. 三维表面粗糙度的表征和应用 [J]. 光学精密工程,2018,26(8):1994-2011. doi: 10.3788/OPE.20182608.1994HE Baofeng, WEI Cuie, LIU Bingxian, et al. Three-dimensional surface characterization and application [J]. Optics and Precision Engineering,2018,26(8):1994-2011. doi: 10.3788/OPE.20182608.1994 [17] LI Z, ZHANG F, LUO X, et al. Material removal mechanism of laser-assisted grinding of RB-SiC ceramics and process optimization [J]. Journal of the European Ceramic Society,2019,39(4):705-717. doi: 10.1016/j.jeurceramsoc.2018.11.002 [18] SHIM D. Effects of process parameters on additive manufacturing of aluminum porous materials and their optimization using response surface method [J]. Journal of Materials Research and Technology,2021,15:119-134. doi: 10.1016/j.jmrt.2021.08.010 [19] 李益兵, 王辉雄, 庄可佳. 航空钛合金高效插铣加工实验与多目标优化研究 [J/OL]. 机械科学与技术.https://doi.org/10.13433/j.cnki.-1003-8728.20200511.LI Yibing, WANG Huixiong, ZHUANG Kejia. Research on multiobjective optimization and high efficiency plunge milling experiment of titanium alloy for aviation [J/OL]. Mechanical Science and Technology for Aerospace Engineering. https://doi.org/10.13433/j.cnki.1003-87-28.20200511. [20] 李志鹏. RB-SiC陶瓷磨削损伤形成机制及抑制技术研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.LI Zhipeng. Research on grinding damage formation mechanism and suppression technology of reaction bonded silicon carbide ceramics [D]. Harbin: Harbin Institute of Technology, 2019. [21] 孙宏雨, 吕兴聪, 袁纳新, 等. 基于响应曲面法的木塑复合材料强度分析及挤出工艺优化 [J]. 复合材料学报,2021,38(6):1838-1846.SUN Hongyu, LV Xingcong, YUAN Naxin, et al. Strength analysis and extrusion process optimi-zation of wood-plastic composite by response surface method [J]. Acta Materiae Compositae Sinica,2021,38(6):1838-1846. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS