Ultrasonic assisted helical grinding of SiCf/SiC ceramic matrix composites

-

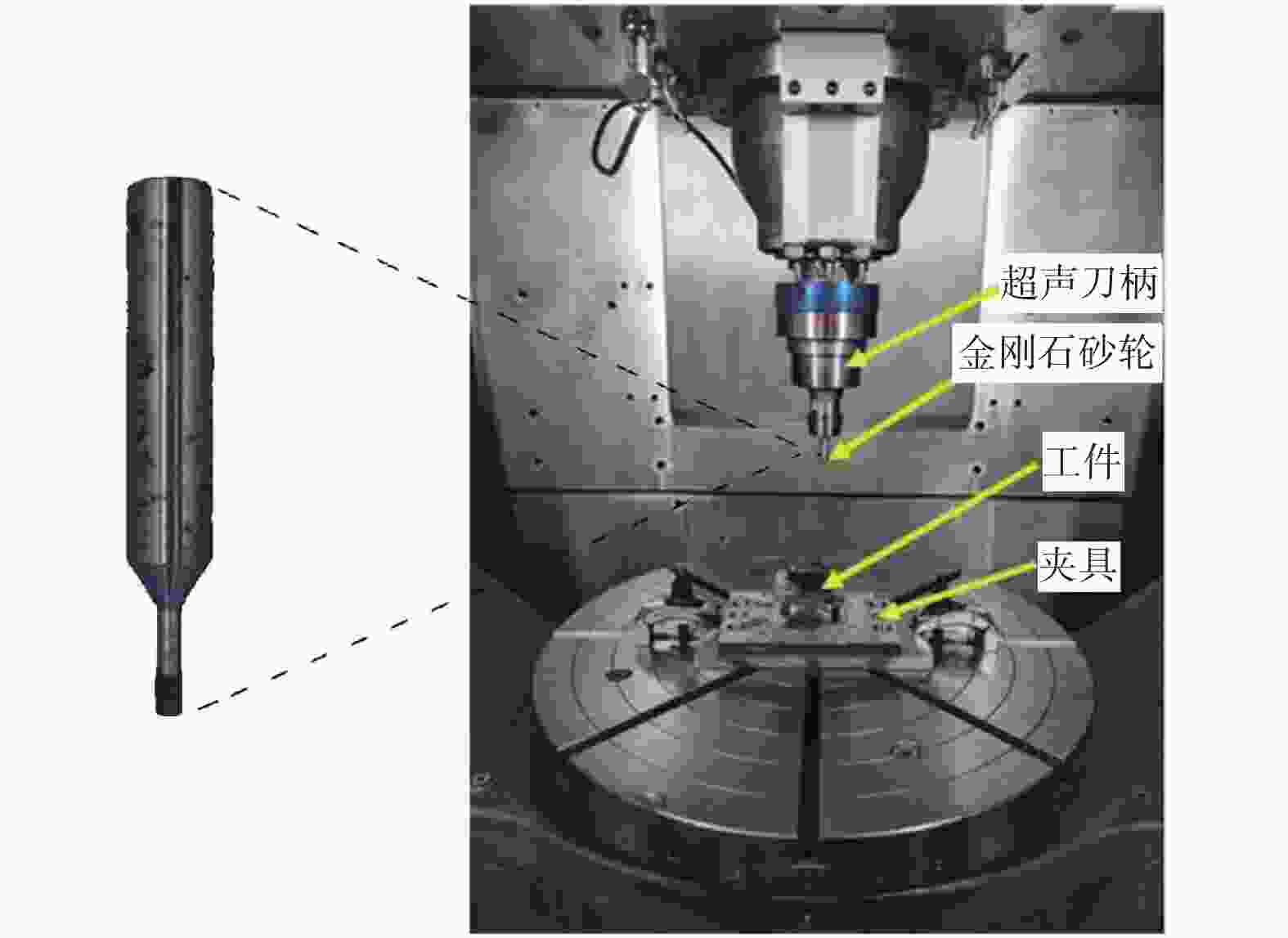

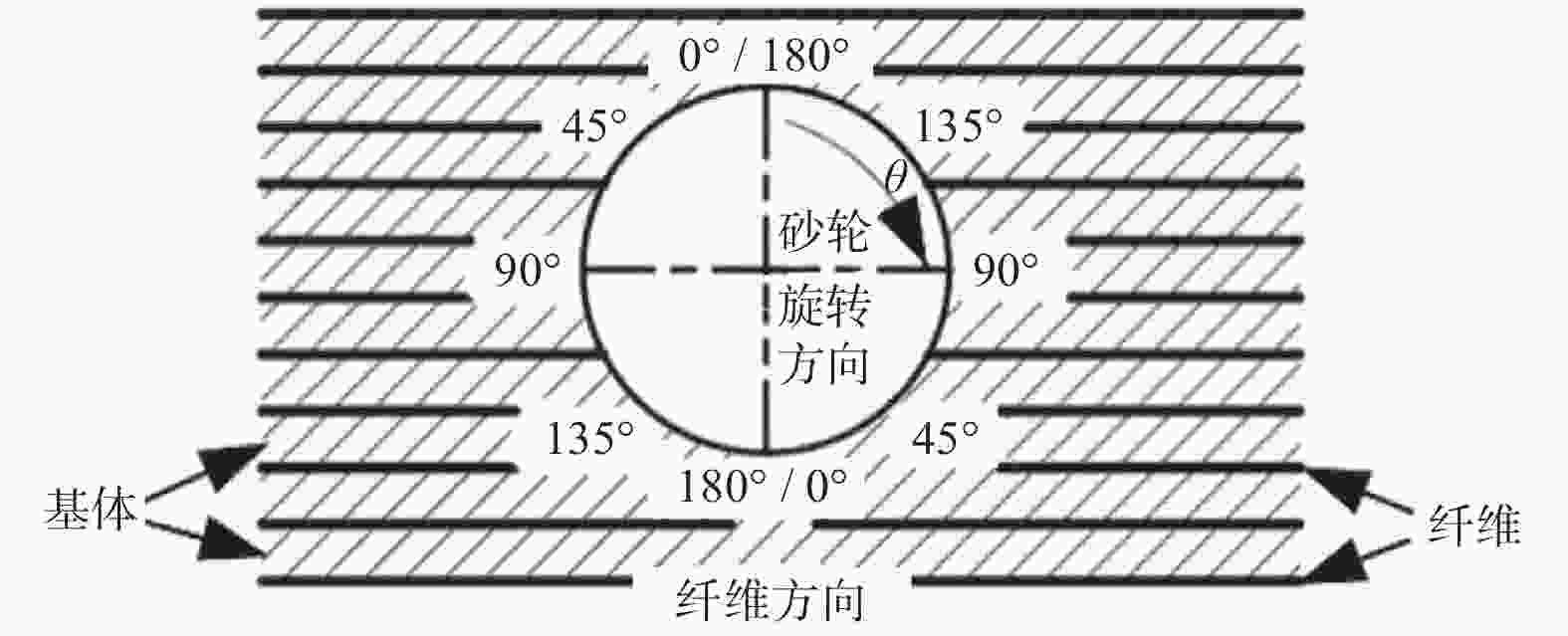

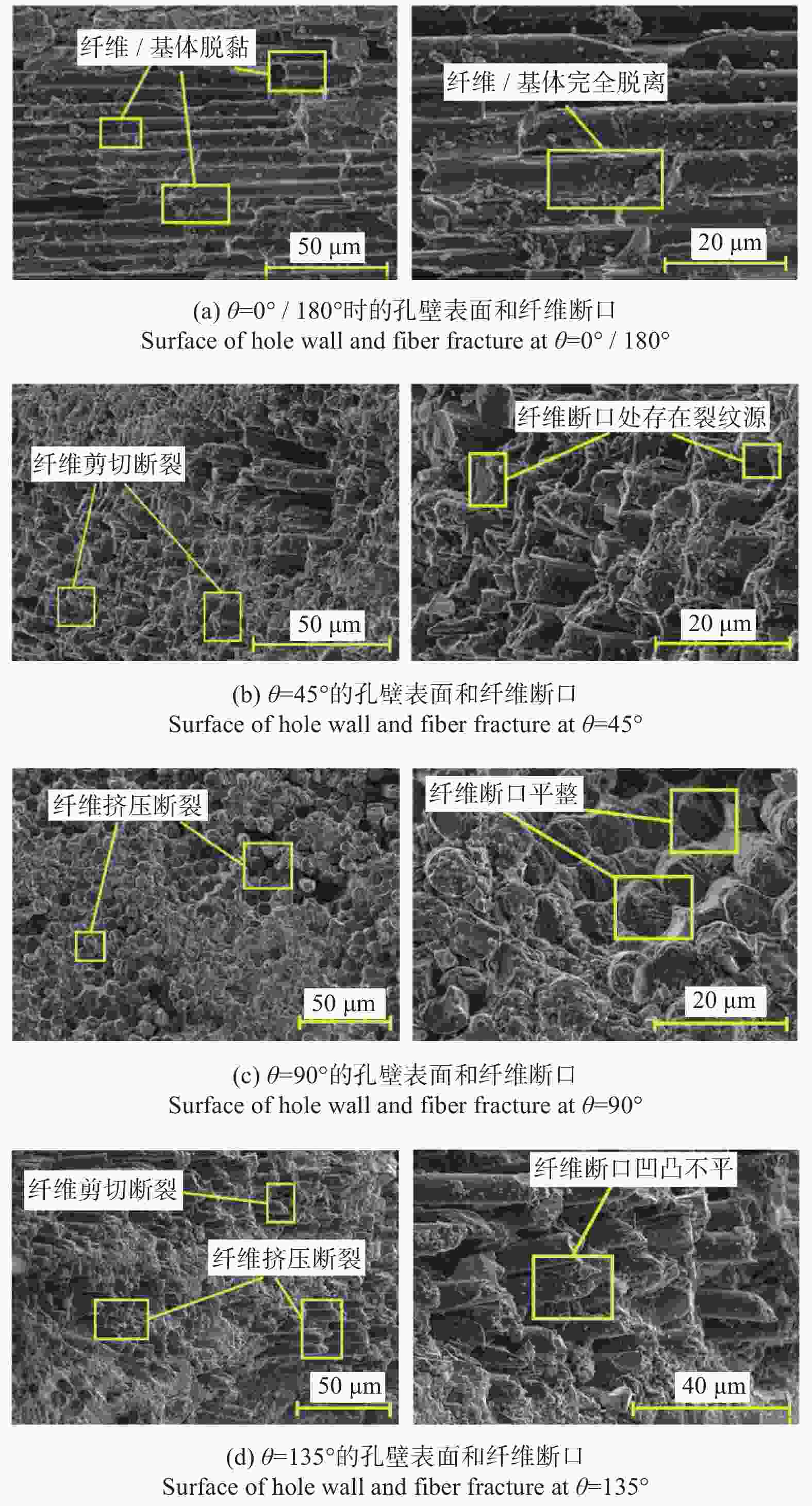

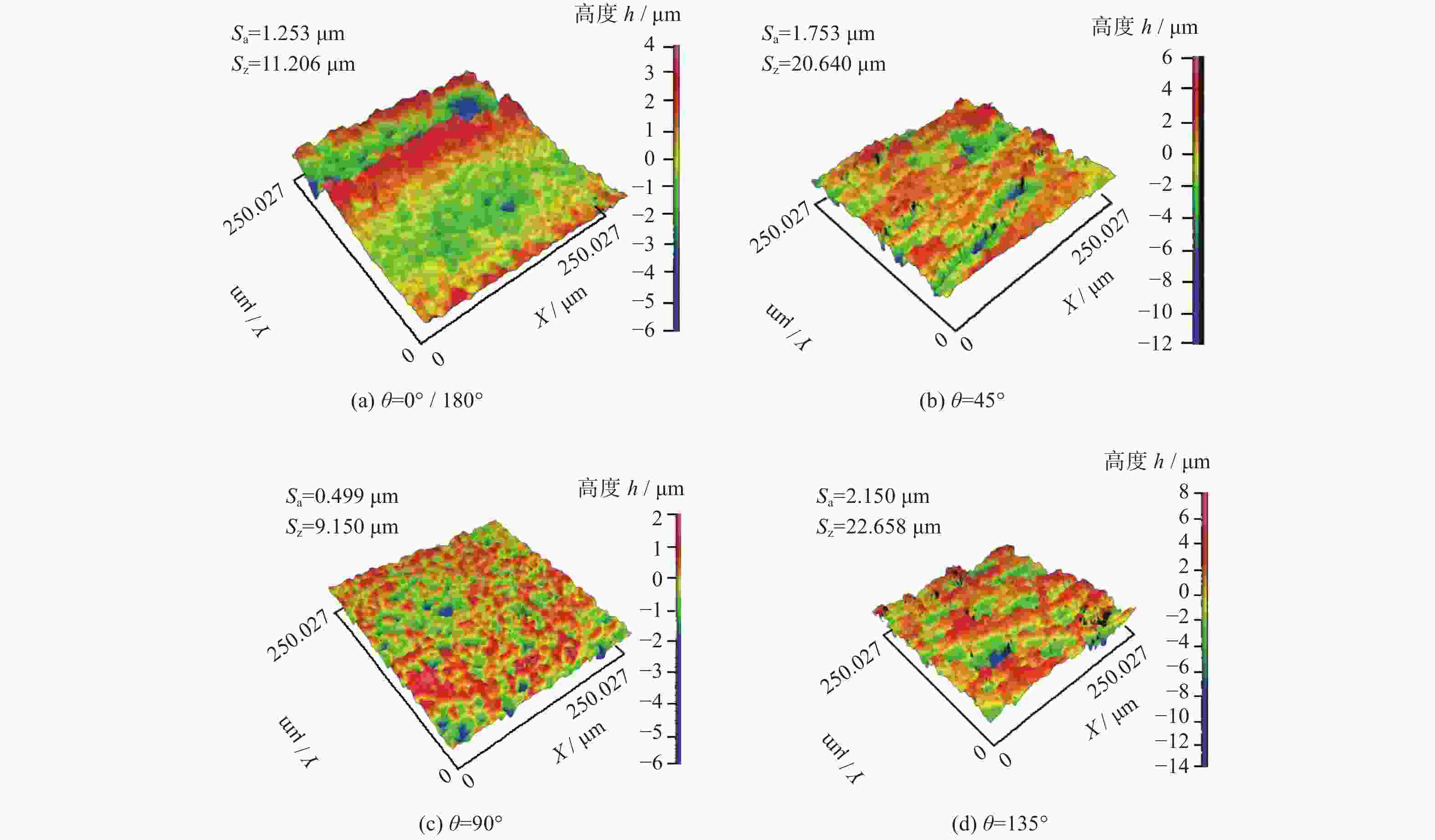

摘要: 针对SiC纤维增强SiC陶瓷基复合材料(SiCf/SiC)存在加工质量差、材料去除困难等问题,开展金刚石砂轮超声辅助螺旋磨削SiCf/SiC陶瓷基复合材料试验,研究其出口质量、孔壁形貌及孔壁表面粗糙度。结果表明:与传统制孔相比,超声辅助螺旋磨削制孔出口处材料无大面积崩边;砂轮磨削速度方向与纤维方向的夹角θ的周期性变化导致孔壁表面形貌呈现规律性变化。当θ在0°/180°时,纤维与基体多发生脱黏现象;当θ在45°时,纤维多发生剪切断裂;当θ在90°时,纤维多发生挤压断裂;当θ在135°时,纤维既发生剪切断裂又发生挤压断裂;孔壁表面粗糙度Sa在θ为90°时最低,在θ为135°时最高。在一定范围内,表面粗糙度Sa随着超声振幅的增大而降低,最大降幅为38.7%;随着进给速度的增大而升高,最大增幅为39.3%。

-

关键词:

- SiCf/SiC陶瓷基复合材料 /

- 超声辅助螺旋磨削 /

- 孔壁质量 /

- 材料去除机理

Abstract: SiC fiber reinforced SiC ceramic matrix composites (SiCf/SiC) have problems such as poor machining quality and difficult material removal. To study these problems, SiCf/SiC composites were processed by ultrasonic-assisted helical grinding. The exit quality of hole, hole wall morphology and three-dimensional surface roughness of hole wall were explored. The results show that compared with traditional hole making, the material at the exit of the hole made by ultrasonic-assisted helical grinding has no large area chipping. The periodic change of the angle θ between the direction of the cutting speed of the grinding wheel and the fiber direction leads to regular changes in the surface morphology of the hole wall. When θ is 0°/180°, the fiber and the matrix are debonded. When θ is 45°, the fiber is sheared and fractured. When θ is 90°, the fiber is crushed and fractured. When θ is 135°, the fiber has both shear fracture and extrusion fracture. The hole wall surface roughness Sa is the lowest value when θ is 90°, and Sa is the highest value when θ is 135°. Within a certain range, the surface roughness value Sa decreases with the increase of the ultrasonic amplitude, with a maximum decrease of 38.7%, and increases with the increase of the feed rate, with a maximum increase of 39.3%. -

表 1 试验参数

Table 1. Testing condition

序号 进给速度 vf /(mm·min−1) 超声振幅 A / μm 1 80 0 2 100 0 3 120 0 4 80 2 5 100 2 6 120 2 7 80 4 8 100 4 9 120 4 -

[1] NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview [J]. Composites Science and Technology,2004,64(2):155-170. doi: 10.1016/S0266-3538(03)00230-6 [2] 王超, 李凯娜, 陈虎, 等. 纤维增强陶瓷基复合材料加工技术研究进展 [J]. 航空制造技术,2016,59(3):55-60.WANG Chao, LI Kaina, CHEN Hu, et al. Research progress of processing technology for fiber reinforced matrix composites [J]. Journal of Materials Processing Technology,2016,59(3):55-60. [3] BHARADWAJ L, FAN Y, ZHANG L G, et al. Oxidation behavior of a fully dense polymer-derived amorphous silicon carbonitride ceramic [J]. Journal of the American Ceramic Society,2004,87(3):483-486. doi: 10.1111/j.1551-2916.2004.00483.x [4] DING K, FU Y, SU H, et al. Experimental studies on drilling tool load and machining quality of C/SiC composites in rotary ultrasonic machining [J]. Journal of Materials Processing Technology,2014,214(12):2900-2907. doi: 10.1016/j.jmatprotec.2014.06.015 [5] 丁凯, 苏宏华, 傅玉灿, 等. 陶瓷基复合材料超声辅助加工技术 [J]. 航空制造技术,2016,59(15):42-49.DING Kai, SU Honghua, FU Yucan, et al. Ultrasonic assisted machining of ceramic matrix composites [J]. Aeronautical Manufacturing Technology,2016,59(15):42-49. [6] TAWAKOLI T, AZARHOUSHANG B. Intermittent grinding of ceramic matrix composites (CMCs) utilizing a developed segmented wheel [J]. International Journal of Machine Tools & Manufacture,2011,51(2):112-119. [7] LUNA G G, AXINTE D, NOVOVIC D. Influence of grit geometry and fibre orientation on the abrasive material removal mechanisms of SiC/SiC ceramic matrix composites (CMCs) [J]. International Journal of Machine Tools & Manufacture,2020,157(9/10/11/12):103580. [8] BERTSCHE E, EHMANN K, MALUKHIN K. Ultrasonic slot machining of a silicon carbide matrix composite [J]. International Journal of Advanced Manufacturing Technology,2013,66(5/6/7/8):1119-1134. doi: 10.1007/s00170-012-4394-7 [9] 张园, 康仁科, 刘津廷, 等. 超声振动辅助钻削技术综述 [J]. 机械工程学报,2017,53(19):33-44. doi: 10.3901/JME.2017.19.033ZHANG Yuan, KANG Renke, LIU Jinting, et al. Review of ultrasonic vibration assisted drilling [J]. Journal of Mechanical Engineering,2017,53(19):33-44. doi: 10.3901/JME.2017.19.033 [10] 林佳杰, 魏昕, 杨宇辉, 等. 超声螺旋磨削制孔磨削力建模与实验研究 [J]. 组合机床与自动化加工技术, 2021(4): 53-56.LIN Jiajie, WEI Xin, YANG Yuhui, et al. Study on cutting force of ultrasonic assisted helical grinding for hole making [J]. Modular Machine Tool & Automatic Manufacturing Technique, 2021(4): 53-56. [11] LI Z, JIAO Y, DEINES T, et al. Rotary ultrasonic machining of ceramic matrix composites: feasibility study and designed experiments [J]. International Journal of Machine Tools & Manufacture,2005,45(12/13):1402-1411. [12] 陈玉荣, 苏宏华, 傅玉灿, 等. 超声振动辅助干式钻削SiCf/SiC陶瓷基复合材料试验研究 [J]. 航空制造技术,2018,61(21):47-51.CHEN Yurong, SU Honghua, FU Yucan, et al. Experimental study on ultrasonic vibration assisted dry drilling for SiCf/SiC ceramic matrix composites [J]. Aeronautical Manufacturing Technology,2018,61(21):47-51. [13] 吴雪峰, 苑忠亮. 氮化硅陶瓷加热辅助铣削过程中边缘碎裂实验与仿真[J]. 哈尔滨理工大学学报, 2017, 22(5): 1-6.WU Xuefeng, YUAN Zhongliang. Experiment and simulation analysis of edge chipping in laser assisted milling of silicon nitride[J]. Journal of Harbin University of Science and Technology, 2017, 22(5): 1-6. [14] 王欢. 钛合金螺旋铣孔试验研究 [D]. 大连: 大连理工大学, 2015.WANG Huan. Experimental study on helical milling of titanium alloy [D]. Dalian: Dalian University of Technology, 2015. [15] 徐雳, 刘冰, 吴石, 等. 双面研磨/抛光机磨削轨迹研究[J]. 哈尔滨理工大学学报, 2018, 23(4): 37-42.XU Li, LIU Bing, WU Shi, et al. Double sided lapping/polishing machine grinding trajectory studies[J]. Journal of Harbin University of Science and Technology, 2018, 23(4): 37-42. [16] WANG J, ZHANG J, FENG P. Effects of tool vibration on fiber fracture in rotary ultrasonic machining of C/SiC ceramic matrix composites [J]. Composites Part B: Engineering,2017,129:233-242. doi: 10.1016/j.compositesb.2017.07.081 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS