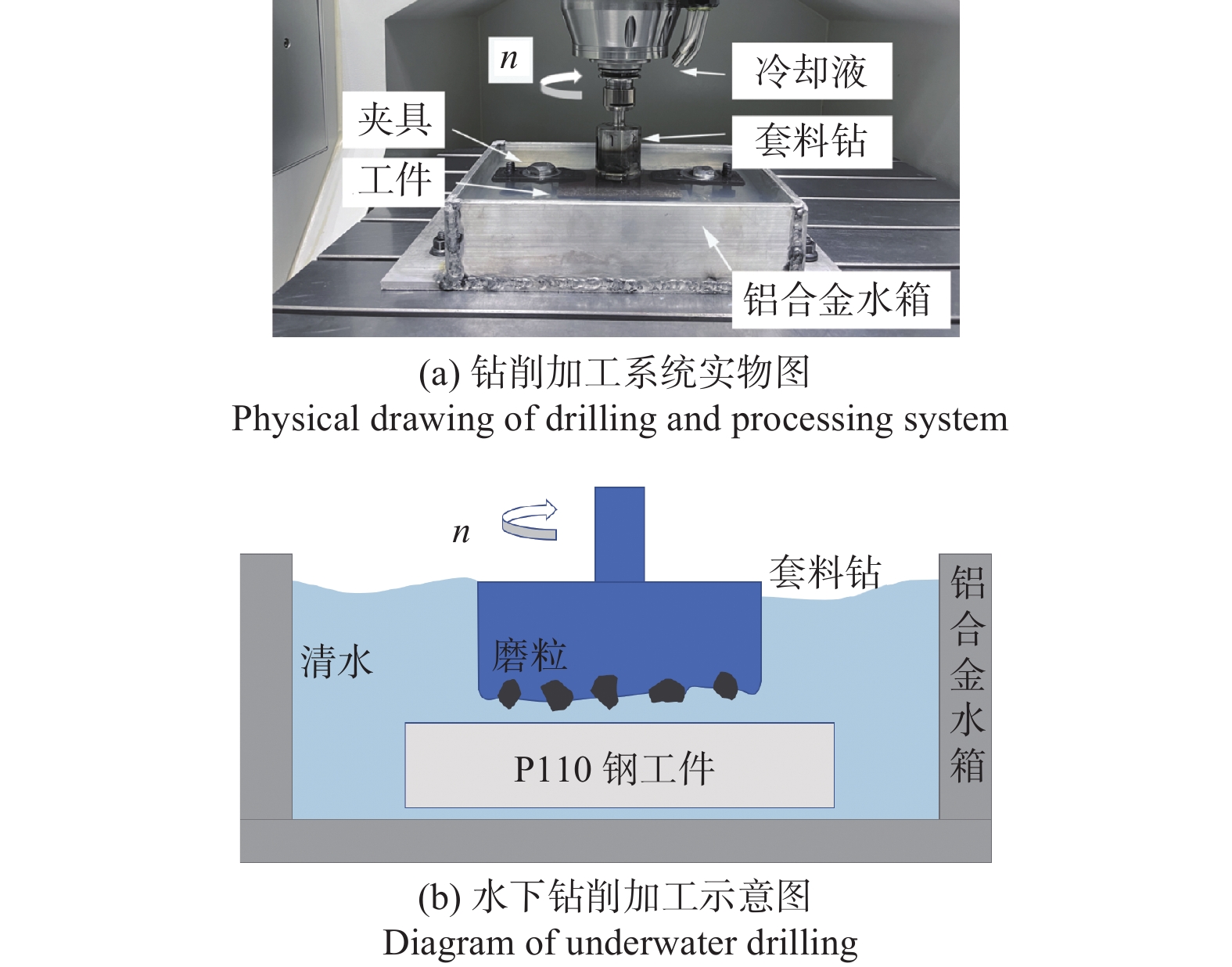

Wear experiment on underwater drilling of P110 steel using superhard abrasive core drill

-

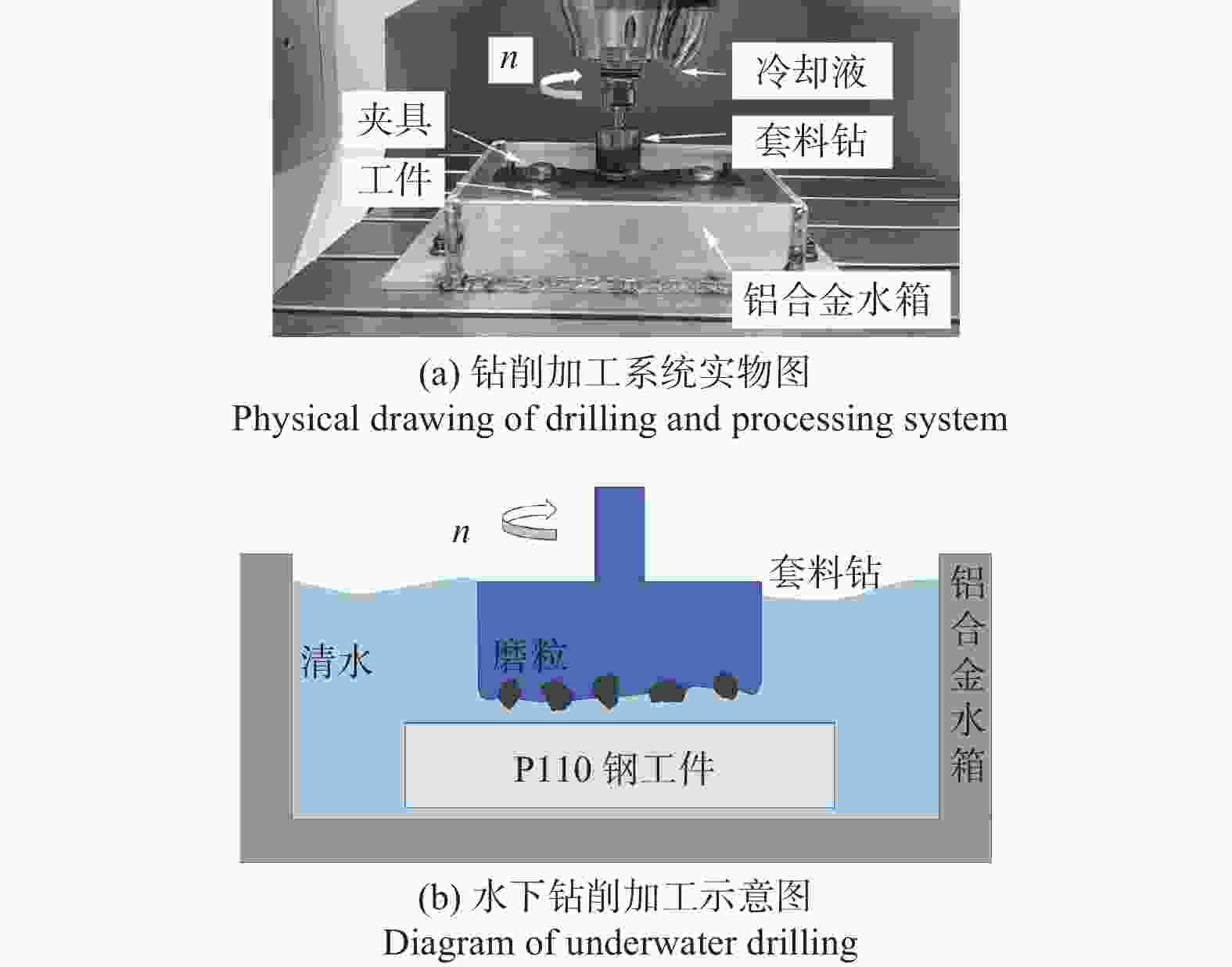

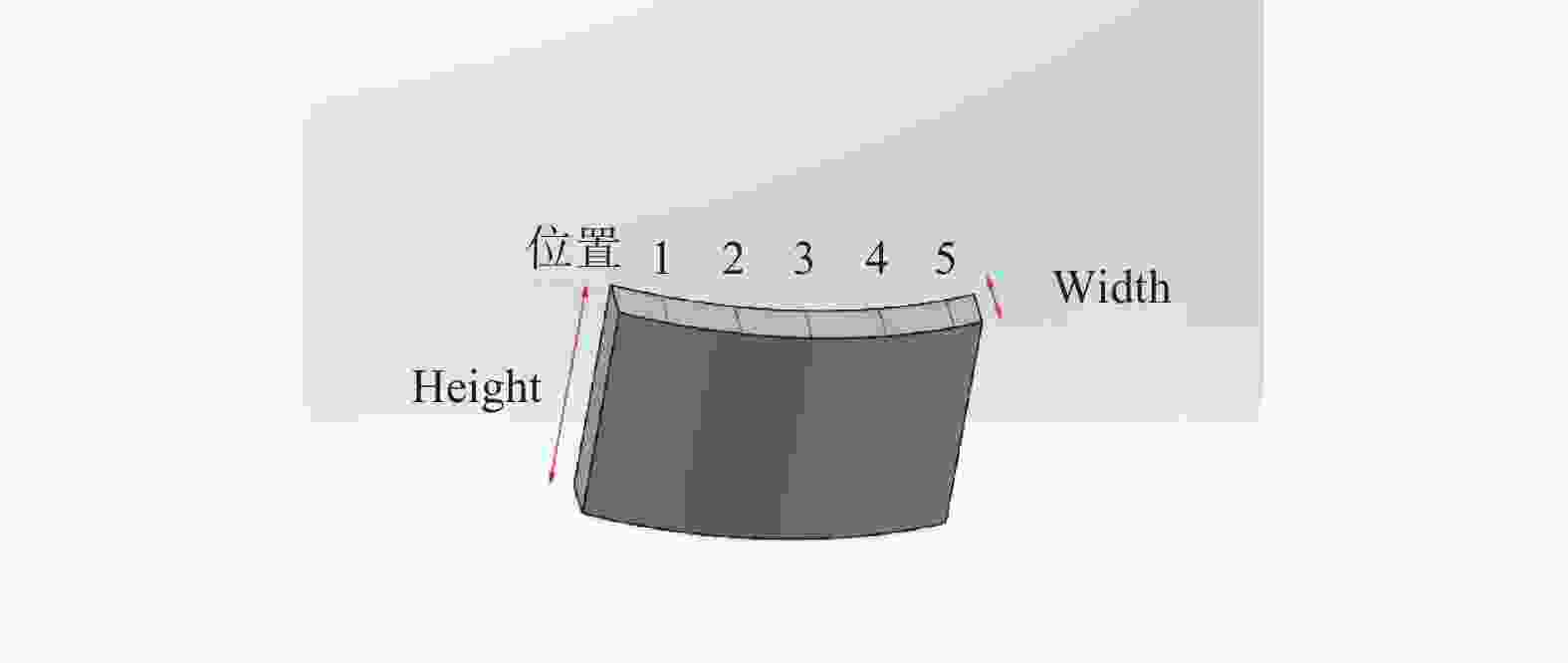

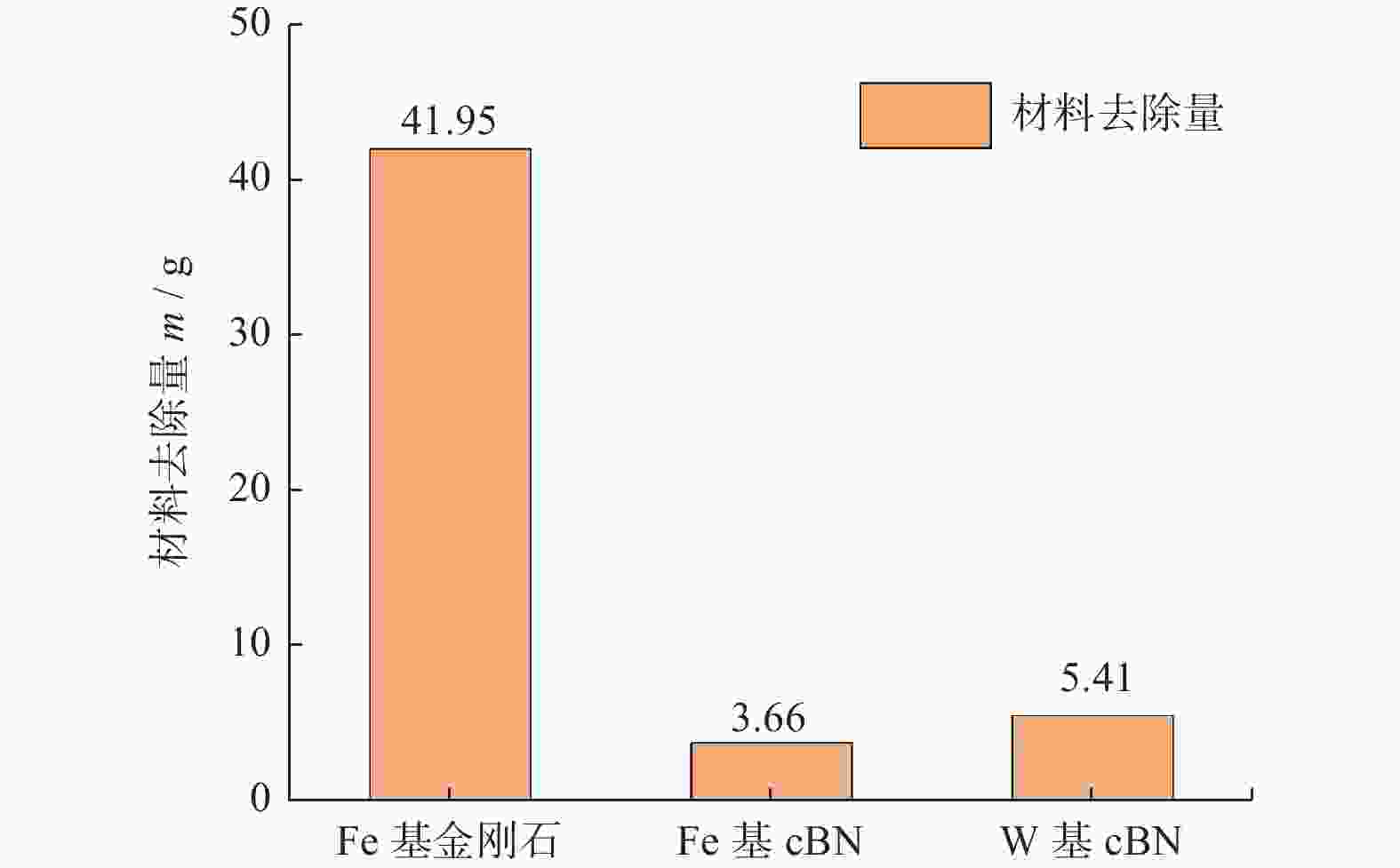

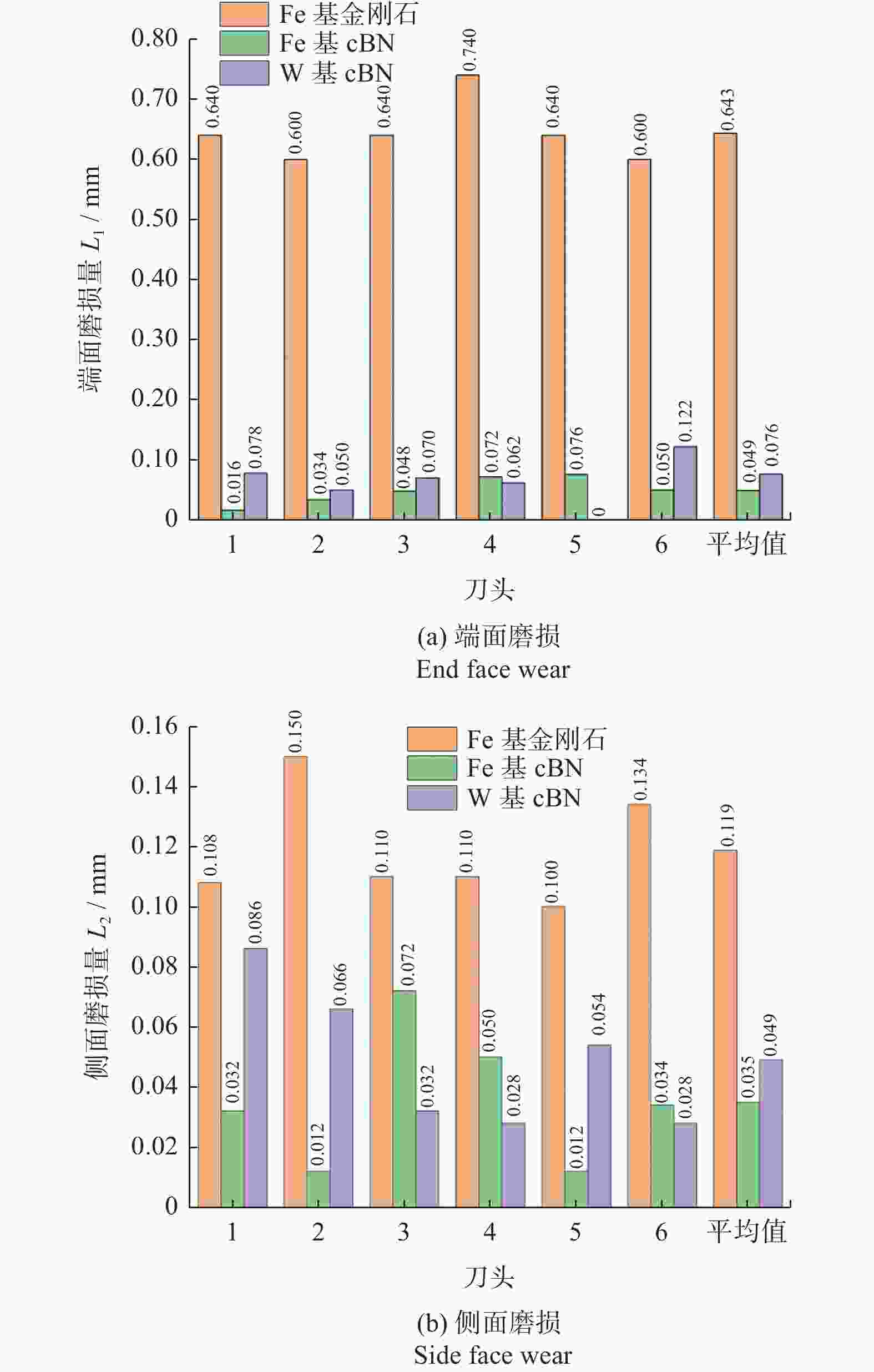

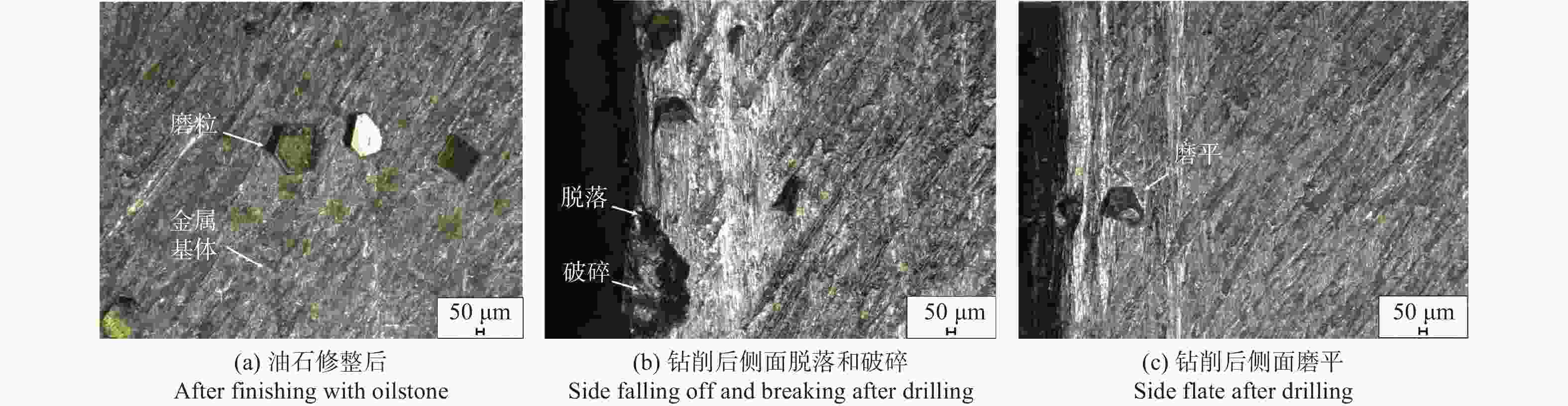

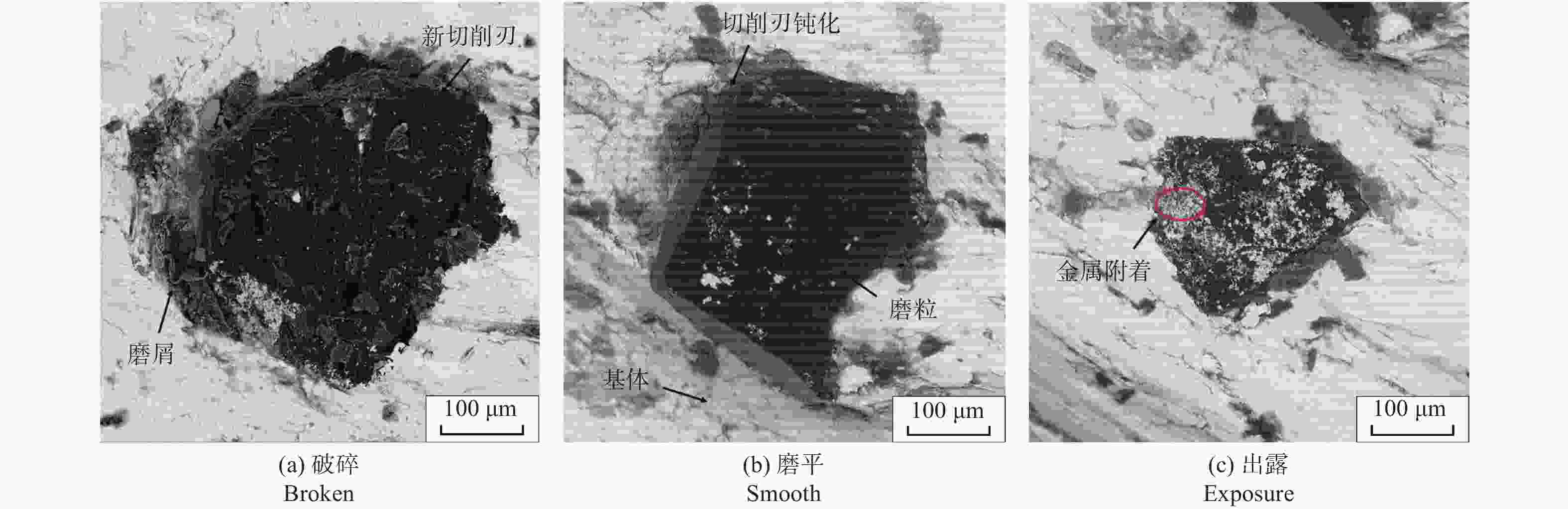

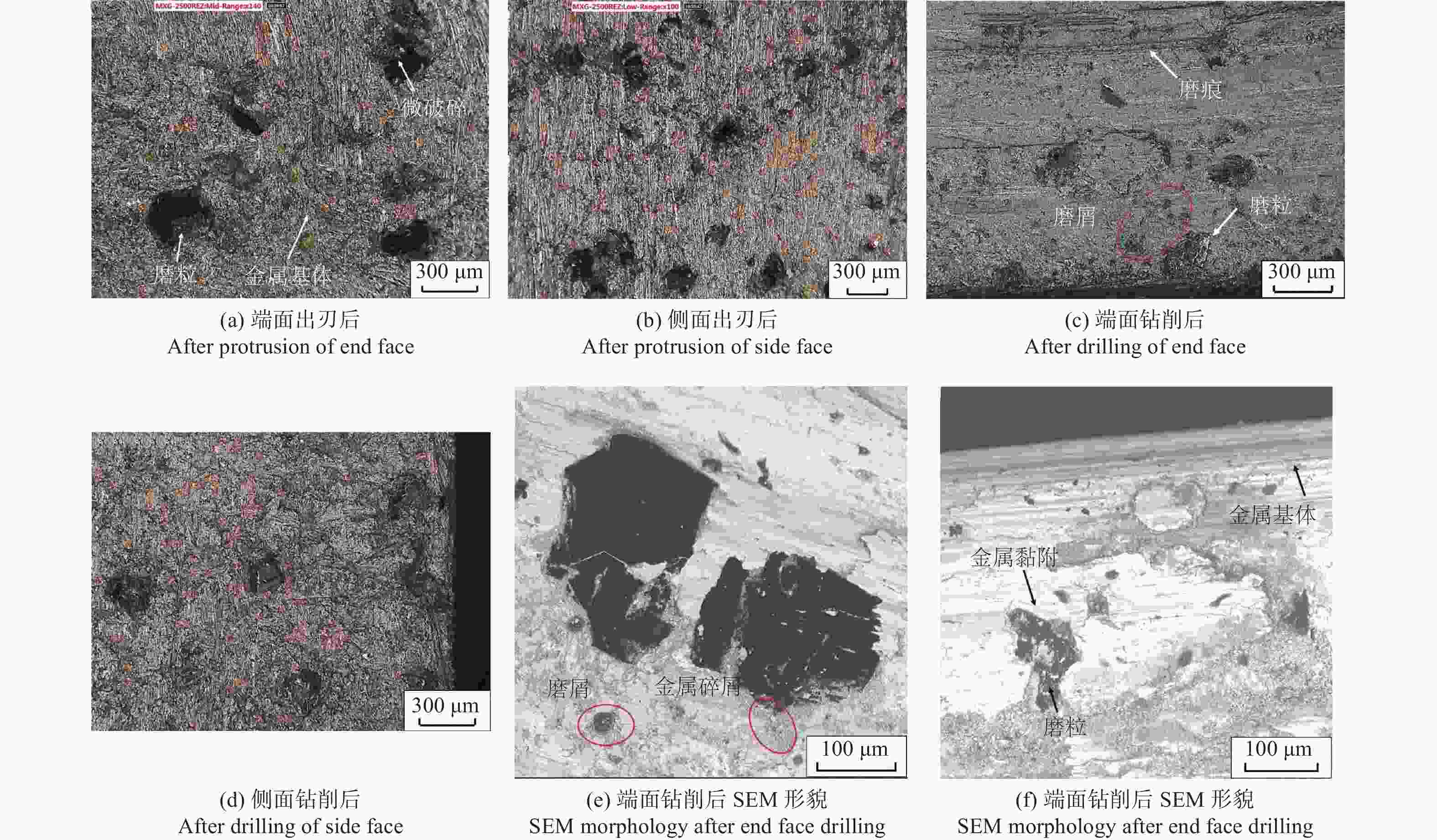

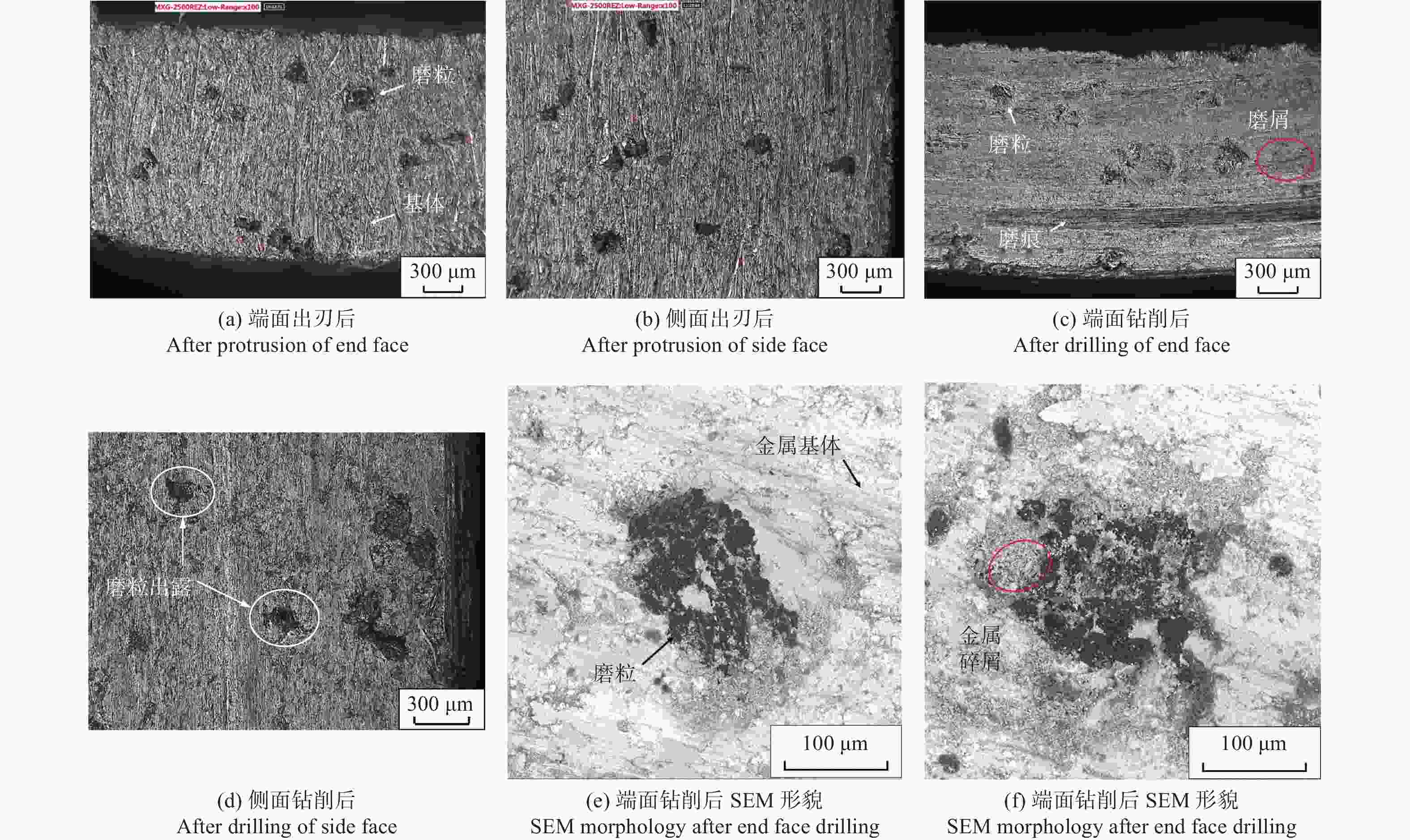

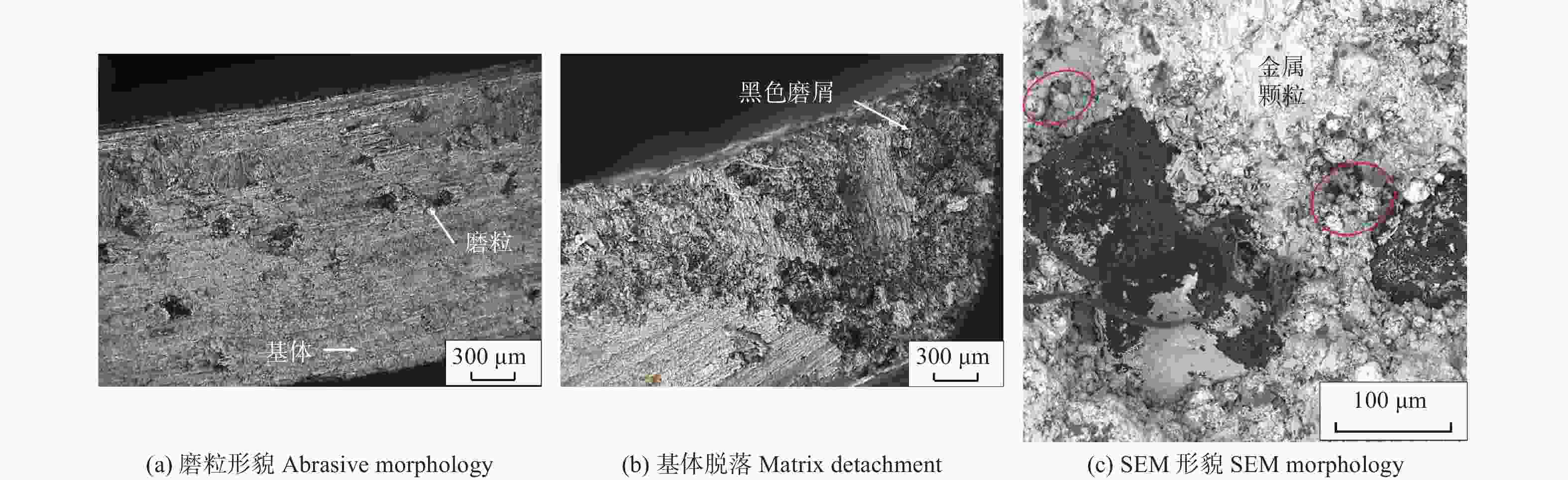

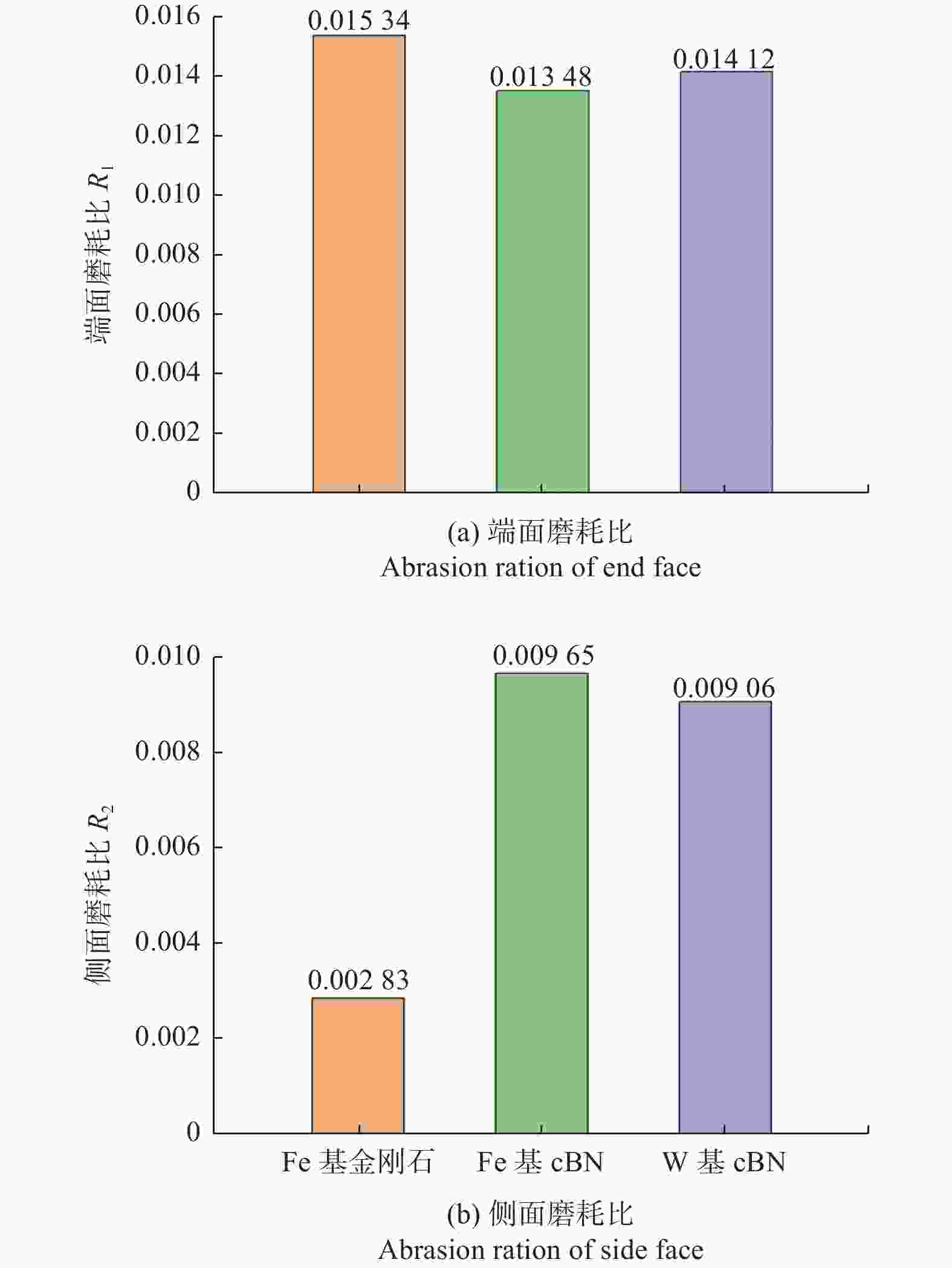

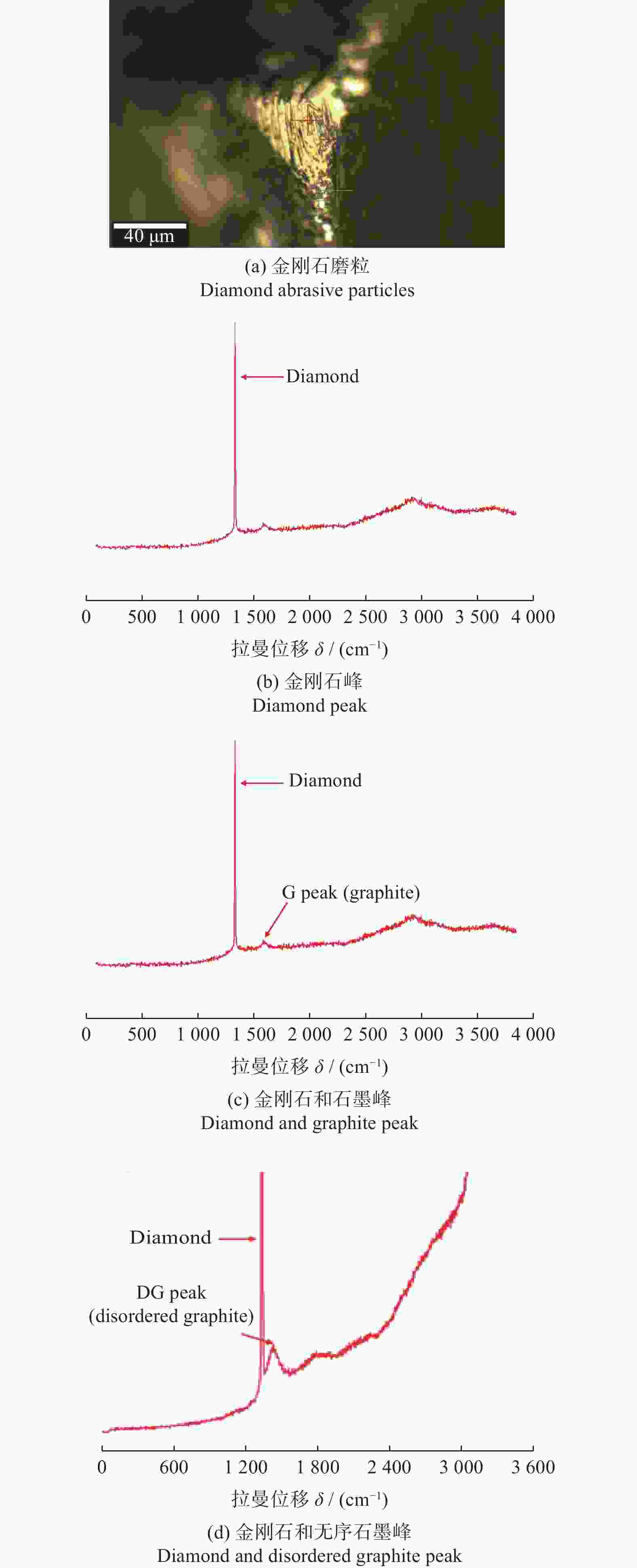

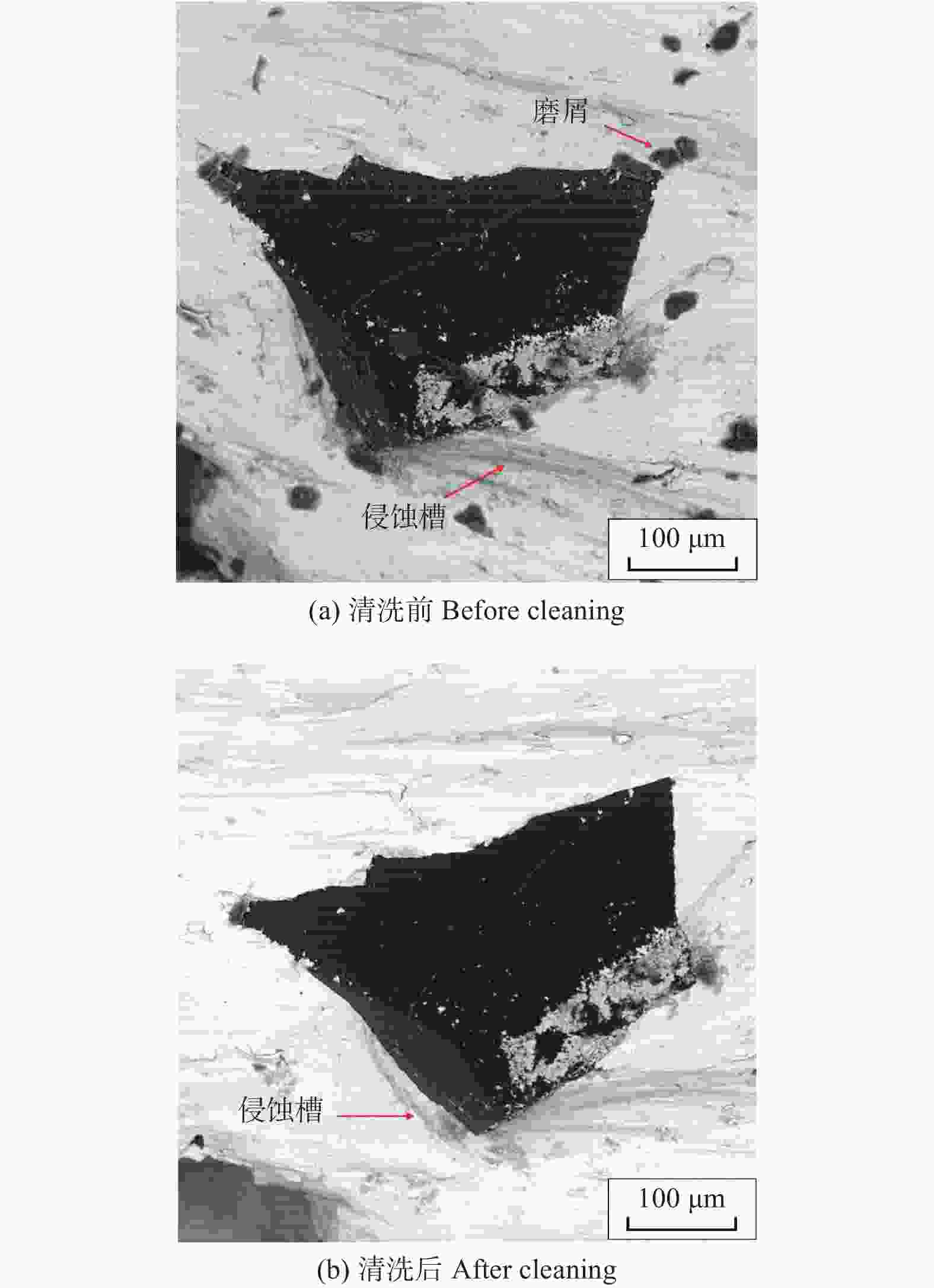

摘要: P110钢具有良好的综合力学性能,广泛用作油气井的套管,使用硬质合金工具对其进行水下钻削时工具磨损严重。实验研究3种不同超硬磨粒及结合剂的套料钻水下钻削P110钢的磨耗比,跟踪观察套料钻表面的磨粒形貌变化,并分析金刚石磨粒表面的石墨化情况。结果表明:在相同加工条件下,3种不同套料钻的端面磨耗大致相同,但使用金刚石磨粒的套料钻侧面磨损明显小于使用立方氮化硼(cBN)磨粒套料钻的;在水下加工条件下,端面金刚石磨粒会产生石墨化,但其仍保持一定的切削能力;结合剂硬度影响磨粒出露,从而导致套料钻在不同工作状态下的性能产生差异。Abstract: P110 steel, renowed for its good comprehensive mechanical properties, is widely used as casing in oil and gas wells. However, it is seriously worn when using cemented carbide tools to drill it underwater. The study delves into the experimental exploration of the wear ratio of P110 steel during underwater drilling using three different kinds of super-hard abrasive grains and binders. The investigation includes tracking and observing the morphological changes of abrasive grains on the core drill's surface, along with the analysis of graphitization on the surface of diamond abrasive grains. The results show that under the same processing conditions, the end wear of the three different core drills is roughly the same. However, the side wear of the core drill using diamond abrasive particles is significantly less than that using cubic Boron Nitride (cBN) abrasive particles. Under the condition of underwater machining, the end face diamond abrasive grains will produce graphitization. Despite this, the diamond abrasive grains still maintain a certain cutting ability. The hardness of the bonding agent affects the exposure of abrasive particles, which results in the difference in the performance of the core drill under different working conditions.

-

Key words:

- super hard abrasive /

- core drill /

- underwater drilling /

- P110 steel /

- wear

-

元素 质量分数 ω / % C 0.260 Si 0.220 Mn 1.500 P 0.008 S 0.002 Cr 0.157 Ni 0.013 Ti 0.035 Cu 0.012 Fe 余量 表 2 套料钻刀头烧结工艺

Table 2. Sintering process of core drill head

实验号 烧结温度θ / ℃ 保温时间

t / min烧结压力

σ /MPaFe基刀头 830 4.5 27.8 W基刀头 920 6.5 30.0 -

[1] 刘长利. 两种典型介质中P110钢的腐蚀行为研究 [D]. 大庆: 东北石油大学, 2011.LIU Changli. Research on the corrosion behavior of P110 steel in two typical solutions [D]. Daqing: Northeast Petroleum University, 2011. [2] 高立新, 谷坛, 闫静, 等. 高酸性条件下元素硫对碳钢腐蚀的影响 [J]. 天然气工业,2015,35(4):94-98.GAO Lixin, GU Tan, Yan Jing, et al. Corrosion of sulfur to carbon steel under the condition of high acidity [J]. Natural Gas Industry,2015,35(4):94-98. [3] 刘志德, 路民旭, 肖学兰, 等. 高含硫气田元素硫腐蚀机理及其评价方法 [J]. 石油与天然气化工,2012,41(5):495-498.LIU Zhide, LU Minxu, XIAO Xuelan, et al. Elemental sulfur corrosion mechanism and evaluation methods for high sour gas fields [J]. Chemical Engineering of Oil & Gas,2012,41(5):495-498. [4] 赵波, 李亮亮, 田岿, 等. SLCD-I型组合齿磨鞋力学性能分析 [J]. 石油机械,2020,48(10):30-38.ZHAO Bo, LI Liangliang, TIAN Kui, et al. Analysis of mechanical properties of SLCD-I composite cutter milling shoe [J]. China Petroleum Machinery,2020,48(10):30-38. [5] 刘彩云, 高伟, 殷红. 立方氮化硼的研究进展 [J]. 人工晶体学报,2022,51(5):781-800.LIU Caiyun, GAO Wei, YIN Hong. Research progress of cubic boron nitride [J]. Journal of Synthetic Crystals,2022,51(5):781-800. [6] 陈建林. 精密磨削用树脂CBN砂轮的研究及磨削试验[D]. 长沙: 湖南大学, 2006.CHEN Jianlin. Research on resin-bonded cubic boron nitride abrasive grinding wheels for finish-grinding and its grinding experiment [D]. Changsha: Hunan University, 2006. [7] 周恒. 基于多层钎焊超硬磨料砂轮的钛合金绿色磨抛加工研究 [D]. 南京: 南京航空航天大学, 2010.ZHOU Heng. Study on dry grinding titanium alloys based on multi-layer brazing super abrasive grinding wheel [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010. [8] 丁文锋. 镍基高温合金高效磨削用单层钎焊立方氮化硼砂轮的研制[D]. 南京: 南京航空航天大学, 2006.DING Wenfeng. Research and development of monolayer brazed CBN wheels for high efficiency grinding nickel-based superalloy [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2006. [9] DU Q, WANG X, ZHANG S, et al. Research status on surface metallization of diamond [J]. Materials Research Express,2019,6(12):122005. [10] 李时春, 周振红, 莫彬, 等. 激光钎焊多层金刚石磨粒Ni-Cr合金成形工艺研究 [J]. 中国机械工程,2021,32(8):967-975.LI Shichun, ZHOU Zhenhong, MO Bin, et al. Study on forming processes for laser brazing of multilayer diamond grains and Ni-Cr alloy [J]. China Mechanical Engineering,2021,32(8):967-975. [11] BAI Q, WANG Z, GUO Y, et al. Graphitization behavior of single crystal diamond for the application in nano-metric cutting [J]. Current Nanoscience,2018,14(5):377-383. doi: 10.2174/1573413714666180517080721 [12] SHIMADA S, TANAKA H, HIGUCHI M, et al. Thermo-chemical wear mechanism of diamond tool in machining of ferrous metals [J]. CIRP Annals,2004,53(1):57-60. doi: 10.1016/S0007-8506(07)60644-1 [13] NARULKAR R, BUKKAPATNAM S, RAFF L M, et al. Graphitization as a precursor to wear of diamond in machining pure iron: A molecular dynamics investigation [J]. Computational Materials Science,2009,45(2):358-366. doi: 10.1016/j.commatsci.2008.10.007 [14] SUN B, JIANG C, ZONG F. Performance and wear of brazing diamond grinding disc in machining gray cast iron [J]. Diamond and Related Materials,2020,106:107820. doi: 10.1016/j.diamond.2020.107820 [15] TONSHOFF H K, HILLMANN-APMANN H. Diamond tools for wire sawing metal components [J]. Diamond and Related Materials,2002,11(3/4/5/6):742-748. doi: 10.1016/S0925-9635(01)00727-0 [16] 毛汀, 吴贵阳, 李珊, 等. 盐浴渗氮对P110钢耐硫腐蚀性能的影响 [J]. 石油与天然气化工,2020,49(6):76-81. doi: 10.3969/j.issn.1007-3426.2020.06.013MAO Ting, WU Guiyang, LI Shan, et al. Effect of salt bath nitriding on sulfur corrosion resistance of P110 steel [J]. Chemical Engineering of Oil & Gas,2020,49(6):76-81. doi: 10.3969/j.issn.1007-3426.2020.06.013 [17] CHEN Z, SUBHASH G, TULENKO J S. Raman spectroscopic investigation of graphitization of diamond during spark plasma sintering of UO2-diamond composite nuclear fuel [J]. Journal of Nuclear Materials,2016,475:1-5. doi: 10.1016/j.jnucmat.2016.03.015 [18] ZOU L, HUANG Y, ZHOU M, et al. Thermochemical wear of single crystal diamond catalyzed by ferrous materials at elevated temperature [J]. Crystals (Basel),2017,7(4):116. doi: 10.3390/cryst7040116 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS