| [1] |

WENTORF R H. Cubic form of boron nitride [J]. The Journal of Chemical Physics,1957,26(4):956.

|

| [2] |

YANG D, JI X, LIU H, et al. The influence of Li-based catalysts / additives on cBN crystal morphologies synthesized under HPHT [J]. Diamond and Related Materials,2011,20(2):174-177. doi: 10.1016/j.diamond.2010.11.023

|

| [3] |

吉晓瑞, 苏作鹏, 杜勇慧, 等. 化学反应直接成核生长立方氮化硼 [J]. 金刚石与磨料磨具工程,2007(4):25-26. doi: 10.3969/j.issn.1006-852X.2007.04.007JI Xiaorui, SU Zuopeng, DU Yonghui, et al. Studies about the growth of cBN nucleated directly by chemical reaction [J]. Diamond and Abrasives Engineering,2007(4):25-26. doi: 10.3969/j.issn.1006-852X.2007.04.007

|

| [4] |

KO E H, KIM T H, CHOI S, et al. Synthesis of cubic boron nitride nanoparticles from boron oxide, melamine and NH3 by non-transferred Ar-N2 thermal plasma [J]. Journal of Nanoscience and Nanotechnology,2015,15(11):8515-8520. doi: 10.1166/jnn.2015.11469

|

| [5] |

BEASON M T, PAULS J M, GUNDUZ I E, et al. Shock-induced reaction synthesis of cubic boron nitride [J]. Applied Physics Letters,2018,112(17):171903. doi: 10.1063/1.5017836

|

| [6] |

BUNDY F P, WENTORF R H. Direct transformation of hexagonal boron nitride to denser forms [J]. The Journal of Chemical Physics,1963,38(5):1144-1149. doi: 10.1063/1.1733815

|

| [7] |

CORRIGAN F R, BUNDY F P. Direct transitions among the allotropic forms of boron nitride at high pressures and temperatures [J]. The Journal of Chemical Physics,1975,63(9):3812-3820. doi: 10.1063/1.431874

|

| [8] |

WAKATSUKI M, ICHINOSE K, AOKI T. Synthesis of polycrystalline cubic BN [J]. Materials Research Bulletin,1972,7(9):999-1003. doi: 10.1016/0025-5408(72)90091-8

|

| [9] |

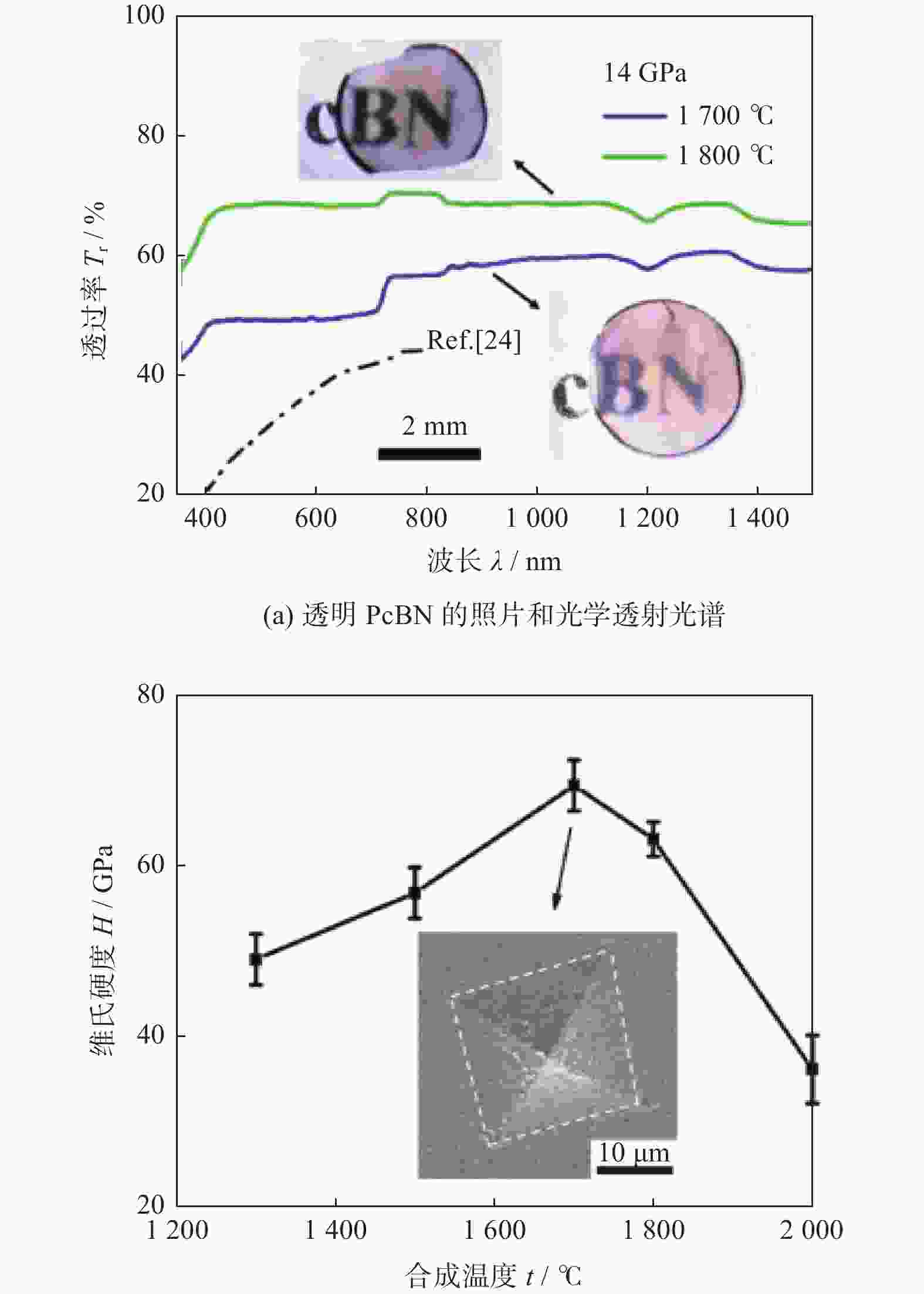

AKAISHI M, SATOH T, ISHII M, et al. Synthesis of translucent sintered cubic boron nitride [J]. Journal of Materials Science Letters,1993,12(24):1883-1885. doi: 10.1007/BF00882529

|

| [10] |

TANIGUCHI T, AKAISHI M, YAMAOKA S. Mechanical properties of polycrystalline translucent cubic boron nitride as characterized by the Vickers indentation method [J]. Journal of the American Ceramic Society,1996,79(2):547-549. doi: 10.1111/j.1151-2916.1996.tb08165.x

|

| [11] |

OHASHI T, YAMAMOTO K, HAMADA Y, et al. Some properties and cutting performance of polycrystalline cubic boron nitride with no additives [J]. International Journal of Refractory Metals and Hard Materials,1998,16(4/5/6):403-407. doi: 10.1016/S0263-4368(98)00057-2

|

| [12] |

SUMIYA H, UESAKA S, SATOH S. Mechanical properties of high purity polycrystalline cBN synthesized by direct conversion sintering method [J]. Journal of Materials Science,2000,35(5):1181-1186. doi: 10.1023/A:1004780218732

|

| [13] |

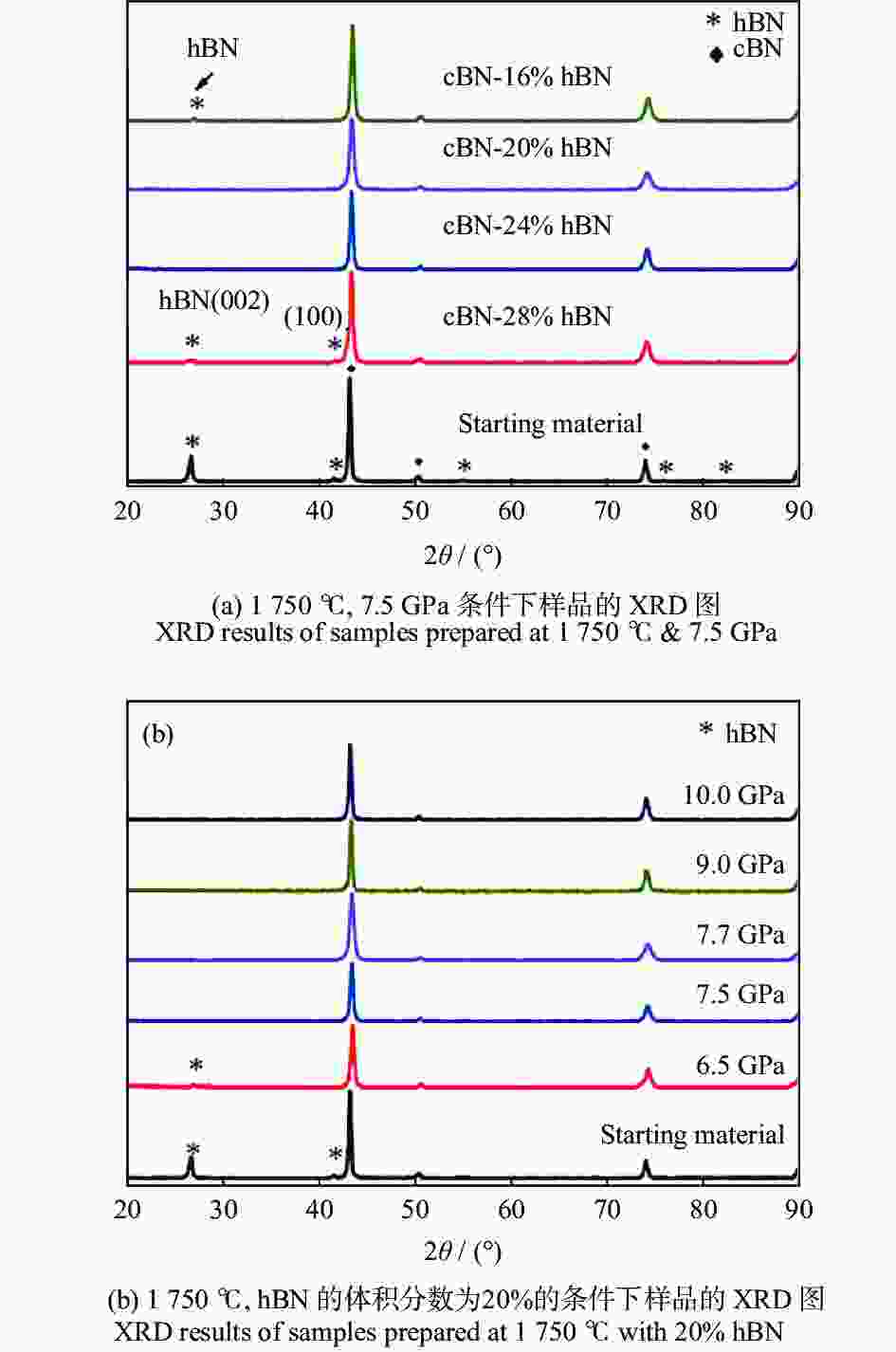

YANG M, KOU Z L, LIU T, et al. Polycrystalline cubic boron nitride prepared with cubic-hexagonal boron nitride under high pressure and high temperature [J]. Chinese Physics B,2018,27(5):056105. doi: 10.1088/1674-1056/27/5/056105

|

| [14] |

DUB S N, PETRUSHA I A. Mechanical properties of polycrystalline cBN obtained from pyrolytic gBN by direct transformation technique [J]. High Pressure Research,2006,26(2):71-77. doi: 10.1080/08957950600764239

|

| [15] |

DUBROVINSKAIA N, SOLOZHENKO V L, MIYAJIMA N, et al. Superhard nanocomposite of dense polymorphs of boron nitride: Noncarbon material has reached diamond hardness [J]. Applied Physics Letters,2007,90(10):101912. doi: 10.1063/1.2711277

|

| [16] |

SOLOZHENKO V L, KURAKEVYCH O O, Le GODEC Y. Creation of nanostuctures by extreme conditions: High‐pressure synthesis of ultra- hard nanocrystalline cubic boron nitride [J]. Advanced Materials,2012,24(12):1540-1544. doi: 10.1002/adma.201104361

|

| [17] |

ICHIDA Y, OHFUJI H, IRIFUNE T, et al. Synthesis of ultrafine nano-polycrystalline cubic boron nitride by direct transformation under ultrahigh pressure [J]. Journal of the European Ceramic Society,2018,38(7):2815-2822. doi: 10.1016/j.jeurceramsoc.2018.02.023

|

| [18] |

TIAN Y, XU B, YU D, et al. Ultrahard nanotwinned cubic boron nitride [J]. Nature,2013,493(7432):385-388. doi: 10.1038/nature11728

|

| [19] |

DUBROVINSKAIA N, DUBROVINSKY L. Controversy about ultrahard nanotwinned cBN [J]. Nature,2013,502(7472):E1-E2. doi: 10.1038/nature12620

|

| [20] |

TANIGUCHI T, AKAISHI M, YAMAOKA S. Sintering of cubic boron nitride without additives at 7.7 GPa and above 2 000 ℃ [J]. Journal of Materials Research,1999,14(1):162-169. doi: 10.1557/JMR.1999.0024

|

| [21] |

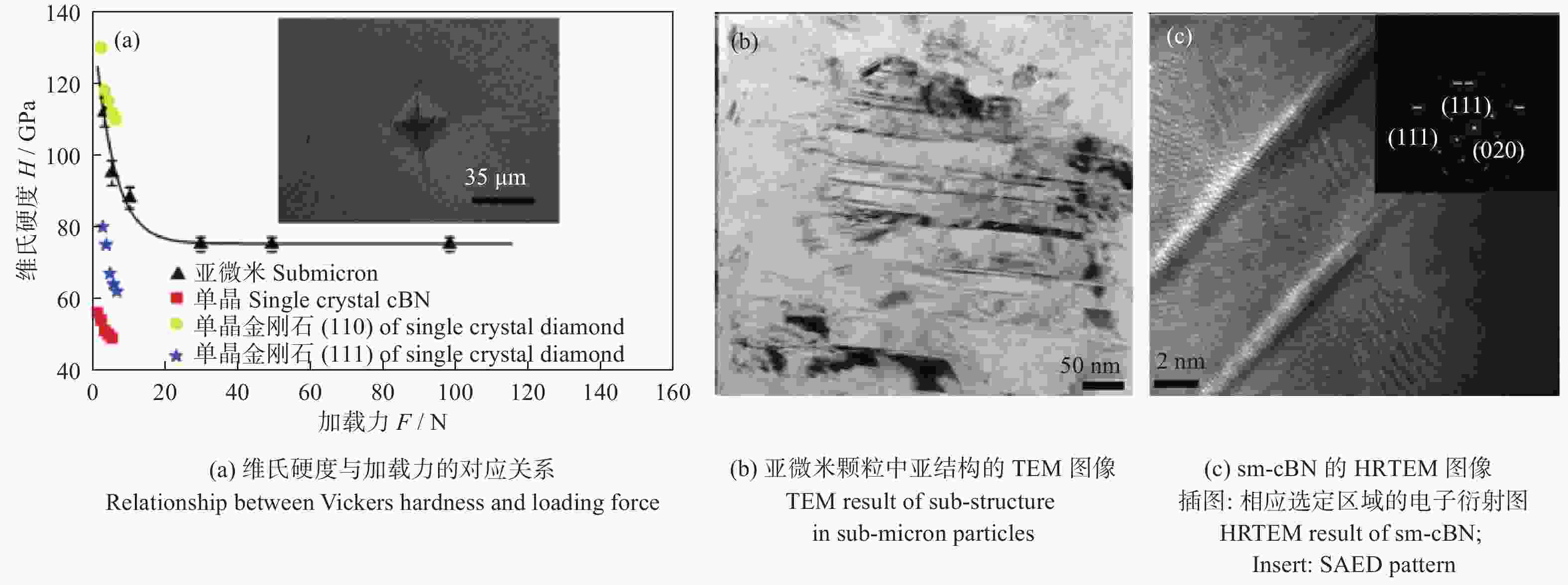

LIU G, KOU Z, YAN X, et al. Submicron cubic boron nitride as hard as diamond [J]. Applied Physics Letters,2015,106(12):121901. doi: 10.1063/1.4915253

|

| [22] |

LIU T, KOU Z, LU J, et al. Preparation of superhard cubic boron nitride sintered from commercially available submicron powders [J]. Journal of Applied Physics,2017,121(12):125902. doi: 10.1063/1.4979312

|

| [23] |

YIN X, KOU Z, WANG Z, et al. Micro-sized polycrystalline cubic boron nitride with properties comparable to nanocrystalline counterparts [J]. Ceramics International,2020,46(7):8806-8810. doi: 10.1016/j.ceramint.2019.12.120

|

| [24] |

ZHAO M, KOU Z, ZHANG Y, et al. Superhard transparent polycrystalline cubic boron nitride [J]. Applied Physics Letters,2021,118(15):151901. doi: 10.1063/5.0045545

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS