Study on grinding force in grinding titanium alloy with diamond grinding wheel

-

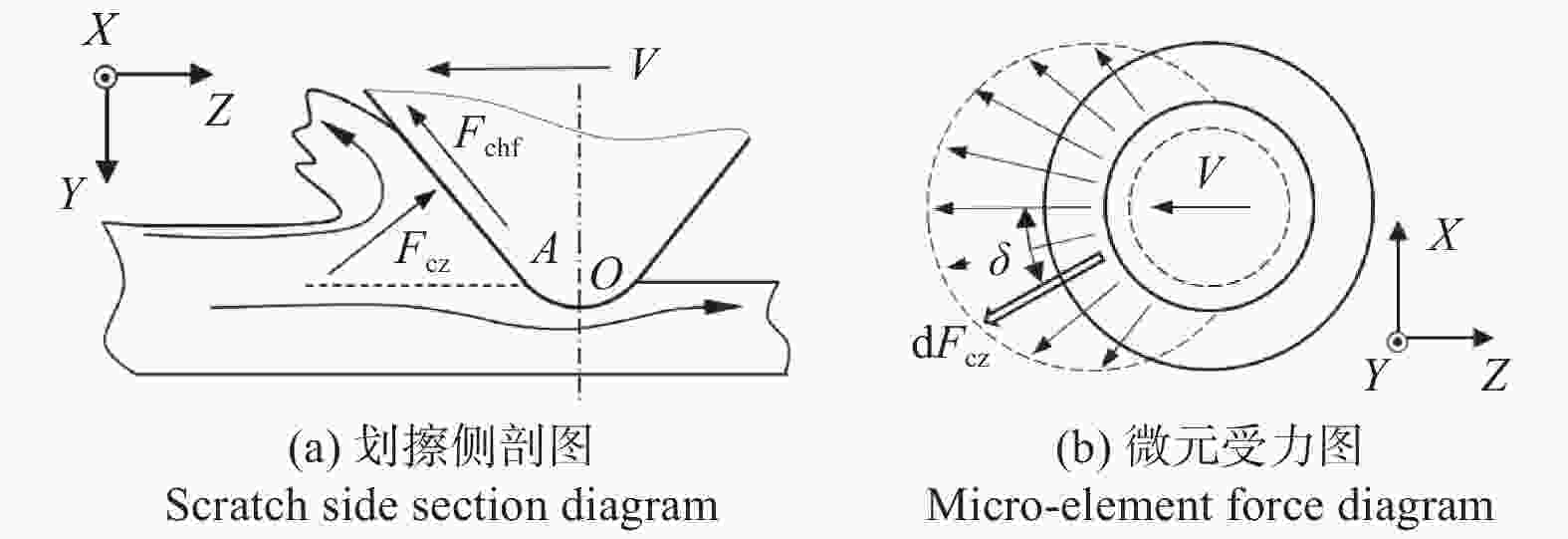

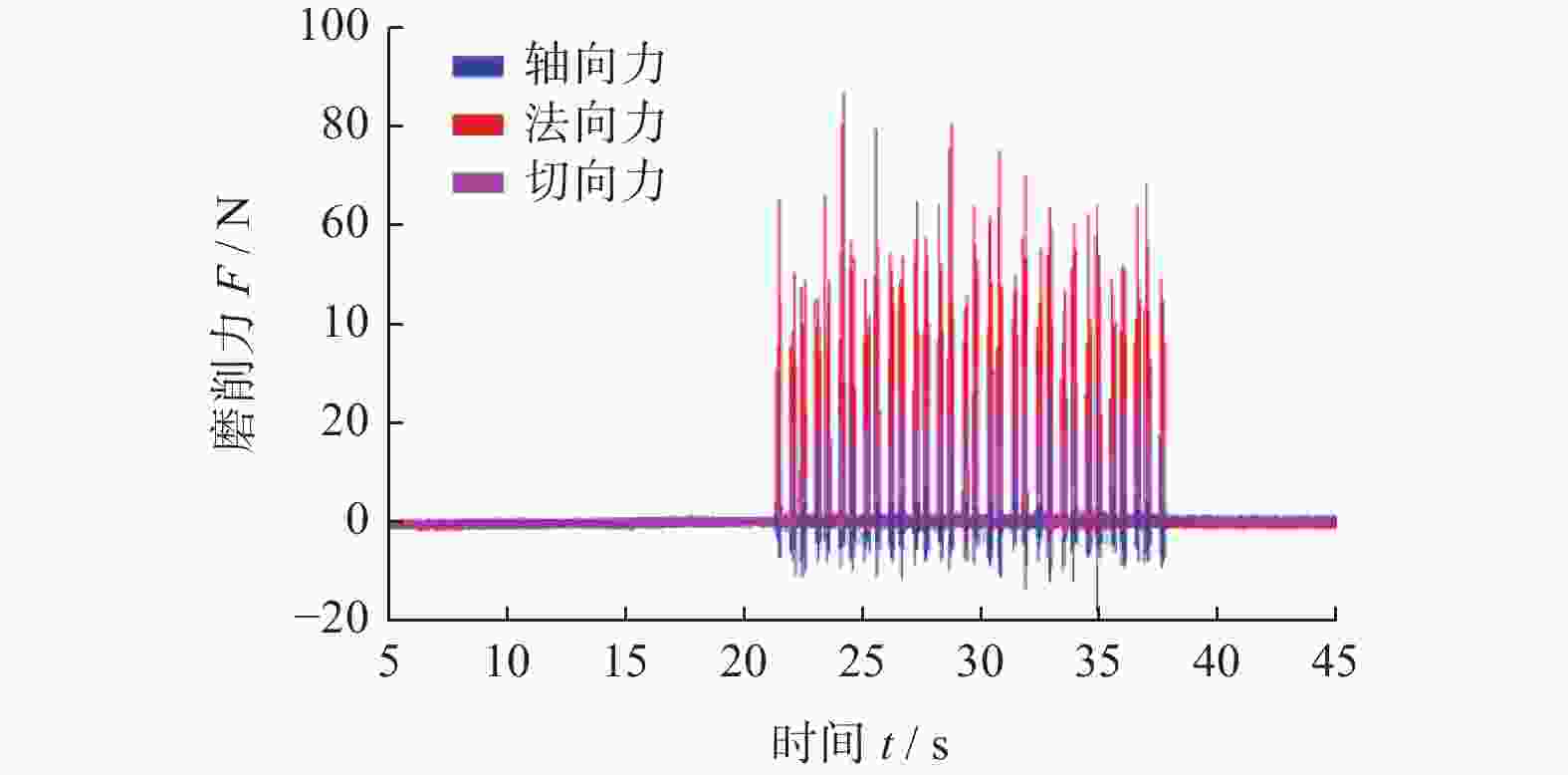

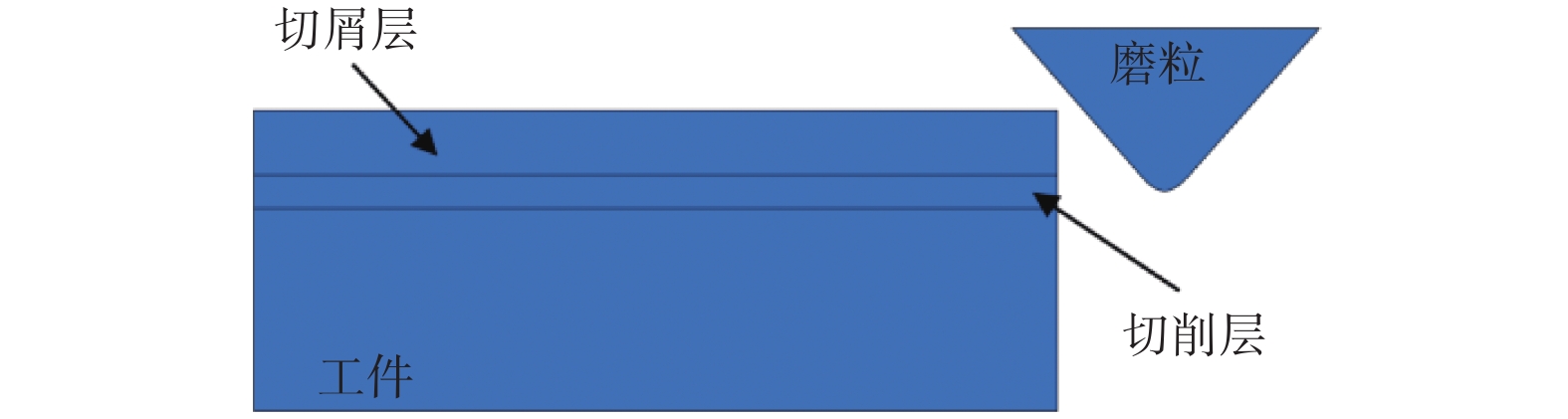

摘要: 为解决金刚石砂轮磨削钛合金时材料弹性模量低、弹性形变大等问题,从理论上对砂轮的受力状态进行分析。基于切屑分离准则和材料摩擦属性,构建钛合金磨削时的受力模型,并对单颗磨粒的受力状态进行有限元仿真。设计钛合金磨削加工试验,研究工艺参数变化对砂轮磨削力的影响规律。结果表明:砂轮磨削速度增加,磨削力逐渐降低;当进给速度和磨削深度增加时,磨削力增加。当磨削工艺参数改变时,砂轮的切向和法向磨削力的变化趋势大致相同,切向和法向磨削力的比值为0.29~0.37。且磨削力的理论值和试验值的变化趋势基本一致,二者相对误差的平均值在5%以内,验证了磨削力理论模型的正确性。Abstract: To solve the problems of low elastic modulus and large elastic deformation when grinding titanium alloy with diamond grinding wheel, the force of grinding wheel was analyzed theoretically. Based on the chip separation criterion and the material friction properties, the cutting force model of titanium alloy grinding was established, and the cutting force state of a single abrasive particle was simulated by finite element method. The grinding experiment of titanium alloy was designed to study the influences of process parameters on the grinding forces of grinding wheel. The results show that the grinding force decreases with the increase of grinding speed. When the feed rate and the grinding depth increase, the grinding forces increase. When the grinding process parameters are changed, the change trend of tangential and normal grinding forces of the grinding wheel is roughly the same, and the ratio of the tangential and the normal force is 0.29~0.37. The variation trend of the theoretical value of grinding force is basically consistent with the experimental value, and the average value of the relative error between the two is within 5%, which verifies the correctness of the theoretical model of grinding force.

-

Key words:

- titanium alloy /

- finite element analysis /

- grinding force /

- diamond grinding wheel

-

表 1 钛合金J-C本构模型参数

Table 1. J-C constitutive model parameters of titanium alloy

参数 取值 A 875 B 793 C 0.011 n 0.386 m 0.71 表 2 模型验证试验参数及磨削力值

Table 2. Model verification test parameters and grinding force values

组别 因素 结果 磨削速度

vs

(m·min−1)进给速度

vw

(mm·min−1)磨削

深度

h / μm法向力

试验值

FNS / N切向力

试验值

FTS / N1 16 50 30 35.4 10.1 2 32 50 30 17.9 5.9 3 24 30 30 15.1 5.4 4 24 70 30 32.2 9.7 5 24 50 10 14.5 4.5 6 24 50 50 50.0 16.7 表 3 未知参数

Table 3. Unknown parameters

参数 取值 k 3.667 γ 22.981 ξ 0.357 表 4 单因素试验参数

Table 4. Single factor test parameters

组别 磨削速度

vs / (m·min−1)进给速度

vw / (mm·min−1)磨削深度

h / μm1 16 50 30 2 20 50 30 3 24 50 30 4 28 50 30 5 32 50 30 6 24 30 30 7 24 40 30 8 24 50 30 9 24 60 30 10 24 70 30 11 24 50 10 12 24 50 20 13 24 50 30 14 24 50 40 15 24 50 50 表 5 钛合金磨削时的磨削力试验值和理论值

Table 5. Experimental and theoretical values of grinding forces during titanium alloy grinding

组别 法向力

试验值

FNS / N切向力

试验值

FTS / N轴向力

试验值

FAS / N法向力

理论值

FNL / N切向力

理论值

FTL / N法向力

相对误差

δN / %切向力

相对误差

δT / %1 34.5 10.5 0.3 32.5 10.8 6.2 2.8 2 29.2 9.7 0.6 27.5 9.2 6.2 5.4 3 23.3 7.9 0.4 23.1 7.7 0.9 2.6 4 20.5 6.8 0.3 21.1 7.0 2.8 2.9 5 18.1 6.2 0.3 19.7 6.6 8.1 6.1 6 15.2 5.3 0.7 16.2 5.4 6.2 1.9 7 18.9 6.3 0.6 19.6 6.5 3.6 3.1 8 23.3 7.9 0.4 23.1 7.7 0.9 2.6 9 28.0 9.3 0.7 26.5 8.8 5.7 5.7 10 32.4 9.5 0.8 30.0 10.0 8.0 5.0 11 14.6 4.6 0.5 15.5 5.1 5.8 9.8 12 18.3 6.9 0.5 19.1 6.4 4.2 7.8 13 23.3 7.9 0.4 23.1 7.7 0.9 2.6 14 35.7 11.2 1.1 33.7 11.0 5.9 1.8 15 50.2 16.9 0.9 47.9 16.0 4.8 5.6 平均值 4.7 4.4 -

[1] 许松, 李文斌. 摩擦系数对微铣削加工的影响 [J]. 工具技术,2018,52(4):116-119. doi: 10.3969/j.issn.1000-7008.2018.04.027XU Song, LI Wenbin. Influence of friction coefficient on micro-milling [J]. Tool Engineering,2018,52(4):116-119. doi: 10.3969/j.issn.1000-7008.2018.04.027 [2] 徐九华. 钛合金切削磨削加工技术研究进展 [J]. 金刚石与磨料磨具工程,2020,40(5):1-4. doi: 10.3969/j.issn.1006-852X.2020.05.001XU Jiuhua. Research progress of titanium alloy cutting and grinding technology [J]. Diamond & Abrasives Engineering,2020,40(5):1-4. doi: 10.3969/j.issn.1006-852X.2020.05.001 [3] 张永强, 余巍, 崔红力, 等. 钛合金阀门的应用及其选材 [J]. 流体机械,2013,41(9):44-48. doi: 10.3969/j.issn.1005-0329.2013.09.011ZHANG Yongqiang, YU Wei, CUI Hongli, et al. Application and material selection of titanium valves [J]. Fluid Machinery,2013,41(9):44-48. doi: 10.3969/j.issn.1005-0329.2013.09.011 [4] 黄智, 董华章, 周振武, 等. 砂带磨削TC4磨削力数字建模及其预测 [J]. 表面技术,2018,47(9):259-267.HUANG Zhi, DONG Huazhang, ZHOU Zhenwu, et al. Modeling and prediction of grinding force on belt grinding TC4 [J]. Surface Technology,2018,47(9):259-267. [5] 梁巧云, 单坤, 李兆瑞, 等. 航发钛合金叶片金刚石砂带磨削的磨粒磨损研究 [J]. 金刚石与磨料磨具工程,2020,40(4):59-64.LIANG Qiaoyun, SHAN Kun, LI Zhaorui, et al. Investigation of grain wear in diamond abrasive belt grinding titanium alloy blade for aeroengine [J]. Diamond & Abrasives Engineering,2020,40(4):59-64. [6] 蔡卫星, 周伟华, 张峰. 21NiCrMo5H齿轮钢超声磨削力建模研究 [J]. 现代制造工程,2020(4):113-118.CAI Weixing, ZHOU Weihua, ZHANG Feng. Research on the grinding force model of ultrasonic grinding for 21NiCrMo5H [J]. Modern Manufacturing Engineering,2020(4):113-118. [7] 朱文博, 黎康顺, 朱欢欢, 等. 圆锥滚子球基面磨削力模型及实验研究 [J]. 中国机械工程,2020,31(6):679-687. doi: 10.3969/j.issn.1004-132X.2020.06.007ZHU Wenbo, LI Kangshun, ZHU Huanhuan, et al. Grinding force model and experimental study of tapered roller ball base surfaces [J]. China Mechanical Engineering,2020,31(6):679-687. doi: 10.3969/j.issn.1004-132X.2020.06.007 [8] 王君明, 叶人珍, 汤漾平, 等. 55钢CBN砂轮平面磨削的磨削力模型研究 [J]. 金刚石与磨料磨具工程,2010,30(1):67-70,79. doi: 10.3969/j.issn.1006-852X.2010.01.017WANG Junming, YE Renzhen, TANG Yangping, et al. Research on the grinding force model of steel 55 during surface grinding with CBN wheel [J]. Diamond & Abrasives Engineering,2010,30(1):67-70,79. doi: 10.3969/j.issn.1006-852X.2010.01.017 [9] 丁书召. 平磨磨削力的数学模型改进与实验 [J]. 机床与液压,2019,47(15):134-138. doi: 10.3969/j.issn.1001-3881.2019.15.029DING Shuzhao. Improvement and experiment of mathematical model of grinding force in flat grinding [J]. Machine Tool & Hydraulics,2019,47(15):134-138. doi: 10.3969/j.issn.1001-3881.2019.15.029 [10] YAO X, BERMINGHAM M, WANG G, et al. FEA modelling of cutting force and chip formation in thermally assisted machining of Ti6Al4V alloy [J]. Materials Science Forum,2013,765:343-347. doi: 10.4028/www.scientific.net/MSF.765.343 [11] AGARWAL S, RAO V P. Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding [J]. International Journal of Machine Tools and Manufacture,2013,65:68-78. doi: 10.1016/j.ijmachtools.2012.10.006 [12] 杨军, 李志鹏, 李伟, 等. 基于不同单颗磨粒模型的微细磨削力研究 [J]. 湖南大学学报(自然科学版),2018,45(8):54-62.YANG Jun, LI Zhipeng, LI Wei, et al. Study on micro-grinding force based on different single abrasive particle models [J]. Journal of Hunan University (Natural Sciences),2018,45(8):54-62. [13] 郎献军, 何玉辉, 唐进元, 等. 基于磨粒突出高度为瑞利分布的磨削力模型 [J]. 中南大学学报(自然科学版),2014,45(10):3386-3391.LANG Xianjun, HE Yuhui, TANG Jinyuan, et al. Grinding force model based on prominent height of abrasive submitted to Rayleigh distribution [J]. Journal of Central South University (Science and Technology),2014,45(10):3386-3391. [14] DURGUMAHANTI S P U, SINGH V, RAO V P. A new model for grinding force prediction and analysis [J]. International Journal of Machine Tools and Manufacture,2009,50(3):231-240. [15] 张黎明. 微晶云母陶瓷超声振动铣磨小孔出口崩边研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.ZHANG Liming. Study on edge chipping at the small hole exit in rotary ultrasonic milling-grinding of microcrystalline mica ceramics [D]. Harbin: Harbin Institute of Technology, 2019. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS