Research progress on exit burr in drilling assembly hole of aerospace aluminum alloy components

-

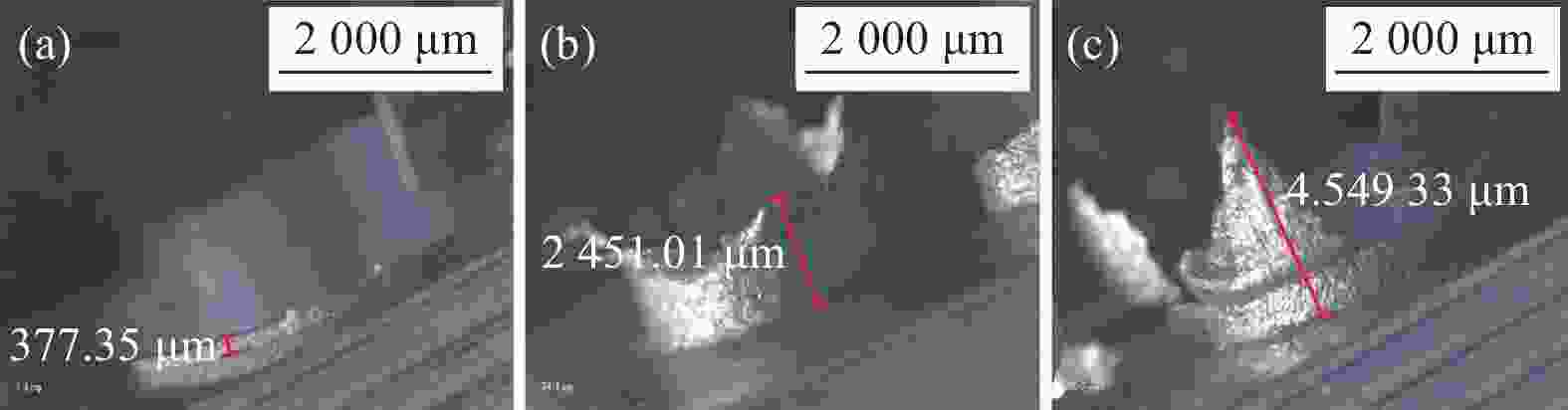

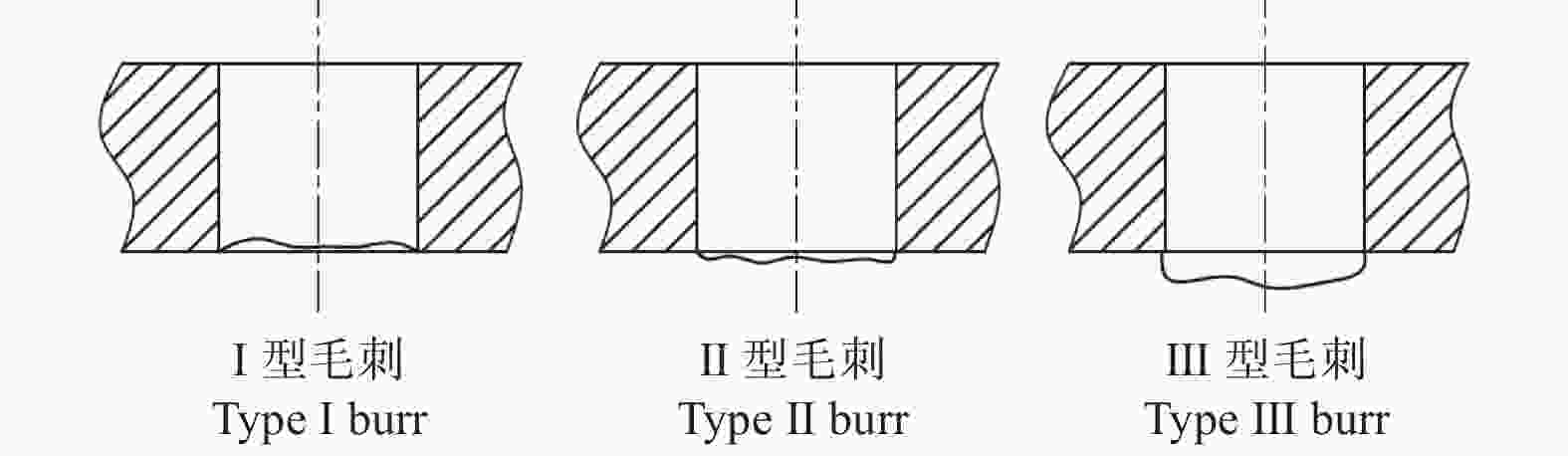

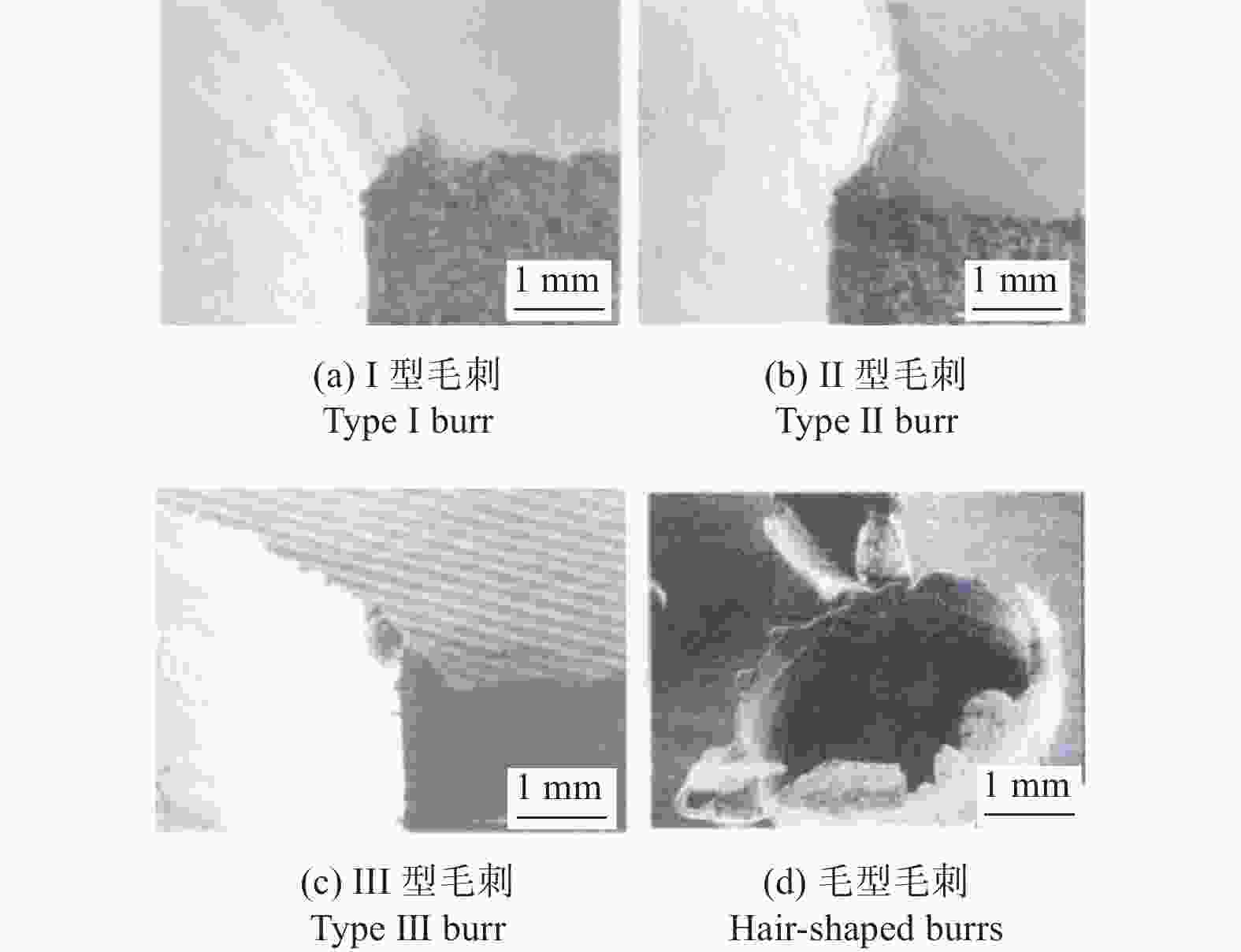

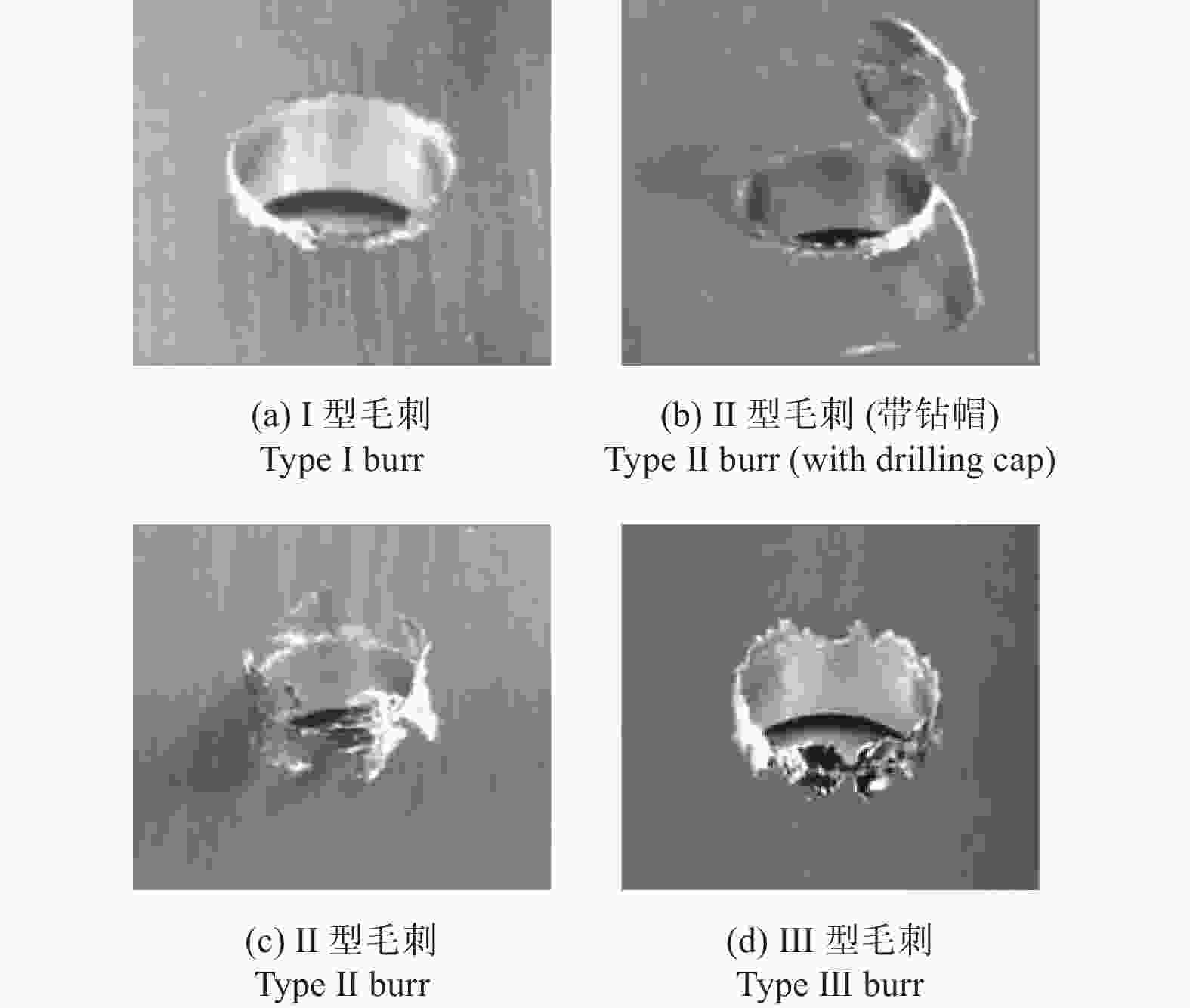

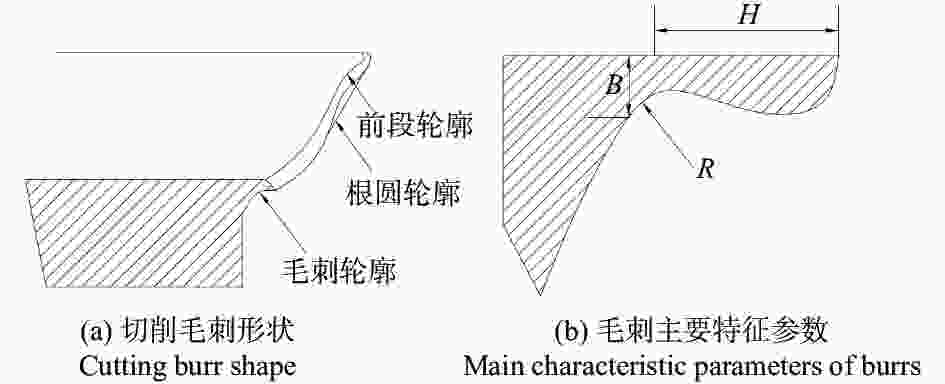

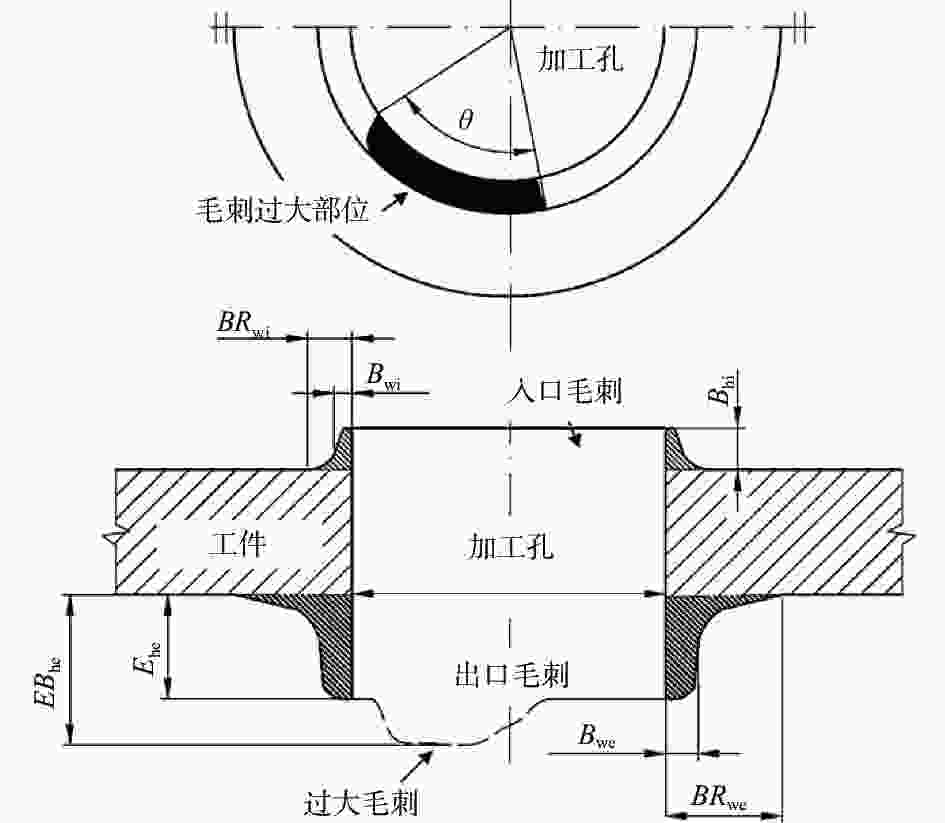

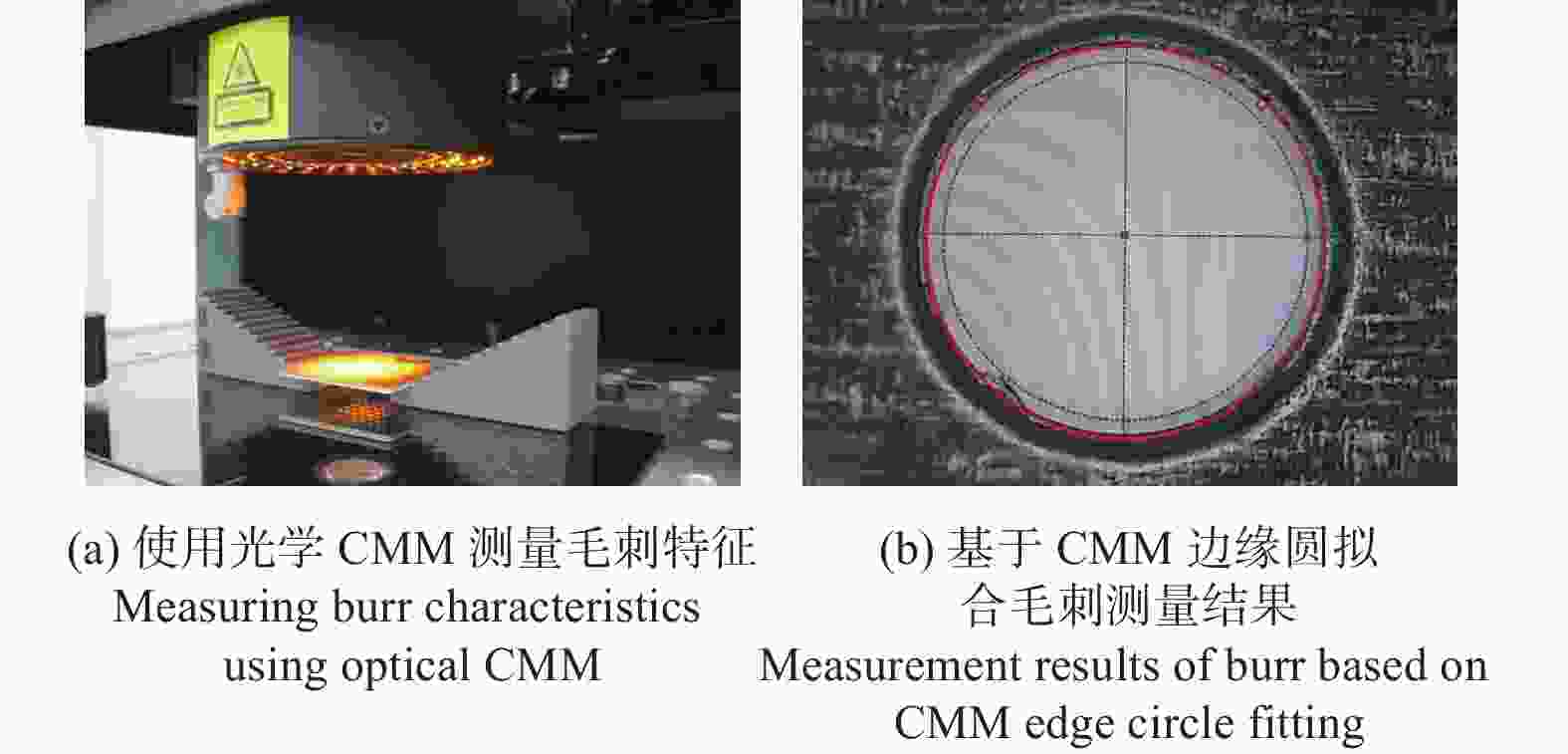

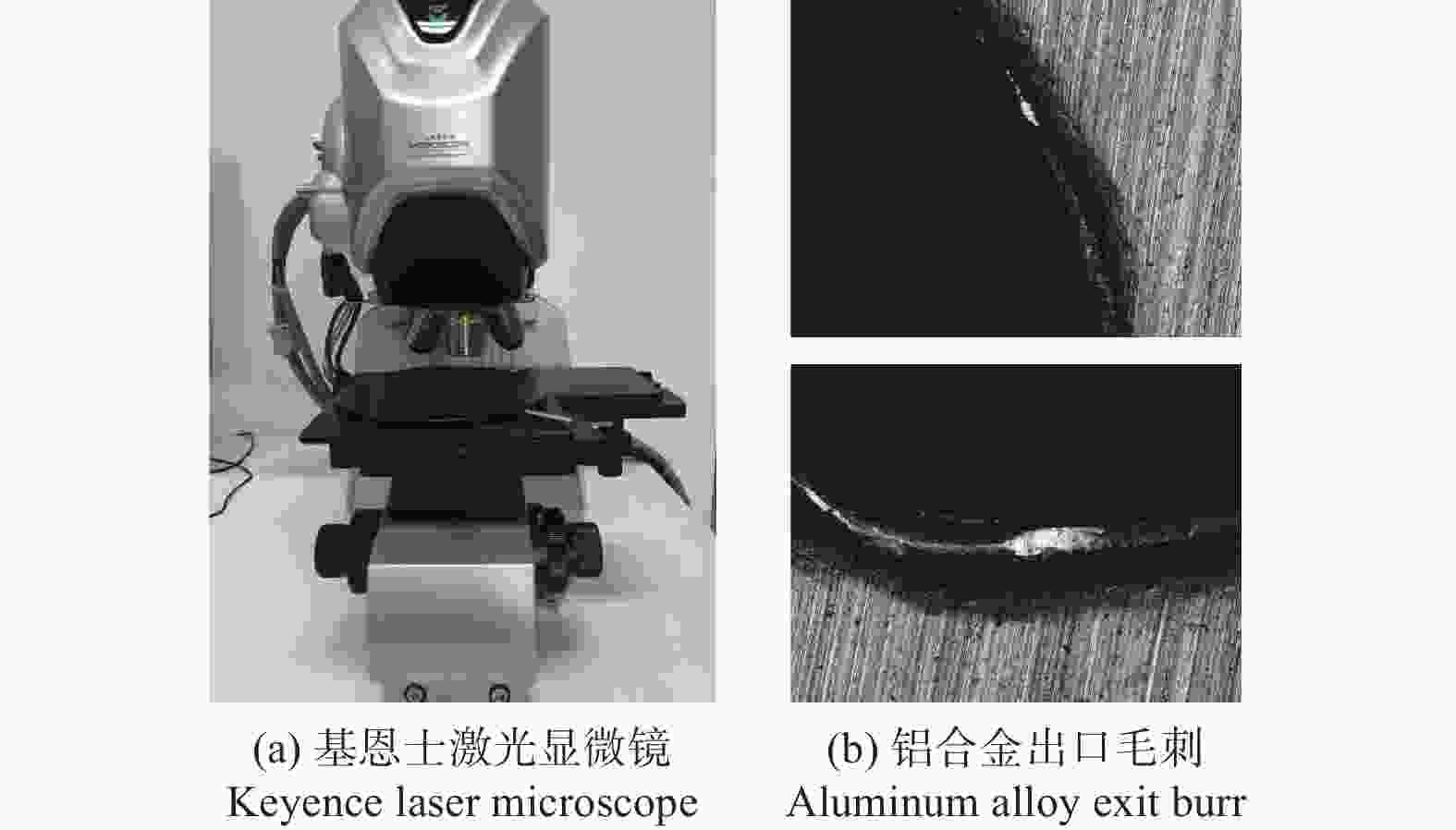

摘要: 航空航天制造业中存在大量的铝合金装配孔加工需求。装配孔主要通过钻削加工实现,加工中存在铝合金出口毛刺过大的问题。出口毛刺直接影响工件的精度、抗疲劳强度、装配性能,去毛刺工序会极大地增加工时和成本。因此有必要对铝合金装配孔钻削出口毛刺进行研究,实现对出口毛刺的控制。从铝合金钻削出口毛刺的类型和测量方法、形成机理和高度预测以及毛刺控制方法等方面进行了系统性的论述,以期为铝合金钻削加工出口毛刺的研究提供帮助。Abstract: There is a large demand for aluminum alloy assembly hole machining in aerospace manufacturing industry. The assembly hole is mainly realized by drilling, and there is a problem that the aluminum alloy exit burr is too large in the processing. The exit burr directly affects the accuracy, fatigue strength and assembly performance of the workpiece. The deburring process will greatly increase the man hour and cost. Therefore, it is necessary to study the exit burr of aluminum alloy assembly hole drilling to realize the control of exit burr. This paper systematically discusses the types, measurement methods, formation mechanism, height prediction and gross control methods of exit burr in aluminum alloy drilling, in order to provide help for the research of exit burr in aluminum alloy drilling.

-

Key words:

- aluminum alloy /

- drilling /

- exit burr /

- formation mechanism /

- control method

-

表 1 毛刺高度预测研究进展

Table 1. Research progress of burr height prediction

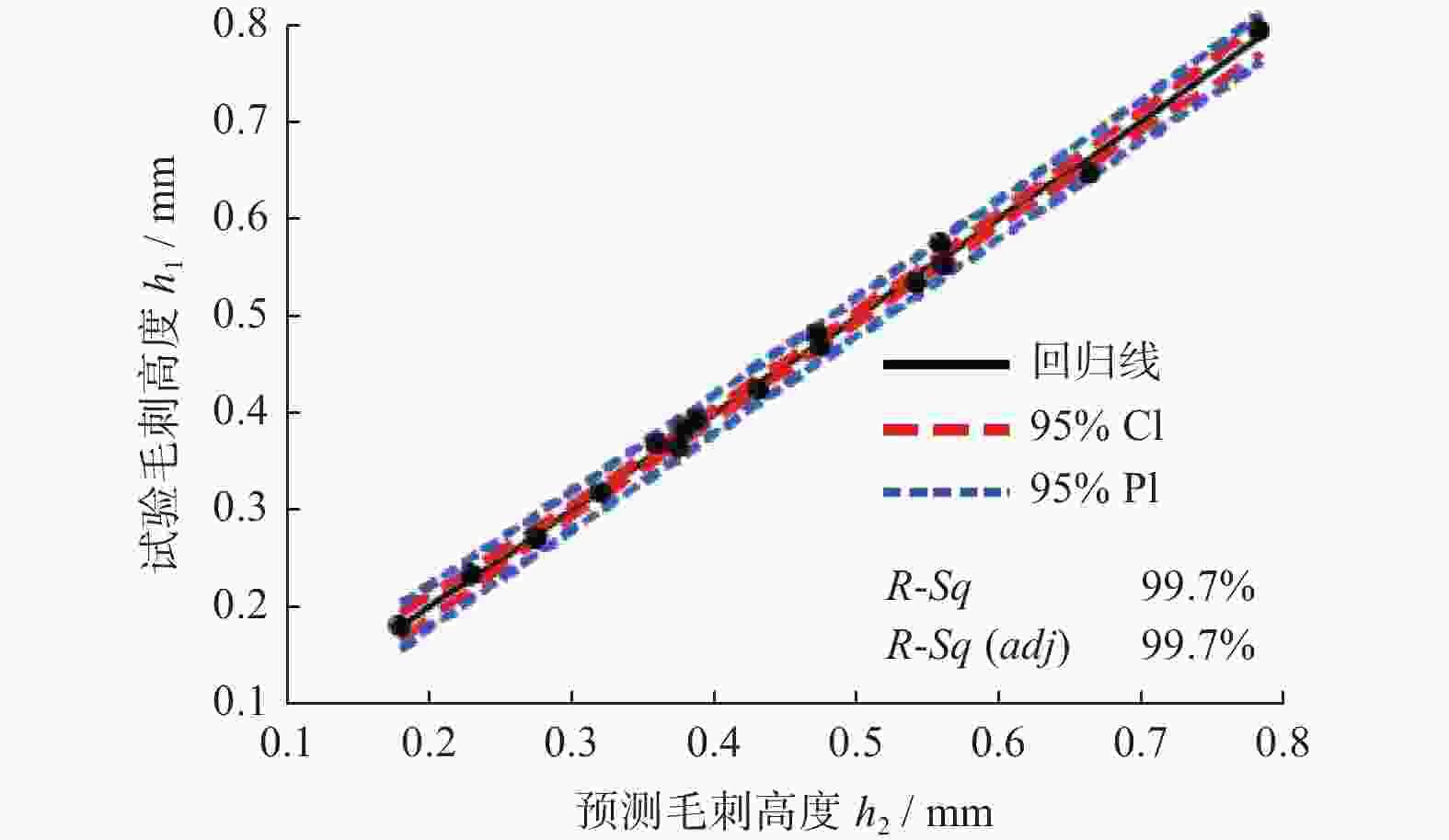

研究学者 预测方法 预测结果 吴丹等[58] 试验获得轴向力经验公式,有限元法预测毛刺生成初始位置,能量法建立毛刺高度理论模型 误差<30% 胡力闯等[59] 试验建立钻削力经验公式,结合经典薄板弯曲理论和能量法建模,考虑钻孔位置对工件刚性和毛刺高度的影响 误差<13% WANG等[61] 轴向定位法获得了内、外切削点,确定工作角度、切削力等参数,根据形成机理进行理论建模 误差1.96% CHANG等[62] 只有切削力的正向部分和工件的弹性变形回弹有助于毛刺的形成,由此建立切削力模型和毛刺高度模型 误差<10% MANDRA等[54] 将钻削轴向力与刀具磨损引起的摩擦力相结合,建立了基于的受力模型,利用力做功与材料变形之间的能量平衡建模 误差<30% LI等[64] 基于毛刺形成的机理、材料的变形机制、运动学模型以及受力分析建立毛刺高度模型 误差<8% 周越等[66] 引入BN和正则化技术,提高训练效率精度,基于蚁群算法的启发式整体调优算法,完成模型的全局优化,预测毛刺高度 误差9.34% GÖKÇE等[55] 使用试验数据预测响应,使用神经拟合工具评估实验数据,使用前馈−反向传播执行ANN模型 预测成功率为99.6% 鲁琦渊[33] 由试验结果,根据最小二乘法,拟合出毛刺高度回归方程 误差15.76% ABDELHAFEEZ等[69] 由响应曲面法建立毛刺高度拟合方程,并分析各参数显著性 实测值、预测值吻合较好 -

[1] 刘科. 铝合金材料的应用及其加工成形技术 [J]. 智能城市,2019,5(14):212-213.LIU Ke. Application and forming technology of aluminum alloy materials [J]. Intelligent City,2019,5(14):212-213. [2] 邓运来, 张新明. 铝及铝合金材料进展 [J]. 中国有色金属学报,2019,29(9):2115-2141. doi: 10.19476/j.ysxb.1004.0609.2019.09.14DENG Yunlai, ZHANG Xinming. Progress of aluminum and aluminum alloy materials [J]. The Chinese Journal of Nonferrous Metals,2019,29(9):2115-2141. doi: 10.19476/j.ysxb.1004.0609.2019.09.14 [3] 范玉青. 现代飞机制造技术 [M]. 北京: 北京航空航天大学出版社, 2001.FAN Yuqing. Modern aircraft manufacturing technology [M]. Beijing: Beijing University of Aeronautics and Astronautics Press, 2001. [4] 朱兆聚. 航空异质构件钻削刀具温度特性及制孔关键技术研究 [D]. 济南: 山东大学, 2019.ZHU Zhaoju. Research on temperature characteristics of drilling tools for aviation heterogeneous components and key technologies of drilling [D]. Jinan: Shandong University, 2019. [5] 刘姿. 飞机壁板叠层材料精密制孔工艺研究 [D]. 南京: 南京航空航天大学, 2015.LIU Zi. Research on precision hole making technology of aircraft wall panel laminated material [D] . Nanjing: Nanjing University of Aeronautics and Astronautics, 2015. [6] 石贵峰. 钻削毛刺形成机理及其控制技术研究 [D]. 镇江: 江苏大学, 2016.SHI Guifeng. Research on formation mechanism and control technology of drilling burr [D]. Zhenjiang: Jiangsu University, 2016. [7] RIMPAULT X, CHATELAIN J F, KLEMBERG-SAPIEHA J E, et al. Burr height monitoring while drilling CFRP/titanium/aluminium stacks [J]. Mechanics & Industry,2017,18(1):114. [8] 胡力闯. 机器人旋转超声钻削铝合金叠层构件毛刺特性研究 [D]. 南京: 南京理工大学, 2020.HU Lichuang. Study on burr characteristics of robot rotary ultrasonic drilling aluminum alloy laminated components [D]. Nanjing: Nanjing University of Technology, 2020. [9] BAHCE E, ÖZEMIR B. Burr measurement method based on burr surface area [J]. International Journal of Precision Engineering and Manufacturing-Green Technology,2020,8(4):1-10. [10] ABDELHAFEEZ A M, SOO S L, ASPINWALL D K, et al. The influence of burr forma tion and feed rate on the fatigue life of drilled titanium and aluminium alloys used in aircraft manufacture [J]. CIRP Annals - Manufacturing Technology,2018,67(1):103-108. doi: 10.1016/j.cirp.2018.03.013 [11] 康仁科, 杨国林, 董志刚, 等. 飞机装配中的先进制孔技术与装备 [J]. 航空制造技术,2016(10):16-24.KANG Renke, YANG Guolin, DONG Zhigang, et al. Advanced hole making technology and equipment in aircraft assembly [J]. Aeronautical Manufacturing Technology,2016(10):16-24. [12] 罗蒙. 金属切削过程中毛刺形成机理及控制方法的研究 [D]. 上海: 上海交通大学, 2007.LUO Meng. Study on burr formation mechanism and control method in metal cutting process [D]. Shanghai: Shanghai Jiaotong University, 2007. [13] 李晓峰. 铝合金与钛合金超声振动辅助钻削工艺研究 [D]. 大连: 大连理工大学, 2016.LI Xiaofeng. Research on ultrasonic vibration assisted drilling technology of aluminum alloy and titanium alloy [D]. Dalian: Dalian University of Technology, 2016. [14] 沈宇峰, 何幸保, 刘媛媛. 金属切削毛刺形成与控制技术研究及发展 [J]. 工具技术,2018,52(9):10-14. doi: 10.3969/j.issn.1000-7008.2018.09.014SHEN Yufeng, HE Xingbao, LIU Yuanyuan. Research and development of burr formation and control technology in metal cutting [J]. Tool Engineering,2018,52(9):10-14. doi: 10.3969/j.issn.1000-7008.2018.09.014 [15] AURICH J C, DORNFELD D, ARRAZOLA P J, et al. Burrs—Analysis, control and removal [J]. CIRP Annals-Manufacturing Technology,2009,58(2):519-542. doi: 10.1016/j.cirp.2009.09.004 [16] 吴宇锋. 钛合金毛刺生成机理及尺寸规律研究 [D]. 重庆: 重庆大学, 2018.WU Yufeng. Study on burr formation mechanism and size law of titanium alloy [D]. Chongqing: Chongqing University, 2018. [17] 奥岛启贰, 人见胜人. 切削におけるがえりの现象について [J]. 精密机械, 1958, 24(8): 470-475.OKUSHIMA Ryuji, HITOMI Katsundo. About the phenomenon of the burrs in cutting [J]. Precision Machinery, 1958, 24 (8): 470-475. [18] GILLESPIE L K, BLOTTER P T. The formation properties of machining burrs [J]. ASME Journal of Engineering for Industry,1976,98(1):66-74. doi: 10.1115/1.3438875 [19] NAKAYAMA K, ARAI M. Burr formation in metal cutting [J]. CIRP Annals-Manufacturing Technology,1987,36(1):33-36. doi: 10.1016/S0007-8506(07)62547-5 [20] 王贵成. 金属切削毛刺 [M]. 吉林: 吉林科学技术出版社, 1997.WANG Guicheng. Metal cutting burr [M]. Jilin: Jilin Science and Technology Press, 1997. [21] 朱云明, 王磊, 王贵成. 钻削毛刺的形成与分析模型 [J]. 科学技术与工程,2010,10(30):7417-7421. doi: 10.3969/j.issn.1671-1815.2010.30.009ZHU Yunming, WANG Lei, WANG Guicheng. Formation and analysis model of drilling burr [J]. Science Technology and Engineering,2010,10(30):7417-7421. doi: 10.3969/j.issn.1671-1815.2010.30.009 [22] 徐国勇. 钻削加工中交叉孔毛刺形成机理及其控制技术研究 [D]. 镇江: 江苏大学, 2019.XU Guoyong. Research on formation mechanism and control technology of cross hole burr in drilling [D]. Zhenjiang: Jiangsu University, 2019. [23] 马文瑞. 碳纤维复合材料/铝合金叠层构件超声振动辅助钻削技术研究 [D]. 南京: 南京理工大学, 2018.MA Wenrui. Research on ultrasonic vibration assisted drilling technology for carbon fiber composite/aluminum alloy laminated members [D]. Nanjing: Nanjing University of technology, 2018. [24] 肖曦辉, 郭迎福, KIM Hochan, 等. 钛合金钻削加工出口毛刺研究进展 [J]. 工具技术,2021,55(4):3-8. doi: 10.3969/j.issn.1000-7008.2021.04.001XIAO Xihui, GUO Yingfu, KIM Hochan, et al. Research Progress on export burr of titanium alloy drilling [J]. Tool Engineering,2021,55(4):3-8. doi: 10.3969/j.issn.1000-7008.2021.04.001 [25] 黄娟. 微细切削毛刺的形成机理及其表征方法研究 [D]. 镇江: 江苏大学, 2019.HUANG Juan. Study on formation mechanism and characterization method of micro cutting burr [D]. Zhenjiang: Jiangsu University, 2019. [26] STEIN J, DORNFELD D. Influence of workpiece exit angle on burr formation in drilling intersecting holes [J]. Transactions of the North American Manufacturing Research Institution of SME, 1996: 39-44. [27] 向胜华. 钻削铝合金薄板过程中工艺参数对切屑与制孔形貌特征影响分析 [J]. 制造技术与机床,2017(11):132-136, 140.XIANG Shenghua. Analysis on the influence of process parameters on chip and hole making morphology during drilling aluminum alloy sheet [J]. Manufacturing Technology & Machine Tool,2017(11):132-136, 140. [28] PULNÝ L, DE CHIFFRE L, PÍŠKA M, et al. Hole quality and burr reduction in drilling aluminium sheets [J]. CIRP Journal of Manufacturing Science and Technology,2012,5(2):102-107. doi: 10.1016/j.cirpj.2012.03.005 [29] JIN S Y, PRAMANIK A, BASAK A K, et al. Burr formation and its treatments-a review [J]. The International Journal of Advanced Manufacturing Technology,2020, 107(5/6):107. [30] 岳玮. 精密切削加工表面完整性及评价方法研究 [D]. 镇江: 江苏大学, 2016.YUE Wei. Research on surface integrity and evaluation method of precision machining [D]. Zhenjiang: Jiangsu University, 2016. [31] KO S. Development of effective measurement method for burr geometry [J]. Journal of the Korean Society for Precision Engineering,2003,20(6):81-87. [32] NAKAO Y, WATANABE Y. Measurements and evaluations of drilling burr profile [J]. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture,2006,220(4):513-523. [33] 鲁琦渊. 机器人旋转超声钻削CFRP/铝合金叠层材料的实验研究 [D]. 南京: 南京理工大学, 2019.LU Qiyuan. Experimental study on robot rotary ultrasonic drilling of CFRP/aluminum alloy laminated materials [D]. Nanjing: Nanjing University of Technology, 2019. [34] ISLAM A, DWIVEDI V K. Effect of drilling speed, bit size and cooling medium on the burr structure for mild steel [J]. Materials Today: Proceedings,2020,28:1407-1411. doi: 10.1016/j.matpr.2020.04.812 [35] 梁杰, 张康宁, 邱益. 基于线激光位移传感器的孔毛刺测量与评价 [J]. 哈尔滨工业大学学报,2022,54(1):156-162. doi: 10.11918/202108114LIANG Jie, ZHANG Kangning, QIU Yi. Measurement and evaluation of burr based on linear laser displacement sensor [J]. Journal of Harbin Institute of Technology,2022,54(1):156-162. doi: 10.11918/202108114 [36] 曲海军. 金属切削毛刺形成的数值模拟及控制技术研究 [D]. 镇江: 江苏大学, 2011.QU Haijun. Research on numerical simulation and control technology of burr formation in metal cutting [D]. Zhenjiang: Jiangsu University, 2011. [37] SOKOLOWSKI A. On burr height estimation based on axial drilling force [J]. Journal of Achievements in Materials and Manufacturing Engineering,2010,43:734-742. [38] MONDAL N, SARDAR B S, HALDER R N, et al. Observation of drilling burr and finding out the condition for minimum burr formation [J]. International Journal of Manufacturing Engineering, 2014,1:93. [39] COSTA E S, SILVA M B, MACHADO A R, et al. Burr produced on the drilling process as a function of tool wear and lubricant-coolant conditions [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2009,31(1):57-63. doi: 10.1590/S1678-58782009000100009 [40] MONDAL N, DAS S, BANERJEE T, et al. Experimental study on drilling burr formation minimization and parameters optimization using BBO algorithm [C]. Materials Today: Proceedings, 2021. [41] 陈俊平, 朱云明, 王贵成, 等. 金属切削毛刺专家系统的研究进展 [J]. 机械设计与制造,2012(2):259-261. doi: 10.3969/j.issn.1001-3997.2012.02.100CHEN Junping, ZHU Yunming, WANG Guicheng, et al. Research progress of metal cutting burr expert system [J]. Machinery Design & Manufacture,2012(2):259-261. doi: 10.3969/j.issn.1001-3997.2012.02.100 [42] 李哲, 杨志波, 王爱春, 等. 八面钻超声振动钻削钛合金出口毛刺形成机理 [J]. 宇航材料工艺,2020,50(1):79-89. doi: 10.12044/j.issn.1007-2330.2020.01.012LI Zhe, YANG Zhibo, WANG Aichun, et al. Mechanism of burr formation in ultrasonic vibration drilling of titanium alloy with octahedral drill [J]. Aerospace Materials & Technology,2020,50(1):79-89. doi: 10.12044/j.issn.1007-2330.2020.01.012 [43] 罗育果, 袁信满, 张也, 等. 飞机叠层材料精密制孔工艺研究 [J]. 制造技术与机床,2019(9):122-126.LUO Yuguo, YUAN xinman, ZHANG Ye, et al. Study on precision hole making technology of aircraft laminated materials [J]. Manufacturing Technology & Machine Tool,2019(9):122-126. [44] 袁定新, 雷斯聪, 赵维刚, 等. 航天铝合金薄板制孔毛刺高度的试验研究 [J]. 制造技术与机床,2018(6):127-130.YUAN Dingxin, LEI Sicong, ZHAO Weigang, et al. Experimental study on burr height in hole making of aerospace aluminum alloy sheet [J]. Manufacturing Technology & Machine Tool,2018(6):127-130. [45] 莫立扬, 甄圣亮, 查长礼, 等. 基于ABAQUS的钻削毛刺形成及控制分析 [J]. 科技风,2019(33):137.MO Liyang, ZHEN Shengliang, CHA Changli, et al. Analysis of burr formation and control in drilling based on ABAQUS [J]. Technology Wind,2019(33):137. [46] 徐晓霞, 胡永祥, 姚振强. 层叠铝合金钻削层间毛刺试验研究 [J]. 组合机床与自动化加工技术,2012(12):109-112. doi: 10.3969/j.issn.1001-2265.2012.12.030XU Xiaoxia, HU Yongxiang, YAO Zhenqiang. Experimental study on drilling interlayer burr of laminated aluminum alloy [J]. Modular Machine Tool & Automatic Manufacturing Technique,2012(12):109-112. doi: 10.3969/j.issn.1001-2265.2012.12.030 [47] 刘庆伦, 冯嫦. 6063铝合金钻孔仿真与毛刺形成机理研究 [J]. 装备制造技术,2016(11):134-135, 140. doi: 10.3969/j.issn.1672-545X.2016.11.044LIU Qinglun, FENG Chang. Study on drilling simulation and burr formation mechanism of 6063 aluminum alloy [J]. Equipment Manufacturing Technology,2016(11):134-135, 140. doi: 10.3969/j.issn.1672-545X.2016.11.044 [48] 王威. 多参数联合作用的单向压紧自动化制孔工艺研究 [D]. 南京: 南京航空航天大学, 2020.WANG Wei. Research on automatic hole making process of unidirectional pressing under the combined action of multiple parameters [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020. [49] 王昌赢, 邱坤贤, 魏莹莹, 等. PTFE/CFRP/铝合金叠层材料钻削试验研究 [J]. 航空制造技术,2015(10):90-93, 97.WANG Changying, QIU Kunxian, WEI Yingying, et al. Experimental study on drilling of PTFE/CFRP/aluminum alloy laminated material [J]. Aeronautical Manufacturing Technology,2015(10):90-93, 97. [50] DEY B, MONDAL N, MONDAL S. Experimental study to minimize the burr formation in drilling process with artifical neural networks (ANN) analysis [J]. IOP Conference Series: Materials Science and Engineering, 2018, 377(1): 012120. [51] KAMBOJ A, KUMAR S, SINGH H. Burr height and hole diameter error minimization in drilling of AL6063/15%/SiC composites using HSS step drills [J]. Journal of Mechanical Science and Technology,2015,29(7):2837-2846. doi: 10.1007/s12206-015-0612-1 [52] KUNDU S, DAS S, SAHA P P. Optimization of drilling parameters to minimize burr by providing back-up support on aluminium alloy [J]. Procedia Engineering,2014,97:230-240. doi: 10.1016/j.proeng.2014.12.246 [53] 林捷. 金属切削毛刺控制技术研究 [J]. 信息记录材料,2020,21(2):133-134.LIN Jie. Research on burr control technology in metal cutting [J]. Information Recording Materials,2020,21(2):133-134. [54] MANDRA A M, JIANG J F, XI F F. A new burr formation model for drilling with tool wear [J]. The International Journal of Advanced Manufacturing Technology,2021,116(5/6):1437-1450. doi: 10.1007/s00170-021-07031-4 [55] GÖKÇE H, BIBERCI M A. Investigation of thrust force, drill bit temperature and burr height in the drilling of aluminum alloy used in ammunition wing drive systems [J]. Experimental Techniques,2021, 46(4):1-15. [56] PARDO A, CSEKE A, HEINEMANN R, et al. The effect of interlayer gap width on burr formation in drilling of aluminium-aluminium aerospace stacks [J]. The International Journal of Advanced Manufacturing Technology,2019,104(5/6/7/8):3035-3043. doi: 10.1007/s00170-019-04202-2 [57] TIAN W, HU J, LIAO W, et al. Formation of interlayer gap and control of interlayer burr in dry drilling of stacked aluminum alloy plates [J]. Chinese Journal of Aeronautics,2016,29(1):283-291. doi: 10.1016/j.cja.2015.11.002 [58] 吴丹, 黄诗剑, 高雨浩, 等. 铝合金叠层板钻削层间毛刺高度预测模型 [J]. 清华大学学报(自然科学版),2017,57(6):591-596, 603.WU Dan, HUANG Shijian, GAO Yuhao, et al. Prediction model of interlayer burr height in drilling aluminum alloy laminates [J]. Journal of Tsinghua University (Science and Technology),2017,57(6):591-596, 603. [59] 胡力闯, 郑侃, 董松, 等. 机器人旋转超声钻削铝合金叠层构件毛刺特性 [J]. 北京航空航天大学学报,2020,46(2):407-413.HU Lichuang, ZHENG Kan, DONG Song, et al. Burr characteristics of robot rotary ultrasonic drilling aluminum alloy laminated components [J]. Journal of Beijing University of Aeronautics and Astronautics,2020,46(2):407-413. [60] HU Y, SONG Y, LI Y, et al. An analytical model to predict interfacial burr height for metal stack drilling [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2019,233(1):99-108. doi: 10.1177/0954405417708224 [61] WANG H L, LI Q Y, ZHANG P K. Calculating of the exit burr in low frequency axial vibration drilling [J]. Advanced Materials Research, 2013,2428(706/707/708):123. [62] CHANG S S F, BONE G M. Burr height model for vibration assisted drilling of aluminum 6061-T6 [J]. Precision Engineering,2009,34(3):369-375. [63] HASSAN M H, ABDULLAH J, MAHMUD A S, et al. Burr height as quality indicator in single shot drilling of stacked CFRP/Aluminium composite [J]. Key Engineering Materials, 2017,744:327-331. [64] LI S, ZHANG D, LIU C, et al. Exit burr height mechanistic modeling and experimental validation for low-frequency vibration-assisted drilling of aluminum 7075-T6 alloy [J]. Journal of Manufacturing Processes, 2020, 56: 350-361. [65] 周越. 基于深度神经网络的航空装配制孔毛刺预测与工艺优化 [D]. 南京: 南京航空航天大学, 2019.ZHOU Yue. Burr prediction and process optimization of aviation assembly hole making based on depth neural network [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. [66] 周越, 田威, 廖文和, 等. 基于卷积神经网络的制孔出口毛刺预测方法 [J]. 机械制造与自动化,2020,49(2):64-68. doi: 10.19344/j.cnki.issn1671-5276.2020.02.016ZHOU Yue, TIAN Wei, LIAO Wenhe, et al. Prediction method of burr at hole making outlet based on convolution neural network [J]. Machine Building & Automation,2020,49(2):64-68. doi: 10.19344/j.cnki.issn1671-5276.2020.02.016 [67] 许敏俊, 刘世民, 沈慧, 等. 数字孪生驱动下的弱刚性钻削毛刺控制 [J/OL]. 计算机集成制造系统, 2021: 1-18.XU Minjun, LIU Shimin, SHEN Hui, et al. Burr control of weakly rigid drilling driven by digital twin [J/OL] . Computer Integrated Manufacturing System, 2021: 1-18. [68] THAKRE A A, SONI S. Modeling of burr size in drilling of aluminum silicon carbide composites using response surface methodology [J]. Engineering Science and Technology, an International Journal,2016,19(3):1199-1205. doi: 10.1016/j.jestch.2016.02.007 [69] ABDELHAFEEZ A M, SOO S L, ASPINWALL D K, et al. Burr formation and hole quality when drilling titanium and aluminium alloys [J]. Procedia CIRP,2015,37:230-235. doi: 10.1016/j.procir.2015.08.019 [70] 徐支凤. 机械零件毛刺去除工艺现状 [J]. 机床与液压,2010,38(8):111-113, 110. doi: 10.3969/j.issn.1001-3881.2010.08.040XU Zhifeng. Present situation of burr removal process of mechanical parts [J]. Machine Tool & Hydraulics,2010,38(8):111-113, 110. doi: 10.3969/j.issn.1001-3881.2010.08.040 [71] 姜俊, 舒鑫, 雍建华, 等. 金属切削毛刺形成与控制技术研究进展 [J]. 工具技术,2021,55(7):3-10. doi: 10.3969/j.issn.1000-7008.2021.07.001JIANG Jun, SHU Xin, YONG Jianhua, et al. Research progress of metal cutting burr formation and control technology [J]. Tool Engineering,2021,55(7):3-10. doi: 10.3969/j.issn.1000-7008.2021.07.001 [72] 苏海, 马兴海, 王娟, 等. 运载火箭铝合金叠层壁板自动化制孔工艺对钻孔毛刺影响的研究 [J]. 航空精密制造技术,2017,53(1):26-29, 59. doi: 10.3969/j.issn.1003-5451.2017.01.006SU Hai, MA Xinghai, WANG Juan, et al. Study on the influence of automatic drilling process of aluminum alloy laminated wall panel of launch vehicle on drilling burr [J]. Aviation Precision Manufacturing Technology,2017,53(1):26-29, 59. doi: 10.3969/j.issn.1003-5451.2017.01.006 [73] 于渊, 臧建新, 朱振江, 等. 铝合金夹层结构自动钻铆工艺参数研究 [J]. 机械工程与自动化,2020(2):155-156. doi: 10.3969/j.issn.1672-6413.2020.02.061YU Yuan, ZANG Jianxin, ZHU Zhenjiang, et al. Study on automatic drilling and riveting process parameters of aluminum alloy sandwich structure [J]. Mechanical Engineering & Automation,2020(2):155-156. doi: 10.3969/j.issn.1672-6413.2020.02.061 [74] DIRHAMSYAH M, TADJUDDIN M, UDINK A, et al. The effect of cutting speed on dimension accuracy and burr development of high-speed micro drill proses on aluminium [J]. IOP Conference Series: Materials Science and Engineering, 2019, 523(1): 012074. [75] GAITONDE V N, KARNIK S R, ACHYUTHA B T, et al. Taguchi optimization in drilling of AISI 316L stainless steel to minimize burr size using multi-performance objective based on membership function [J]. Journal of Materials Processing Technology,2007,202(1):374-379. [76] BAHCE E, OZDEMIR B. Investigation of the burr formation during the drilling of free-form surfaces in al 7075 alloy [J]. Journal of Materials Research and Technology,2019,8(5):4198-4298. doi: 10.1016/j.jmrt.2019.07.028 [77] 雷鸣宇. 用于高强度钢加工的钻头结构参数优化 [D]. 西安: 西安工业大学, 2018.LEI Mingyu. Optimization of structural parameters of drill bit for machining high strength steel [D]. Xi'an: Xi'an University of Technology, 2018. [78] 张文盟. TC4钛合金钻削刀具几何参数优化 [D]. 太原: 太原理工大学, 2019.ZHANG Wenmeng. Optimization of geometric parameters of TC4 titanium alloy drilling tool [D]. Taiyuan: Taiyuan University of Technology, 2019. [79] 郭伟民. 可抑制毛刺的钻头结构 [J]. 制造技术与机床,2017(10):85-88. doi: 10.19287/j.cnki.1005-2402.2017.10.018GUO Weimin. Bit structure capable of suppressing burr [J]. Manufacturing Technology & Machine Tool,2017(10):85-88. doi: 10.19287/j.cnki.1005-2402.2017.10.018 [80] DORNFELD D A, KIM J S, DECHOW H, et al. Drilling burr formation in titanium alloy, Ti−6AI−4V [J]. CIRP Annals- Manufacturing Technology, 1999, 48(1): 73-76. [81] FRANCZYK E, SLUSARCZYK L, ZEBALA W. Drilling burr minimization by Changing Drill Geometry [J]. Materials, 2020, 13(14): 3207. [82] 施志辉, 冯立伟. 麻花钻三维建模及切削刃几何参数研究 [J]. 机械制造,2017,55(6):62-65. doi: 10.3969/j.issn.1000-4998.2017.06.018SHI Zhihui, FENG Liwei. 3D modeling of twist drill and Study on geometric parameters of cutting edge [J]. Machinery,2017,55(6):62-65. doi: 10.3969/j.issn.1000-4998.2017.06.018 [83] 曾腾辉. 不同刃口形貌的S钻尖麻花钻钻削性能研究 [J]. 机械工程师,2020(10):31-34.ZENG Tenghui. Study on drilling performance of S drill point twist drill with different edge morphology [J]. Mechanical Engineer,2020(10):31-34. [84] LIANG W, XU J, REN W, et al. Study on the influence of tool point angle on ultrasonic vibration–assisted drilling of titanium alloy [J]. The International Journal of Advanced Manufacturing Technology,2019,105(1/2/3/4):1069-1082. doi: 10.1007/s00170-019-04231-x [85] 郭伟民, 李泰祥, 李义龙, 等. 二重顶角钻头抑制钻出毛刺的应用研究 [J]. 机床与液压, 2017, 45(8): 43-45.GUO Weimin, LI Taixiang, LI Yilong, et al. Application Research on burr suppression by double top angle bit [J]. Machine Tool & Hydraulics. 2017, 45(8): 43-45. [86] ZHU Z, GUO K, SUN J, et al. Evaluation of novel tool geometries in dry drilling aluminium 2024−T351/titanium Ti6Al4V stack [J]. Journal of Materials Processing Technology,2018,259:270-281. doi: 10.1016/j.jmatprotec.2018.04.044 [87] REZENDE B A, SILVEIRA M L, VIEIRA L M G. Investigation on the effect of drill geometry and pilot holes on thrust force and burr height when drilling an aluminium/PE sandwich material [J]. Materials,2016,9(9):774. doi: 10.3390/ma9090774 [88] QIU X Y, YU Z, LI C P, et al. Influence of main cutting edge structure on hole defects in CFRP/titanium alloy stacks drilling [J]. Journal of Manufacturing Processes,2021,69:503-513. doi: 10.1016/j.jmapro.2021.07.061 [89] KO S L, CHANG J E, YANG G E. Burr minimizing scheme in drilling [J]. Journal of Materials Processing Technology,2003,140(1/2/3):237-242. doi: 10.1016/S0924-0136(03)00719-2 [90] JIA Z Y, ZHANG C, WANG F J, et al. An investigation of the effects of step drill geometry on drilling induced delamination and burr of Ti/CFRP stacks [J]. Composite Structures,2020,235:111786. [91] 张观福, 谢安, 高帅. 钻头钻尖角对铝合金材料加工清洁度影响分析 [J]. 时代汽车,2019(3):152-153. doi: 10.3969/j.issn.1672-9668.2019.03.065ZHANG Guanfu, XIE An, GAO Shuai. Analysis of the influence of drill tip angle on the machining cleanliness of aluminum alloy materials [J]. Auto Time,2019(3):152-153. doi: 10.3969/j.issn.1672-9668.2019.03.065 [92] 刘凯. 铝/钛叠层结构钻铰锪一体化制孔刀具开发与工艺参数优化 [D]. 济南: 山东大学, 2018.LIU Kai. Development of drilling, reaming and spot facing integrated hole making tool with aluminum/titanium laminated structure and optimization of process parameters [D]. Jinan: Shandong University, 2018. [93] 王彬杰. 铝合金加工用变导程钻头研究 [D]. 大连: 大连工业大学, 2015.WANG Binjie. Research on variable lead bit for aluminum alloy processing [D]. Dalian: Dalian University of Technology, 2015. [94] 刘澍彬, 张伟, 李铸宇. 铝合金加工用变导程钻头切削试验 [J]. 工具技术,2017,51(6):94-96. doi: 10.3969/j.issn.1000-7008.2017.06.021LIU Shubin, ZHANG Wei, LI Zhuyu. Cutting test of variable lead bit for aluminum alloy machining [J]. Tool Engineering,2017,51(6):94-96. doi: 10.3969/j.issn.1000-7008.2017.06.021 [95] 林涛, 李国和, 刘蒙, 等. 刀具材料对运载火箭叠层厚板高速制孔影响的实验研究 [J]. 航空精密制造技术,2017,53(4):24-28. doi: 10.3969/j.issn.1003-5451.2017.04.007LIN Tao, LI Guohe, LIU Meng, et al. Experimental study on the influence of tool material on high-speed hole making of launch vehicle laminated thick plate [J]. Aviation Precision Manufacturing Technology,2017,53(4):24-28. doi: 10.3969/j.issn.1003-5451.2017.04.007 [96] 王共冬, 周丽, 种强, 等. 碳纤维复合材料/铝合金叠层制孔工艺研究 [J]. 科学技术与工程,2017,17(6):152-157. doi: 10.3969/j.issn.1671-1815.2017.06.027WANG Gongdong, ZHOU Li, ZHONG Qiang, et al. Study on hole making process of carbon fiber composite / aluminum alloy lamination [J]. Science Technology and Engineering,2017,17(6):152-157. doi: 10.3969/j.issn.1671-1815.2017.06.027 [97] 徐国勇, 庞涛, 王贵成. 轴向振动钻削对进给方向毛刺形成的影响 [J]. 工具技术,2019,53(9):71-73. doi: 10.3969/j.issn.1000-7008.2019.09.017XU Guoyong, PANG Tao, WANG Guicheng. Effect of axial vibration drilling on burr formation in feed direction [J]. Tool Engineering,2019,53(9):71-73. doi: 10.3969/j.issn.1000-7008.2019.09.017 [98] 张园, 康仁科, 刘津廷, 等. 超声振动辅助钻削技术综述 [J]. 机械工程学报,2017,53(19):33-44. doi: 10.3901/JME.2017.19.033ZHANG Yuan, KANG Renke, LIU Jinting, et al. Overview of ultrasonic vibration assisted drilling technology [J]. Journal of Mechanical Engineering,2017,53(19):33-44. doi: 10.3901/JME.2017.19.033 [99] ZAI P, TONG J, LIU Z, et al. Analytical model of exit burr height and experimental investigation on ultrasonic-assisted high-speed drilling micro-holes [J]. Journal of Manufacturing Processes,2021,68:807-817. [100] 杨淇耀, 吴丹, 陈恳. 钛合金/铝合金叠层低温与干式钻削实验研究 [J]. 组合机床与自动化加工技术,2021(6):1-5. doi: 10.13462/j.cnki.mmtamt.2021.06.001YANG Qiyao, WU Dan, CHEN Ken. Experimental study on low temperature and dry drilling of titanium alloy/aluminum alloy lamination [J]. Modular Machine Tool & Automatic Manufacturing Technique,2021(6):1-5. doi: 10.13462/j.cnki.mmtamt.2021.06.001 [101] NAM J S, LEE P, LEE S W. Experimental characterization of micro-drilling process using nanofluid minimun quantity lubrication [J]. International Journal of Machine Tools and Manufacture,2011,51(7/8):649-652. doi: 10.1016/j.ijmachtools.2011.04.005 [102] BIERMANN D, HARTMANN H. Reduction of burr formation in drilling using cryogenic process cooling [J]. Procedia CIRP,2012,3:85-90. doi: 10.1016/j.procir.2012.07.016 [103] 张玉玺, 吴丹, 杨亚鹏, 等. 冷却润滑方式对CFRP/Al叠层钻孔质量及轴向力的影响 [J]. 清华大学学报(自然科学版),2018,58(4):402-410. doi: 10.16511/j.cnki.qhdxxb.2018.22.016ZHANG Yuxi, WU Dan, YANG Yapeng, et al. Effect of cooling and lubrication methods on drilling quality and axial force of CFRP/Al laminate [J]. Journal of Tsinghua University (Science and Technology),2018,58(4):402-410. doi: 10.16511/j.cnki.qhdxxb.2018.22.016 [104] 郑璐晗, 杜兆才, 姚艳彬. 机器人制孔系统与制孔工艺参数优化方法研究 [J]. 装备制造技术,2020(2):6-15, 20. doi: 10.3969/j.issn.1672-545X.2020.02.002ZHENG Luhan, DU Zhaocai, YAO Yanbin. Research on robot drilling system and optimization method of drilling process parameters [J]. Equipment Manufacturing Technology,2020(2):6-15, 20. doi: 10.3969/j.issn.1672-545X.2020.02.002 [105] 卢志军. 制孔质量约束的铝合金薄壁叠层结构单向预压钻孔工艺研究 [J]. 航空制造技术,2015(S2):152-156.LU Zhijun. Study on unidirectional preloading drilling technology of aluminum alloy thin-walled laminated structure with hole making quality constraints [J]. Aeronautical Manufacturing Technology,2015(S2):152-156. [106] 李源, 胡永祥, 姚振强. 预压紧力下叠层铝合金钻孔层间毛刺试验研究 [J]. 组合机床与自动化加工技术,2014(2):110-113. doi: 10.13462/j.cnki.mmtamt.2014.02.029LI Yuan, HU Yongxiang, YAO Zhenqiang. Experimental study on interlayer burr of laminated aluminum alloy drilling under pre compression force [J]. Modular Machine Tool & Automatic Manufacturing Technique,2014(2):110-113. doi: 10.13462/j.cnki.mmtamt.2014.02.029 [107] 宋尧. 机器人自动制孔末端执行器研制及制孔质量控制方法研究 [D]. 上海: 上海交通大学, 2017.SONG Yao. Development of robot automatic drilling end effector and Research on drilling quality control method [D]. Shanghai: Shanghai Jiaotong University, 2017. [108] 刘雪锋, 朱伟东, 杨国荣, 等. 基于有限元法的叠层薄壁工件自动化制孔压紧力预测 [J]. 中南大学学报 (自然科学版),2018,49(2):339-344.LIU Xuefeng, ZHU Weidong, YANG Guorong, et al. Prediction of pressing force for automatic hole making of laminated thin-walled workpiece based on finite element method [J]. Journal of Central South University(Science and Technology),2018,49(2):339-344. -

下载:

下载:

邮件订阅

邮件订阅 RSS

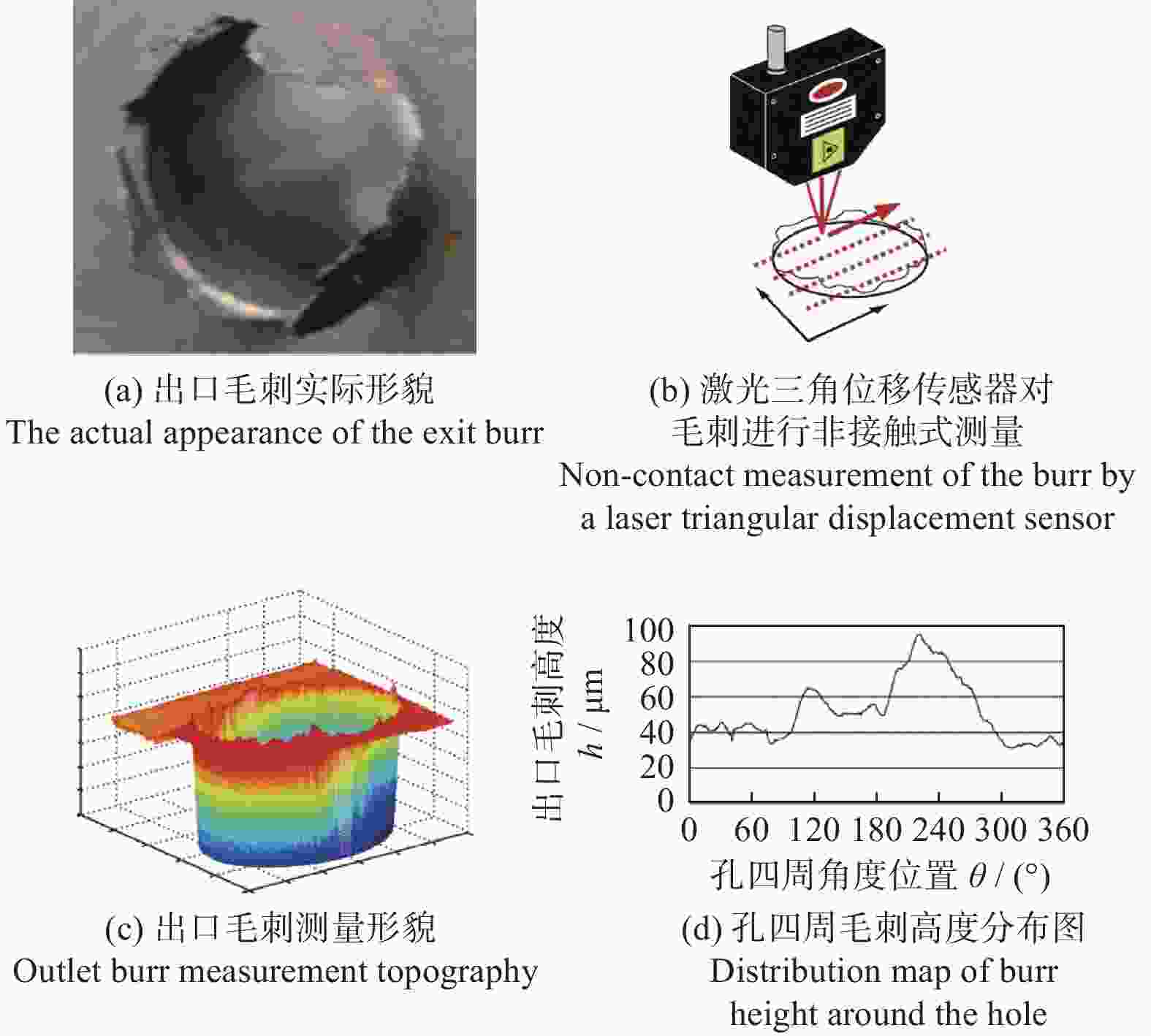

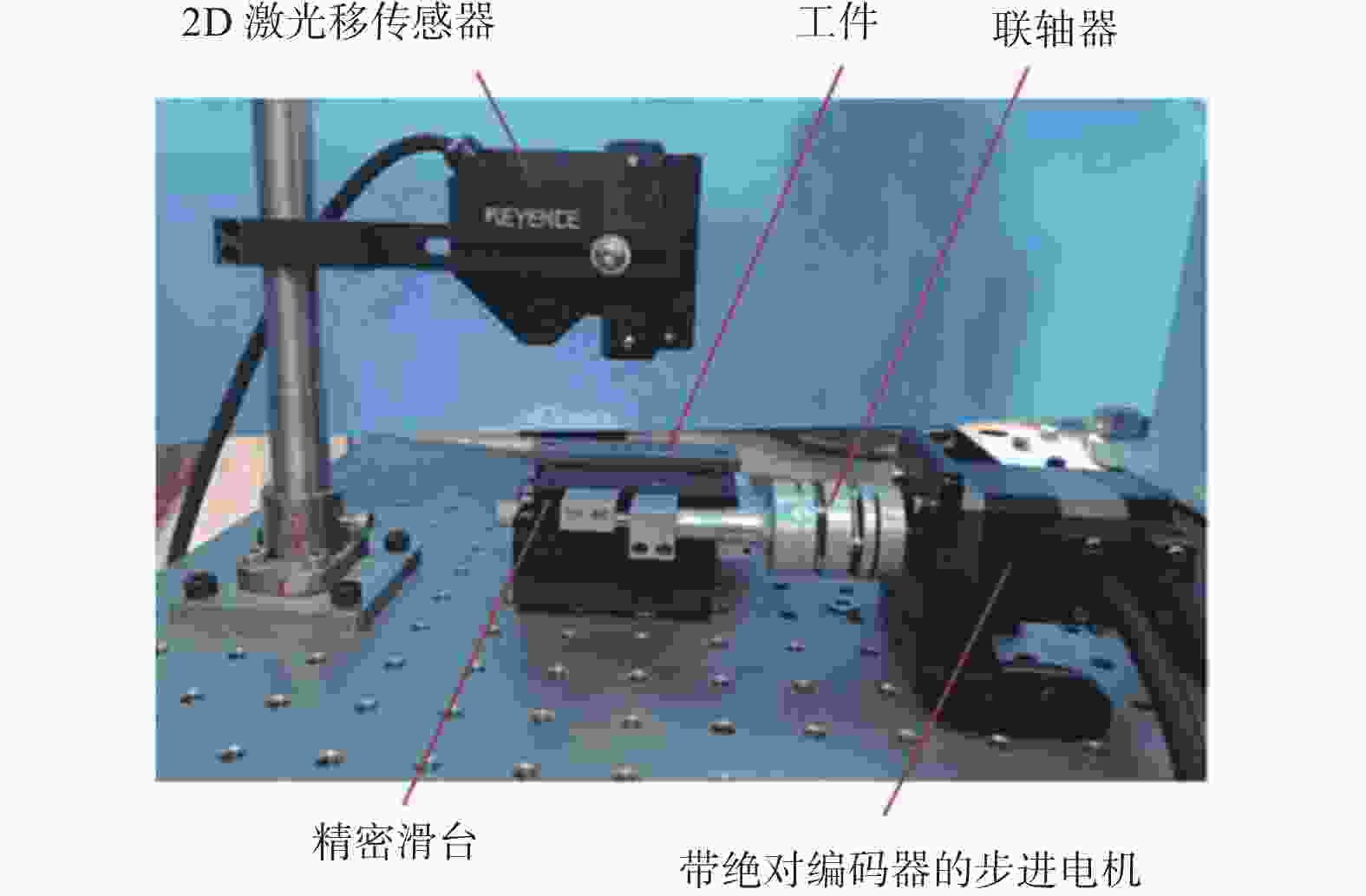

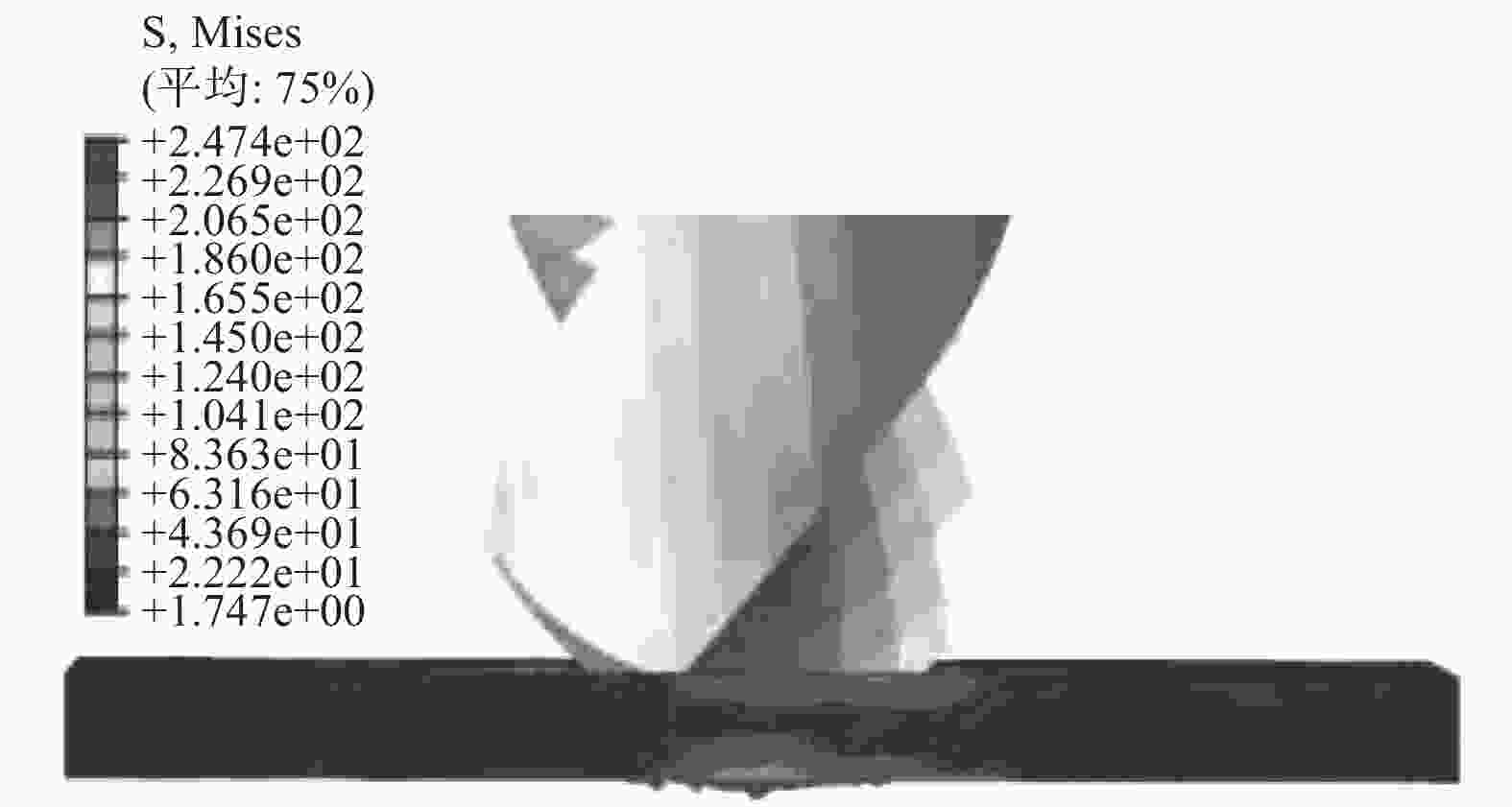

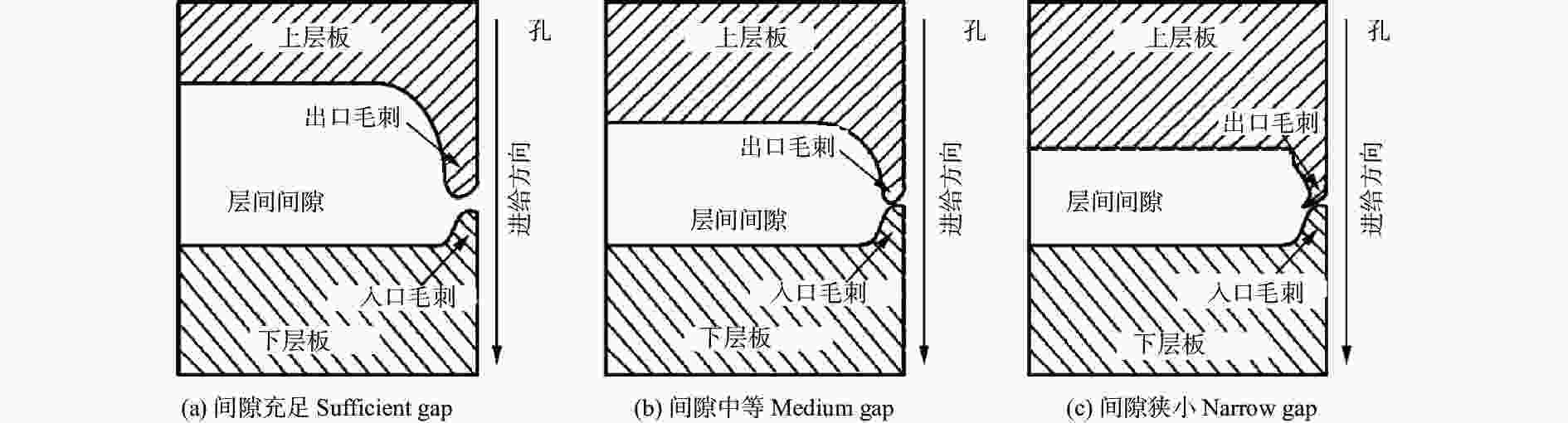

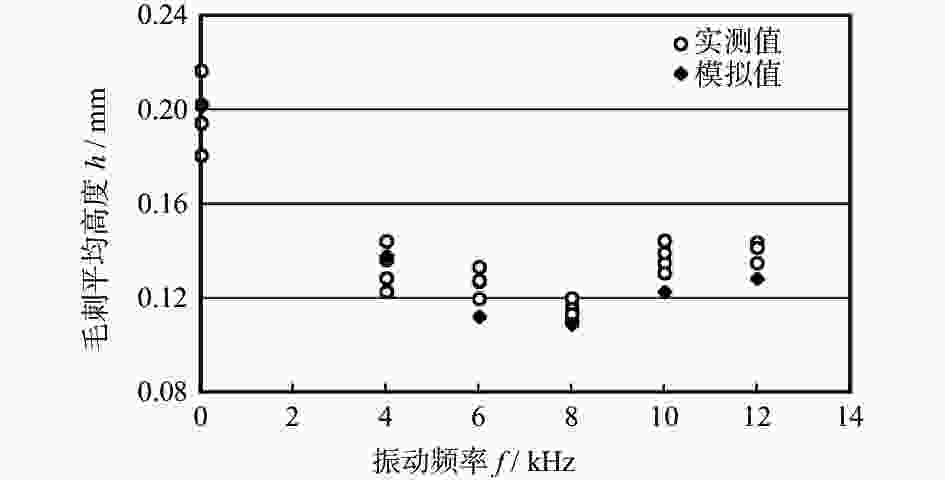

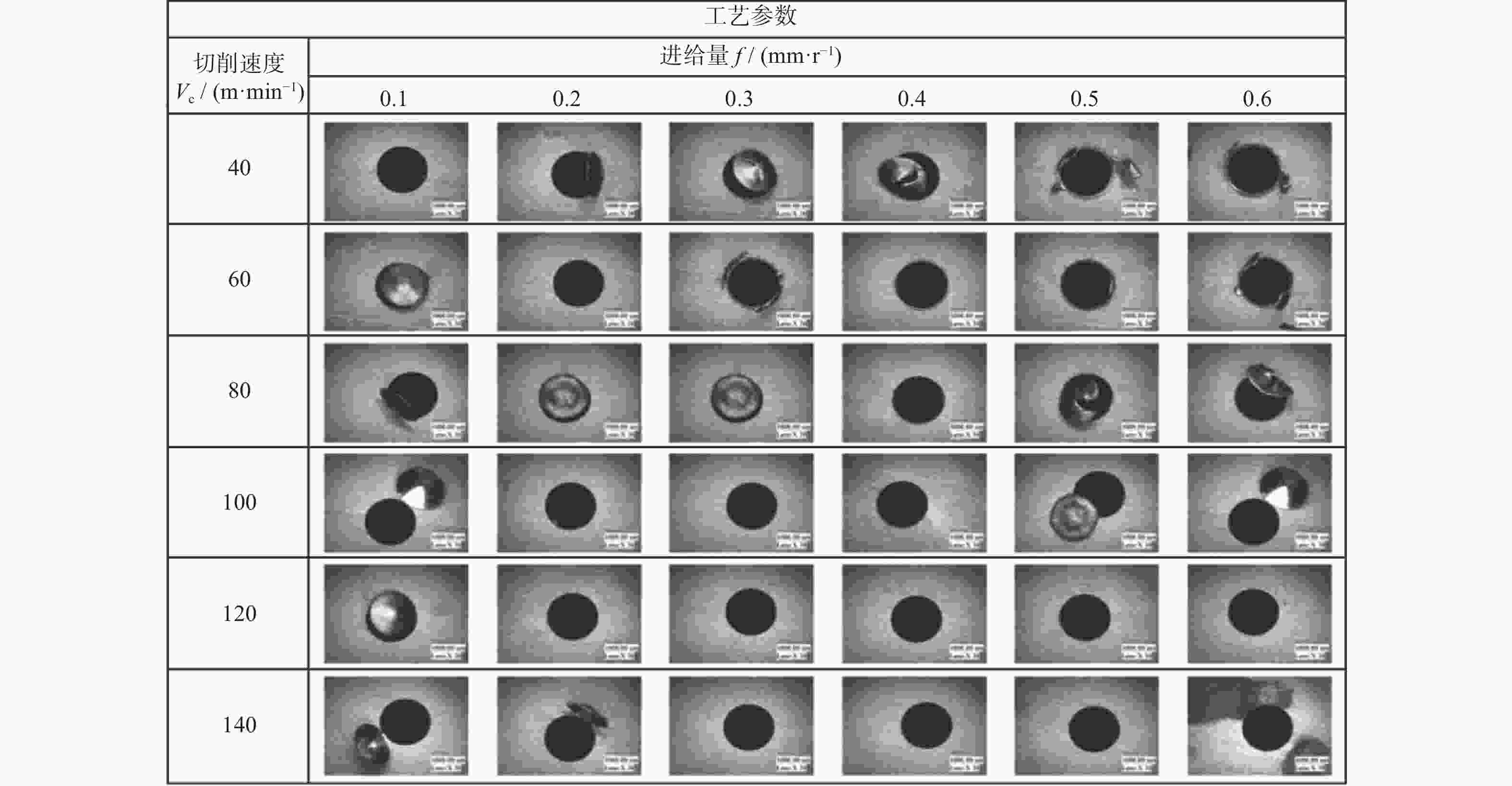

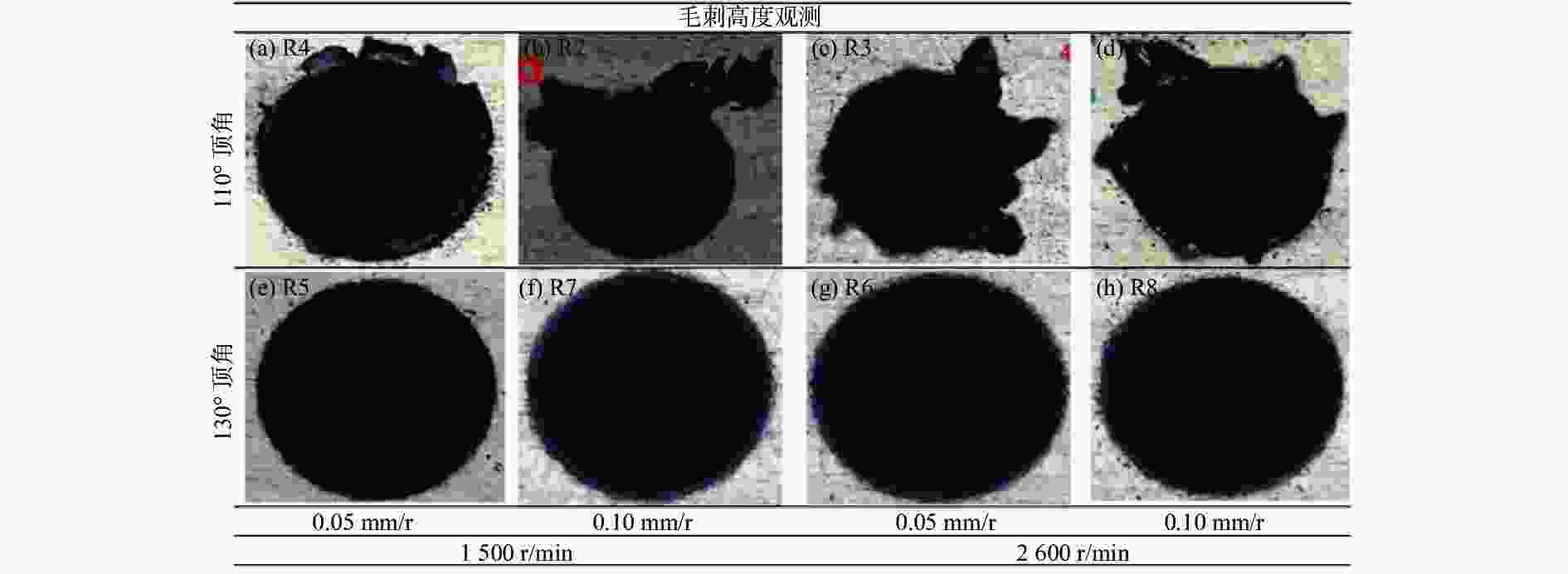

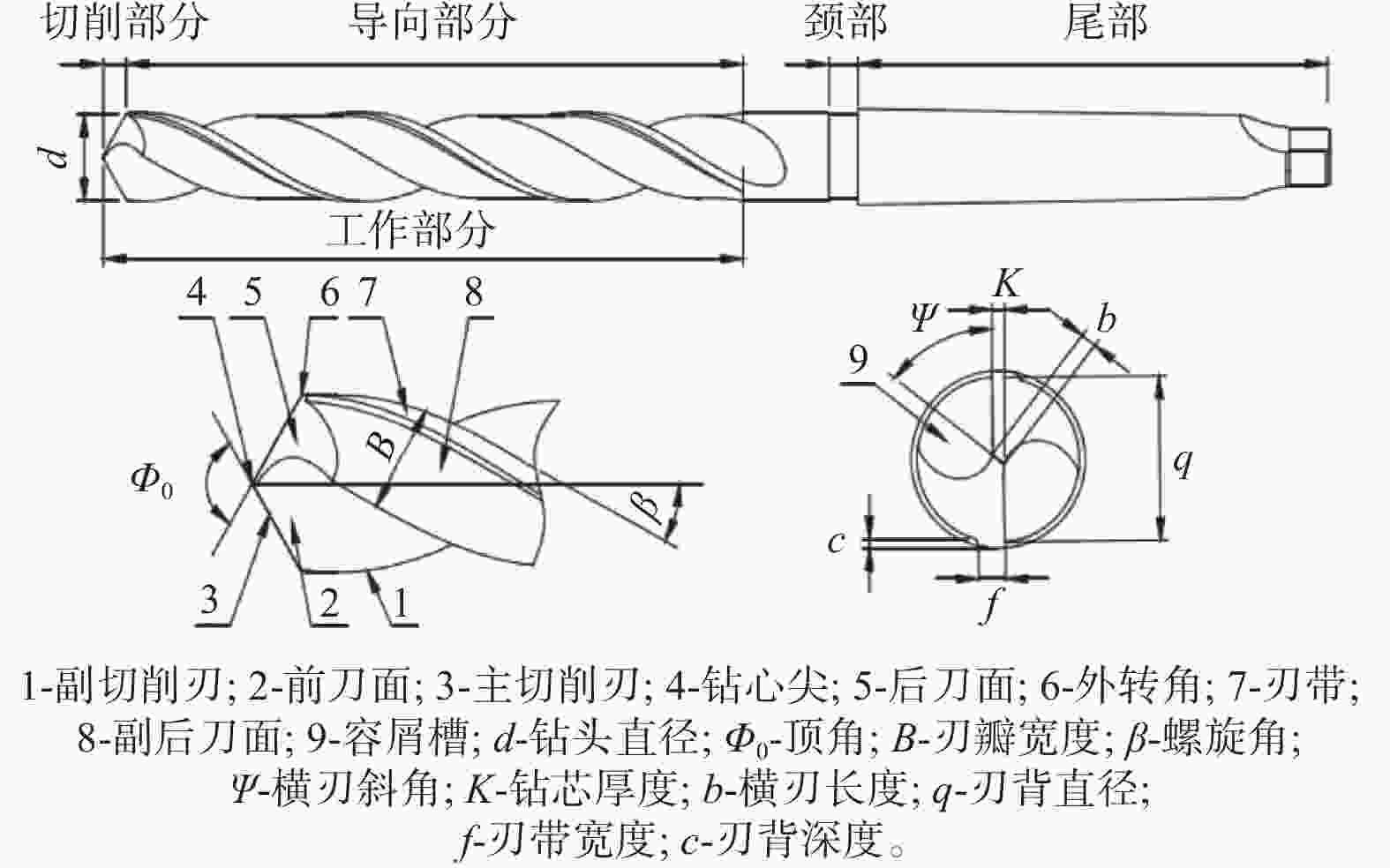

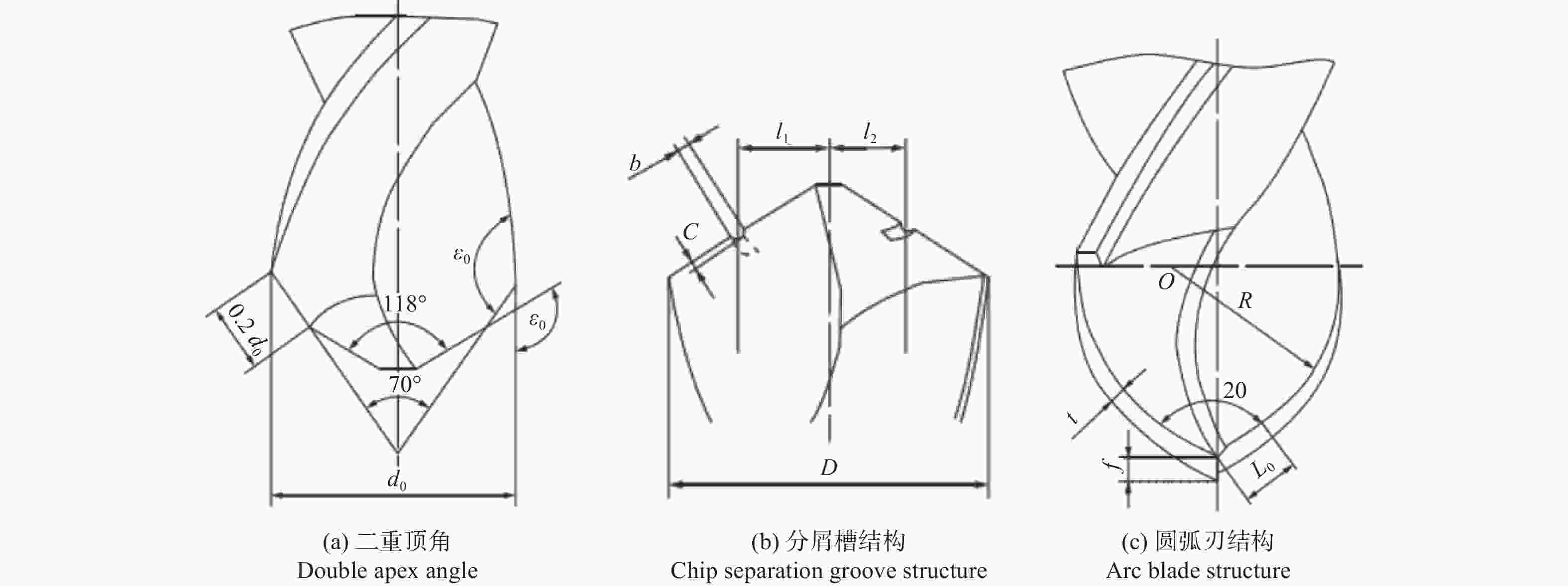

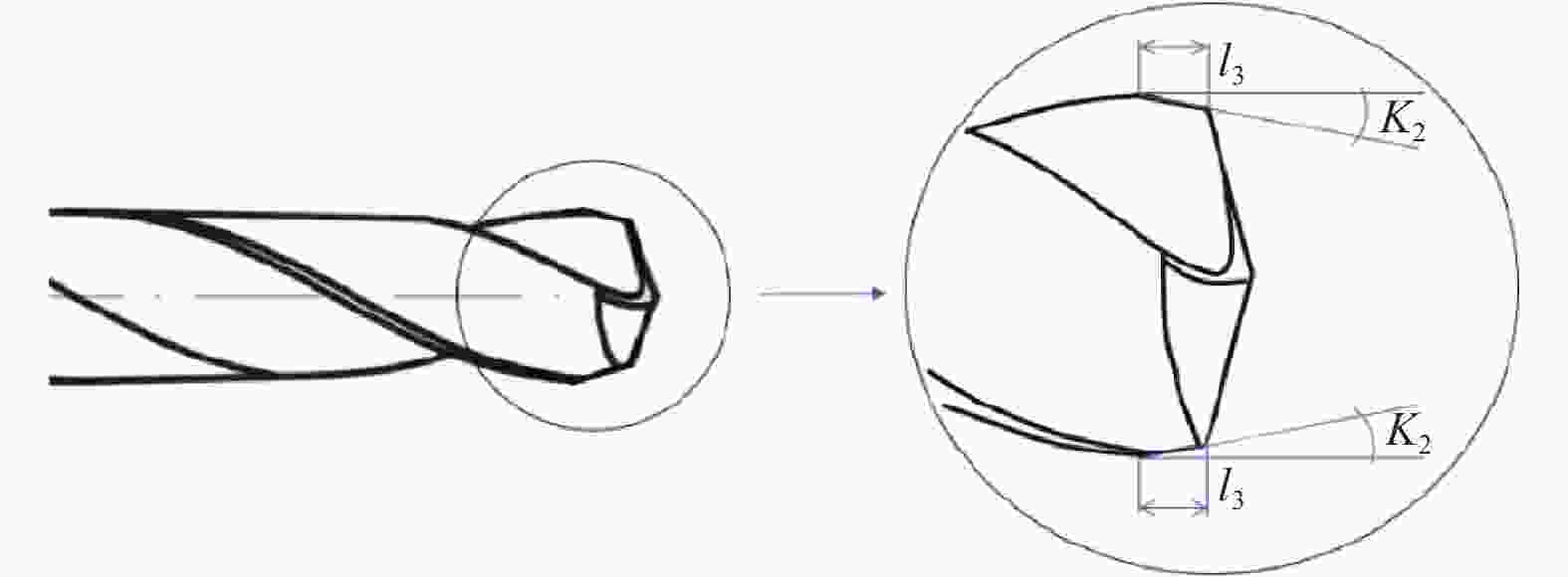

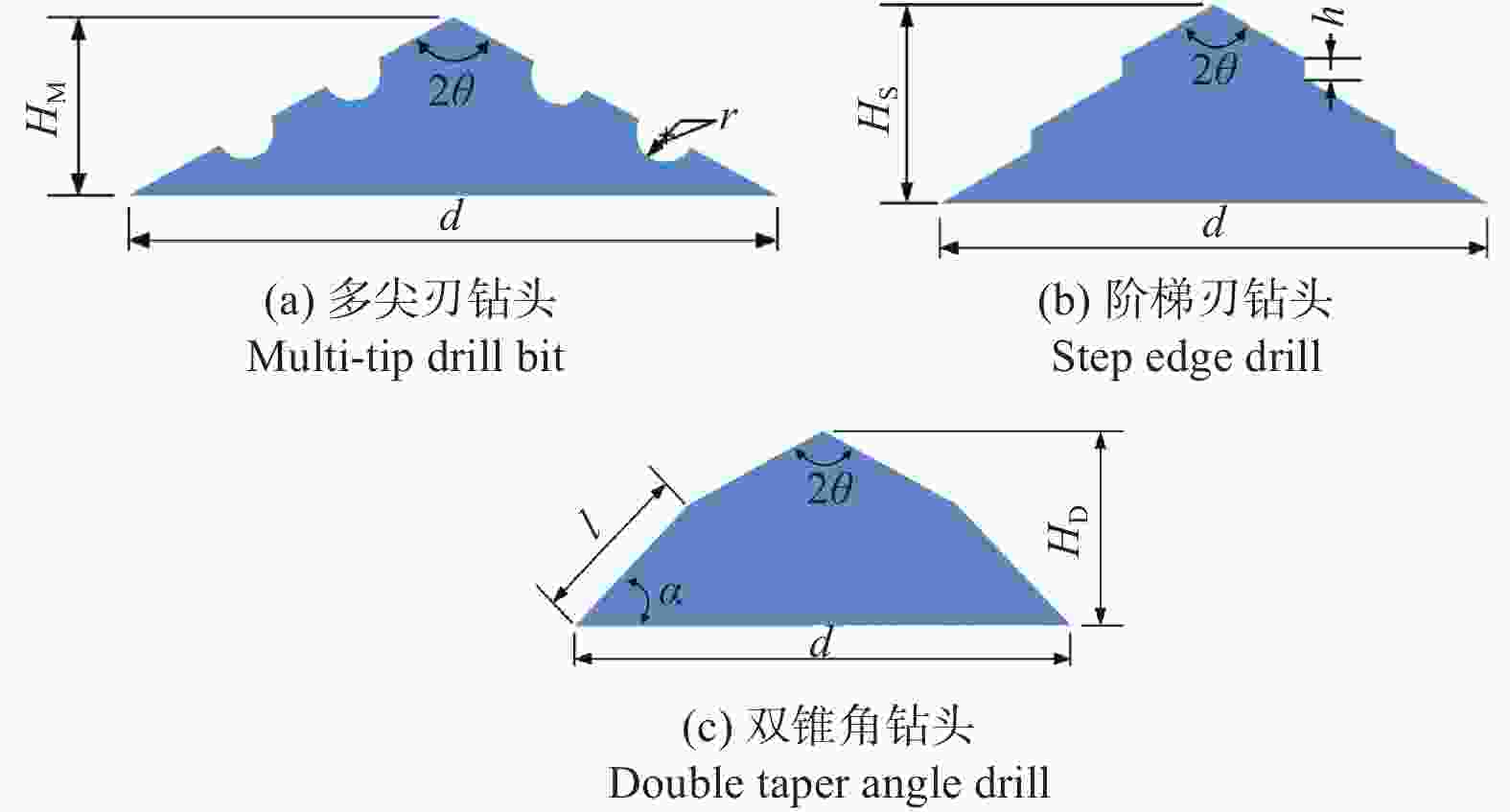

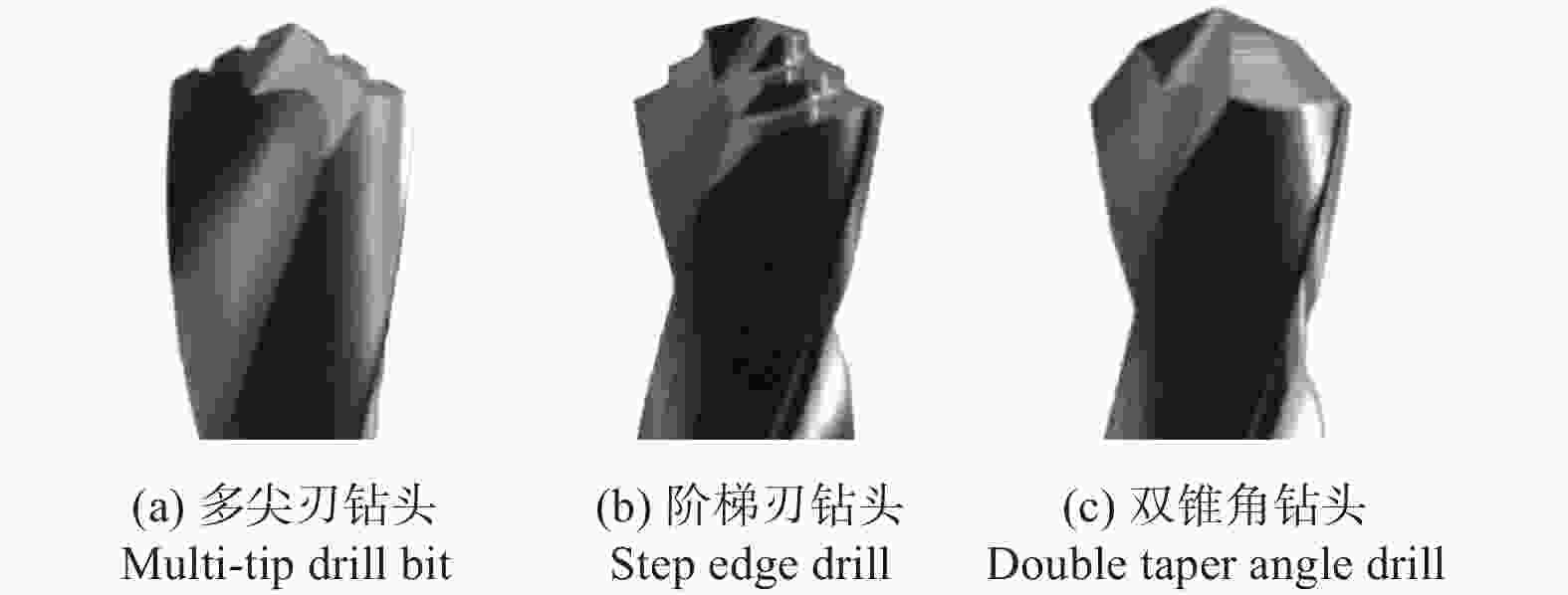

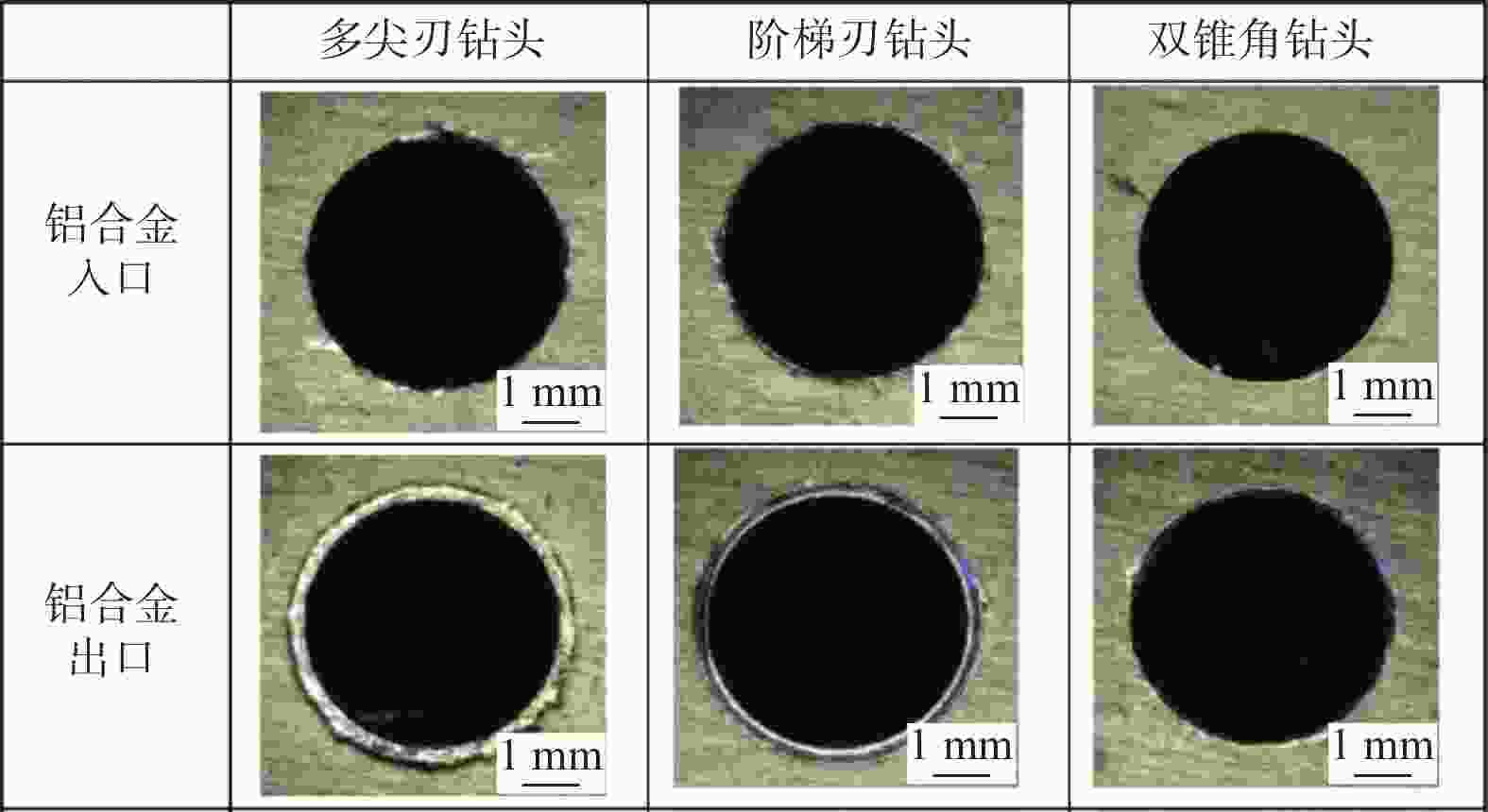

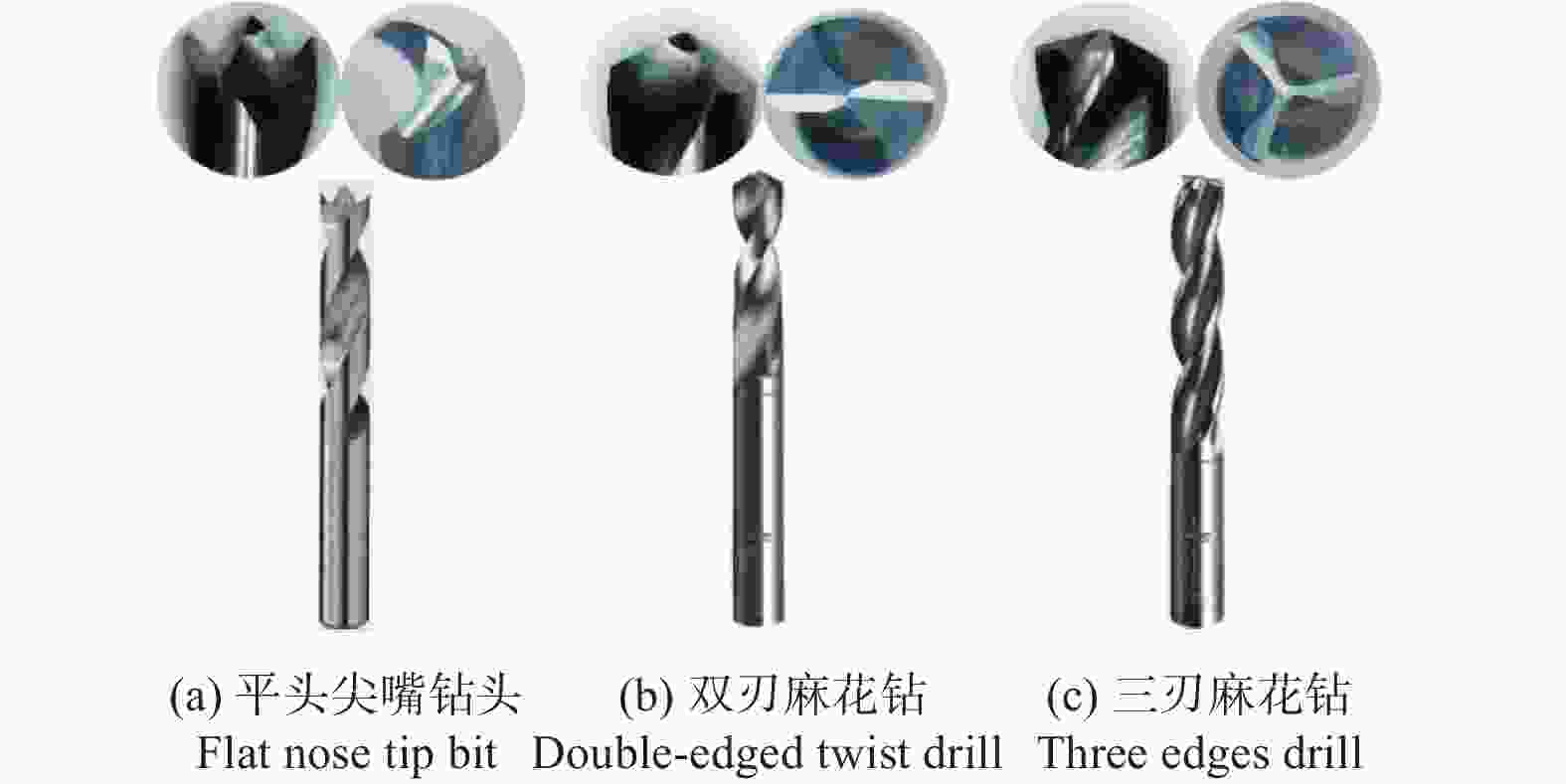

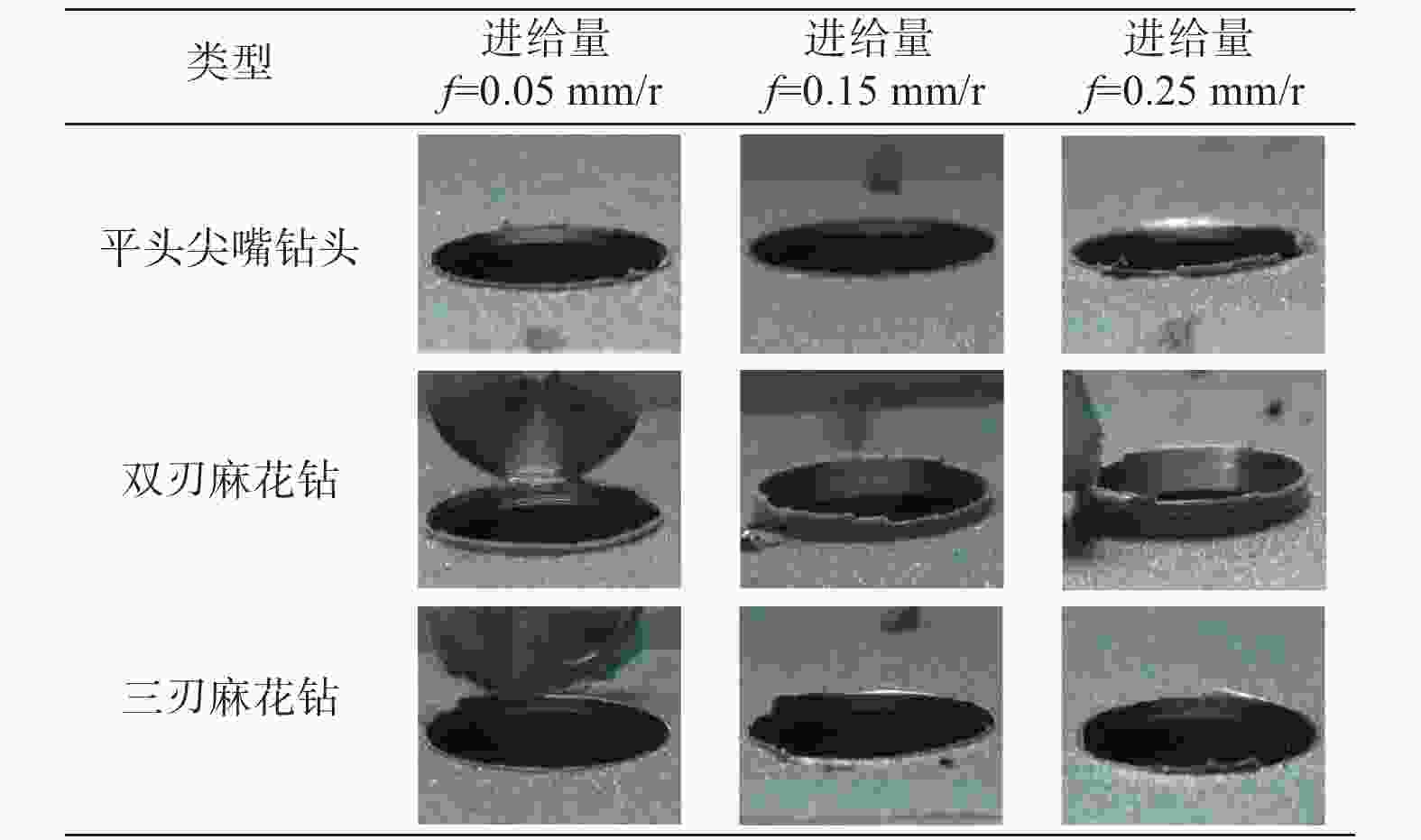

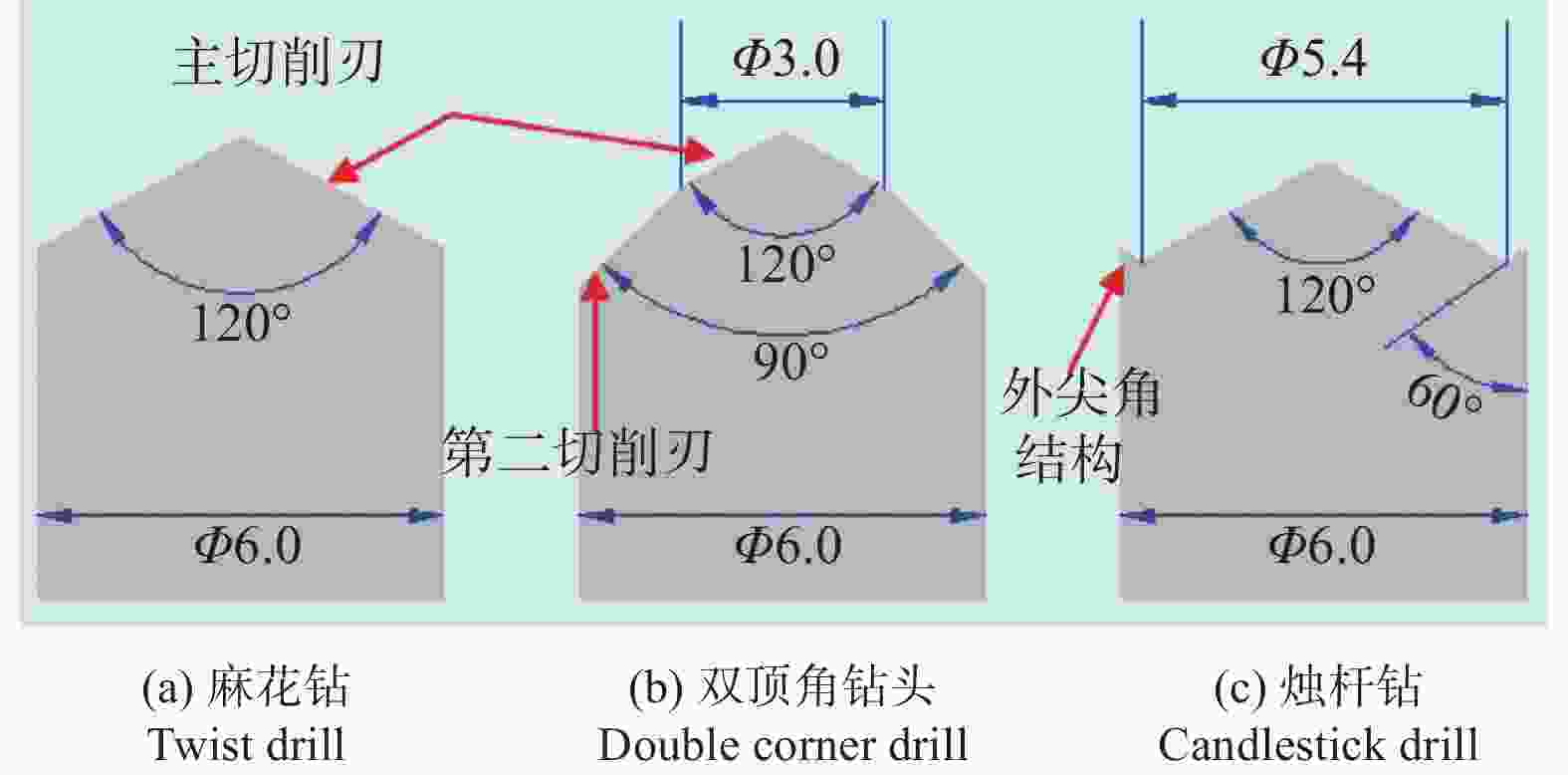

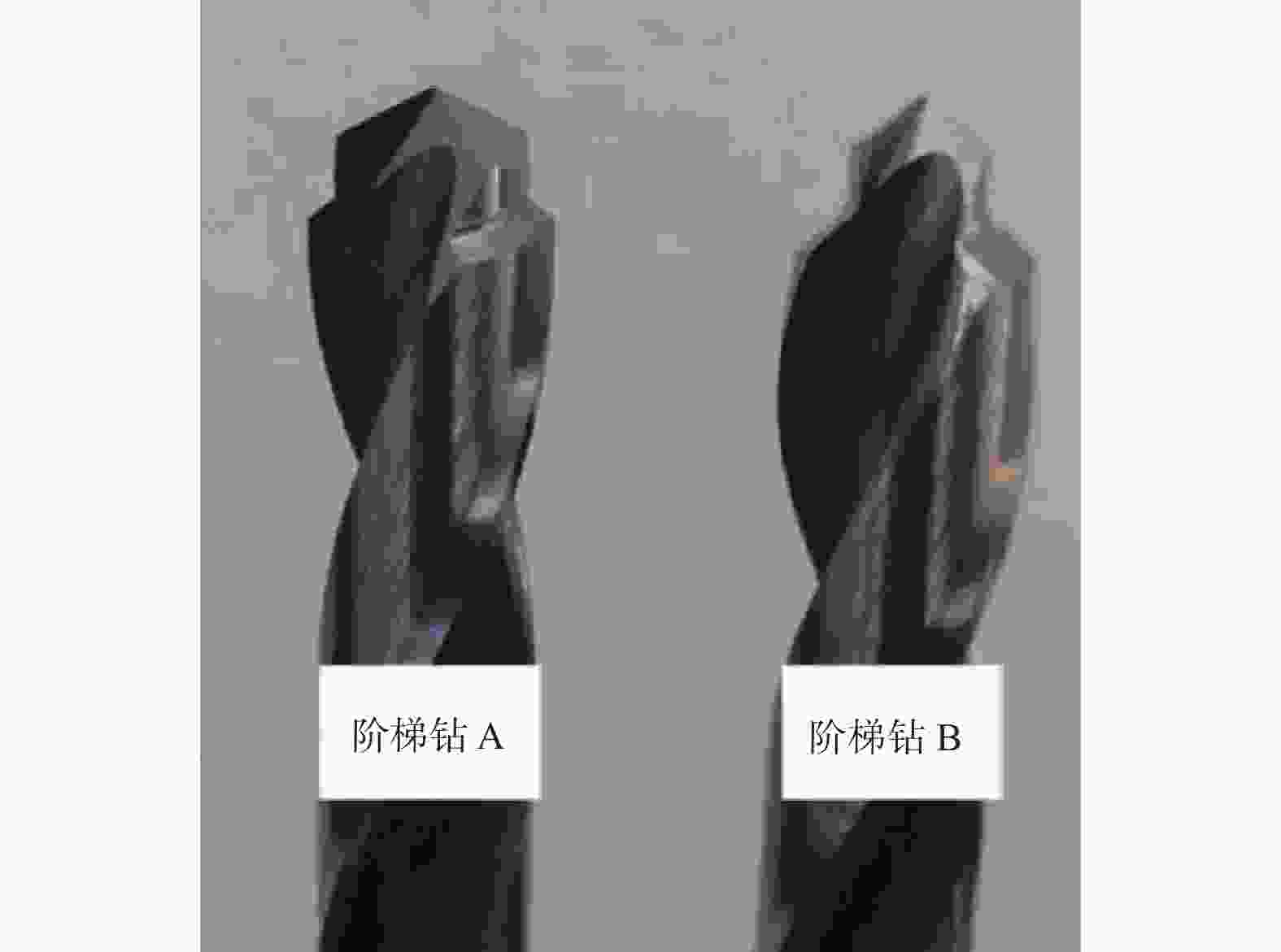

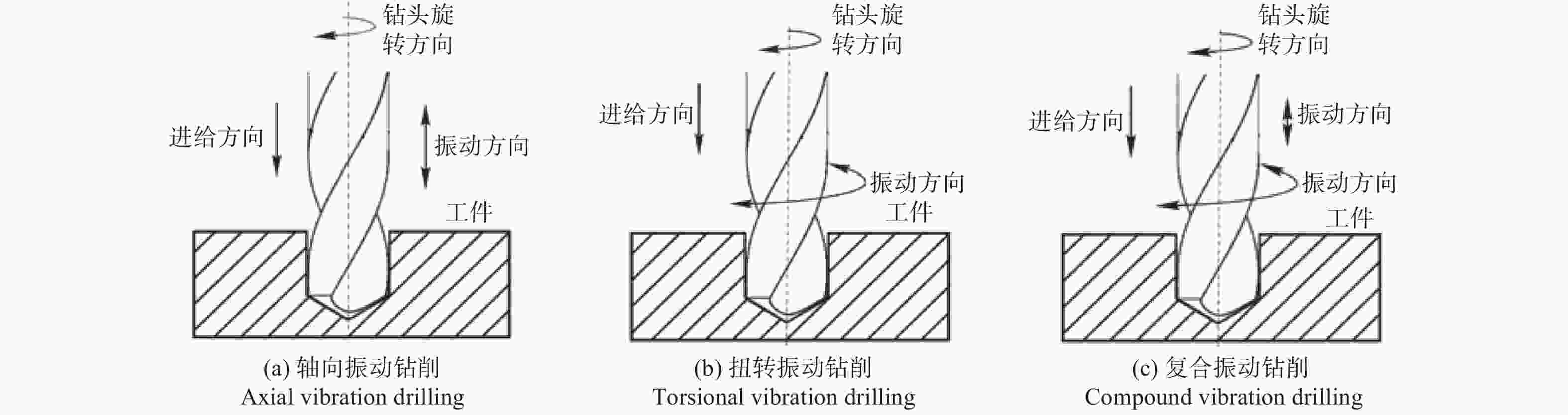

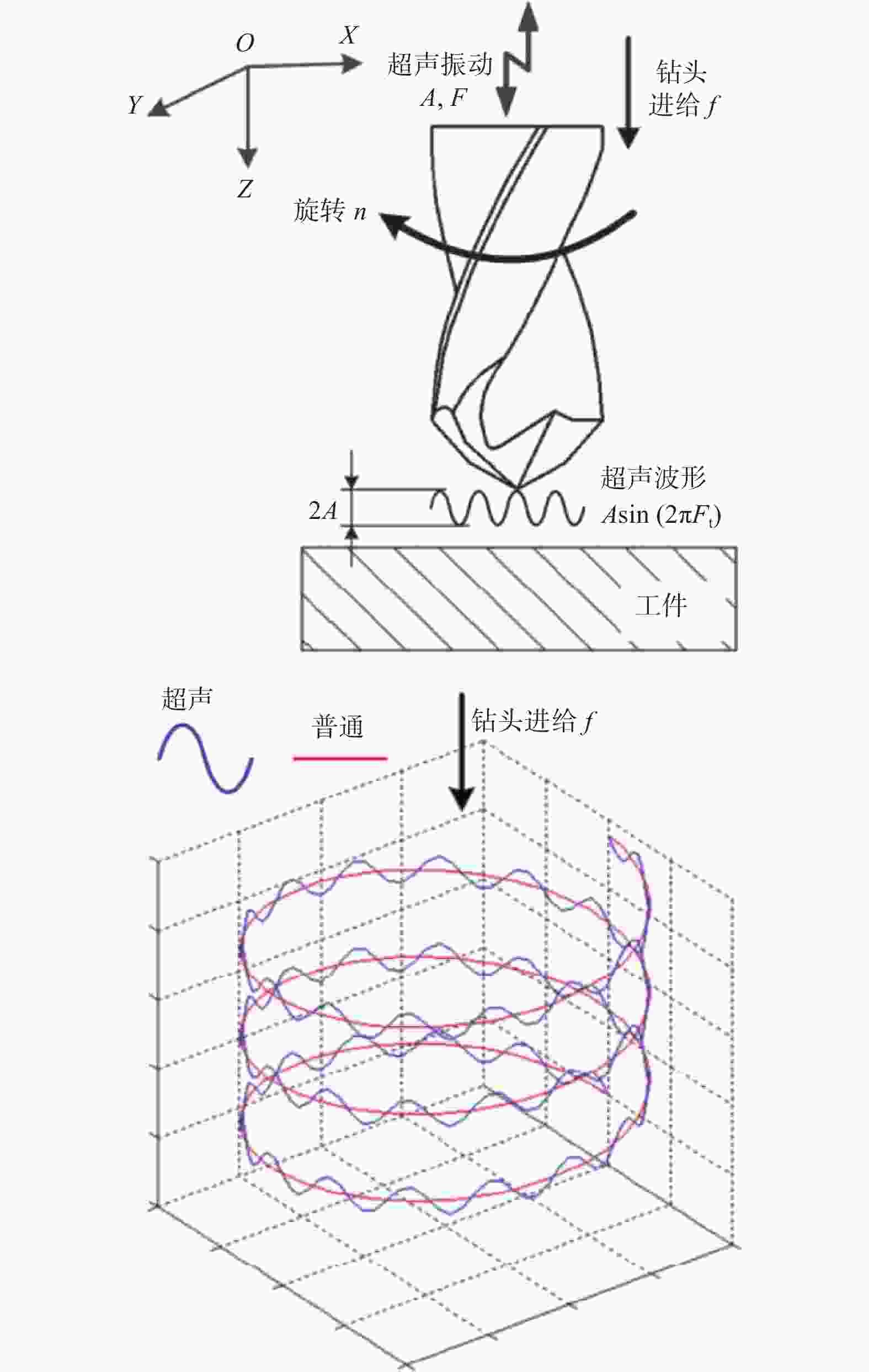

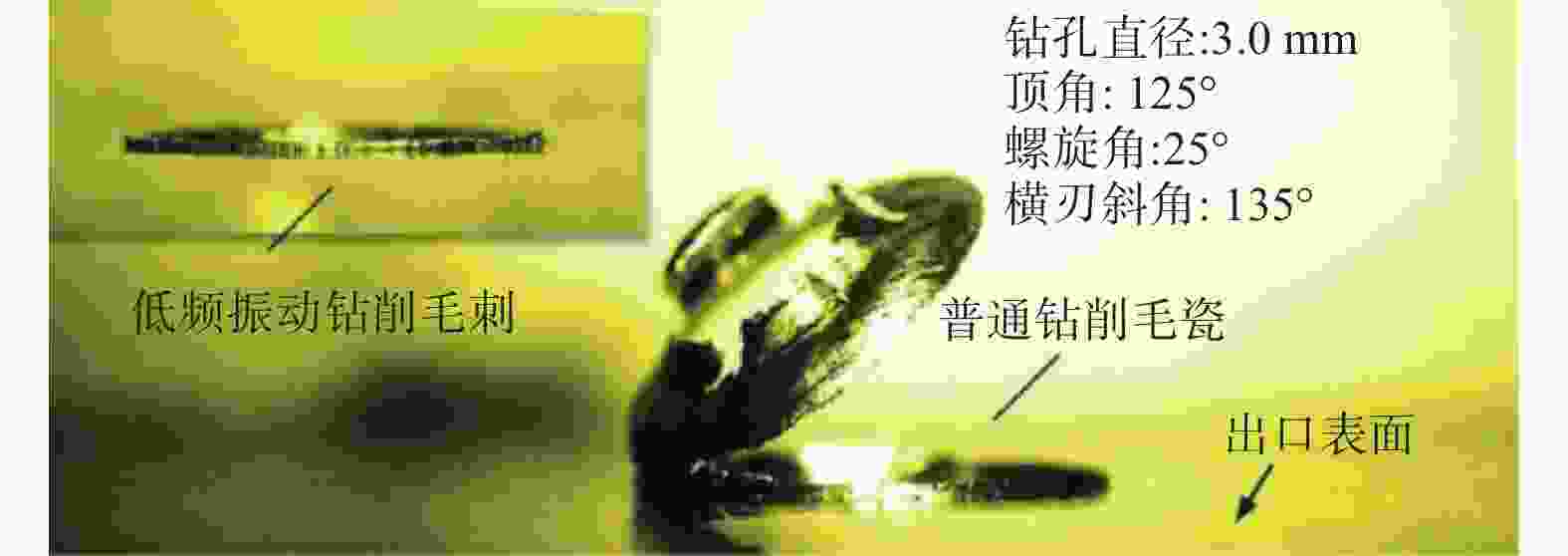

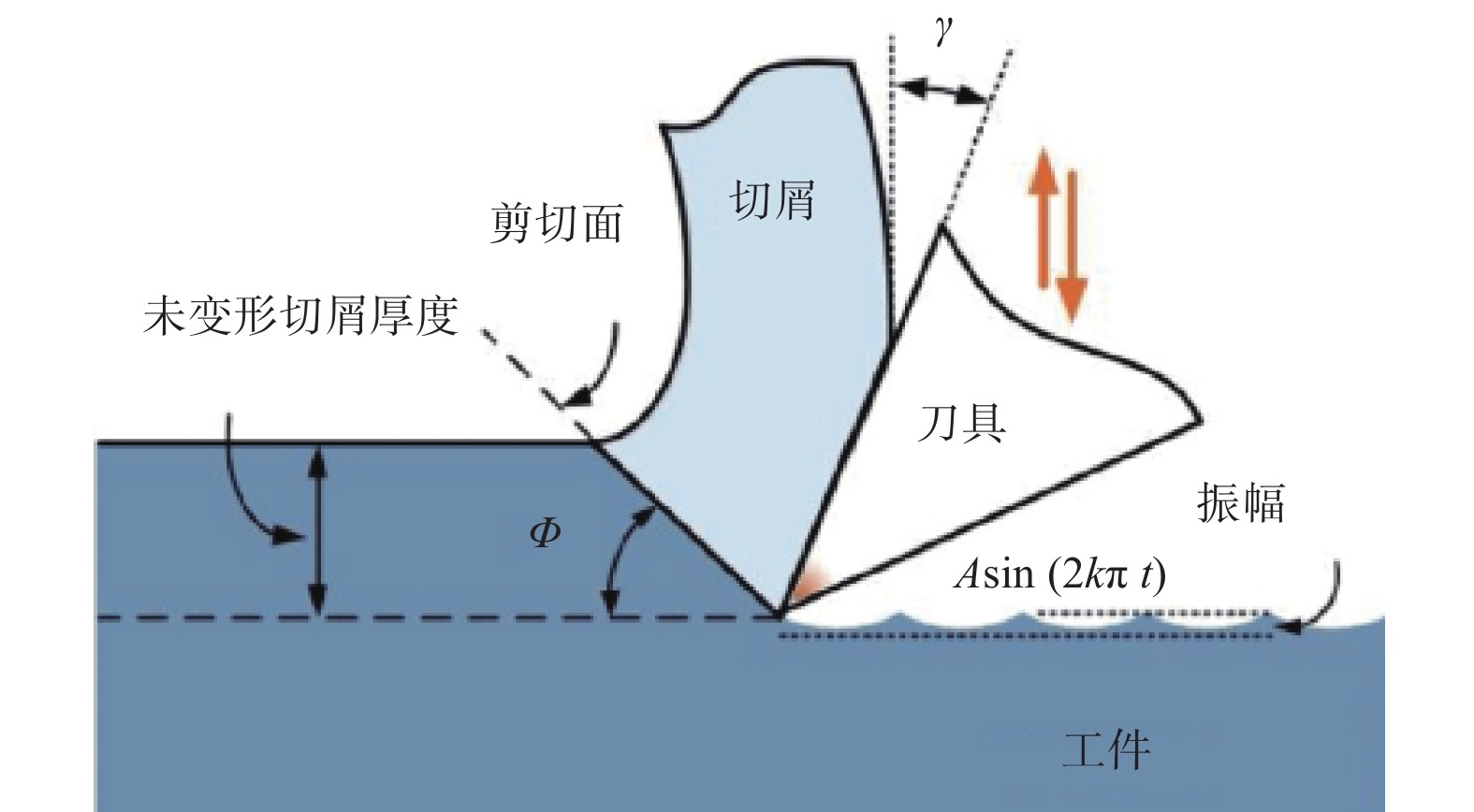

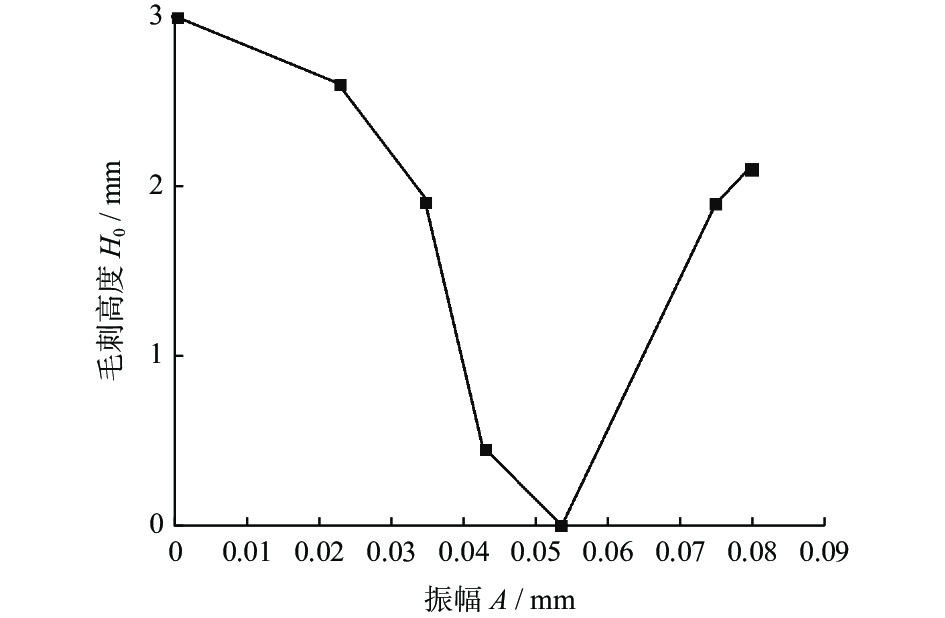

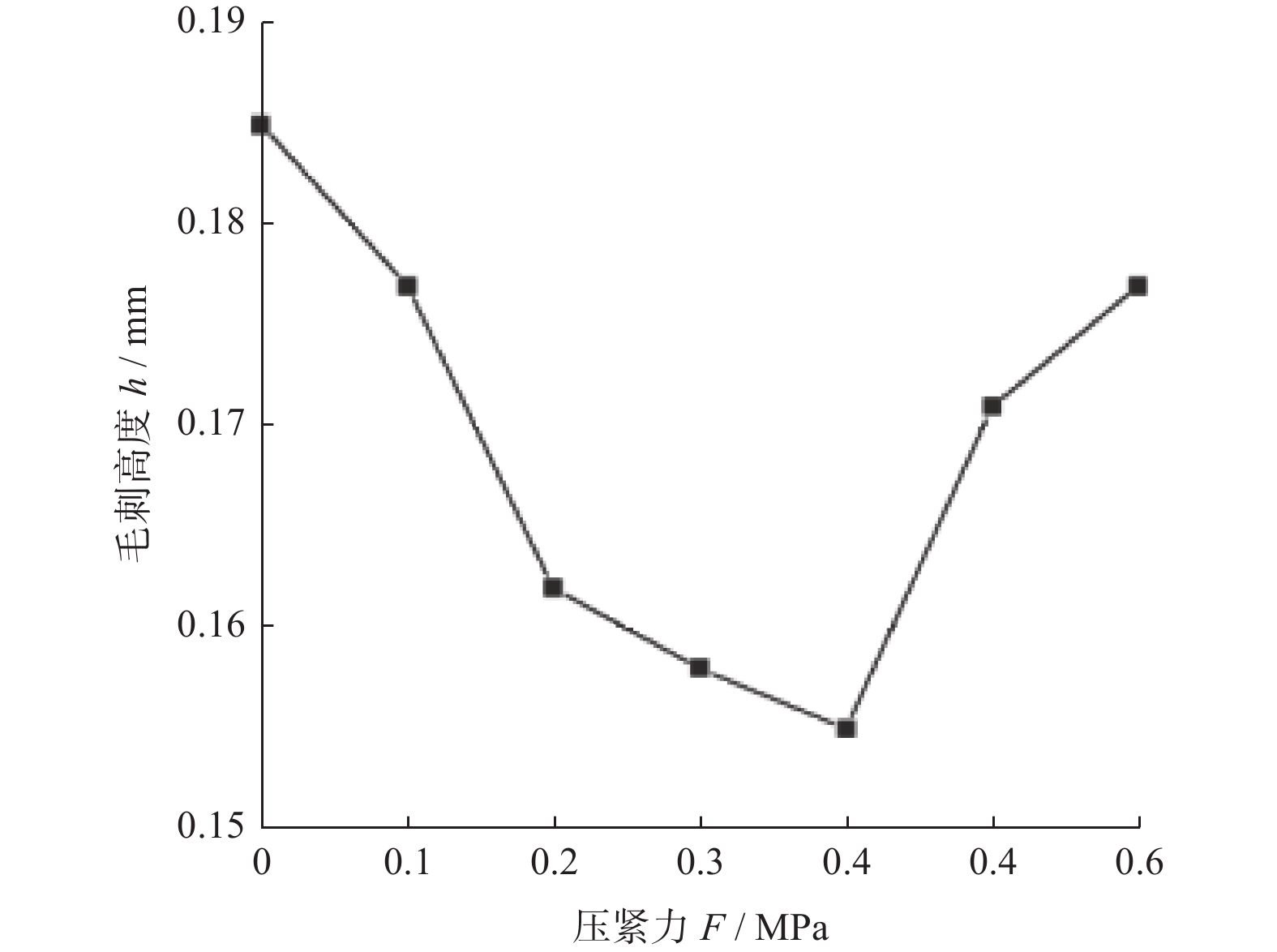

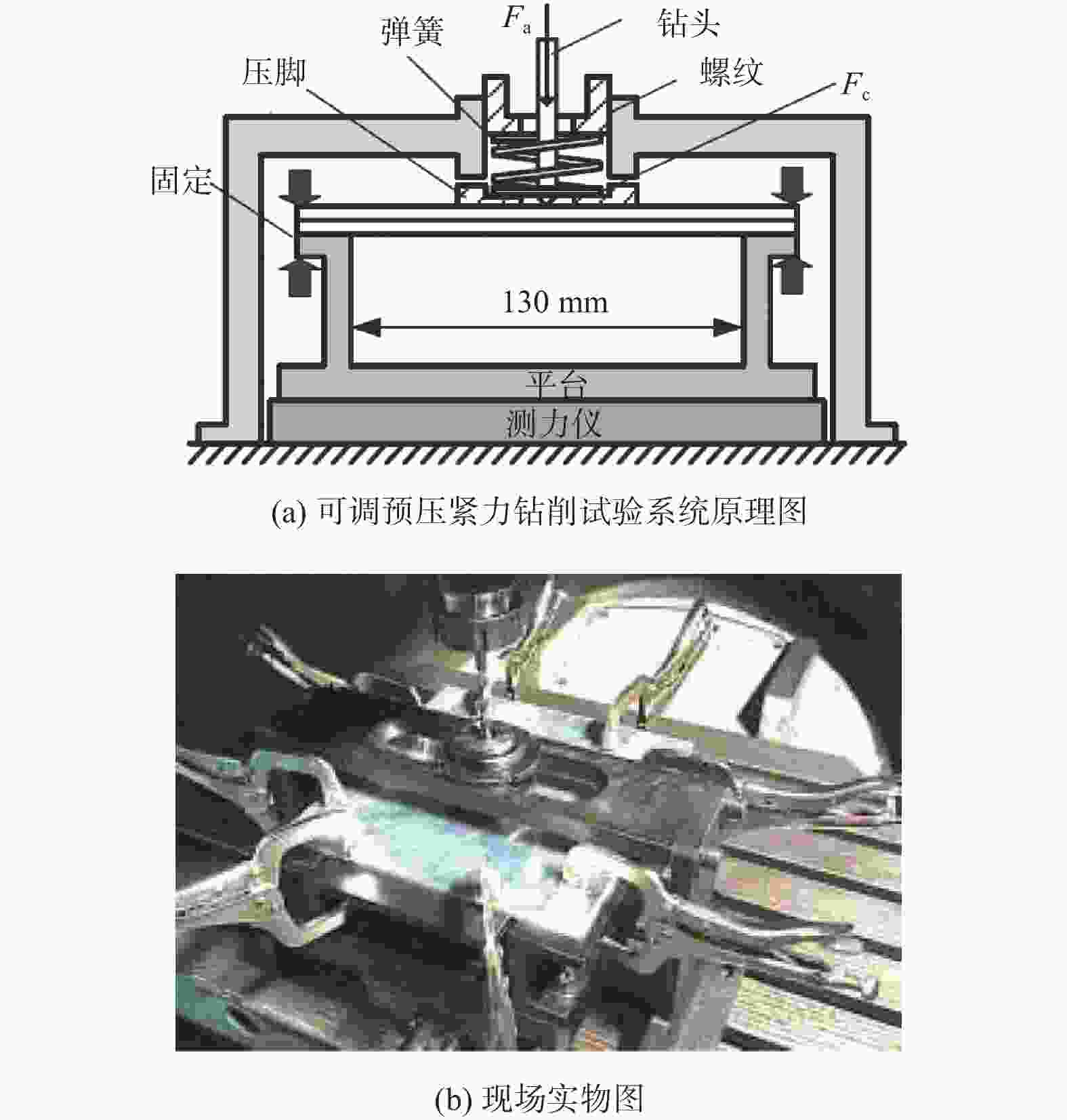

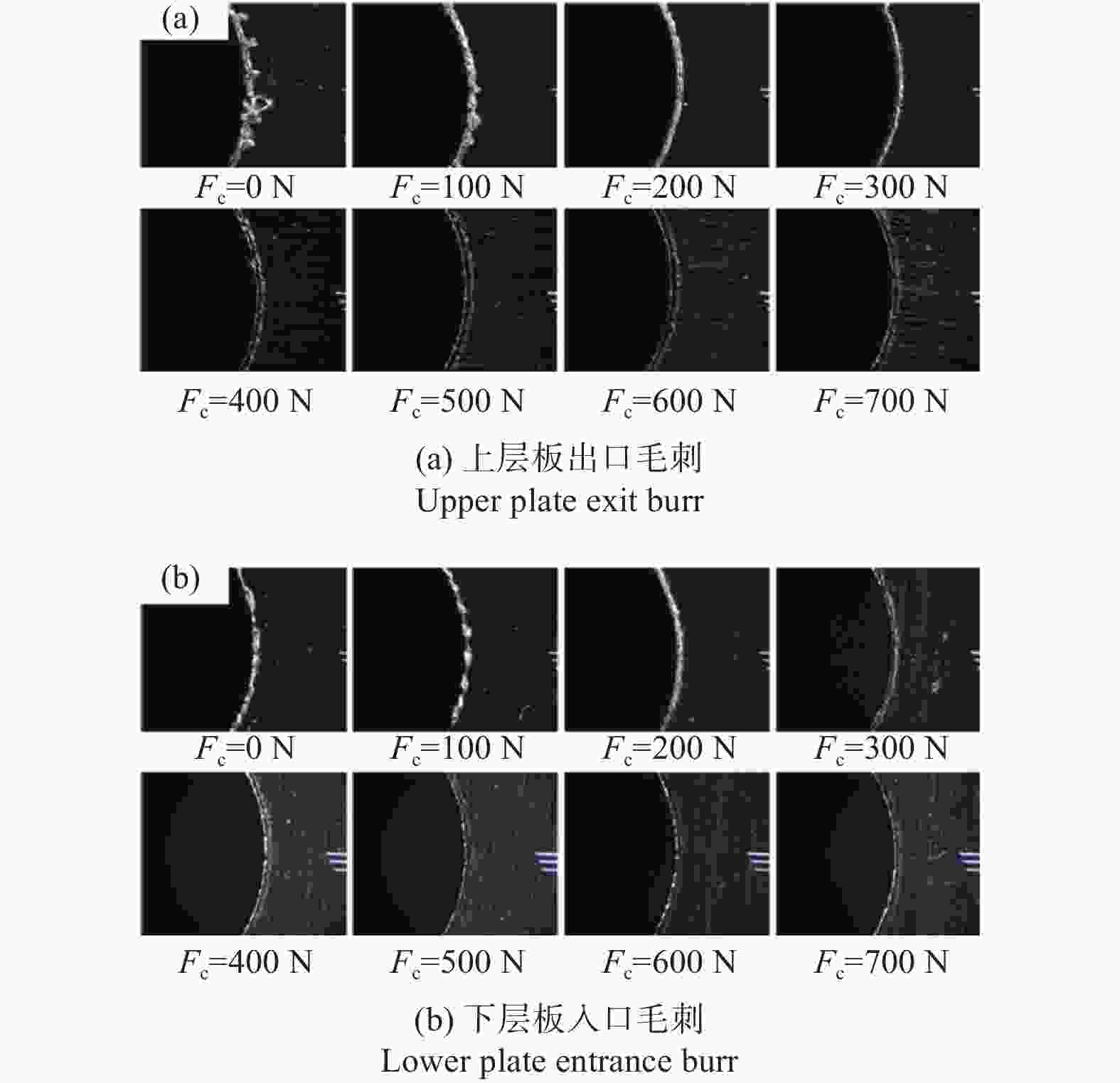

RSS