On-line discrimination of radial runout state during diamond roller trimming

-

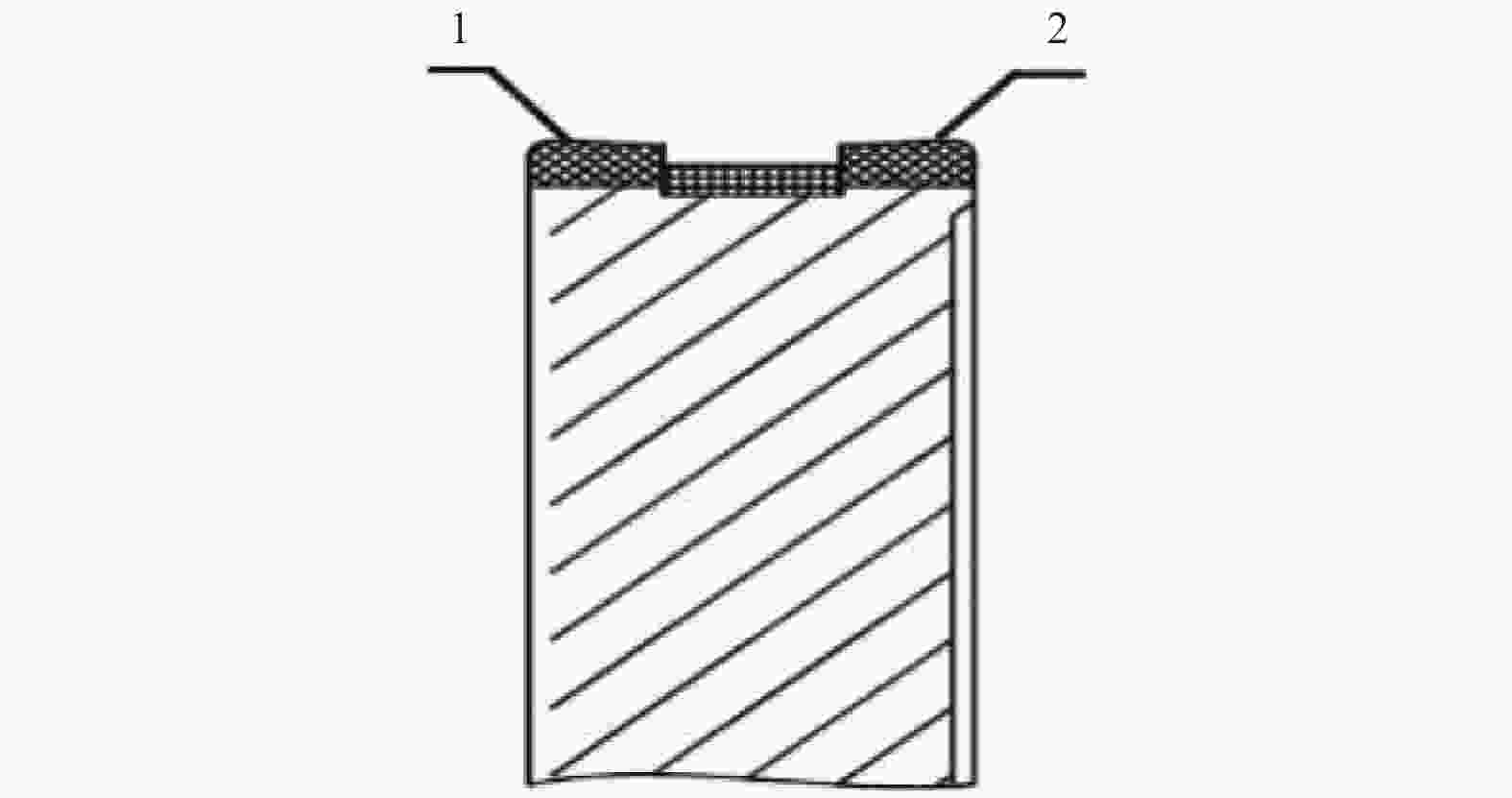

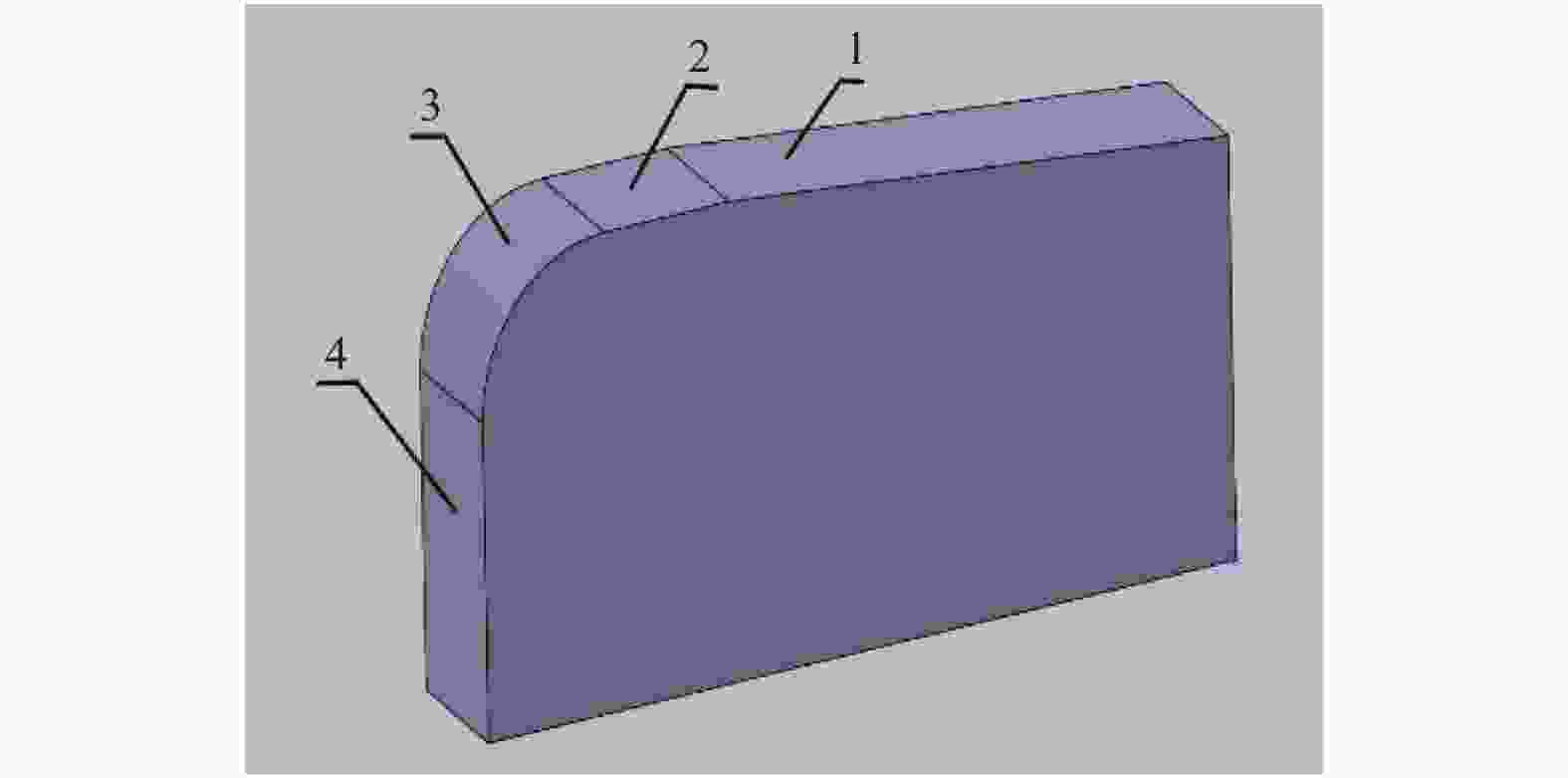

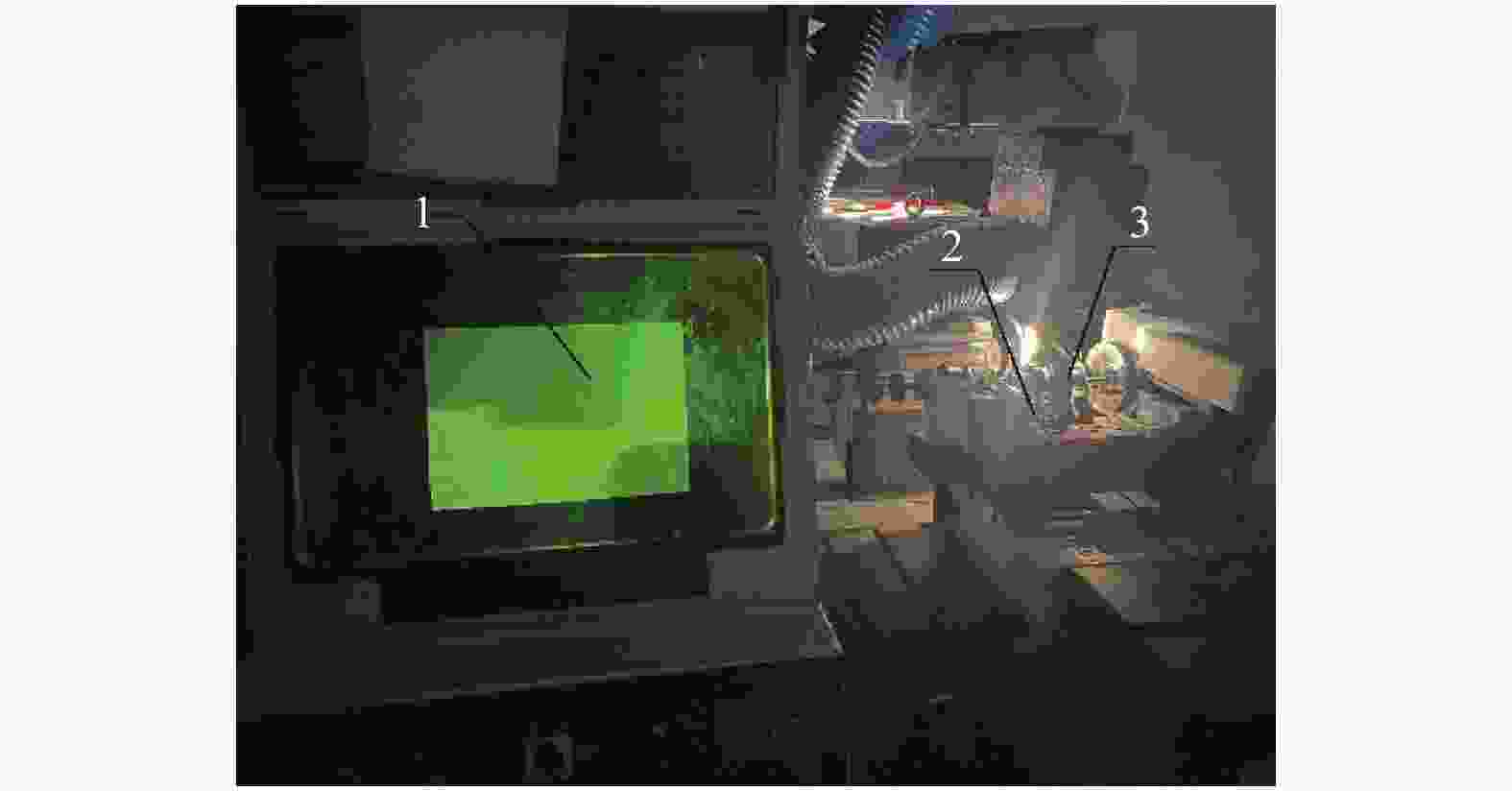

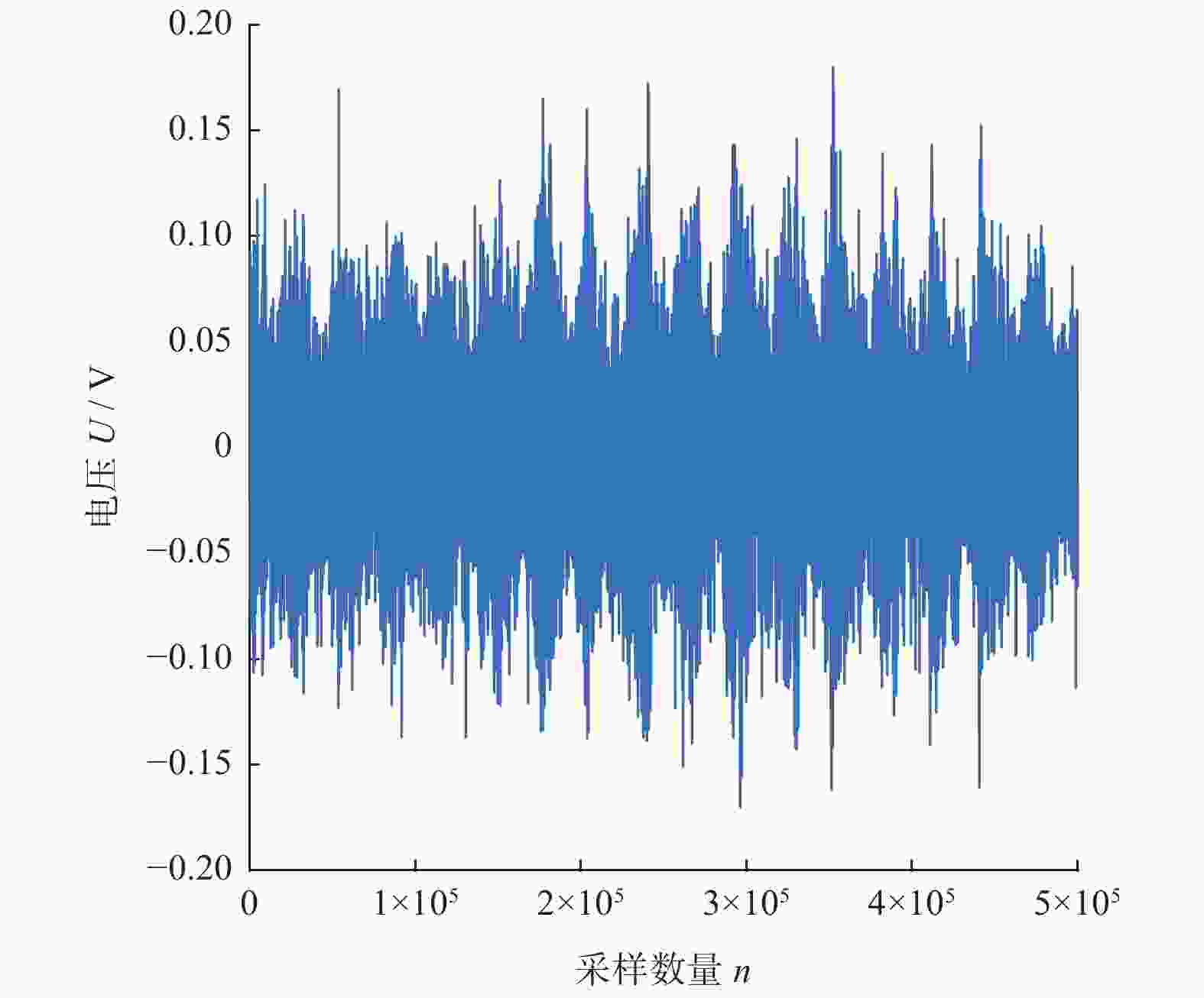

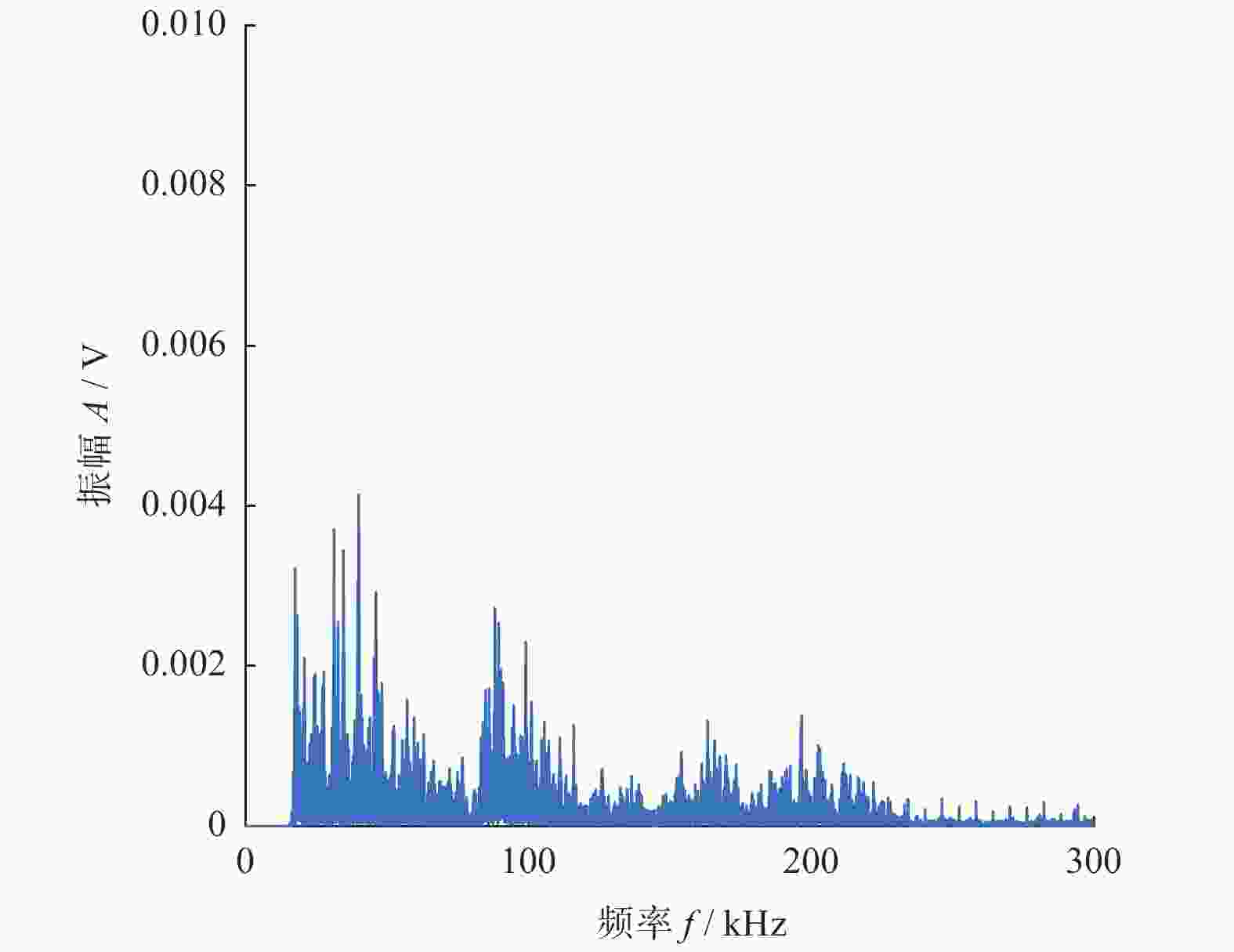

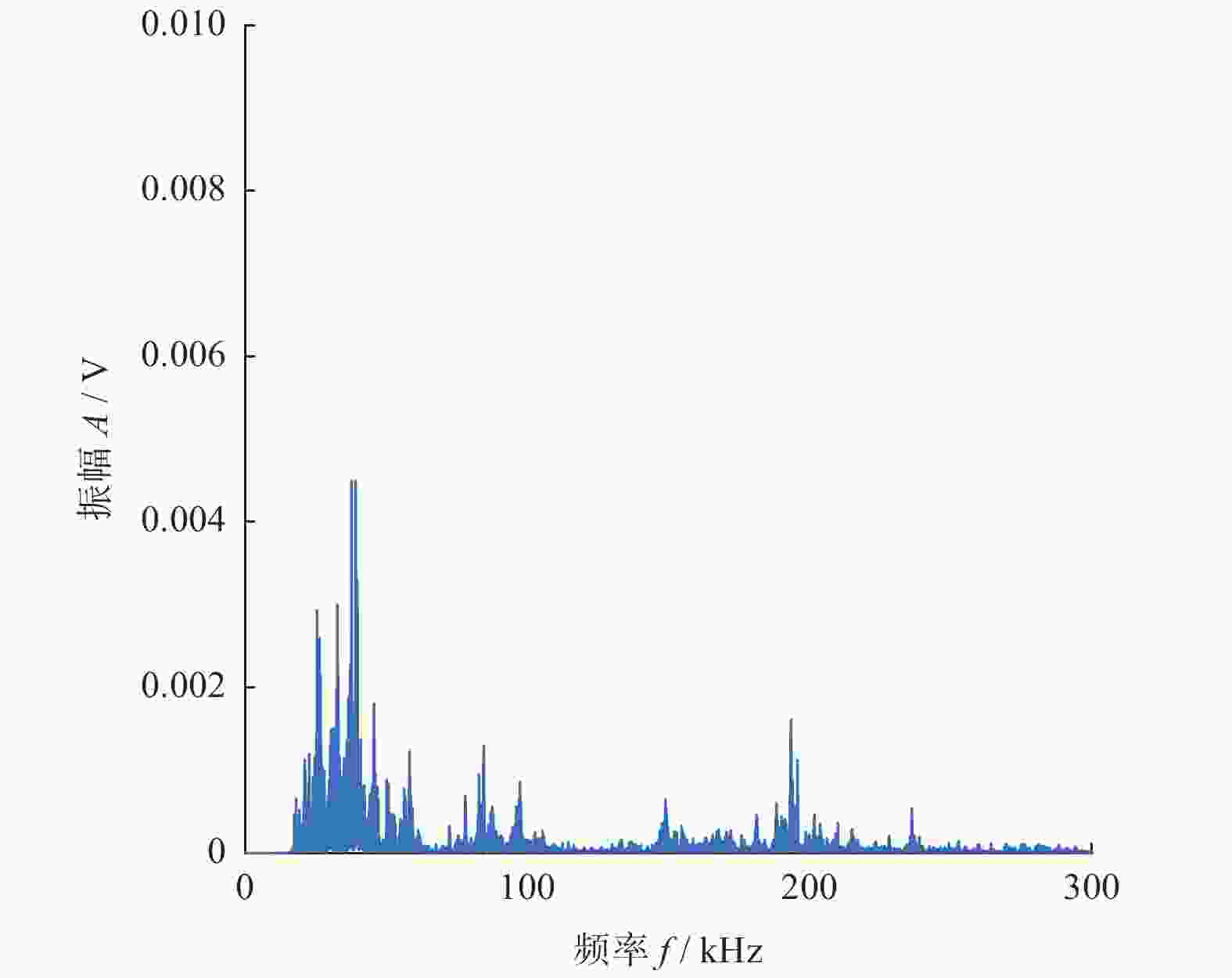

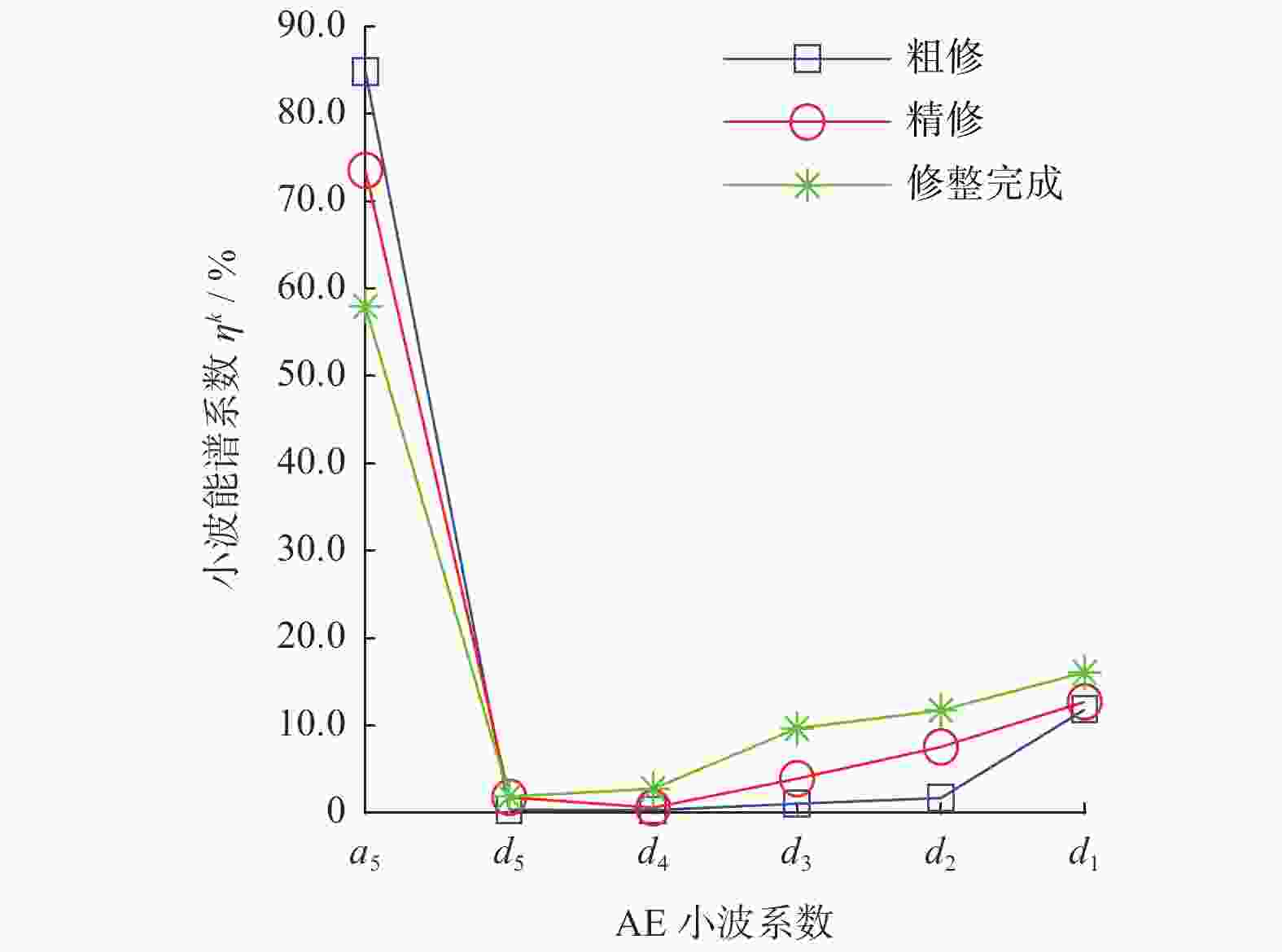

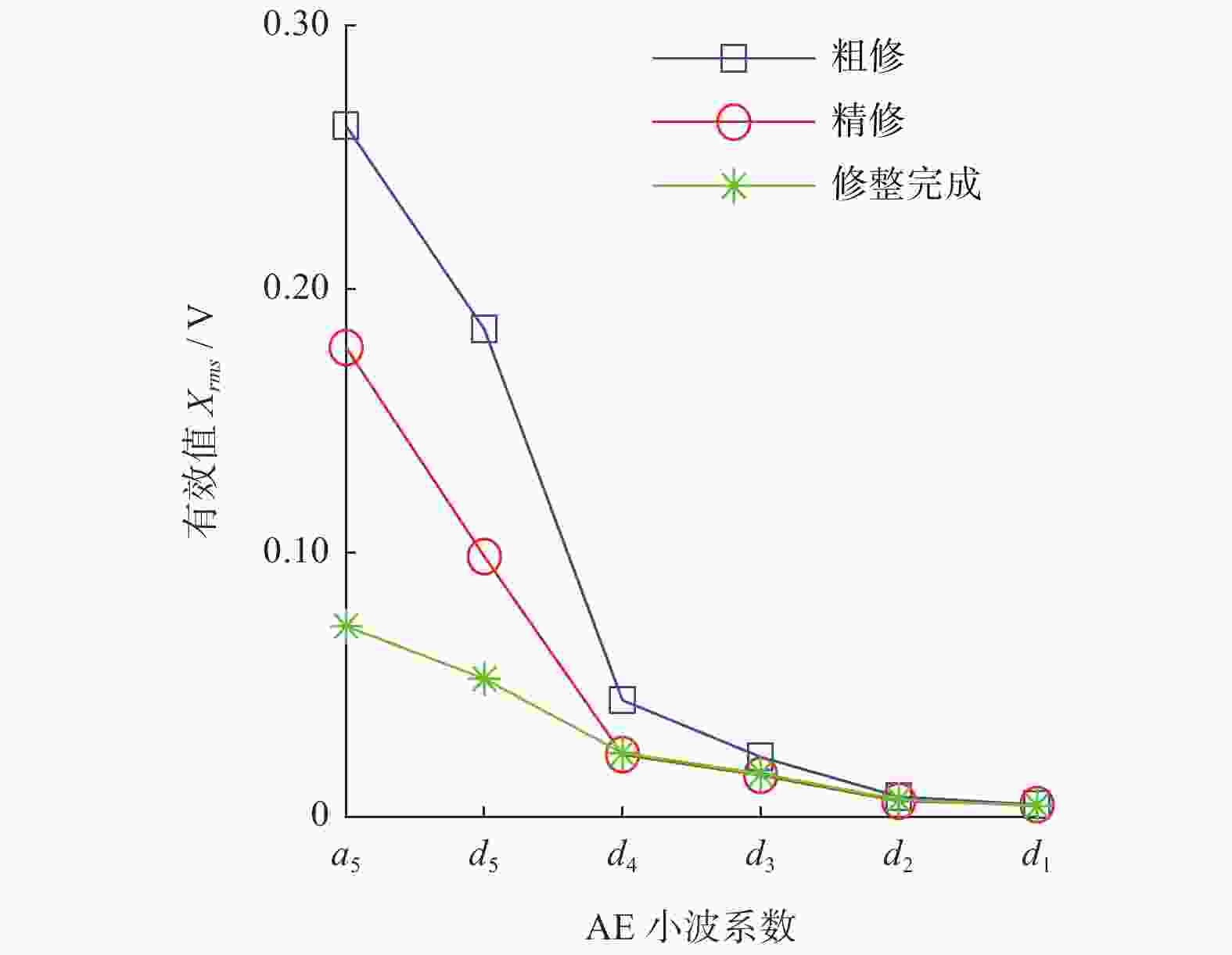

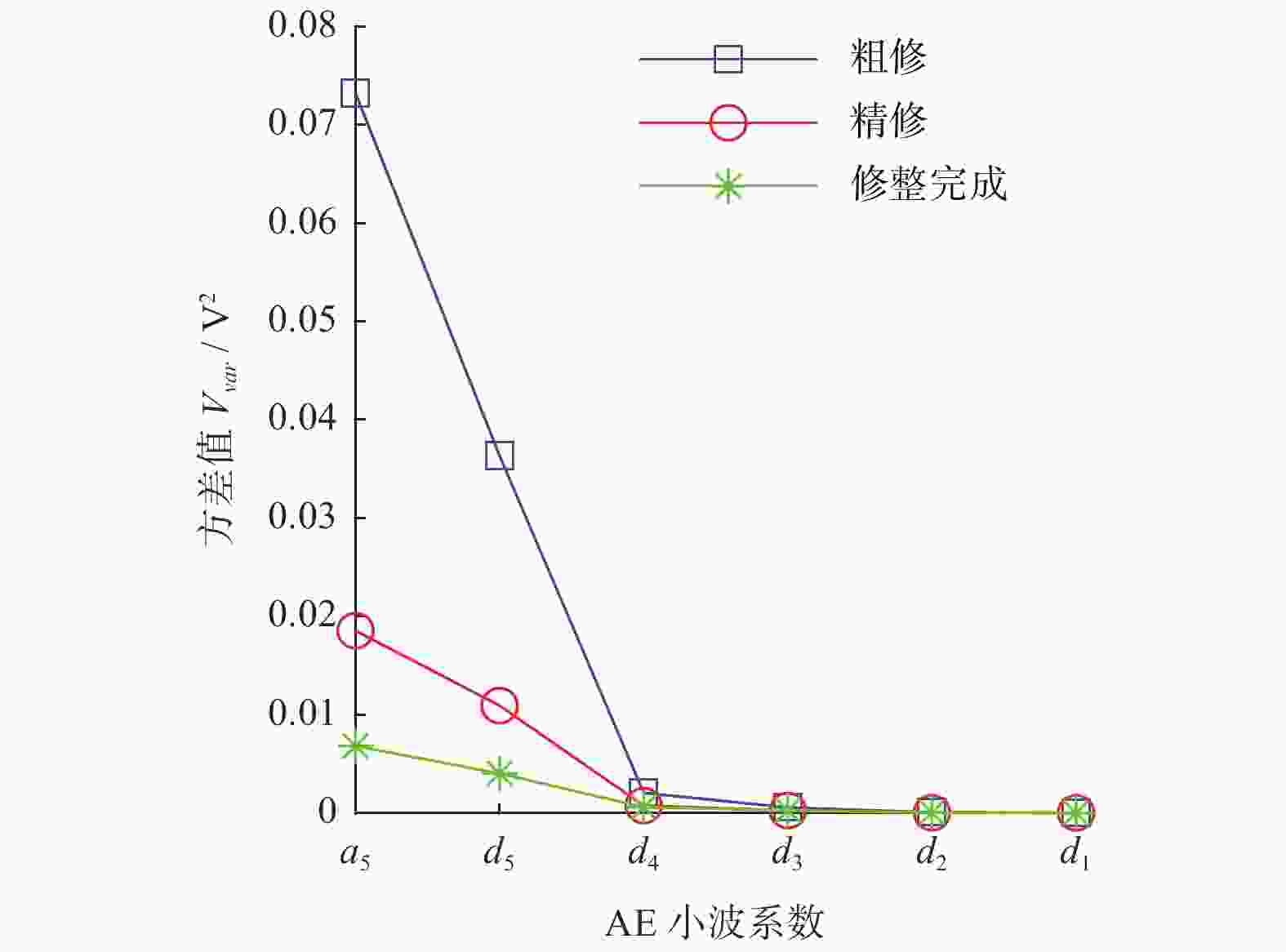

摘要: 金刚石滚轮修整砂轮时的性能受其径向圆跳动的影响,而其径向圆跳动状态判别的智能化程度较低。为此,对金刚石滚轮修整状态下的径向圆跳动磨削声发射信号,提出一种基于小波分解和SVM的在线检测方法。将磨削声发射信号通过小波变换并分解,提取小波分解系数的有效值、方差及能谱系数3种特征参数。结果表明:将3种特征参数彼此组合输入到SVM中进行状态识别时的准确率都在96.0%以上;3种特征参数同时输入时的准确率最高,达到了98.3%。该检测方法具有实际应用价值。Abstract: The performance of diamond roller when dressing grinding wheel was affected by its radial runout, but the intelligent degree of judging its radial runout state was low. Therefore, an on-line detection method based on wavelet decomposition and SVM was proposed for the grinding acoustic emission signal of radial runout under the trimming state of diamond roller. The grinding acoustic emission signal was transformed and decomposed by wavelet transform, and the three characteristic parameters of wavelet decomposition coefficients were extracted, which were effective value, variance value and energy spectrum coefficient. The results show that the accuracies of combining the three feature parameters into SVM for state recognition are more than 96.0%. When the three characteristic parameters are input at the same time, the accuracy is the highest, reaching 98.3%. The detection method has practical application value.

-

表 1 修整试验参数

Table 1. Trimming test parameters

参数 类型或取值 滚轮直径 D1 / mm 130 滚轮宽度 W1 / mm 16 砂轮直径 D2 / mm 200 砂轮中金刚石粒度代号 120/140 砂轮宽度 W2 / mm 3 砂轮中金刚石浓度 C / % 120 砂轮结合剂 V 砂轮转速 n1 / (r·min−1) 4 000 滚轮转速 n2 / (r·min−1) 70 纵向走刀速度 n3 / (mm·min−1) 2.4 粗修时的进给量 s1 / μm 8 精修时的进给量 s2 / μm 2 精修完成时的进给量 s3 / μm 2 表 2 小波系数有效值

Table 2. Effective values of wavelet coefficients

序号 a5 d5 d4 d3 d2 d1 1 0.177 0.210 0.051 0.026 0.009 0.005 2 0.255 0.201 0.047 0.024 0.008 0.004 3 0.215 0.136 0.037 0.021 0.008 0.004 4 0.023 0.122 0.029 0.016 0.006 0.004 $ \vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ 597 0.197 0.195 0.046 0.027 0.009 0.004 598 0.207 0.160 0.041 0.021 0.071 0.004 599 0.238 0.124 0.032 0.018 0.061 0.004 600 0.207 0.160 0.041 0.021 0.071 0.004 表 3 小波系数方差

Table 3. Variances of wavelet coefficients

序号 a5 d5 d4 d3 d2 d1 1 3.1×10−2 4.4×10−2 0.3×10−2 6.8×10−4 8.1×10−5 2.0×10−5 2 3.5×10−2 3.1×10−2 0.1×10−2 5.0×10−4 5.9×10−5 1.8×10−5 3 3.6×10−2 2.4×10−2 0.2×10−2 3.6×10−4 6.2×10−5 2.3×10−5 4 3.5×10−2 1.6×10−2 0.1×10−2 3.9×10−4 4.4×10−5 1.7×10−5 $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ 597 3.6×10−2 3.6×10−2 2.2×10−2 6.1×10−4 5.6×10−5 1.9×10−5 598 2.8×10−2 1.8×10−2 1.3×10−2 5.5×10−4 6.5×10−5 1.8×10−5 599 3.4×10−2 3.2×10−2 1.9×10−2 5.2×10−4 5.8×10−5 2.0×10−5 600 3.7×10−2 2.3×10−2 1.2×10−2 3.4×10−4 3.8×10−5 1.9×10−5 表 4 小波能谱系数

Table 4. Wavelet energy spectrum coefficients

序号 a5 d5 d4 d3 d2 d1 1 67.23 0.258 0.394 1.749 2.552 27.82 2 81.04 0.312 0.297 1.283 1.804 15.26 3 71.53 0.296 0.266 1.082 2.492 24.33 4 67.07 0.632 0.556 2.219 3.257 26.26 $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ 597 52.97 0.748 1.031 3.956 4.895 36.61 598 61.74 0.256 0.419 1.875 3.101 32.61 599 53.27 0.239 0.242 0.983 1.323 43.94 600 53.94 0.329 0.357 1.620 2.447 41.31 表 5 修整状态分类测试的准确率

Table 5. Accuracy of trimming state classification test

输入的AE信号

特征参数输入特征个数m SVM的准确率

Ac / %$ {X}_{rms}^{m} $和$ {V}_{var}^{m} $ 12 96.8 $ {X}_{rms}^{m} $和$ {\eta }^{k} $ 12 96.5 $ {V}_{var}^{m} $和$ {\eta }^{k} $ 12 97.2 $ {X}_{rms}^{m} $、$ {V}_{var}^{m} $和$ {\eta }^{k} $ 18 98.3 -

[1] 龚子维. 磨削砂轮钝化识别与声发射特征参数研究 [D]. 南京: 南京大学, 2020.GONG Ziwei. Identification of blunting state of grinding wheel and study on characteristic parameters of acoustic emission [D]. Nanjing: Nanjing University, 2020. [2] 吕长飞, 吴小玉, 王茵, 等. 外圆磨削颤振监测方法设计 [J]. 机床与液压,2019,47(8):166-168, 66. doi: 10.3969/j.issn.1001-3881.2019.08.036LYU Changfei, WU Xiaoyu, WANG Yin, et al. Design of chatter detection in external cylindrical grinding [J]. Machine Tool & Hydraulics,2019,47(8):166-168, 66. doi: 10.3969/j.issn.1001-3881.2019.08.036 [3] LIU G J, WANG Q, KANG R K. Study on the wavelet transform based monitor signal processing method for grinding wheel dull [J]. Key Engineering Materials,2008,375/376:598-602. doi: 10.4028/www.scientific.net/KEM.375-376.598 [4] 徐水竹, 杨京, 张仲宁, 等. 基于小波变换的磨削噪声在线监测方法 [J]. 声学技术,2011,30(3):275-279. doi: 10.3969/j.issn.1000-3630.2011.03.014XU Shuizhu, YANG Jing, ZHANG Zhongning, et al. On-line grinding state monitoring with wavelet transform of noise signal [J]. Acoustical Technology,2011,30(3):275-279. doi: 10.3969/j.issn.1000-3630.2011.03.014 [5] 巩亚东, 吕洋, 王宛山, 等. 基于多传感器融合的磨削砂轮钝化的智能监测 [J]. 东北大学学报,2003(3):248-251.GONG Yadong, LYU Yang, WANG Wanshan, et al. Intelligent monitoring for grinding wheel passivation based on multi-sensor fusion [J]. Journal of Northeastern University,2003(3):248-251. [6] 陈俊奇. 基于磨削声音信号特征的砂带磨损状态监测方法研究 [D]. 上海: 上海交通大学, 2018.CHEN Junqi. Acoustic signal based grinding belt wear condition monitoring [D]. Shanghai: Shanghai Jiao Tong University, 2018. [7] 王起硕. 基于多传感器融合的微晶刚玉砂轮磨削性能在线检测系统的研究 [D]. 济南: 山东大学, 2017.WANG Qishuo. Online detection system of grinding performance of microcrystalline corundum grinding wheel based on multi-sensor fusion [D]. Jinan: Shandong University, 2017. [8] 丁宁, 段景淞, 石建, 等. 基于声发射砂轮磨损监测系统的研究 [J]. 南京航空航天大学学报,2020,52(1):48-52.DING Ning, DUAN Jingsong, SHI Jian, et al. Research on grinding wheel wear monitoring system based on acoustic emission [J]. Journal of Nanjing University of Aeronautics & Astronautics,2020,52(1):48-52. [9] 朱欢欢, 迟玉伦, 闻章, 等. 断续磨削表面烧伤机理与在线监测方法研究 [J]. 表面技术,2021(9):379-389.ZHU Huanhuan, CHI Yulun, WEN Zhang, et al. Research on burn mechanism of intermittent grinding surface and online monitoring method [J]. Surface Technology,2021(9):379-389. [10] CHEN X, OPOZ T T. Effect of different parameters on grinding efficiency and its monitoring by acoustic emission [J]. Production & Manufacturing Research,2016,4(1):190-208. [11] 郭力, 郭君涛, 霍可可. 金刚石砂轮与氧化锆磨削接触的声发射监测 [J]. 制造技术与机床,2019(5):94-98.GUO Li, GUO Juntao, HUO Keke. Acoustic emission monitoring on grinding contact between diamond grinding wheel and zirconia [J]. Manufacturing Technology and Machine Tool,2019(5):94-98. [12] 郑敏敏, 高小榕, 谢海鹤. 心电信号小波去噪的改进算法研究 [J]. 中国生物医学工程学报,2017,36(1):114-118. doi: 10.3969/j.issn.0258-8021.2017.01.015ZHENG Minmin, GAO Xiaorong, XIE Haihe. Research on an improved algorithm for wavelet denoising of ECG [J]. Chinese Journal of Biomedical Engineering,2017,36(1):114-118. doi: 10.3969/j.issn.0258-8021.2017.01.015 [13] 李鹏瑞. 基于贝叶斯分类器的煤层底板破坏程度预测 [D]. 济南: 山东科技大学, 2016LI Pengrui. Prediction of failure degree of coal seam floor based on bayesian classifier [D]. Jinan: Shandong University of Science and Technology, 2016. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS