Research status and prospect of additive manufacturing diamond tools

-

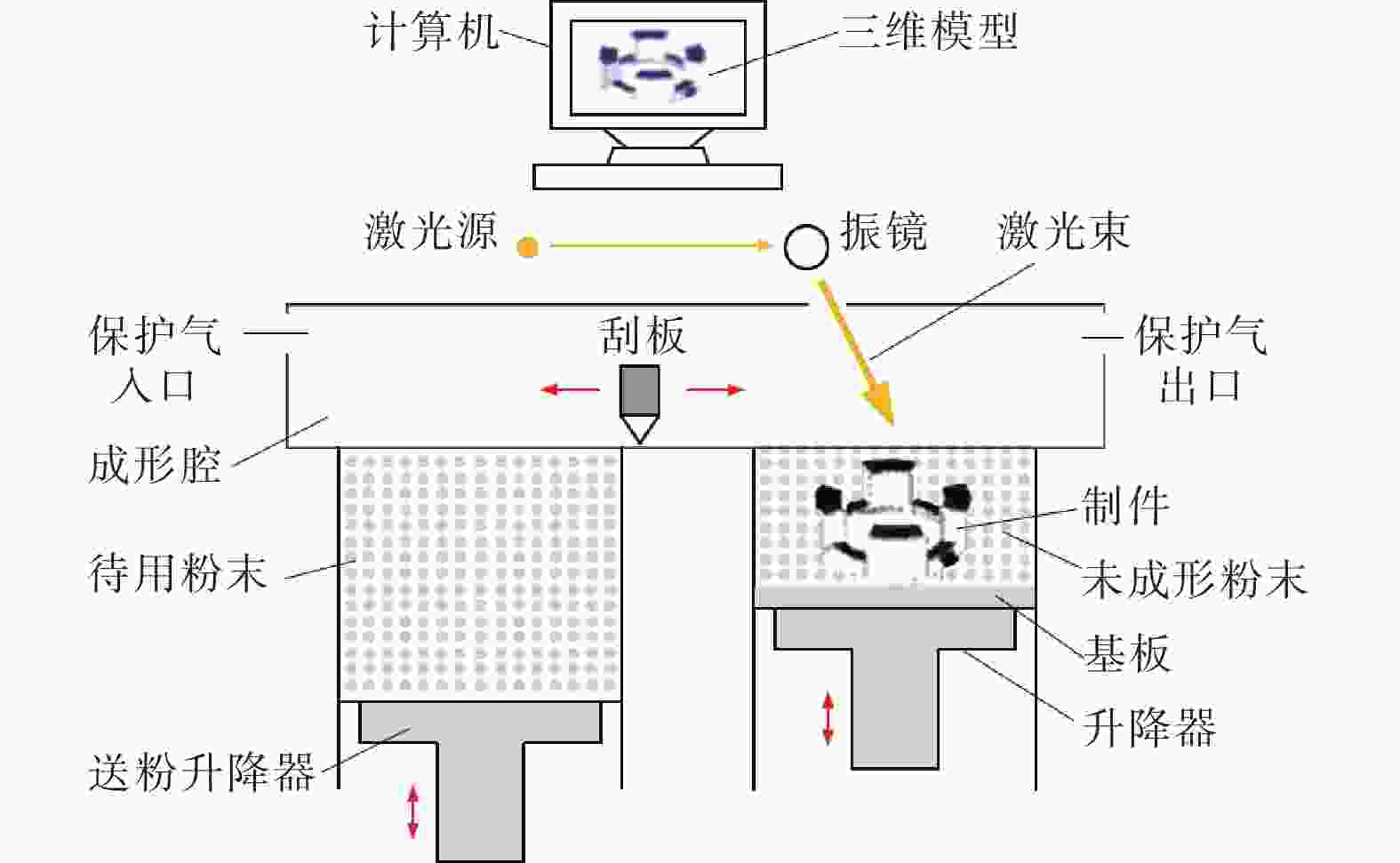

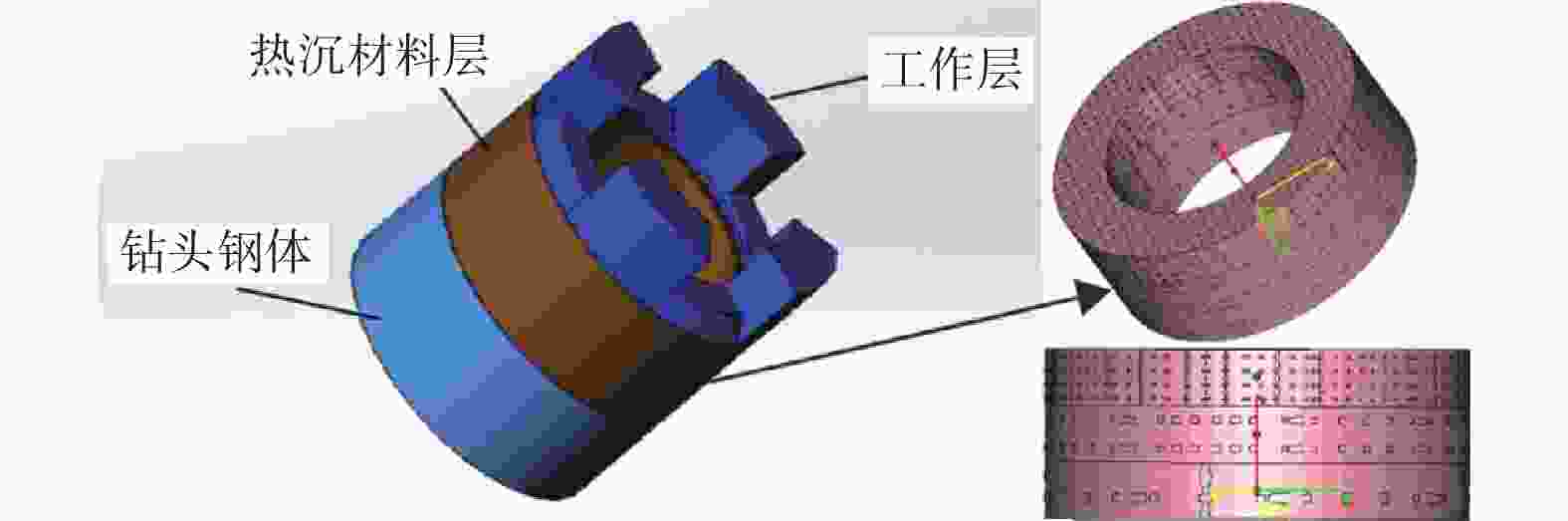

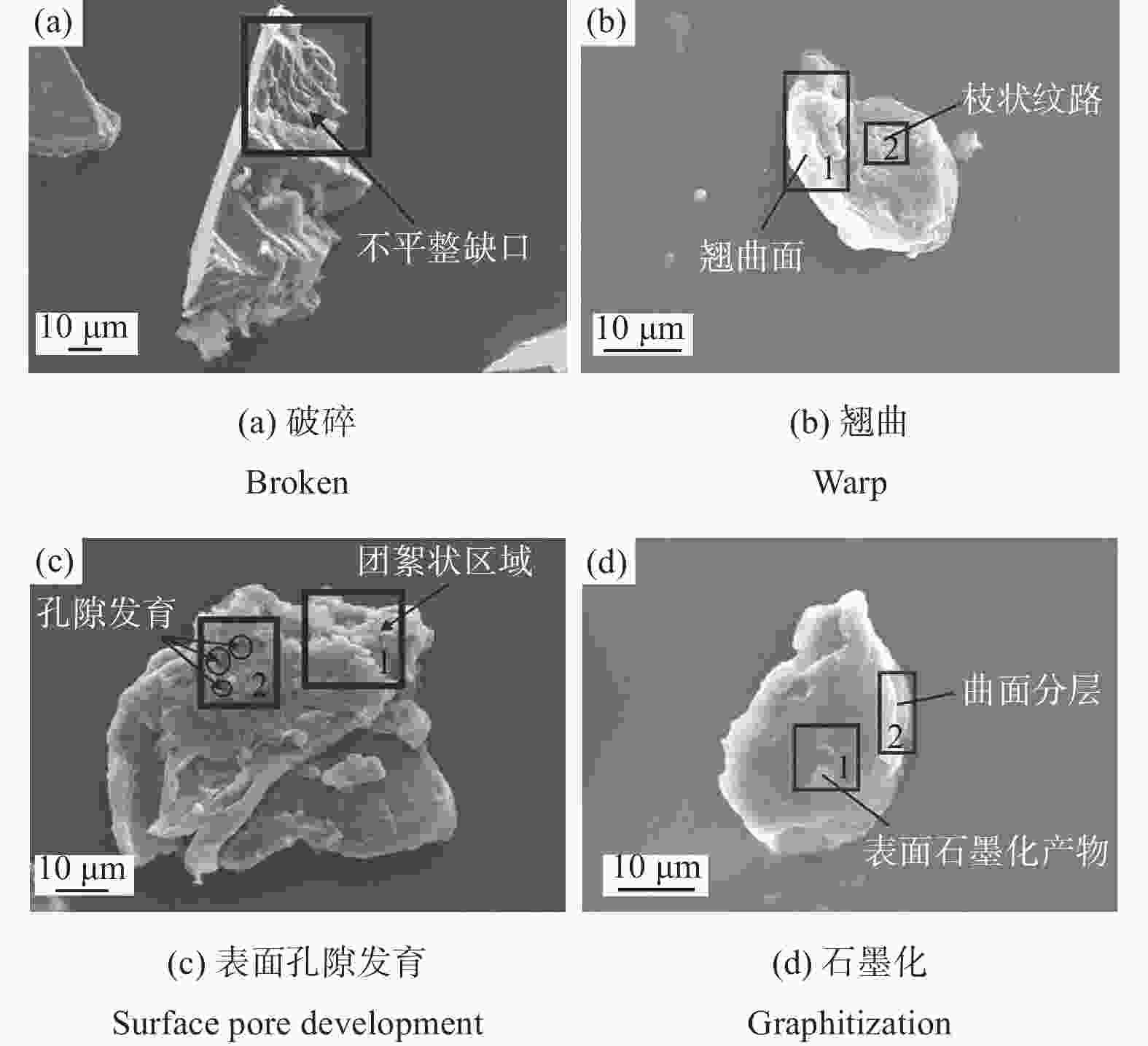

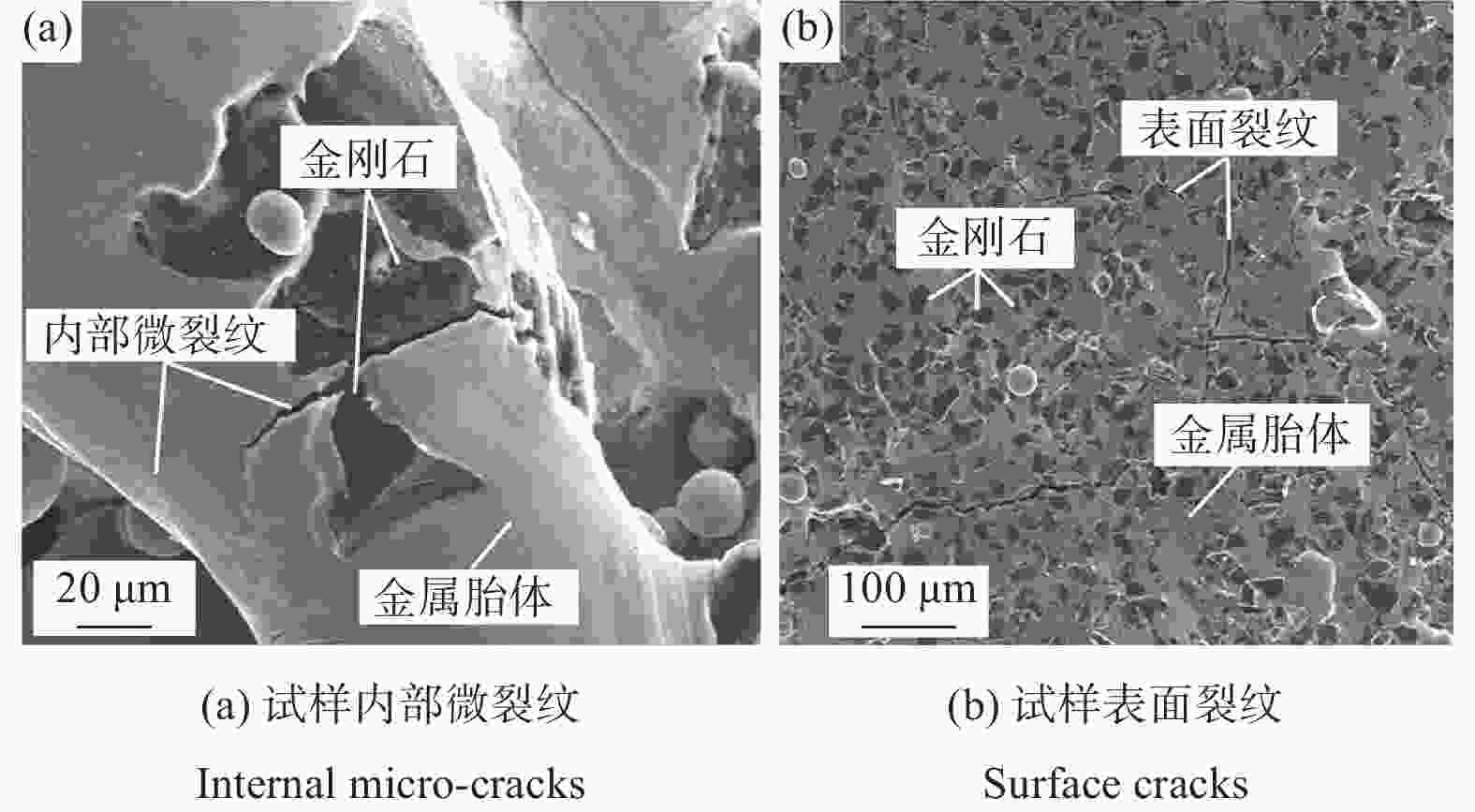

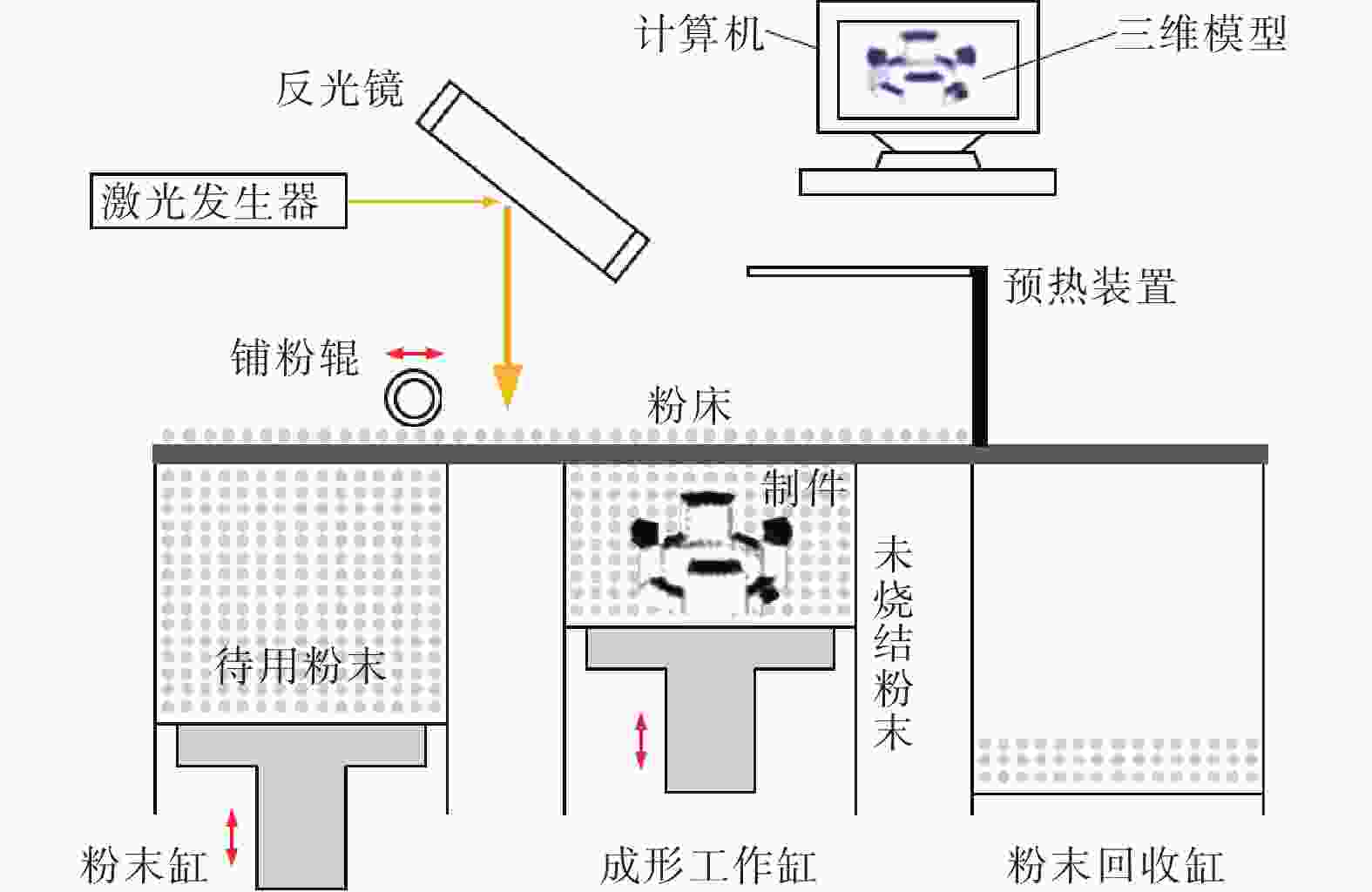

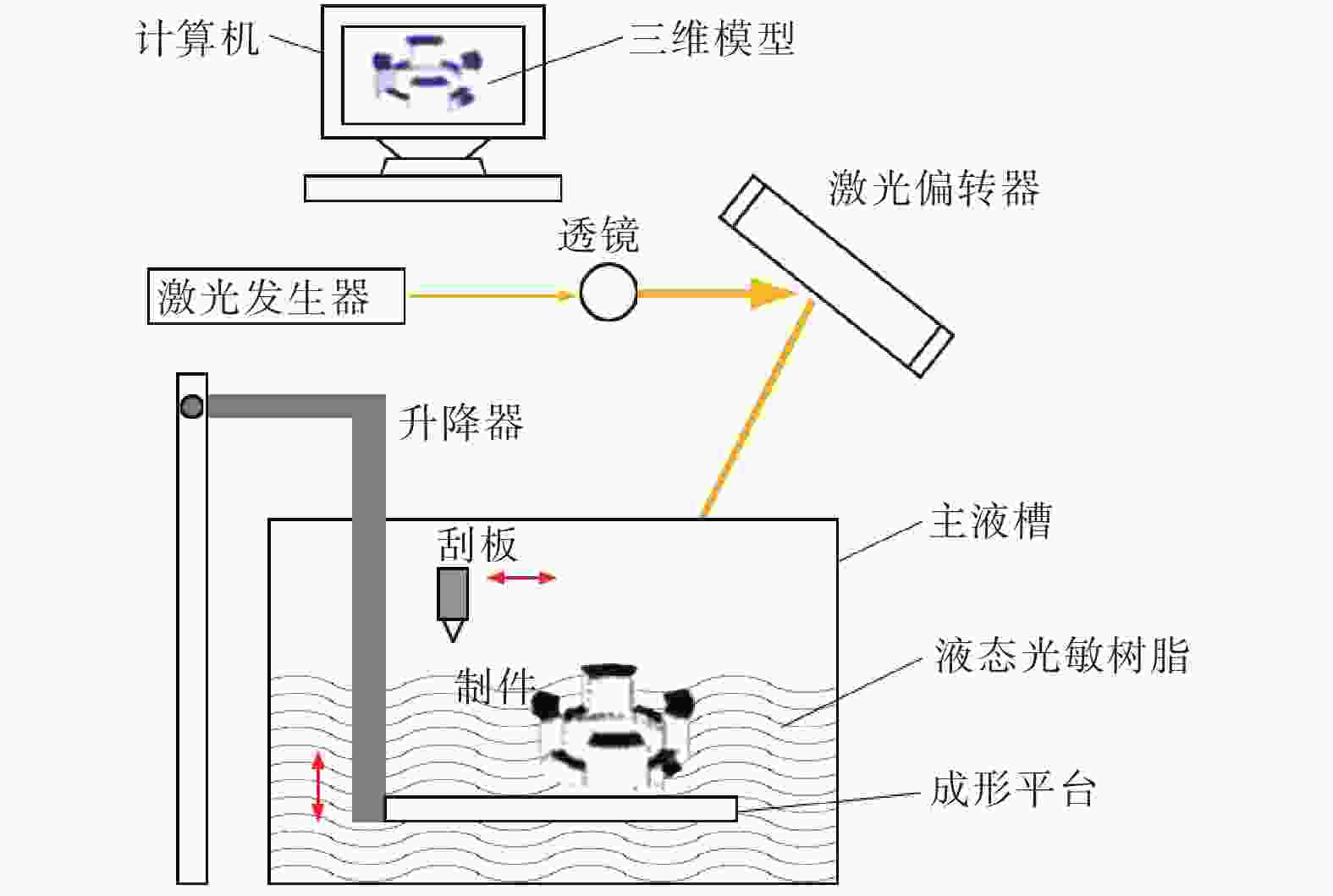

摘要: 随着金刚石工具朝着形状复杂化、结构精密化、性能高端化等方向发展,常规金刚石制造工艺受成形原理限制较难满足上述要求,亟须寻求新的金刚石工具制造工艺。增材制造是一项新兴的、降三维制造为二维制造的技术,近年来开始应用于复杂结构金刚石工具的制造。本文综述了激光选区熔化、激光选区烧结、立体光固化成形等目前主流增材制造工艺成形金刚石工具的研究进展,详细介绍了3种工艺的成形原理,重点阐述了不同工艺中金刚石与胎体材料的界面结合问题,简要对比了3种增材制造工艺成形金刚石工具的差异。最后,对未来增材制造金刚石工具的研究重点进行了展望。Abstract: In recent years, diamond tools are developing in new directions such as complex shape, precise structure and high-end performance. However, limited by the forming principle, it is difficult to meet the above requirements through conventional manufacturing processes. Therefore, there is an urgent need to seek new methods. As an emerging manufacturing technology, additive manufacturing technology has been applied to the manufacture of diamond tools with complex structures in recent years owing to its characteristics of turning three-dimensional manufacturing into two-dimensional manufacturing. This paper reviews the research progress of the current mainstream means to fabricate diamond tools through additive manufacturing processes, such as selective laser melting, selective laser sintering and stereo lithography appearance. The forming principles of the three methods are introduced in detail, focusing on the interface combination of diamond and matrix material under different processes. At the same time, the differences of the three additive manufacturing methods for forming diamond tools are briefly compared. Finally, the future research priorities are prospected and some suggestions are put forward.

-

Key words:

- additive manufacturing /

- diamond tools /

- matrix material /

- interface combination

-

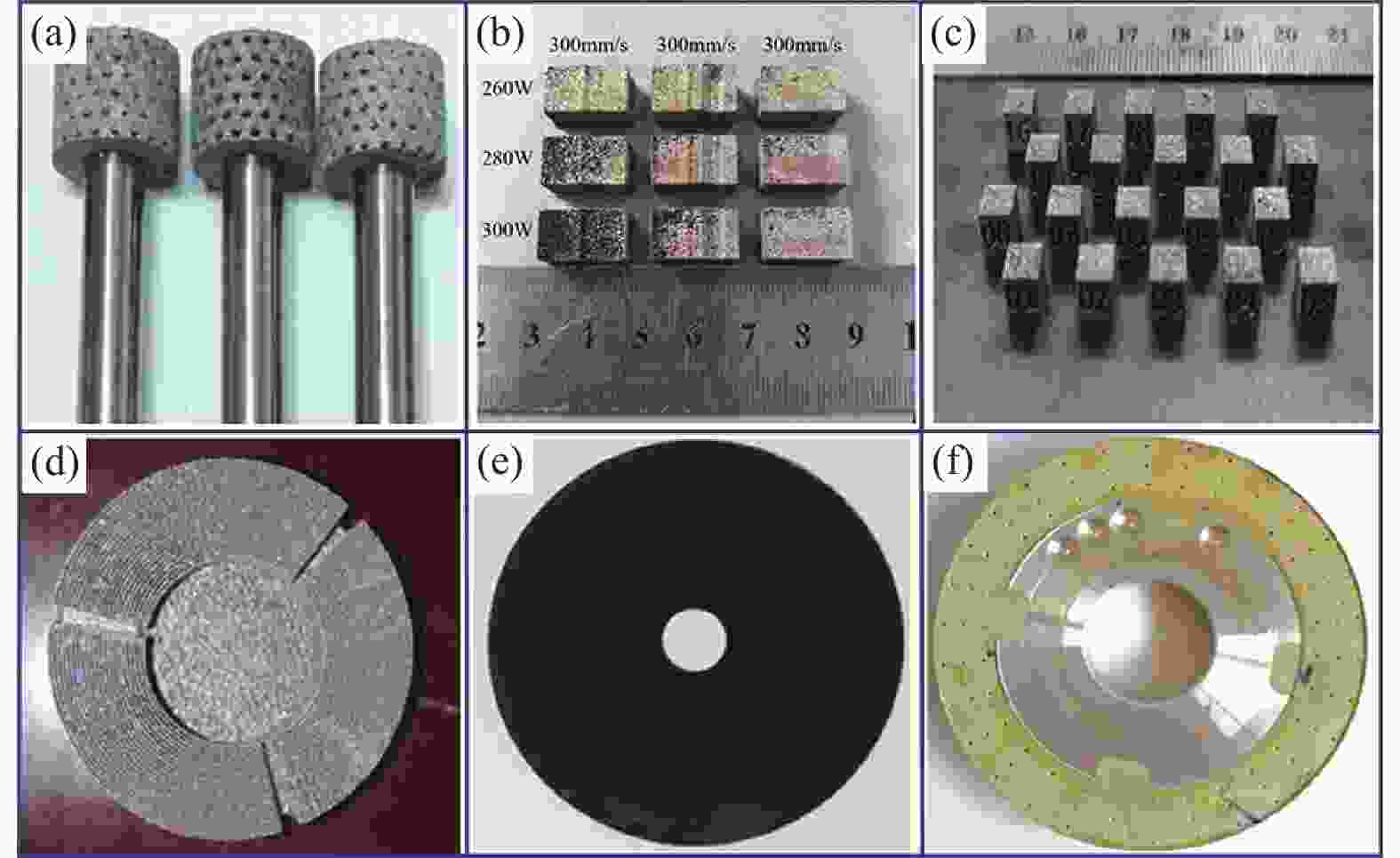

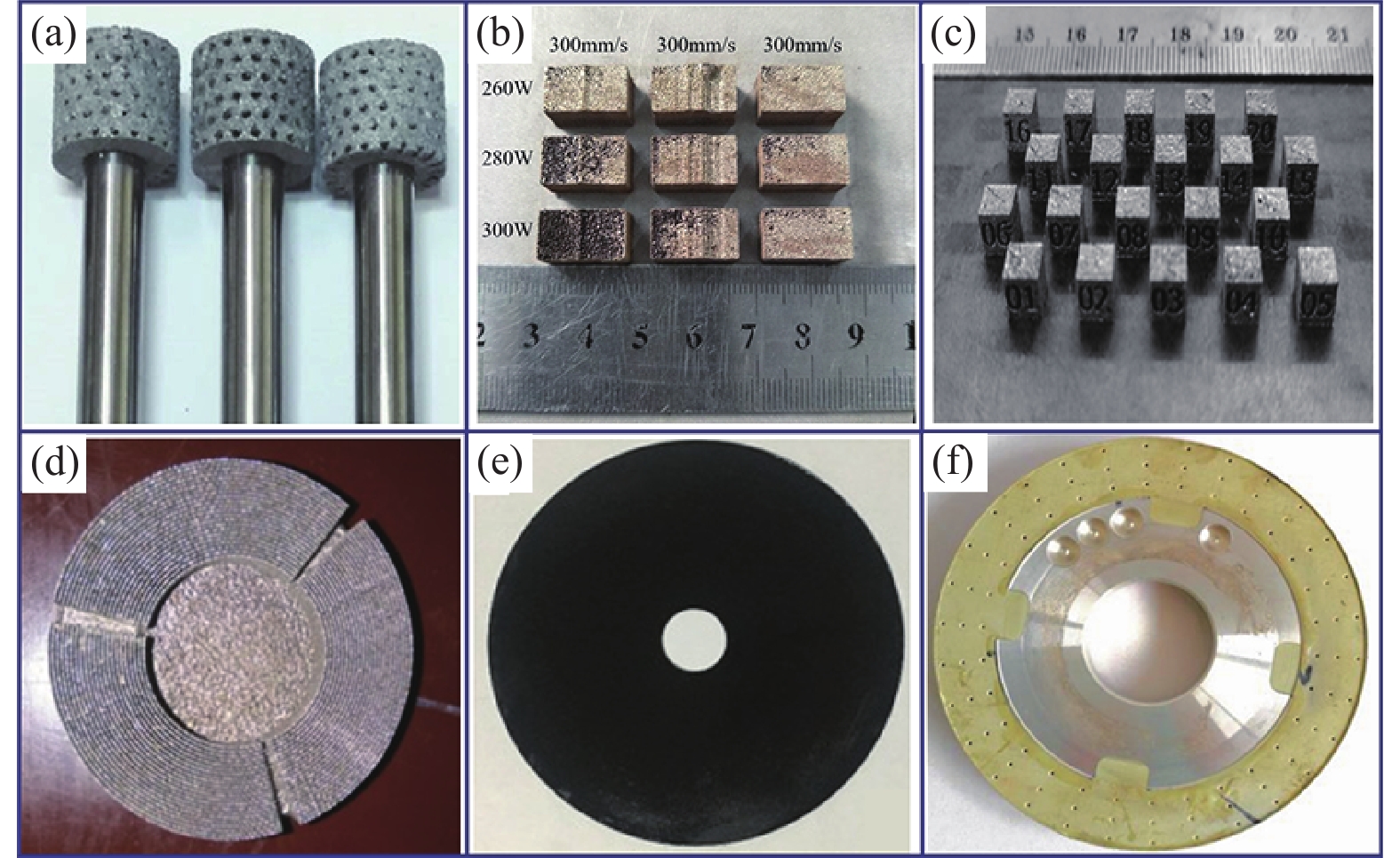

图 1 AM成形的金刚石工具

(a)八面通孔砂轮Porous grinding wheel (b)Cu-Sn-Ti结合剂工作层Cu-Sn-Ti binder working layer (c)Ti6Al4V结合剂工作层Ti6Al4V binder working layer(d)栅格状砂轮Grid-shaped grinding wheel(e)Co-Cr-Mo结合剂砂轮 Co-Cr-Mo binder grinding wheel(f)尼龙填料结合剂砂轮Nylon filler binder grinding wheel

Figure 1. Diamond tools formed by AM

表 1 不同AM工艺成形金刚石工具情况对比

Table 1. Comparison of different AM processes

成形工艺 常用胎体材料 材料成形方式 胎体与金刚石结合强度 金刚石热损伤及石墨化 生产成本 常用后处理方法 SLM 金属 熔化–凝固 强 严重 高 热处理 SLS 金属、陶瓷、高分子 半固态液相烧结 较强 较轻 中 清粉处理 SLA 光敏树脂 液态–固态 适中 轻微 低 后固化、缺陷处修补 -

[1] 陈石林. 聚晶金刚石复合体界面及复合机理的研究 [D]. 长沙: 中南大学, 2004.CHEN Shilin. Study on interface and composite mechanism of polycrystalline diamond composite [D]. Changsha: Central South University, 2004. [2] 阎雄伟. 3D打印在复杂钣金试制焊接工装中的应用 [J]. 模具制造,2019,19(11):59-61.YAN Xiongwei. Application of 3D printing in complex sheet metal trial welding tooling [J]. Mold Manufacturing,2019,19(11):59-61. [3] TIAN C, LI X, ZHANG S, et al. Porous structure design and fabrication of metal-bonded diamond grinding wheel based on selective laser melting (SLM) [J]. The International Journal of Advanced Manufacturing Technology,2019,100(5/6/7/8):1451-1462. doi: 10.1007/s00170-018-2734-y [4] GAN J, GAO H, WEN S, et al. Simulation, forming process and mechanical property of Cu-Sn-Ti/diamond composites fabricated by selective laser melting [J]. International Journal of Refractory Metals and Hard Materials,2020,87:105144. doi: 10.1016/j.ijrmhm.2019.105144 [5] 张俊涛, 黄淼俊, 胡子健, 等. 选区激光熔化制备金刚石/TC4复合材料的成型工艺及性能分析 [J]. 机电信息,2021(15):4-5. doi: 10.3969/j.issn.1671-0797.2021.15.002ZHANG Juntao, HUANG Miaojun, HU Zijian, et al. Forming process and performance analysis of diamond /TC4 composites prepared by selective laser melting [J]. Mechanical and Electrical Information,2021(15):4-5. doi: 10.3969/j.issn.1671-0797.2021.15.002 [6] WU J, ZHANG S, QU F, et al. Matrix material for a new 3D-printed diamond-impregnated bit with grid-shaped matrix [J]. International Journal of Refractory Metals and Hard Materials,2019,82:199-207. doi: 10.1016/j.ijrmhm.2019.04.017 [7] 张绍和, 苏舟, 刘磊磊, 等. SLS和FDMS制造超薄金刚石锯片对比研究 [J]. 金刚石与磨料磨具工程,2022,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007ZHANG Shaohe, SU Zhou, LIU Leilei, et al. Comparative study on ultra-thin diamond saw blades made by SLS and FDMS [J]. Diamond & Abrasives Engineering,2022,41(1):38-43. doi: 10.13394/j.cnki.jgszz.2021.1.0007 [8] WU J, ZHANG S, LIU L, et al. Rock breaking characteristics of a 3D printing grid-matrix impregnated diamond bit [J]. International Journal of Refractory Metals and Hard Materials,2020,89:105212. doi: 10.1016/j.ijrmhm.2020.105212 [9] 陈家泓, 张凤林, 许琼生, 等. 选区激光烧结3D打印树脂结合剂金刚石砂轮初探 [J]. 超硬材料工程,2018,30(4):1-5. doi: 10.3969/j.issn.1673-1433.2018.04.001CHEN Jiahong, ZHANG Fenglin, XU Qiongsheng, et al. Research on fabrication of resin bond diamond grinding wheel using selective laser sintering technology [J]. Superhard Material Engineering,2018,30(4):1-5. doi: 10.3969/j.issn.1673-1433.2018.04.001 [10] CEPEDA-JIMÉNEZ C M, MOLINA- ALDAREGUIA J M, PÉREZ-PRADO M T. Effect of grain size on slip activity in pure magnesium polycrystals [J]. Acta Materialia,2015,84:443-456. doi: 10.1016/j.actamat.2014.10.001 [11] 周燕, 甘杰, 段隆臣, 等. 一种基于3D打印的热沉取心金刚石钻头及其制备方法: CN110344768A [P]. 2019-10-18.ZHOU Yan, GAN Jie, DUAN Longchen, et al. A heat sink coring diamond bit based on 3D printing and its preparation method: CN110344768A [P]. 2019-10-18. [12] YANG Z, HU J, LI K, et al. 3D Printing of diamond tools for dental ceramics processing [J]. Advanced Engineering Materials,2017,20(3):1700747. doi: 10.1002/adem.201700747 [13] 傅凤理, 戚晓红. 人造金刚石热性能分析 [J]. 磨料磨具与磨削,1994(3):10-13.FU Fengli, QI Xiaohong. Analysis of thermal properties of synthetic diamond [J]. Abrasives and Grinding,1994(3):10-13. [14] 苏振华, 刘刚, 代兵, 等. 选区激光熔化制备金刚石/铝复合材料的缺陷研究 [J]. 金刚石与磨料磨具工程,2020,40(3):46-51. doi: 10.13394/j.cnki.jgszz.2020.3.0007SU Zhenhua, LIU Gang, DAI Bing, et al. Study on defects of diamond/aluminum composites prepared by selective laser melting [J]. Diamond & Abrasives Engineering,2020,40(3):46-51. doi: 10.13394/j.cnki.jgszz.2020.3.0007 [15] 王丽莉, 万强, 胡文军, 等. 金刚石与石墨局域态密度和能带结构的第一原理分析 [J]. 计算机与应用化学,2010,27(6):735-738. doi: 10.3969/j.issn.1001-4160.2010.06.005WANG Lili, WAN Qiang, HU Wenjun, et al. The local states density and band structure of diamond and graphite studied by first principles molecular dynamics [J]. Computers and Applied Chemistry,2010,27(6):735-738. doi: 10.3969/j.issn.1001-4160.2010.06.005 [16] 高峰, 贾晓鹏, 王琰弟, 等. 人工合成的400目细颗粒金刚石与破碎料的热稳定性比较 [J]. 金刚石与磨料磨具工程,2008(3):1-4. doi: 10.3969/j.issn.1006-852X.2008.03.001GAO Feng, JIA Xiaopeng, WANG Yandi, et al. Comparison of thermal stability of synthetic and milled diamonds with grain size of 400 mesh [J]. Diamond & Abrasives Engineering,2008(3):1-4. doi: 10.3969/j.issn.1006-852X.2008.03.001 [17] SPIERINGS A B, LEINENBACH C, KENEL C, et al. Processing of metal-diamond-composites using selective laser melting [J]. Rapid Prototyping Journal,2014,21(2):130-136. doi: 10.1108/RPJ-11-2014-0156 [18] 柯明月. 金刚石颗粒表面镀覆铬包覆层的研究 [D]. 广州: 广东工业大学, 2013.KE Mingyue. Study on chromium coating on diamond particles [D]. Guangzhou: Guangdong University of Technology, 2013. [19] 郭晓光, 刘涛, 翟昌恒, 等. 过渡金属作用下的金刚石石墨化机理研究 [J]. 机械工程学报,2016,52(20):23-29. doi: 10.3901/JME.2016.20.023GUO Xiaoguang, LIU Tao, ZHAI Changheng, et al. Study on the mechanism of diamond graphite with the action of transition metals [J]. Journal of Mechanical Engineering,2016,52(20):23-29. doi: 10.3901/JME.2016.20.023 [20] XIE Z, GUO H, ZHANG Z, et al. Thermal expansion behaviour and dimensional stability of diamond/Cu composites with different diamond content [J]. Journal of Alloys and Compounds,2019,797:122-130. doi: 10.1016/j.jallcom.2019.05.077 [21] 陈振华. 现代粉末冶金技术 [M]. 第2版. 北京: 化学工业出版社, 2013.CHEN Zhenhua. Modern powder metallurgy technology [M]. 2nd ed. Beijing: Chemical Industry Press, 2013. [22] 张俊涛. 金刚石颗粒增强工具材料3D打印研究 [D]. 广州: 广东工业大学.ZHANG Juntao. Research on 3D printing of diamond particle reinforced tool materials [D]. Guangzhou: Guangdong University of Technology. [23] 顾冬冬, 沈以赴. 基于选区激光熔化的金属零件快速成形现状与技术展望 [J]. 航空制造技术,2012(8):32-37. doi: 10.3969/j.issn.1671-833X.2012.08.003GU Dongdong, SHEN Yifu. Research status and technical prospect of rapid manufacturing of metallic part by selective laser melting [J]. Aeronautical Manufacturing Technology,2012(8):32-37. doi: 10.3969/j.issn.1671-833X.2012.08.003 [24] 李鹏, 熊惟皓. 选择性激光烧结的原理及应用 [J]. 材料导报,2002,16(6):56-58. doi: 10.3321/j.issn:1005-023X.2002.06.016LI Peng, XIONG Weihao. Principles and applications of selective laser sintering [J]. Materials Reports,2002,16(6):56-58. doi: 10.3321/j.issn:1005-023X.2002.06.016 [25] 闫春泽. 高分子材料3D打印成形原理与实验 [M]. 武汉: 华中科技大学出版社, 2019.YAN Chunze. Principle and experiment of 3D printing forming of polymer materials [M]. Wuhan: Huazhong University of science and Technology Press, 2019. [26] ZAKERI S, VIPPOLA M, LEVNEN E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography [J]. Additive Manufacturing,2020,35:101177. doi: 10.1016/j.addma.2020.101177 [27] 刘洪成, 王琦, 王珏, 等. 金刚石工具结合剂的研究进展 [J]. 广州化工,2017,45(14):40-41. 44. doi: 10.3969/j.issn.1001-9677.2017.14.015LIU Hongcheng, WANG Qi, WANG Yu, et al. Research progress on diamond tool binders [J]. Guangzhou Chemical Industry,2017,45(14):40-41. 44. doi: 10.3969/j.issn.1001-9677.2017.14.015 [28] BORRELLO J, NASSER P, LATRIDIS J C, et al. 3D printing a mechanically-tunable acrylate resin on a commercial DLP-SLA printer [J]. Additive Manufacturing,2018,23:374-380. doi: 10.1016/j.addma.2018.08.019 [29] 高涛. 光固化树脂结合剂磨具的关键技术研究 [D]. 杭州: 浙江工业大学, 2007.GAO Tao. Research on key technology of light curing resin bonded abrasive tools [D]. Hangzhou: Zhejiang University of Technology, 2007. [30] 张云鹤, 黄景銮, 宋运运, 等. 3D打印金刚石工具的研究进展 [J]. 金刚石与磨料磨具工程,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006ZHANG Yunhe, HUANG Jingluan, SONG Yunyun, et al. Research progress of 3D printing diamond tools [J]. Diamond & Abrasives Engineering,2021,41(3):40-47. doi: 10.13394/j.cnki.jgszz.2021.3.0006 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS