Tribological performances of alternating multilayer diamond films on Si3N4 ceramic substrates

-

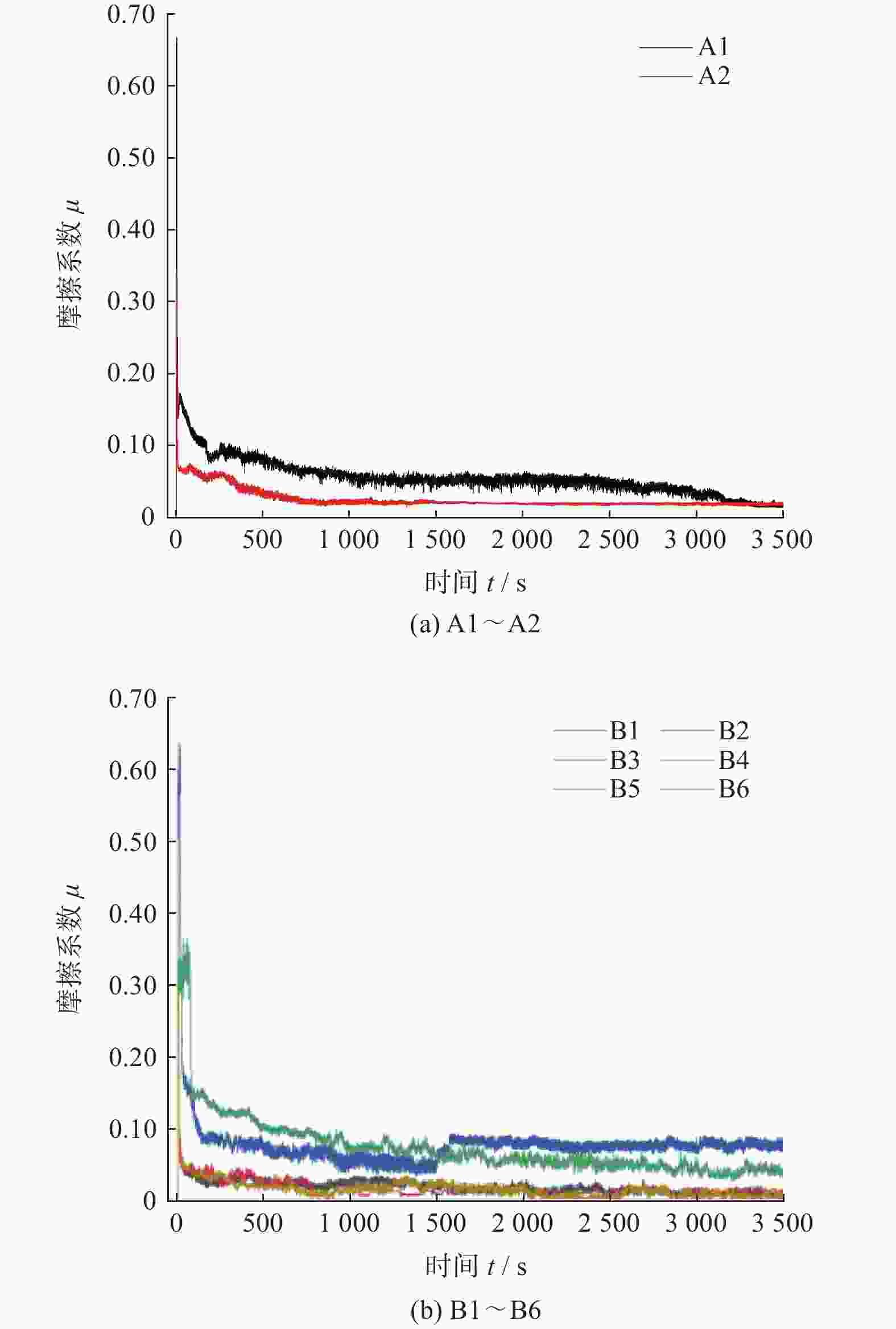

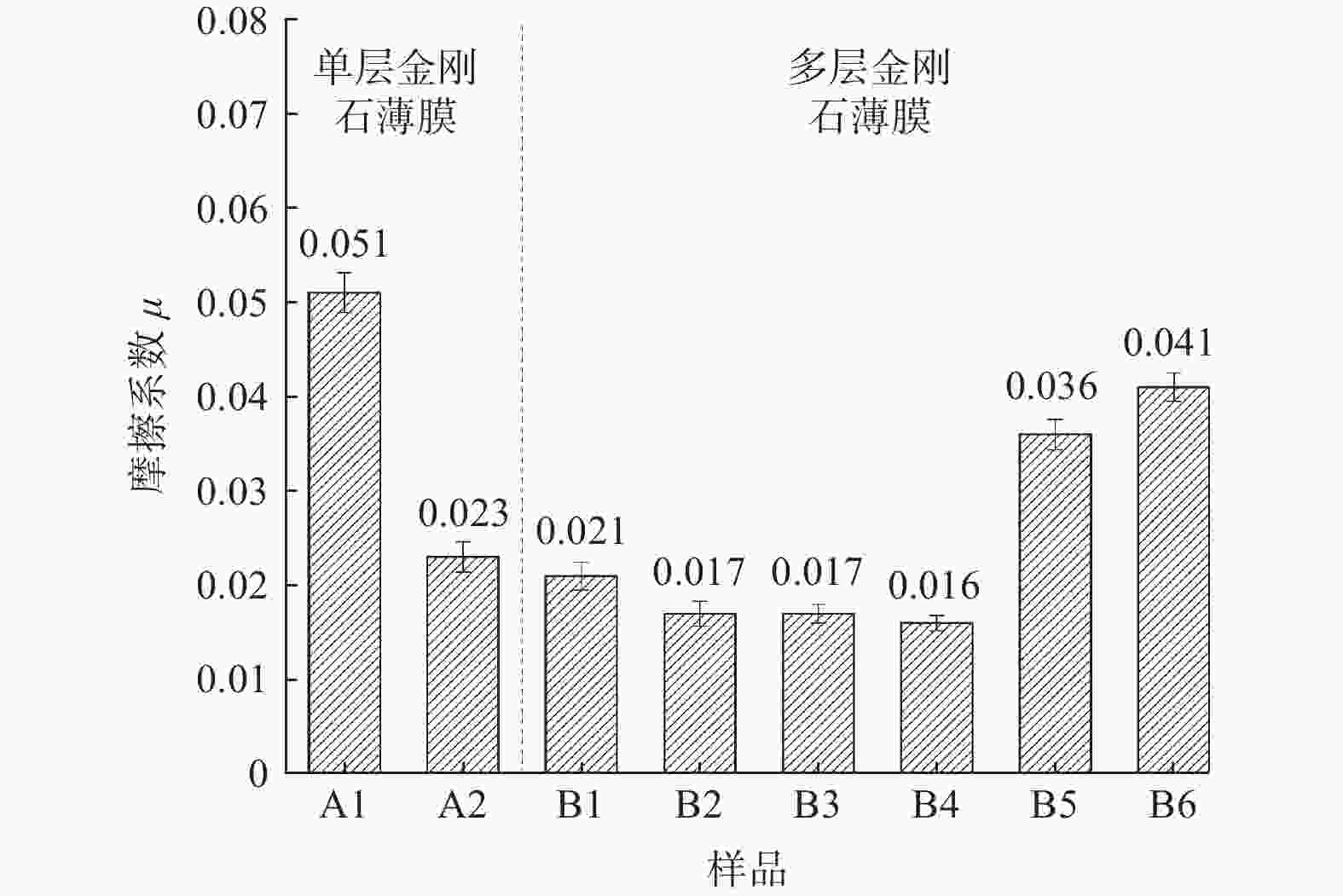

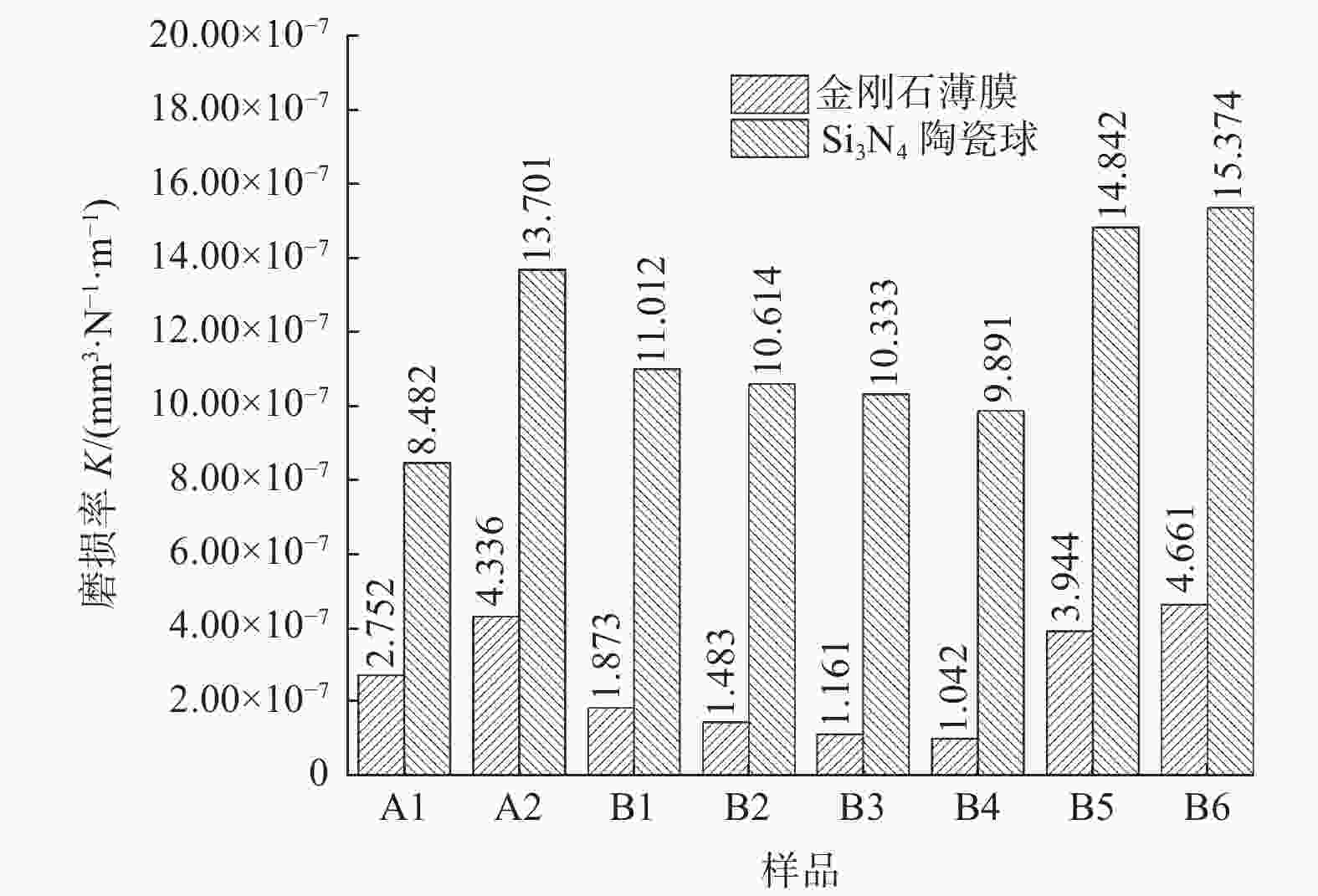

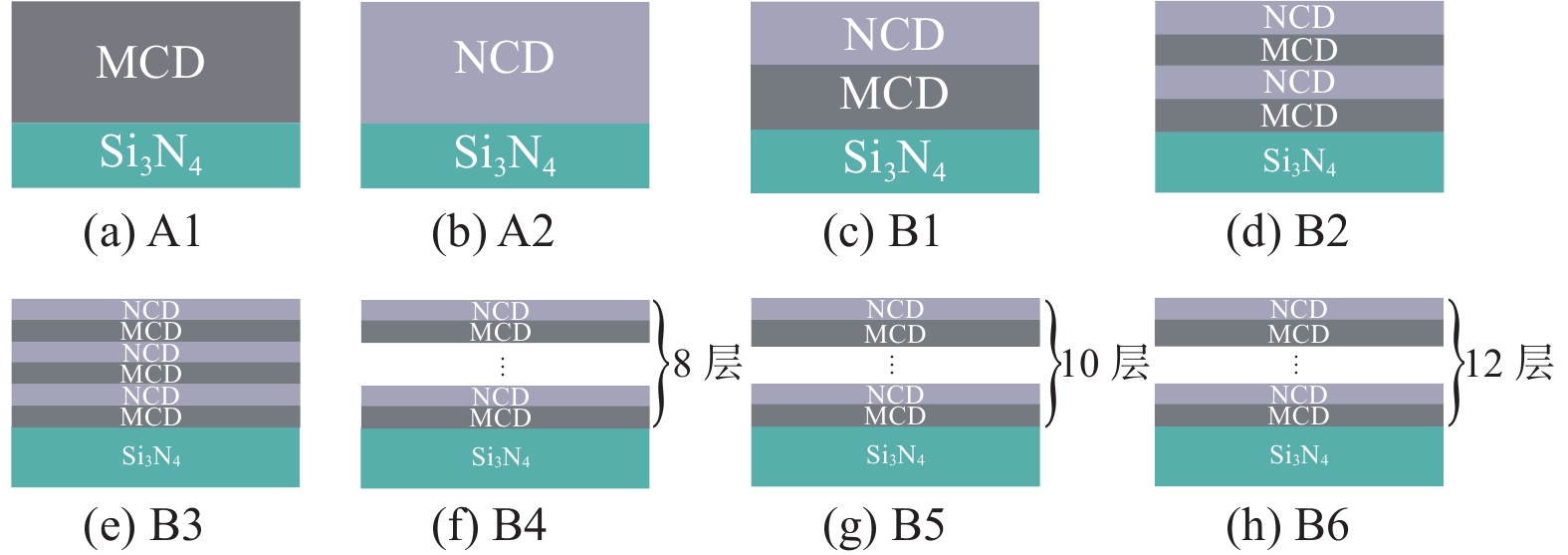

摘要: 为避免Si3N4材料因摩擦磨损造成的失效,利用热丝化学气相沉积技术在Si3N4基底表面沉积单层和交替多层的金刚石薄膜,采用X射线衍射仪、扫描电子显微镜、原子力显微镜和拉曼光谱仪对制备的金刚石薄膜的形核、薄膜质量、表面和截面形貌、表面粗糙度等进行表征;利用“球−盘”往复式摩擦磨损实验机测试金刚石薄膜的摩擦系数并计算其磨损率,分析不同结构薄膜的摩擦磨损性能。结果表明:相比于单层金刚石薄膜,交替多层膜结构表现出更好的摩擦学性能,当交替次数为4、多层结构层数为8时,薄膜的摩擦系数和磨损率最低,分别为0.016和1.042 × 10−7 mm3/(N·m);但随着薄膜的多层结构层数增加,层间厚度减小,摩擦过程中薄膜发生破裂和剥落现象,薄膜与基底的结合强度降低,薄膜质量下降,且其摩擦系数增大为0.042,磨损率增大为4.661 × 10−7 mm3/(N·m),薄膜的耐磨性下降。Abstract:

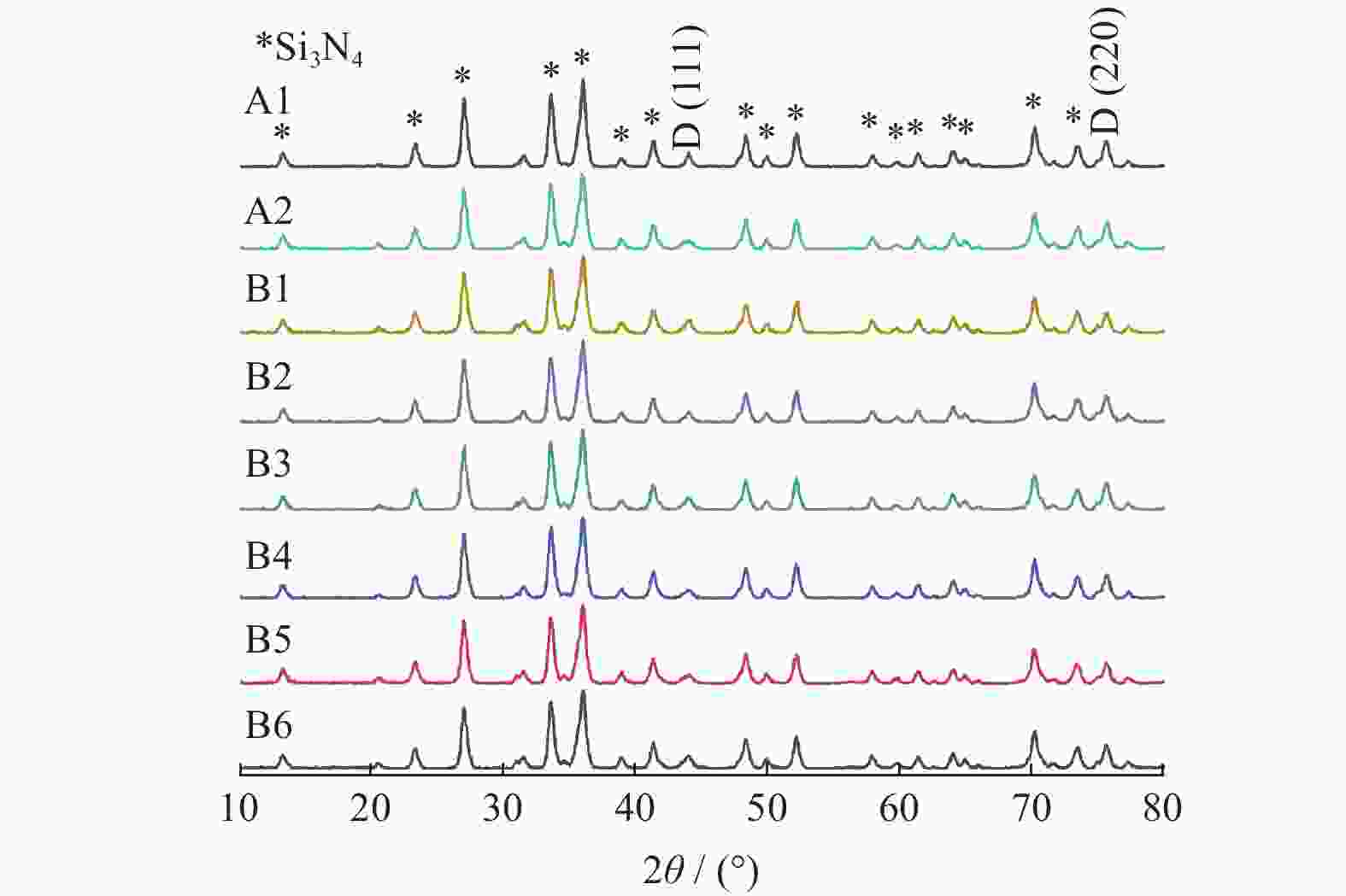

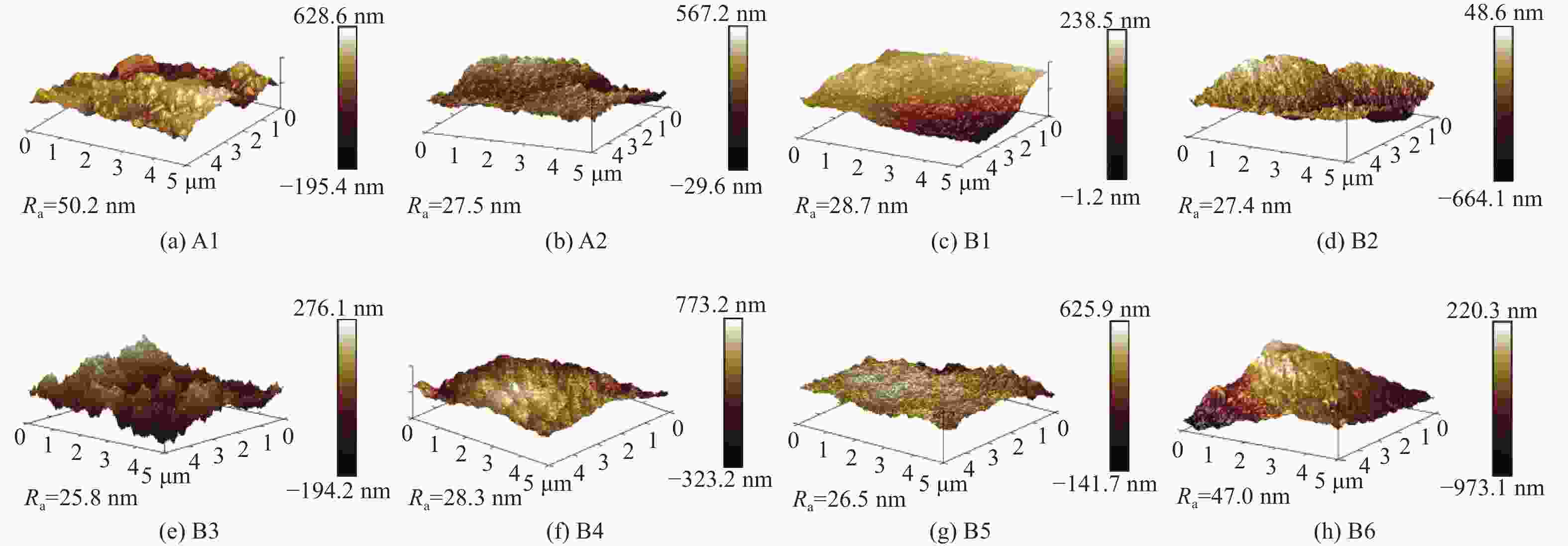

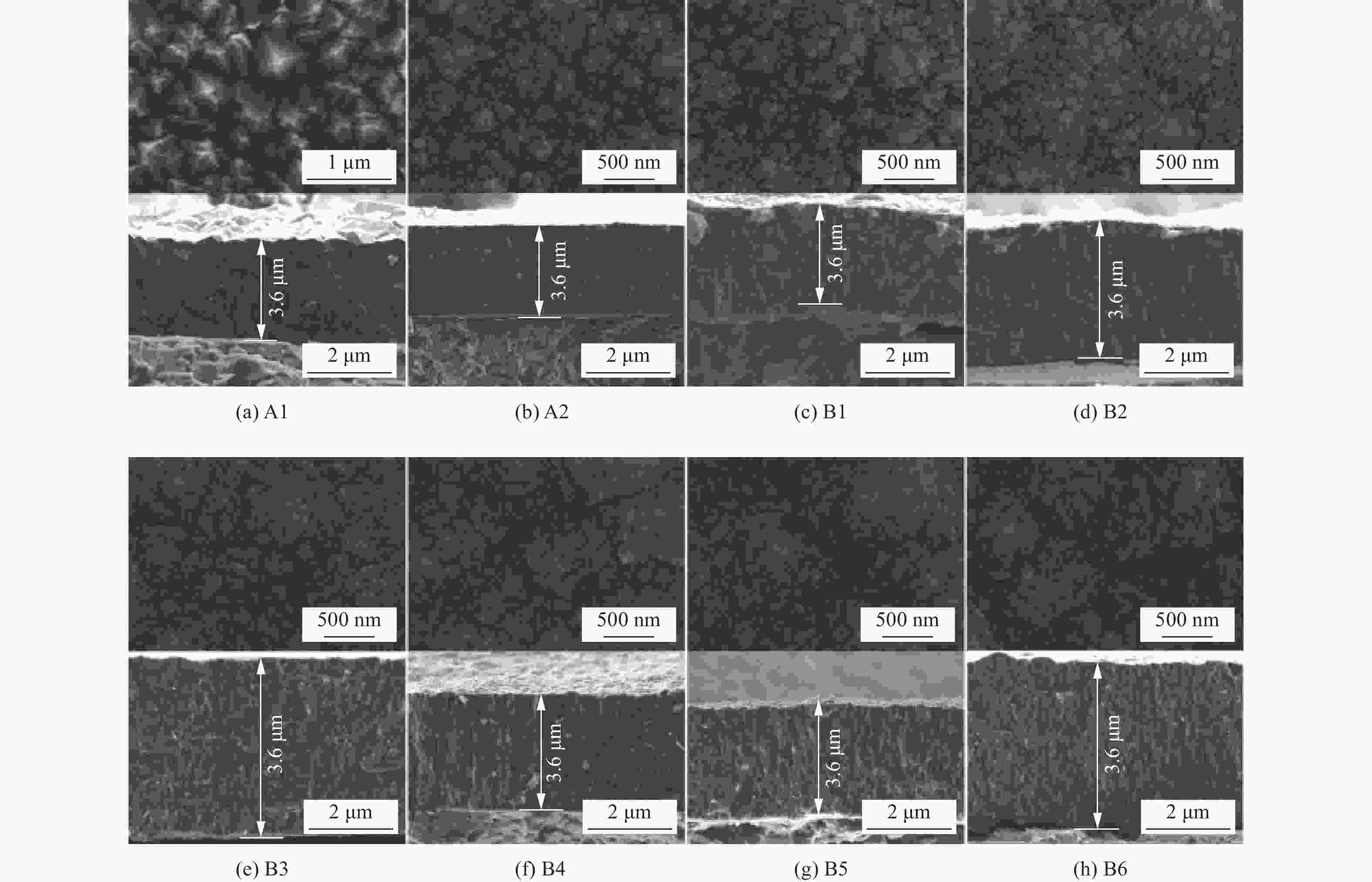

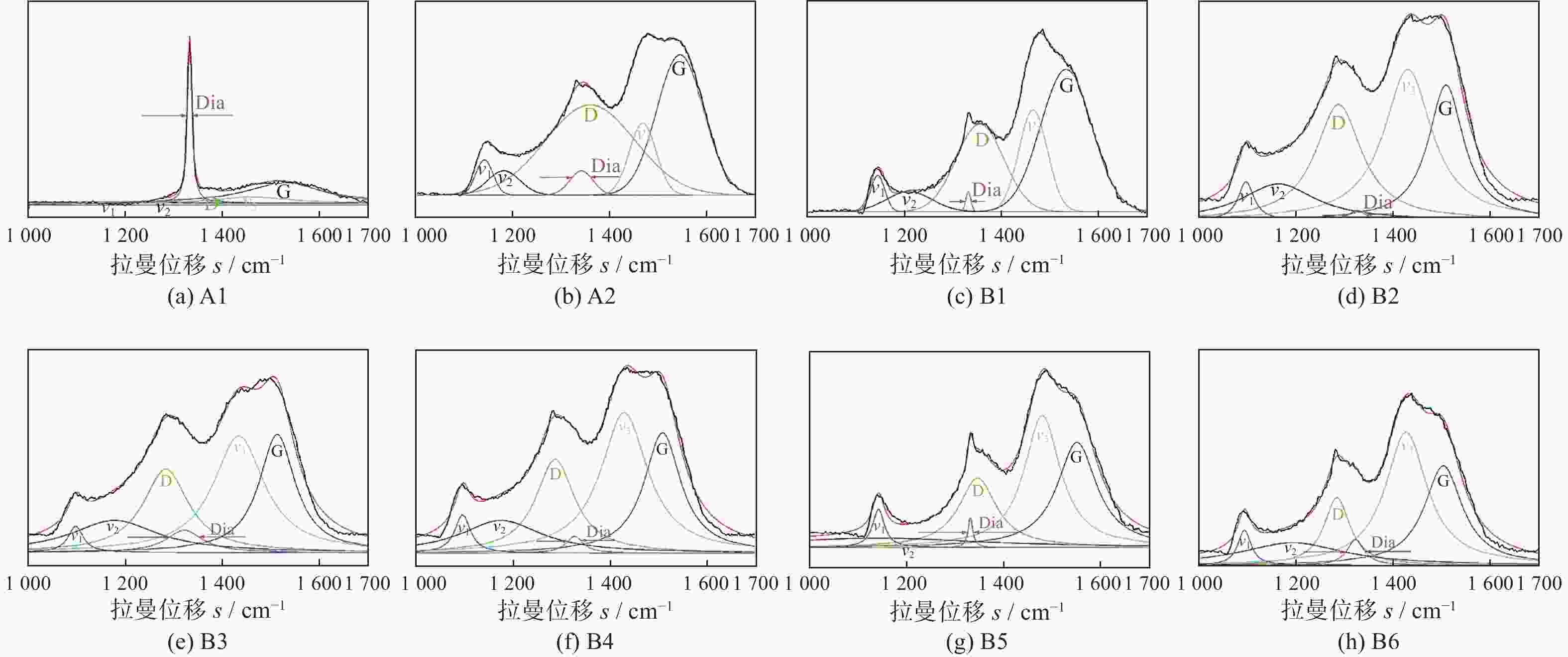

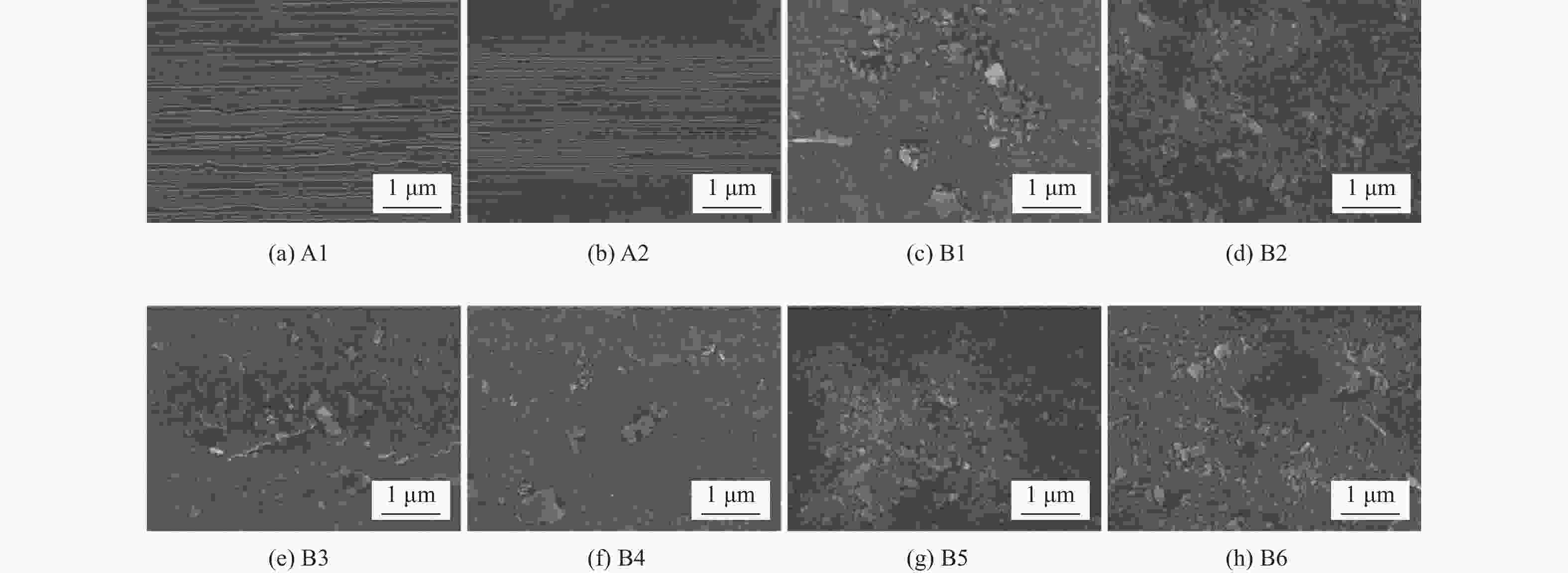

Objectives With the development of science and technology, silicon nitride ceramics have excellent physical and chemical properties such as high strength, high hardness, high temperature resistance, corrosion resistance, and wear resistance. They can maintain good mechanical properties and chemical stability under harsh working conditions, and have been widely used in many fields. However, silicon nitride has great brittleness, low toughness, and poor plastic deformation ability, which makes it prone to cracking and brittle fracture under the action of stress. At the same time, the friction coefficient of silicon nitride ceramics, as wear-resistant devices, is high under dry friction conditions, and the loss caused by friction and wear will reduce its accuracy and affect the working stability of parts. The diamond film has the properties such as high hardness, low thermal expansion coefficient, low friction coefficient, and excellent chemical stability, making it an excellent anti-wear and wear-resistant film material. However, the two common single-layer diamond films have their own shortcomings. Therefore, diamond films with multilayer structures are designed and prepared on silicon nitride substrates to improve the tribological properties of silicon nitride ceramics. Methods The single-layer and alternate multilayer diamond films with different structures were designed and prepared on silicon nitride ceramic substrates by hot filament chemical vapor deposition (HFCVD) technique. The surface and the cross-section morphology, crystal quality, crystal orientation, surface roughness, and phase compositions of single and alternate multilayer diamond films were analyzed by scanning electron microscope, X-ray diffractometer, atomic force microscope, and Raman spectroscopy. Results (1) For alternating multilayer films, the surfaces exhibit clustered nano-diamonds. When the number of alternations is small, the interlayer thickness is thick, the thin film is clearly layered, the layers are tightly connected, the surface roughness is small, and the film quality is good. When the number of alternations is more, the interlayer thickness is thin, the film does not have obvious layering, the surface roughness is large, and the film quality is poor. The Raman spectra of the alternating multilayer structures are similar to those of the nano-diamond film, with a higher content of trans-polyacetylene and non-diamond phases in the film. (2) For alternating multilayer structured films, the friction coefficients are generally lower than those of single-layer diamond films. When the number of alternations is small, the surface roughness of the film is reduced by the nano-diamond layer on the surface, and the tightly connected micro/nano interlocking structures and the micro-diamond layer at the bottom enhance the cohesion and bonding force of the film. The friction process of the film is stable, the wear rate of the film is low, and there is less film detachment during the friction process. When the number of alternations is high, the quality of the film is poor, and during the friction process, the film falls off and breaks, and the debris enters the friction surface of the film. The friction coefficient fluctuates greatly, and the wear rate of the film is high. When the number of alternations is 4 and the number of film layers is 8, the film has the lowest average friction coefficient and wear rate, which are 0.016 and 1.04×10−7 mm3/(N·m), respectively. Conclusions The surface morphology of diamond films has a significant impact on their tribological properties. The sharp (111) edge of the micro diamond film surface generates a strong plowing effect when interacting with the grinding ball, making it easier for diamond abrasive particles and debris to enter the grinding surface, resulting in an increase in friction coefficient and wear rate. The nano-grain size on the surface of the nano-diamond film is relatively small and has no sharp edges, which reduces the friction coefficient of the film. However, its bonding ability with the substrate is poor, and the partial detachment of the film under the shear stress increases the wear rate. The friction coefficient and the wear rate of alternating multilayer structures are generally reduced compared to single-layer diamond films. The reason is that the nano-diamond layer on the surface of the alternating structure reduces the surface roughness of the film, enhances its toughness, and the columnar growth of micro-diamond grains at the bottom of the film enhances the bonding performance between the film and the substrate, making the film less prone to peeling during friction. The crystalline quality of alternating multilayer thin films with thin interlayer thickness is poor, and the film rupture and peeling are prone to occur during the friction process, thereby increasing the friction coefficient and the wear rate. A reasonable alternating multilayer structure design can significantly reduce the maximum friction coefficient, the average friction coefficient, and the wear rate of the film during the friction process, reduce the plowing effect between the film and the wear pair, and reduce the wear scar area, thus improving the wear resistance of the film. -

表 1 沉积参数

Table 1. Deposition parameters

薄膜样品及编号 薄膜类型 CH4浓度

c1 / %交替次数

n / 次基底温度

T / ℃气体流量 c2 / sccm CH4 H2 单层 A1 MCD 1.0 900 ± 10 4 400 A2 NCD 5.0 880 ± 10 20 400 多层 B1 NCD + MCD共2层 1.0,5.0 1 900 ± 10,880 ± 10 4,20 400 B2 NCD + MCD共4层 1.0,5.0 2 900 ± 10,880 ± 10 4,20 400 B3 NCD + MCD共6层 1.0,5.0 3 900 ± 10,880 ± 10 4,20 400 B4 NCD + MCD共8层 1.0,5.0 4 900 ± 10,880 ± 10 4,20 400 B5 NCD + MCD共10层 1.0,5.0 5 900 ± 10,880 ± 10 4,20 400 B6 NCD + MCD共12层 1.0,5.0 6 900 ± 10,880 ± 10 4,20 400 表 2 不同结构金刚石薄膜的残余应力

Table 2. Residual stress of diamond films with different structures

薄膜样品

及编号金刚石峰的

位置 v / cm−1位移偏移

量δ / cm−1残余应

力σ / GPa单层 A1 1331.15 −0.85 0.48 A2 1334.26 2.26 −1.28 多层 B1 1334.62 2.62 −1.49 B2 1333.39 1.39 −0.79 B3 1331.31 −0.69 0.39 B4 1331.24 −0.76 0.43 B5 1333.59 1.59 −0.90 B6 1330.73 −1.27 0.72 -

[1] 李成明, 任飞桐, 邵思武, 等. 化学气相沉积(CVD)金刚石研究现状和发展趋势 [J]. 人工晶体学报,2022,51(5):759-780. doi: 10.16553/j.cnki.issn1000-985x.2022.05.008LI Chengming, REN Feitong, SHAO Siwu, et al. Progress of chemical vapor deposition (CVD) diamond [J]. Journal of Synthetic Crystals,2022,51(5):759-780. doi: 10.16553/j.cnki.issn1000-985x.2022.05.008 [2] 王贺, 沈建辉, 刘鲁生, 等. SiC基底HFCVD金刚石薄膜摩擦磨损性能 [J]. 金刚石与磨料磨具工程,2022,42(3):283-289. doi: 10.13394/j.cnki.jgszz.2021.0206WANG He, SHEN Jianhui, LIU Lusheng, et al. Wear properties of HFCVD diamond films on SiC substrate [J]. Diamond & Abrasives Engineering,2022,42(3):283-289. doi: 10.13394/j.cnki.jgszz.2021.0206 [3] 吕反修. 化学气相沉积金刚石膜的研究与应用进展 [J]. 材料热处理学报,2010,31(1):15-28. doi: 10.13289/j.issn.1009-6264.2010.01.014LV Fanxiu. Progress in research and application development of CVD diamond film [J]. Transactions of Materials and Heat Treatment,2010,31(1):15-28. doi: 10.13289/j.issn.1009-6264.2010.01.014 [4] 魏秋平, 王玲, 余志明, 等. 进气方式对热丝CVD制备金刚石薄膜的影响 [J]. 中国表面工程,2009,22(6):36-41. doi: 10.3969/j.issn.1007-9289.2009.06.006WEI Qiuping, WANG Ling, YU Zhiming, et al. Effect of reacting gas admission way on HFCVD diamond films [J]. China Surface Engineering,2009,22(6):36-41. doi: 10.3969/j.issn.1007-9289.2009.06.006 [5] 张旺玺. 化学气相沉积法合成金刚石的研究进展 [J]. 陶瓷学报,2021,42(4):537-546. doi: 10.13957/j.cnki.tcxb.2021.04.002ZHANG Wangxi. Research progress in synthesis of diamond prepared with chemical vapour deposition (CVD) [J]. Journal of Ceramics,2021,42(4):537-546. doi: 10.13957/j.cnki.tcxb.2021.04.002 [6] 吴玉程. 金刚石薄膜制备方法与应用的研究现状 [J]. 材料热处理学报,2019,40(5):1-16. doi: 10.13289/j.issn.1009-6264.2018-0411WU Yucheng. Research trends of preparation and application of diamond film [J]. Transactions of Materials and Heat Treatment,2019,40(5):1-16. doi: 10.13289/j.issn.1009-6264.2018-0411 [7] ALMEIDA F A, AMARAL M, OLIVEIRA F J, et al. Nano to micrometric HFCVD diamond adhesion strength to Si3N4 [J]. Vacuum,2007,81:1443-1447. doi: 10.1016/j.vacuum.2007.04.008 [8] 位少博, 王兵, 熊鹰. 超纳米金刚石薄膜的快速生长及结构分析 [J]. 金刚石与磨料磨具工程,2023,43(2):176-181. doi: 10.13394/j.cnki.jgszz.2022.0122WEI Shaobo, WANG Bing, XIONG Ying. Research on the rapid growth and structure of ultra-nanocrystalline diamond thin films [J]. Diamond & Abrasives Engineering,2023,43(2):176-181. doi: 10.13394/j.cnki.jgszz.2022.0122 [9] 孔帅斐, 刘一波, 陈春晖. 金刚石薄膜的发展及展望 [J]. 超硬材料工程,2020,32(3):32-36. doi: 10.3969/j.issn.1673-1433.2020.03.008KONG Shuaifei, LIU Yibo, CHEN Chunhui. Advancement and prospects in diamond films [J]. Superhard Material Engineering,2020,32(3):32-36. doi: 10.3969/j.issn.1673-1433.2020.03.008 [10] CHEN N C, PU L W, SUN F H, et al. Tribological behavior of HFCVD multilayer diamond film on silicon carbide [J]. Surface & Coatings Technology,2015,272:66-71. doi: 10.1016/j.surfcoat.2015.04.023 [11] YAN G Y, WU Y H, LU F, et al. Mechanical properties and wear behavior of multi-layer diamond films deposited by hot-filament chemical vapor deposition [J]. Applied Surface Science,2019,494:401-411. doi: 10.1016/j.apsusc.2019.07.110 [12] SALGUEIREDO E, ABREU C S, AMARAL M, et al. Self-mated tribological systems based on multilayer micro/ nanocrystalline CVD diamond coatings [J]. Wear,2013,303:225-234. doi: 10.1016/j.wear.2013.03.049 [13] AMARAL M, SILVA D J, FERNANDES A, et al. Surface activation pre-treatments for NCD coatings grown by HFCVD [J]. Vacuum,2009,83(10):1228-1232. doi: 10.1016/j.vacuum.2009.03.014 [14] ZHOU D, QIN L C, KRAUSS A R, et al. Synthesis of nanocrystalline diamond thin coatings from an Ar-Ch4 microwave plasma [J]. Journal of Applied Physics,1998,83(1):540-543. doi: 10.1063/1.366668 [15] ALI M, URGEN M, KAWASHIMA A. High purity diamond films synthesised by chemical vapour deposition [J]. Surface Engineering,2012,28(10):791-795. doi: 10.1179/1743294412Y.0000000060 [16] CHEN S L, SHEN B, ZHANG J G. Evaluation on residual stresses of silicon-doped CVD diamond coatings using X-ray diffraction and Raman spectroscopy [J]. Transactions of Nonferrous Metals Society of China,2012,22(12):3021-3026. doi: 10.1016/S1003-6326(11)61565-3 [17] FERREIRA N G, ABRAMOF E, LEITE N F, et al. Analysis of residual stress in diamond coatings by X-ray diffraction and micro-Raman spectroscopy [J]. Journal of Applied Physics,2002,91(4):2466-2472. doi: 10.1063/1.1431431 [18] TIAN Q, YANG B, ZHUANG H, et al. Hybrid diamond/graphite films: Morphological evolution, microstructure and tribological properties [J]. Diamond & Related Materials,2016,70:179-185. doi: 10.1016/j.diamond.2016.10.020 [19] BARROS M, VANDENBULCKE L, BLECHET J J. Influence of diamond characteristics on the tribological behaviour of metals against diamond-coated Ti–6Al–4V alloy [J]. Wear,2001,249(1/2):67-77. doi: 10.1016/S0043-1648(01)00529-4 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS