Preparation of Ti3SiC2/diamond composites by Ni-Al assisted microwave self-propagating sintering

-

摘要:

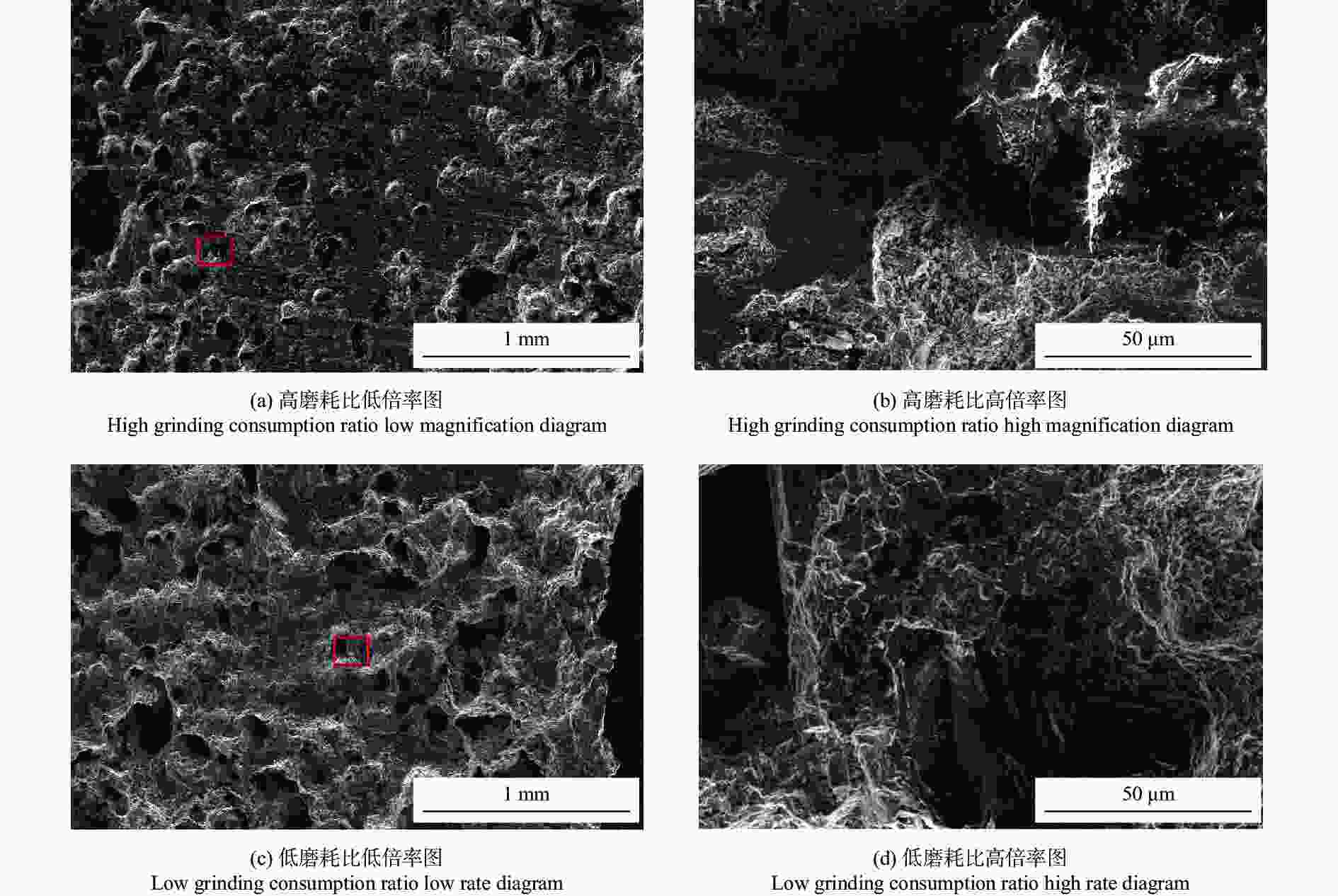

为降低金刚石磨削工具的制造成本和能耗,探寻一种在低能耗下实现高性能陶瓷结合剂金刚石磨具的制备工艺,同时研究助燃剂Si和金刚石粒度等因素对样品物相组成、显微形貌和磨削性能的影响。采用Ti、Si、石墨粉和金刚石磨料作为原料,经冷压成型至生胚,通过Ni-Al辅助在微波场加热诱发Ti-Si-C体系发生自蔓延高温合成(SHS)反应以制备Ti3SiC2基金刚石复合材料。结果表明,高热值Ni-Al合金辅助可以缩短样品的烧结时间,还可以将诱发SHS反应的温度点控制在金刚石石墨化温度以下。在Ar保护气氛下,Ti-Si-C体系发生SHS反应,可生成Ti3SiC2、TiC和Ti5Si3等3种物相。随Si含量升高,Ti3SiC2相先增多后减少,当n (Ti): n (Si): n (C)= 3∶1.1∶2时,复合材料的磨削性能最佳,磨耗比最高可达286.53。分析不同原料配比下的试样磨耗比差异的产生机制,认为基体组织中存在微小且分布均匀的气孔结构,在磨削时可产生大区域的平整磨削面,易于发挥金刚石磨料的磨削效果,有利于提升复合材料样品的磨削性能。

Abstract:[OBJECTIVES] Low carbon economy and green economy are the strategic direction of sustainable development, in order to reduce the manufacturing cost and energy consumption of diamond grinding tools, this study aims to explore a process of preparing high-performance ceramic bond diamond grinding tools under low energy consumption, to reduce the manufacturing cost and energy consumption of diamond grinding tools. The specific objectives include preparing Ti3SiC2-based diamond composite materials, and studying the effects of combustion-supporting agent Si and diamond particle size on the phase composition, microstructure and grinding performance of the samples.

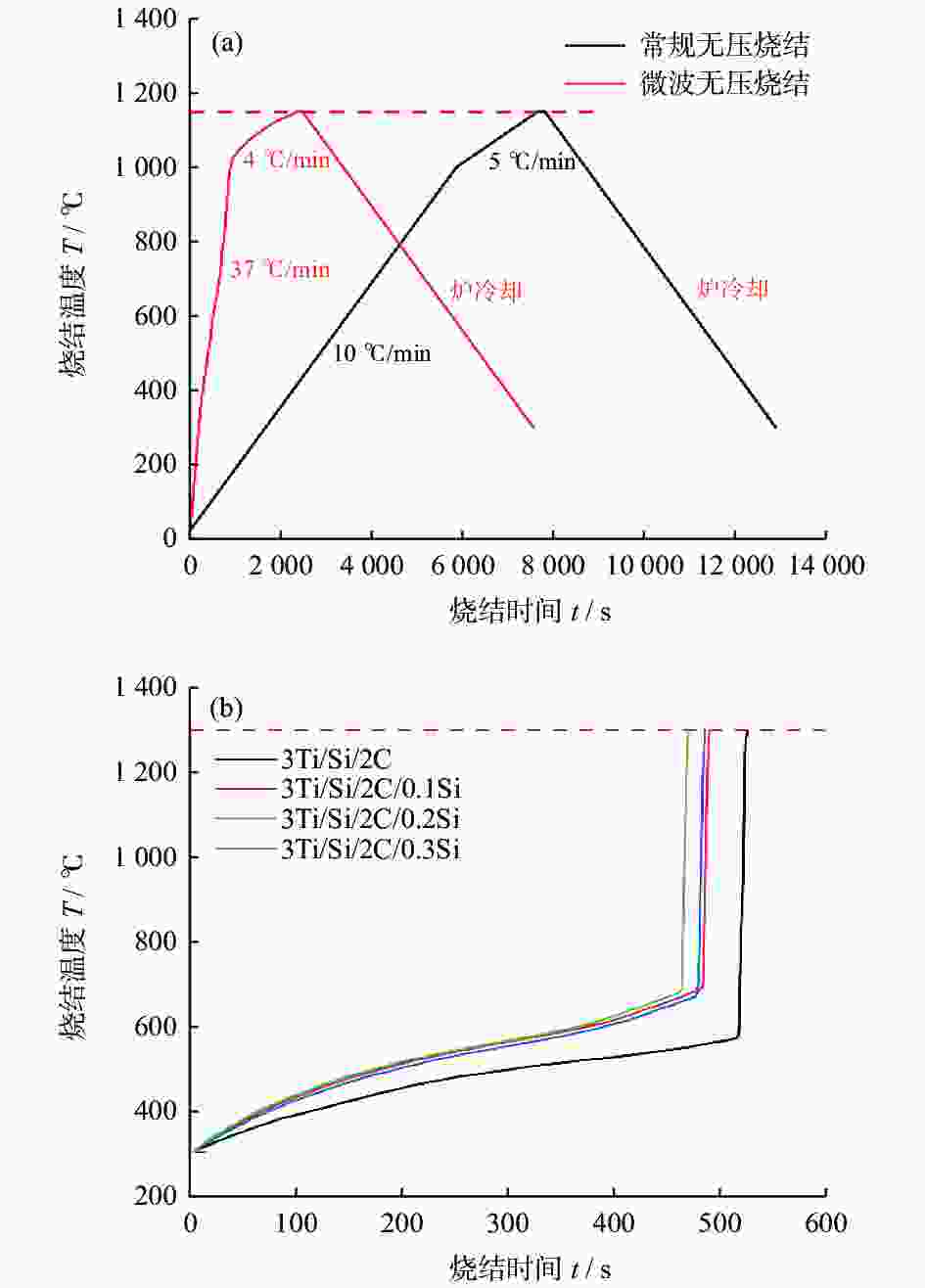

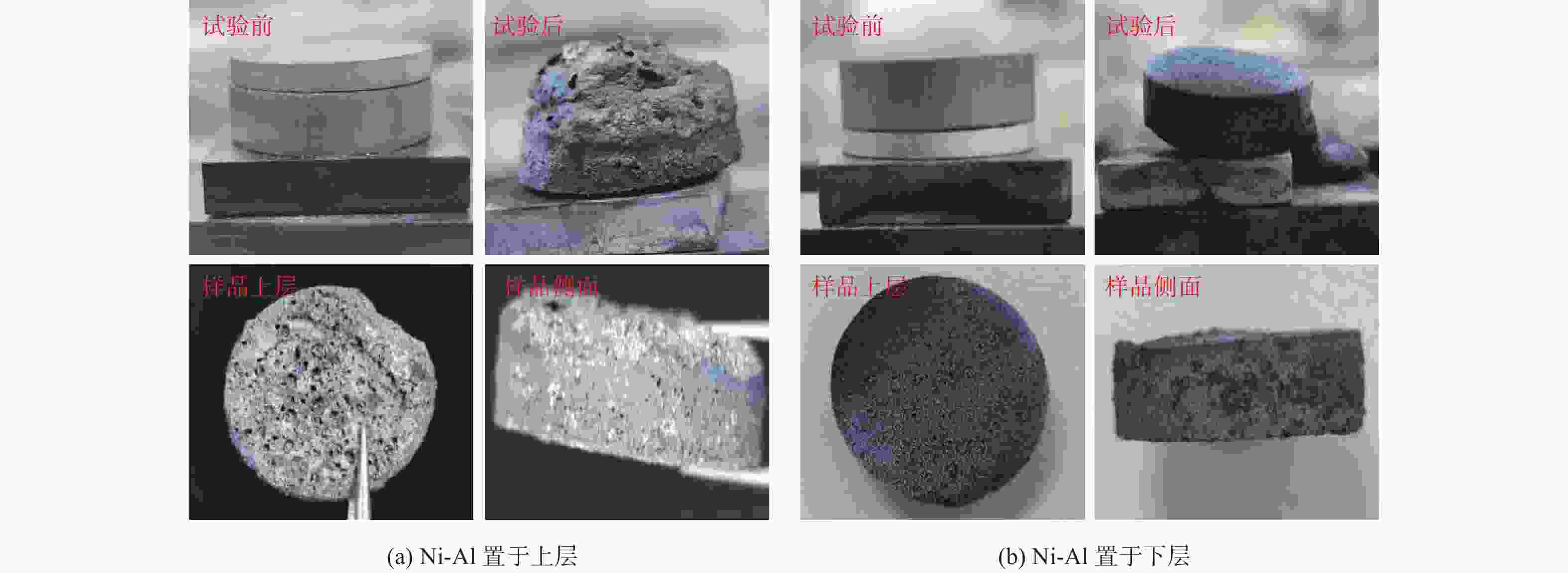

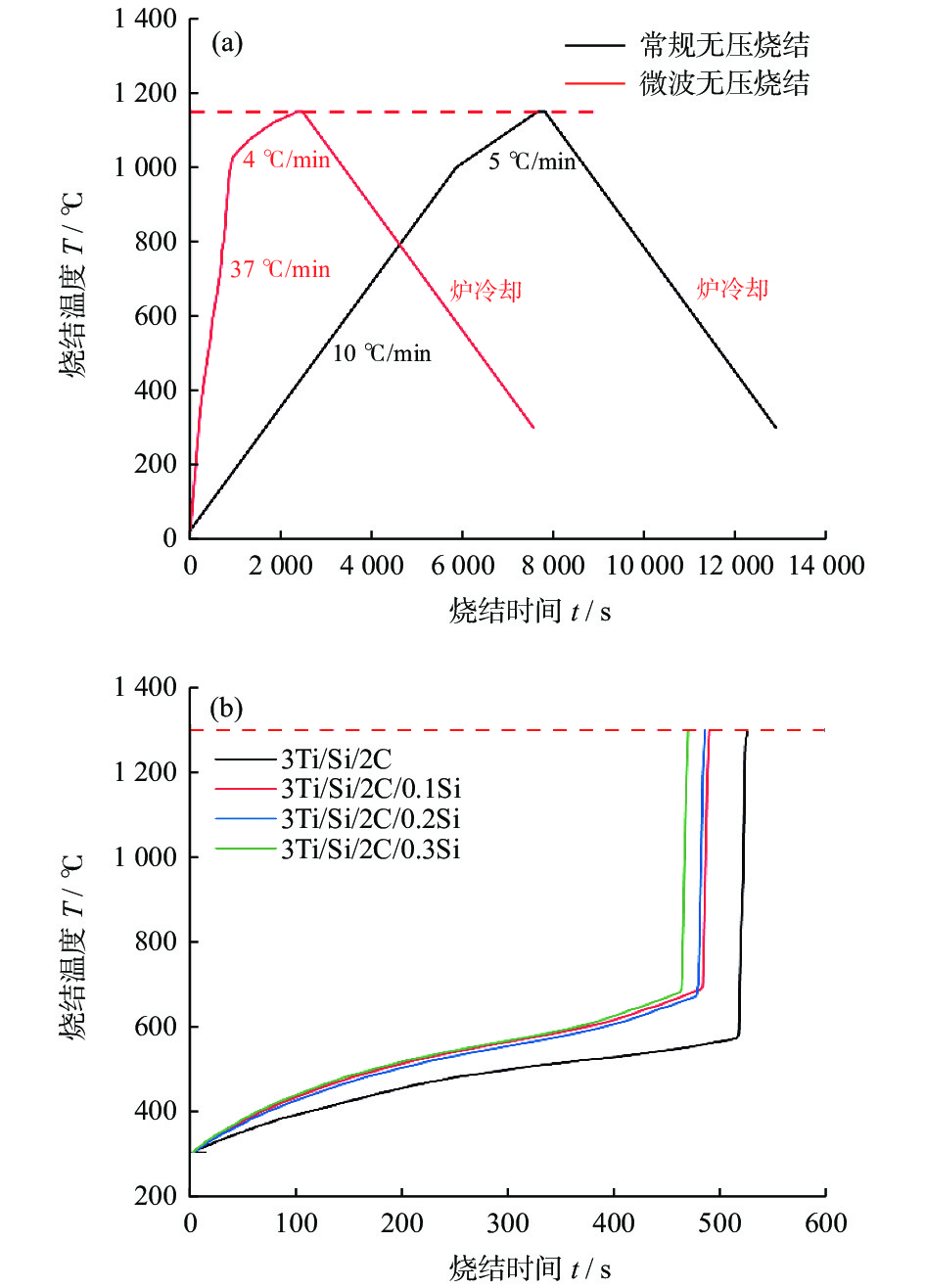

[METHODS] Ti, Si, graphite powder, and diamond abrasives are selected as raw materials. After proportioning and weighing, they are cold-pressed to prepare green bodies. Ni powder and Al powder are cold-pressed into auxiliary heating green bodies according to the proportion. The material green body is horizontally placed on the auxiliary heating green body and then placed on the graphite block, then placed in a microwave tube furnace, Ar atmosphere is introduced for protection, and the temperature is quickly raised to the thermal explosion temperature point under the condition of 3kW power. After 30 seconds, the microwave source is cut off, and the furnace is cooled to room temperature before the Ar atmosphere input is turned off. At the end of the experiment, Ti3SiC2-based diamond composite material can be obtained.

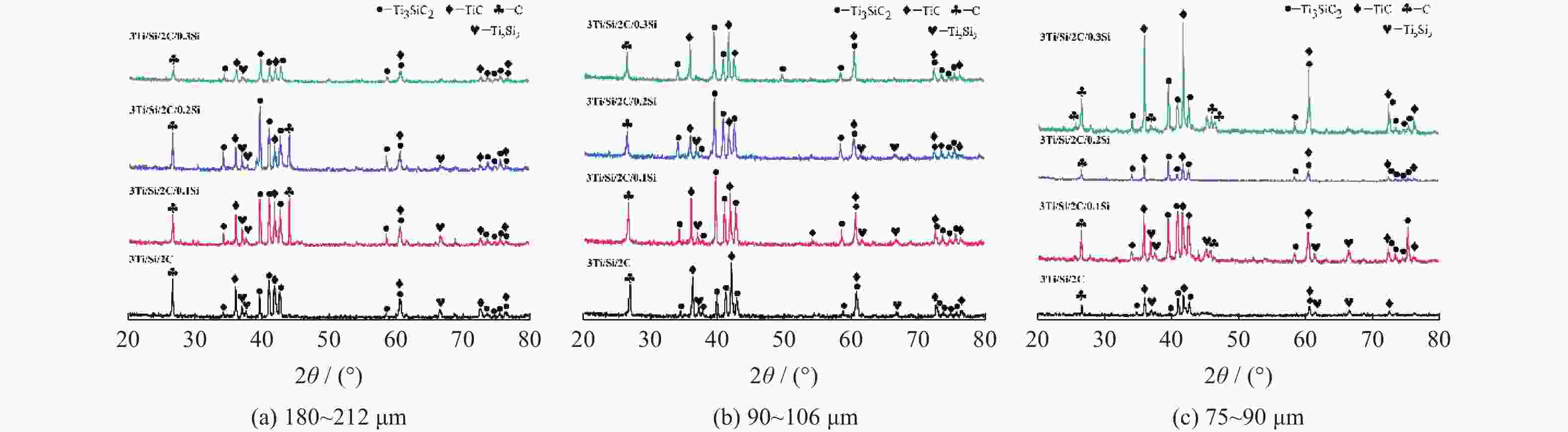

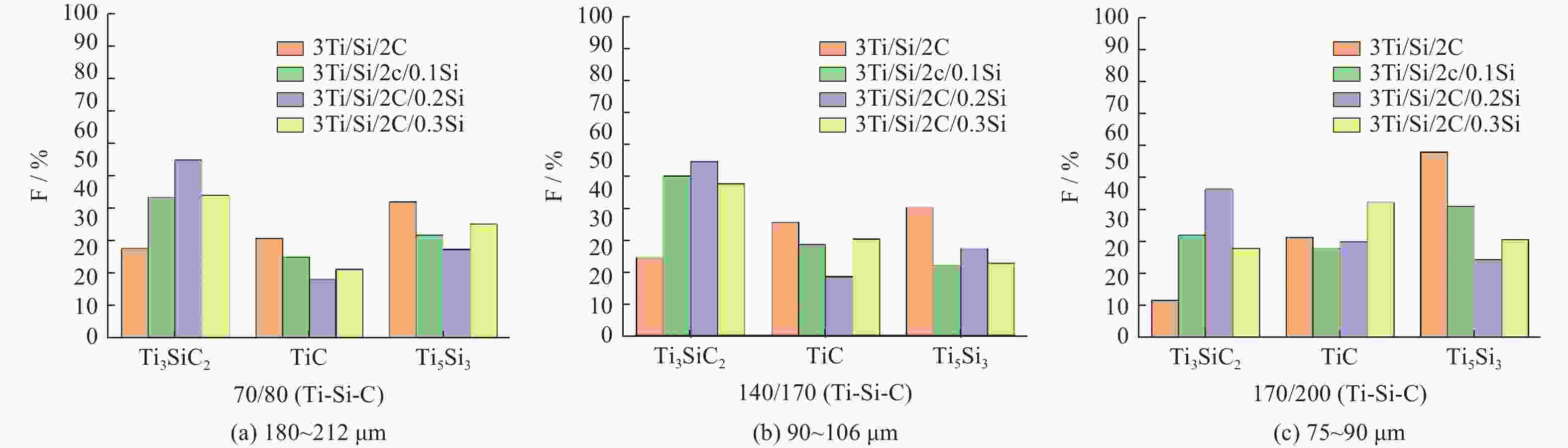

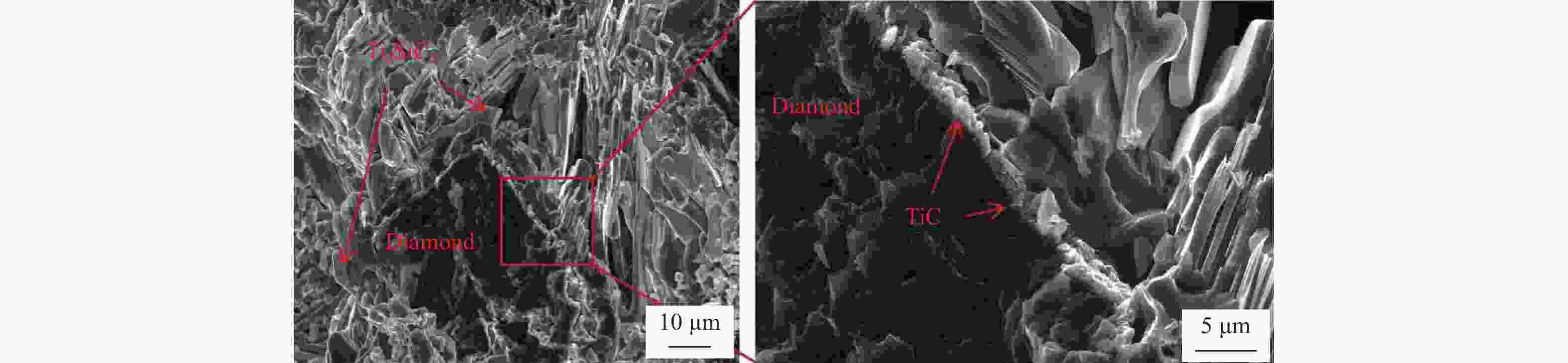

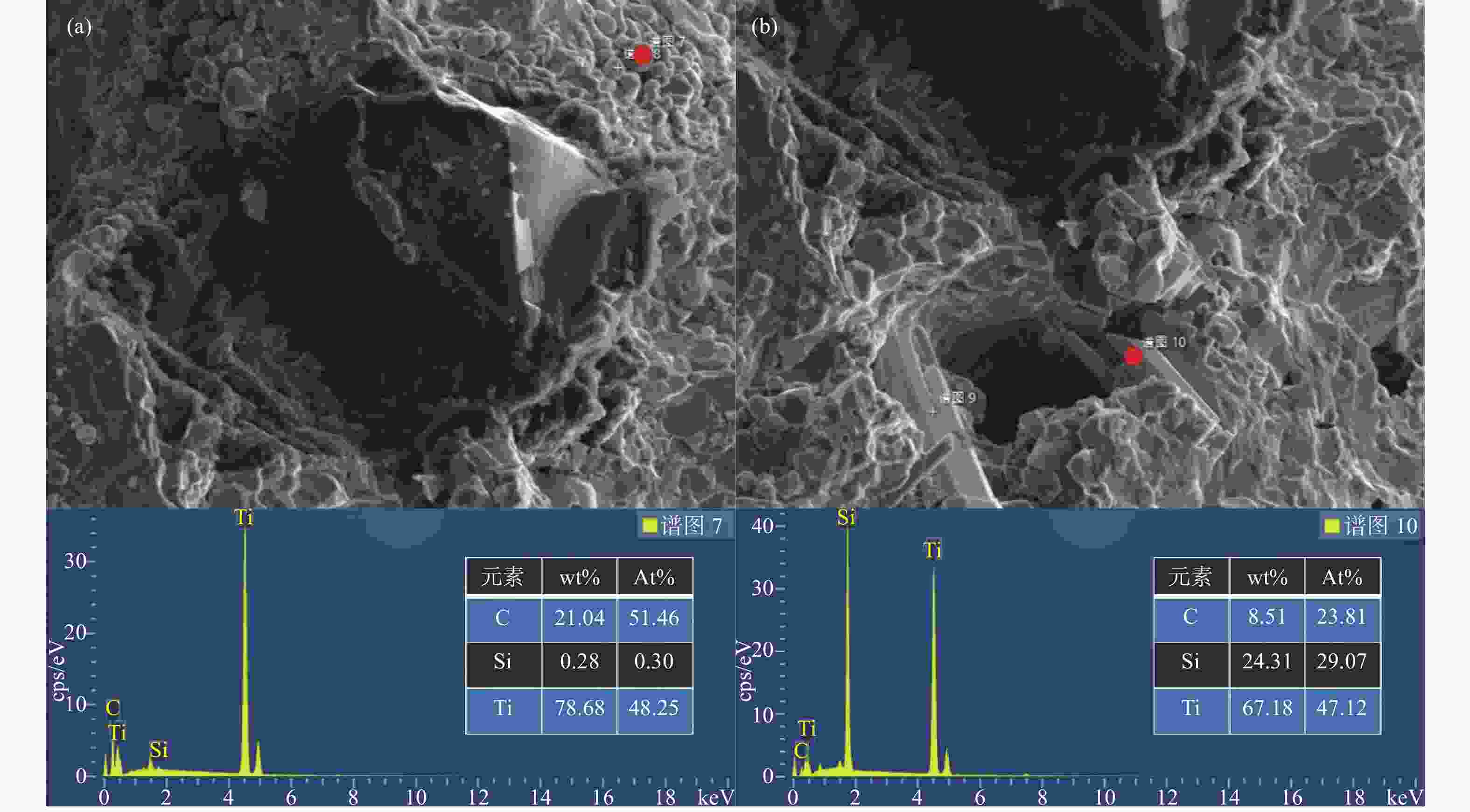

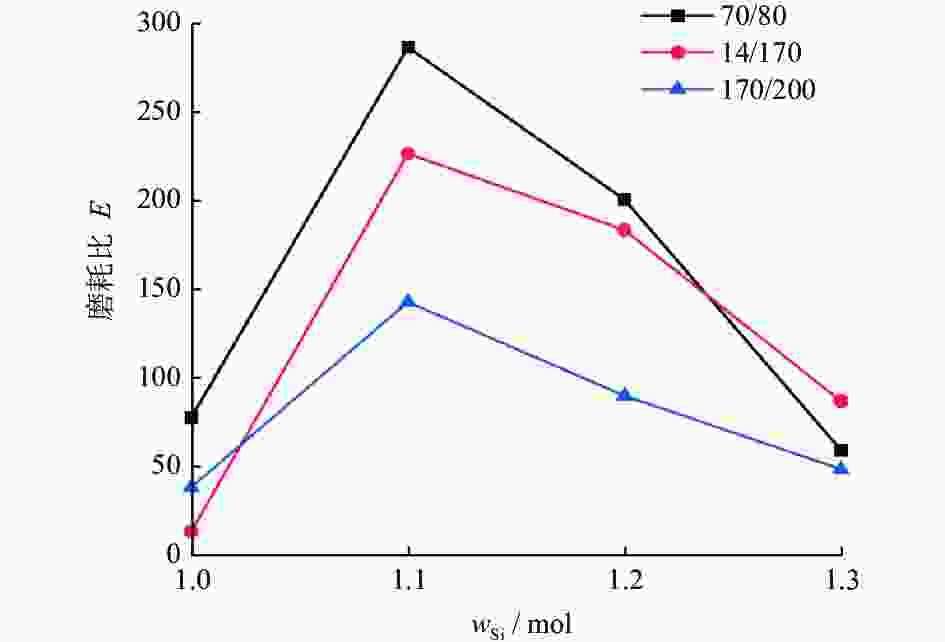

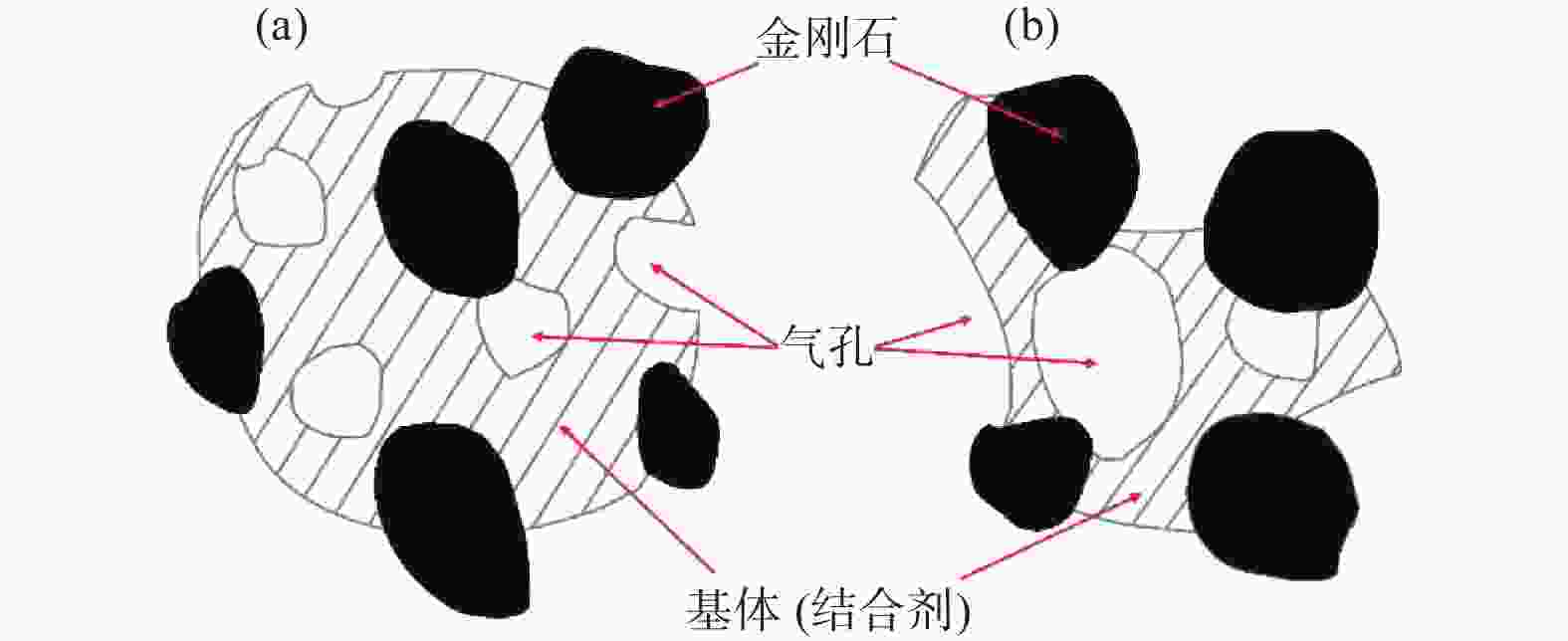

[RESULTS] Microwave pressureless sintering is more efficient than conventional heating methods below 1000 ℃. High calorific value Ni-Al alloy assistance can shorten the experimental time of sample sintering, and can control the temperature point of inducing SHS reaction below the graphitization temperature of diamond. Under the protection of Ar atmosphere, the Ti-Si-C system undergoes an SHS reaction, which can generate three phases of Ti3SiC2, TiC, and Ti5Si3. Adding a certain amount of Si as a combustion-supporting agent in the experiment will be beneficial to the generation of the target phase of Ti3SiC2. When Ti3SiC2, TiC, and Ti5Si3 are at a certain proportion of equilibrium points, they can stably combine with diamond abrasives to exert the maximum grinding performance. As the Si content increases, the Ti3SiC2 phase first increases and then decreases. When n (Ti): n (Si): n (C) = 3: 1.1: 2, the grinding performance of Ti3SiC2-based diamond composite material is the best, and the diamond particle size is 70/80 mesh. The sample has the highest wear ratio, which can reach 286.53. Through the analysis of the friction wear test section of the composite material, the overall pores of the sample are small and evenly distributed, providing a good grip for the diamond abrasive. The diamond fits tightly with the surrounding matrix, the exposed part of the diamond is slightly higher than the grinding surface of the matrix, and the remaining part is tightly wrapped by the matrix, maximizing the grinding ability of the sample. It is known from the above analysis that the size of the pores, the distribution of the pores, the ratio of the raw materials, and the particle size of the diamond are the keys to the overall grinding performance. The pores are small and evenly distributed, and the matrix is more likely to form a flat grinding plane during the grinding process, which is easy for the diamond to exert good grinding performance. Adding a combustion-supporting agent and increasing the particle size of the diamond can both improve the grinding performance of the sample. When the Si combustion-supporting agent is added to 0.1 mol and the diamond particle size is 180~212 μm, it reaches the highest.

[CONCLUSIONS] By optimizing the raw material ratio and preparation process, using Ni-Al to assist microwave sintering, an SHS reaction is induced at 482 s and 685.5 ℃, preparing a Ti3SiC2-based diamond composite material containing Ti3SiC2, TiC, and Ti5Si3, which has excellent grinding performance. By analyzing the mechanism of the difference in the wear ratio of samples under different raw material ratios, it is found that the small and evenly distributed pore structure in the matrix organization is conducive to producing a flat grinding surface and improving the grinding performance of the composite material samples. This research provides a new method for preparing diamond grinding tools for green and low-carbon circular development, and is expected to reduce energy consumption and improve efficiency in practical applications.

-

Key words:

- microwave self-propagating sintering /

- Ti3SiC2 /

- diamond composite material /

- Ni-Al alloy

-

表 1 Ti3SiC2基金刚石复合材料的性能参数

Table 1. Performance parameters of Ti3SiC2/diamond composites

性能类型 取值 磨耗比 286.53 相对致密度 ρd / % 83.62 导电率 σ / (S·m-1) 2.15 × 106 热导率 λ / (W·m-1·K-1) 7.67 抗折强度 R / MPa 223.66 硬度(HRC) 32.85 -

[1] 廖原时. 由我国石材矿山机械化开采看行业进步 [J]. 石材,2016(2):20-24. doi: 10.3969/j.issn.1005-3352.2016.02.007LIAO Yuanshi. Looking at the progress of the industry from the mechanized mining of stone mines in China [J]. Stone,2016(2):20-24. doi: 10.3969/j.issn.1005-3352.2016.02.007 [2] 赵民. 近十年中国石材加工装备与技术评述 [J]. 石材,2016(2):25-29. doi: 10.3969/j.issn.1005-3352.2016.02.008ZHAO Min. Review of stone processing equipment and technology in China in recent ten years [J]. Stone,2016(2):25-29. doi: 10.3969/j.issn.1005-3352.2016.02.008 [3] 王超超, 张凤林, 李伟雄, 等. 空心玻璃微珠对陶瓷结合剂金刚石砂轮微观结构和力学性能的影响 [J]. 工具技术,2017,51(10):36-39. doi: 10.16567/j.cnki.1000-7008.2017.10.008WANG Chaochao, ZHANG Fenglin, LI Weixiong, et al. Effect of glass bubble as pore former on micro-structure and mechanical properties of vitrified bond diamond grinding wheels [J]. Tool Engineering,2017,51(10):36-39. doi: 10.16567/j.cnki.1000-7008.2017.10.008 [4] 丁玉龙, 苗卫鹏, 骆苗地, 等. 陶瓷结合剂金刚石砂轮组织结构对其性能的影响 [J]. 金刚石与磨料磨具工程,2020,40(4):19-23. doi: 10.13394/j.cnki.jgszz.2020.4.0003DING Yulong, MIAO Weipeng, LUO Miaodi, et al. Influence of structure of vitrified bond diamond grinding wheel on its performance [J]. Diamond & Abrasives Engineering,2020,40(4):19-23. doi: 10.13394/j.cnki.jgszz.2020.4.0003 [5] 周琪. 金刚石砂轮用陶瓷结合剂制备以及结构与性能的研究 [D]. 武汉: 武汉理工大学, 2014.ZHOU Qi. Preparation and research on structure and properties of vitrified bond for diamond grinding wheel [D]. Wuhan: Wuhan University of Technology, 2014. [6] BARSOUM M, RADOVIC M. Elastic and mechanical properties of the MAX phases [J]. Annual Review of Materials Research,2010,41:195-227. doi: 10.1146/annurev-matsci-062910-100448 [7] BARSOUM M. MAX phases: Properties of machinable ternary carbides and nitrides [M]. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2013. [8] INGASON A, PETRUHINS A, ROSEN J. Toward structural optimization of MAX phases as epitaxial thin films [J]. Materials Research Letters,2016,4(3):1-9. doi: 10.1080/21663831.2016.1157525 [9] RADOVIC M, BARSOUM M. MAX phases: Bridging the gap between metals and ceramics [J]. American Ceramic Society Bulletin,2013,92(3):20-27. [10] JAWORSKA L, STOBIERSKI L, TWARDOWSKA A, et al. Preparation of materials based on Ti-Si-C system using high temperature high pressure method [J]. Journal of Materials Processing Technology,2015,162/163:184-189. doi: 10.1016/j.jmatprotec.2005.02.172 [11] MERZHANOV A G. Thermal explosion and ignition as a method for formal kinetic studies of exothermic reactions in the condensed phase [J]. Combustion and Flame,1967,11(3):201-211. doi: 10.1016/0010-2180(67)90046-6 [12] JAWORSKA L, SZUTKOWSKA M, MORGIEL J, et al. Ti3SiC2 as a bonding phase in diamond composites [J]. Journal of Materials Science Letters,2001,20(19):1783-1786. doi: 10.1023/A:1012535100330 [13] 梁宝岩, 张旺玺, 王艳芝, 等. 微波烧结制备MAX相-金刚石复合材料 [J]. 金刚石与磨料磨具工程,2016,36(1):25-30. doi: 10.13394/j.cnki.jgszz.2016.1.0006LIANG Baoyan, ZHANG Wangxi, WANG Yanzhi, et al. MAX phase-diamond composites fabricated by microwave sintering [J]. Diamond & Abrasives Engineering,2016,36(1):25-30. doi: 10.13394/j.cnki.jgszz.2016.1.0006 [14] 李正阳, 周爱国, 李良, 等. 无压烧结制备Ti3SiC2-金刚石复合材料的反应机理与微观结构 [J]. 兵器材料科学与工程,2013,36(6):29-31. doi: 10.3969/j.issn.1004-244X.2013.06.011LI Zhengyang, ZHOU Aiguo, LI Liang, et al. Reaction mechanisms and microstructure of Ti3SiC2-diamond composites synthesized by pressureless sintering [J]. Ordnance Material Science and Engineering,2013,36(6):29-31. doi: 10.3969/j.issn.1004-244X.2013.06.011 [15] 陈国清, 赵薇, 任媛媛, 等. 微波烧结WC-ZrO2复合材料的微观组织及增韧机理 [J]. 现代技术陶瓷,2018,39(4):287-294. doi: 10.16253/j.cnki.37-1226/tq.2018.03.002CHEN Guoqing, ZHAO Wei, REN Yuanyuan, et al. Microstructure and toughening mechanism of WC-ZrO2 composites by microwave sintering [J]. Advanced Ceramics,2018,39(4):287-294. doi: 10.16253/j.cnki.37-1226/tq.2018.03.002 [16] WANG L, GUO S, GAO J, et al. Microwave sintering behavior of FeCuCo based metallic powder for diamond alloy tool bit [J]. Journal of Alloys and Compounds,2017,727:94-99. doi: 10.1016/j.jallcom.2017.08.132 [17] MANIÈRE C, ZAHRAH T, OLEVSKY E A. Fully coupled electromagnetic‐thermal‐mechanical comparative simulation of direct vs hybrid microwave sintering of 3Y‐ZrO2 [J]. Journal of the American Ceramic Society,2017. doi: 10.1111/jace.14762 [18] 叶小磊, 郭胜惠, 高冀芸, 等. 微波无压烧结Fe-Cu-WC基金属结合剂 [J]. 金刚石与磨料磨具工程,2018,38(1):41-44,54. doi: 10.13394/j.cnki.jgszz.2018.1.0007YE Xiaolei, GUO Shenghui, GAO Jiyun, et al. Sinter Fe-Cu-WC based metal bonding agent by using microwave pressureless method [J]. Diamond & Abrasives Engineering,2018,38(1):41-44,54. doi: 10.13394/j.cnki.jgszz.2018.1.0007 [19] 姜元昊, 朱和国. 金属材料微波烧结的研究现状 [J]. 热加工工艺,2018,47(2):19-22. doi: 10.14158/j.cnki.1001-3814.2018.02.005JIANG Yuanhao, ZHU Heguo. Research Progress of Microwave Sintering for Metal Materials [J]. Hot Working Technology,2018,47(2):19-22. doi: 10.14158/j.cnki.1001-3814.2018.02.005 [20] 代振, 张旺玺, 梁宝岩, 等. 微波诱发热爆法制备钛铝碳结合剂金刚石复合材料 [J]. 金刚石与磨料磨具工程,2021,41(2):4-8. doi: 10.13394/j.cnki.jgszz.2021.2.0001DAI Zhen, ZHANG Wangxi, LIANG Baoyan, et al. Preparation of titanium-aluminum-carbon bond diamond composite material by microwave induced thermal explosion [J]. Diamond & Abrasives Engineering,2021,41(2):4-8. doi: 10.13394/j.cnki.jgszz.2021.2.0001 [21] 梁宝岩, 张旺玺, 王艳芝, 等. 微波烧结制备Ti3SiC2-金刚石复合材料的显微形貌及界面反应机理 [J]. 硅酸盐通报,2016,35(3):725-731. doi: 10.16552/j.cnki.issn1001-1625.2016.03.011LIANG Baoyan, ZHANG Wangxi, WANG Yanzhi, et al. Microstructure and interfacial reaction mechanism of Ti3SiC2-diamond composites fabricated by microwave sintering [J]. Bulletin of the Chinese Ceramic Society,2016,35(3):725-731. doi: 10.16552/j.cnki.issn1001-1625.2016.03.011 [22] JIAO X, LIU Y, CAI X, et al. Progress of porous Al-containing intermetallics fabricated by combustion synthesis reactions: A review [J]. Journal of Materials Science,2021,56:11605-11630. doi: 10.1007/s10853-021-06035-5 [23] 梁宝岩. 自蔓延高温合成Ti3SiC2陶瓷及形成机理研究 [D]. 秦皇岛: 燕山大学, 2011.LIANG Baoyan. Investigations of synthesis and formation mechanism of Ti3SiC2 ceramic by self-propagation high-temperature sintering [D]. Qinhuangdao: Yanshan University, 2011. [24] ZOU Y, SUN Z M, TADA S, et al. Effect of Al addition on low-temperature synthesis of Ti3SiC2 powder [J]. Journal of Alloys and Compounds,2008,461(1/2):579-584. doi: 10.1016/j.jallcom.2007.07.090 [25] 吴佩, 韩兵强, 魏佳炜, 等. 板状刚玉骨料气孔结构及性能分析 [J]. 耐火材料,2022,56(6):481-484. doi: 10.3969/j.issn.1001-1935.2022.06.005WU Pei, HAN Bingqiang, WEI Jiawei, et al. Pore structure and performance of tabular corundum aggregates [J]. Refractories,2022,56(6):481-484. doi: 10.3969/j.issn.1001-1935.2022.06.005 [26] 胡晓, 程寓, 袁勤, 等. 微波烧结制备陶瓷结合剂金刚石砂轮的研究 [J]. 陶瓷学报,2019,40(2):191-195. doi: 10.13957/j.cnki.tcxb.2019.02.011HU Xiao, CHENG Yu, YUAN Qin, et al. Preparation of vitrified bond diamond grinding wheels by microwave sintering [J]. Journal of Ceramics,2019,40(2):191-195. doi: 10.13957/j.cnki.tcxb.2019.02.011 [27] 胡晓. 微波烧结陶瓷结合剂金刚石砂轮的研究 [D]. 南京: 南京理工大学, 2018.HU Xiao. Study on microwave sintering vitrified bond diamond grinding wheel [D]. Nanjing: Nanjing University of Science and Technology, 2018. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS