Influence of hot-pressed sintering temperature on properties of SiCp/Al composites

-

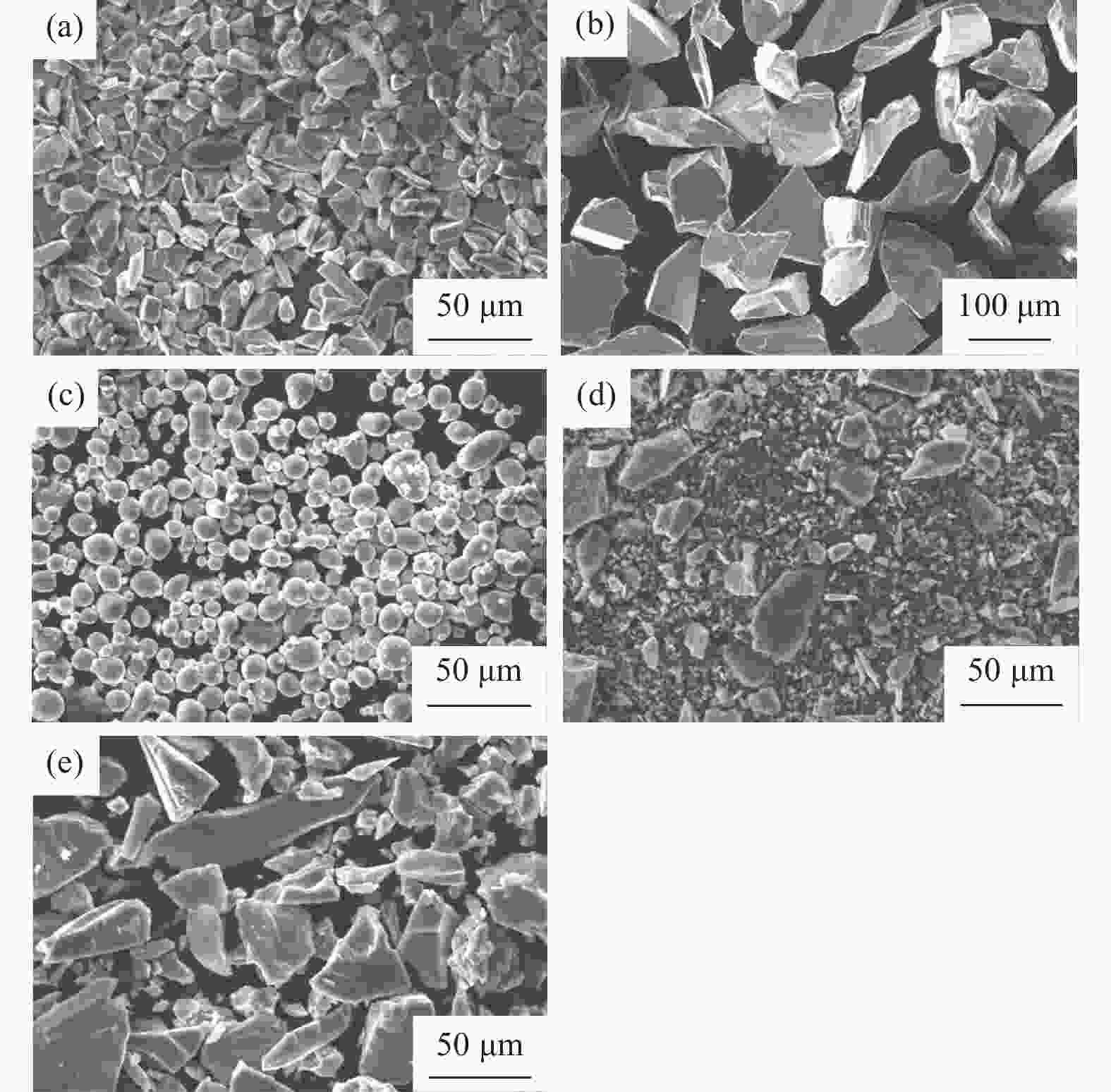

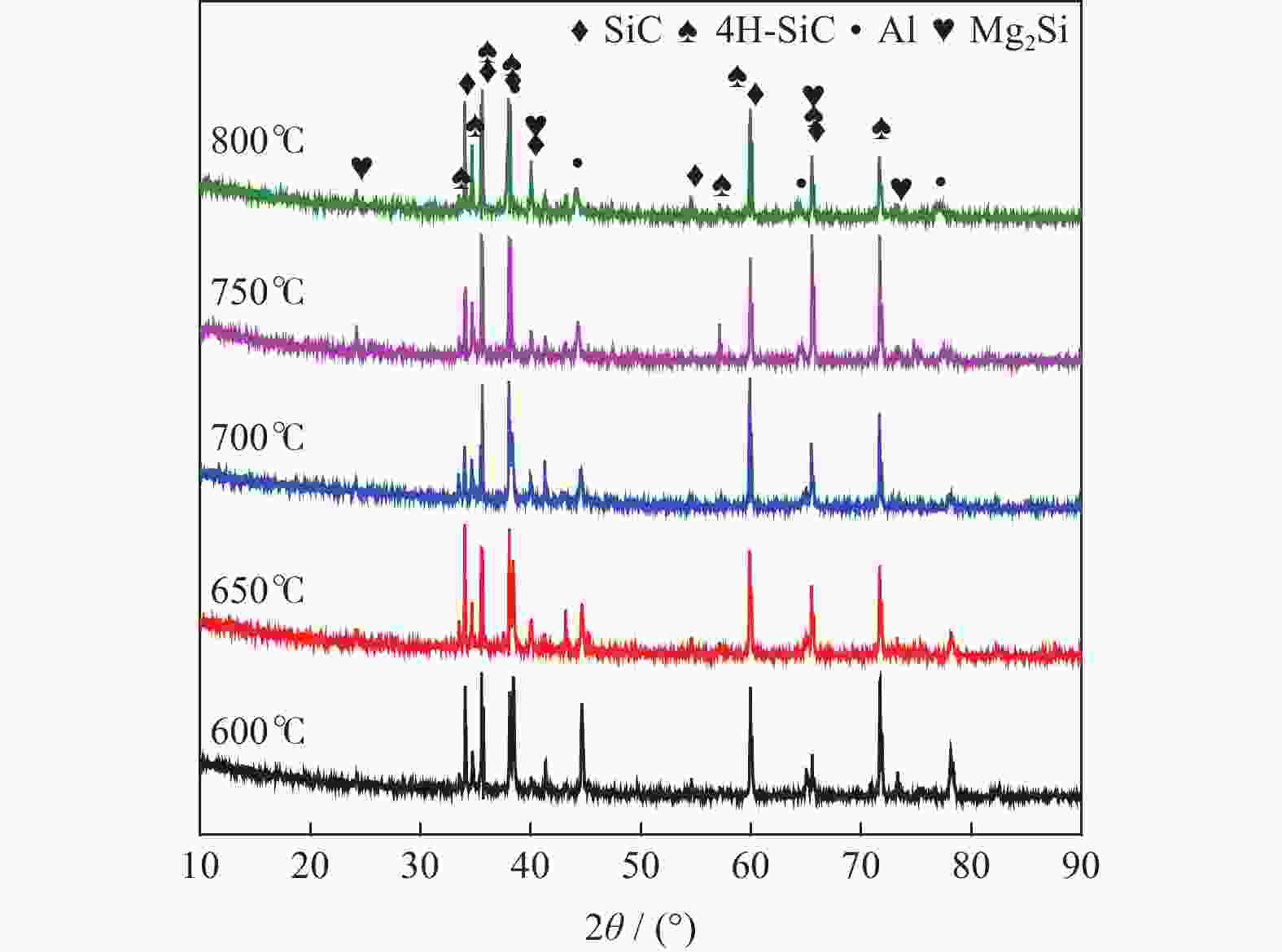

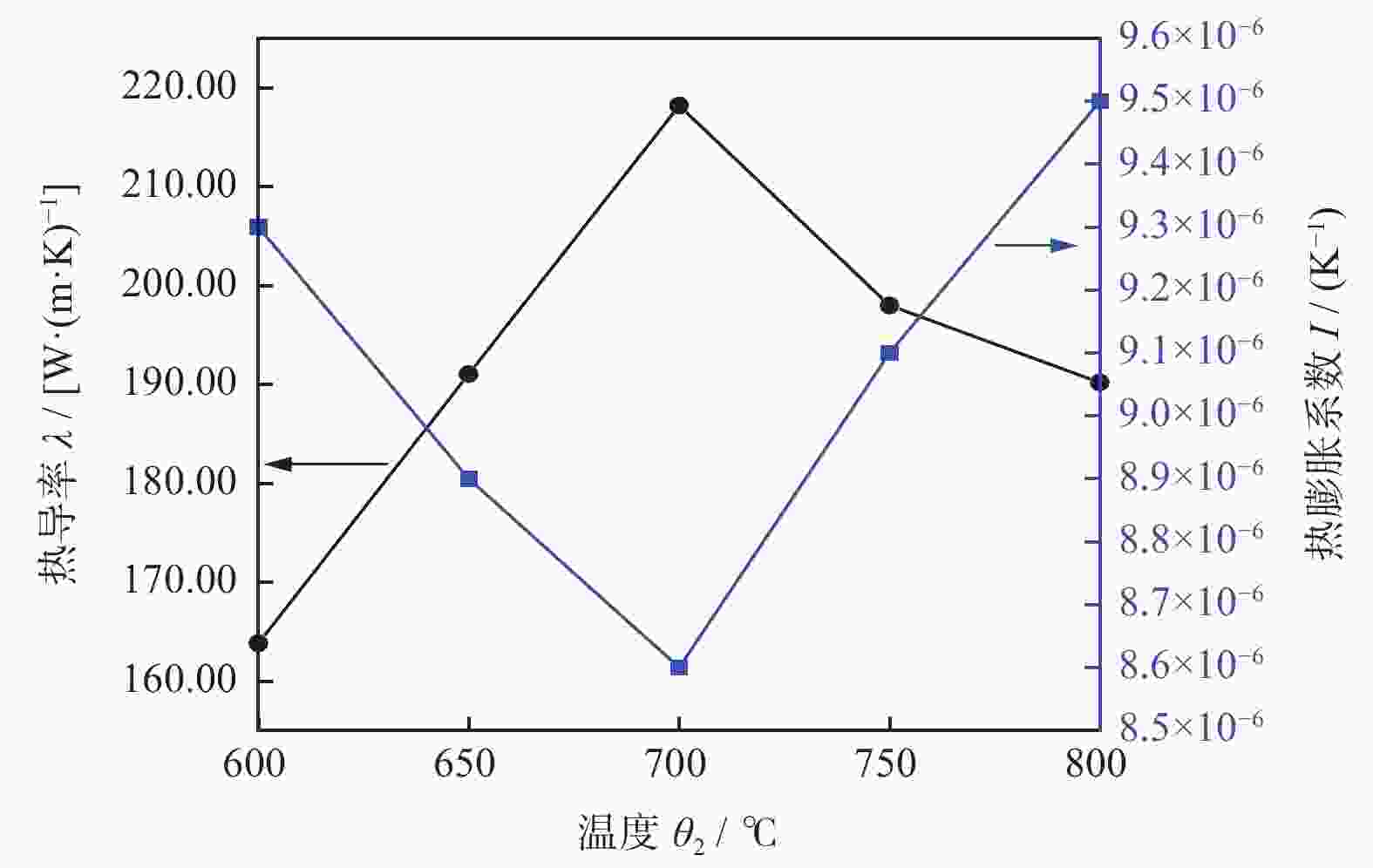

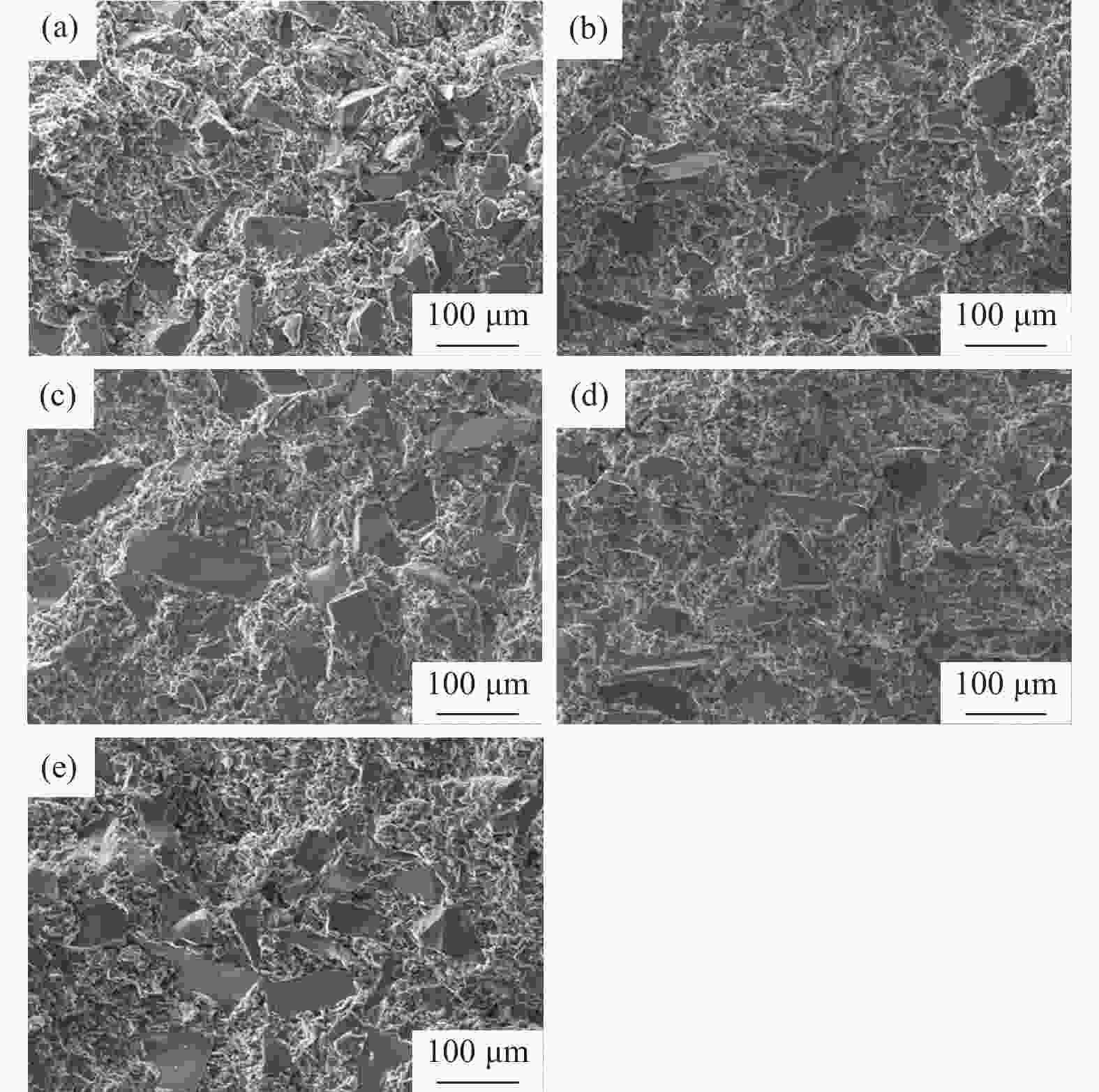

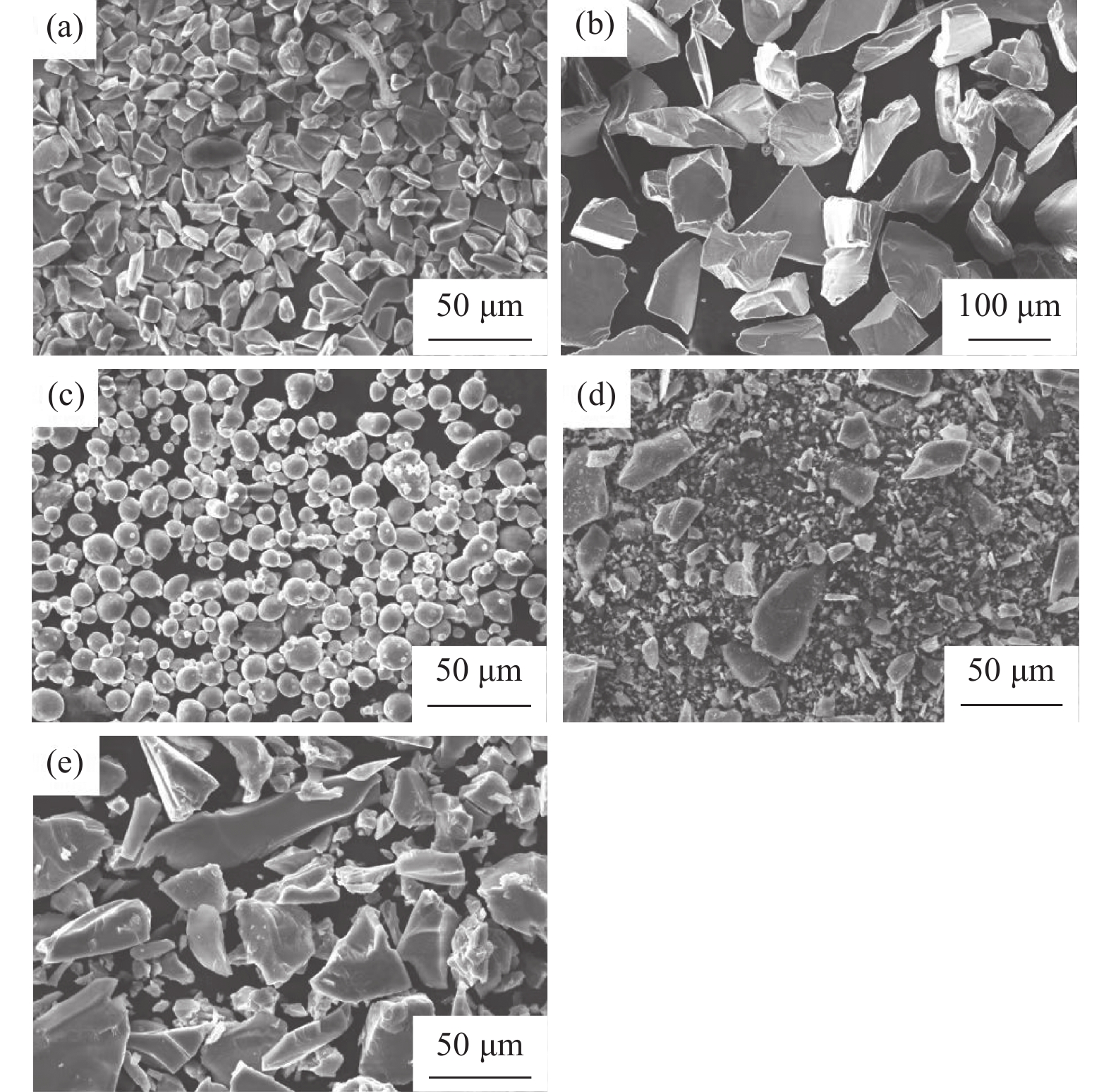

摘要: 采用热压烧结法制备SiCp/Al复合材料,研究烧结温度对复合材料性能的影响。用X射线衍射、阿基米德排水法、三点弯曲法和扫描电镜分析复合材料样品的物相组成、相对密度、力学性能及微观形貌,并测定其热导率和热膨胀系数。结果表明: SiCp/Al复合材料由SiC、Al和Mg2Si相组成,加入Mg提高了基体和SiC颗粒之间的浸润性。随着烧结温度升高,复合材料的硬度和抗弯强度先增加后下降,在700 ℃时达到最大值98 HRB和275 MPa;复合材料的热导率先增加后下降,热膨胀系数先下降后增加,在700 ℃时分别达到最大值218.187 W/(m·K)和最小值8.6 × 10−6 K−1。

-

关键词:

- SiCp/Al复合材料 /

- 热压温度 /

- 力学性能 /

- 显微结构 /

- 热学性能

Abstract: SiCp/Al composites were prepared by hot-pressing sintering method, and the effect of sintering temperature on the properties of the composites was studied. The phase compositions, relative density, mechanical properties and micro morphology of the composite samples were analyzed through X-ray diffraction, Archimedes drainage method, the three-point bending method and scanning electron microscope. Additionally, the thermal conductivity and thermal expansion coefficient were measured. The results show that SiCp/Al composites are composed of SiC, Al and Mg2Si phases. The addition of Mg improves the wettability between the matrix and SiC particles. With the increase of sintering temperature, the hardness and bending strength of the composites first increase and then decrease, reaching the maximum values of 98 HRB and 275 MPa at 700 ℃, respectively. The thermal conductivity of the composites first increases and then decreases, and the thermal expansion coefficient first decreases and then increases, reaching the maximum value of 218.187 W/(m·K) and the minimum value of 8.6 × 10−6 K−1 at 700 ℃, respectively. -

表 1 SiC颗粒增强Al的复合材料制备工艺特点

Table 1. Preparation process characteristics of SiC particle reinforced Al composites

制备方法 工艺特点 优点 缺点 粉末冶金法 工艺设备成熟,但结构复杂 成分自由度宽,

制得的材料性能及稳定性较好烧结不易控制,成本高 搅拌铸造法 工艺设备简单,成本低廉 可进行批量化工业生产 材料中的缺陷难以解决,

制品体积分数较低压力铸造法 工艺成熟,成本低 生产周期短,可批量生产 工艺难度大 喷射共沉积法 对设备要求低 工序简单,流程缩短,效率提高,

一次成形,适用面广成本昂贵,过程难控制 无压自浸渗法 工艺相对简单 不用考虑系统压力,成本低,

可达到净成形基体与增强相的润湿性较差 热等静压法 工艺相对简单 力学性能好,实用范围广,

材料利用率高封装技术难以掌控 表 2 SiCp/Al复合材料的热性能

Table 2. Thermal properties of SiCp/Al composites

名称 烧结温度

θ1

℃导热率

$ \lambda $

W/(m·K)热膨胀系数

l

K−1参考文献 60vol%SiCp/Al 600 165 5.00 × 10−6 [17] 50vol%SiCp/6061Al 680 153 8.10 × 10−6 [18] 60vol%SiCp/Al-5Si-2.5Mg 510 214 9.80 × 10−6 [19] (50~70)vol%SiCp/Al 1 100 120~177 (6~10) × 10−6 [20] 55vol%SiCp/Al (CPS) 200 10.56 × 10−6 [21] 60vol%SiCp/Al (PCC-AFT) 175 8.00 × 10−6 [21] 表 3 实验原料及参数

Table 3. Experimental raw material parameters

原料 体积分数

φ

%D10

μmD50

μmD90

μm氧含量

ωo

%碳含量

ωc

%硫含量

ωs

%密度

ρ1

g/cm3松装密度

ρ2

g/cm3振实密度

ρ3

g/cm3SiC-1 32 8.59 14.22 22.86 0.260 10.79 0.005 3.20 1.19 1.40 SiC-2 32 59.31 94.95 148.90 0.310 8.46 0.005 3.20 1.71 1.70 Al粉 14 10.61 17.10 27.49 0.350 0.16 0.005 2.70 1.15 1.50 镁铝合金粉 20 11.98 32.34 70.55 0.009 0.35 0.003 2.20 0.63 1.08 硅粉 2 2.15 12.86 63.64 0.460 0.03 0.003 2.34 0.44 0.90 表 4 样品相对密度与温度的关系

Table 4. Relationship between relative density and temperature of samples

温度

θ2 / ℃理论密度

ρ理 / (g·cm−3)实测密度

ρ测 /(g·cm−3)相对密度

ρ相对 / %600 2.93 2.77 94.8 650 2.93 2.81 96.2 700 2.93 2.87 98.1 750 2.93 2.86 97.9 800 2.93 2.79 95.5 -

[1] 董翠鸽, 王日初, 彭超群, 等. SiCp/Al复合材料研究进展 [J]. 中国有色金属学报,2021,11:3161-3181. doi: 10.11817/j.ysxb.1004.0609.2021-42310DONG Cuige, WANG Richu, PENG Chaoqun, et al. Research progress in SiCp/Al composites [J]. The Chinses Journal of Nonferrous Metals,2021,11:3161-3181. doi: 10.11817/j.ysxb.1004.0609.2021-42310 [2] LEE H, SOHN S S, JEON C, et al. Dynamic compressive deformation behavior of SiC-particulate-reinforced A356 Al alloy matrix composites fabricated by liquid pressing process [J]. Materials Science & Engineering,2017,680(5):368-377. [3] 刘春轩, 罗任, 谢屹, 等. 轨道交通制动盘用颗粒增强铝基复合材料研究及进展 [J]. 现代城市轨道交通,2022(7):11-16.LIU Chunxuan, LUO Ren, XIE Yi, et al. Research progress on particle reinforced aluminummatrix composites for brake discs in rail transit [J]. Modern Urban Transit,2022(7):11-16. [4] 周岩, 张冬云, 王卫东, 等. 选区激光熔化成形碳化硅颗粒增强铝基复合材料研究现状及航空航天应用 [J]. 航空制造技术,2018,61(10):68-73. doi: 10.16080/j.issn1671-833x.2018.10.068ZHOU Yan, ZHANG Dongyun, WANG Weidong, et al. Current situation and aerospace applications analysis based on SiC particle reinforced aluminum matrix composites manufactured by selective laser melting [J]. Aeronautical Manufacturing Technology,2018,61(10):68-73. doi: 10.16080/j.issn1671-833x.2018.10.068 [5] 修子扬, 张强, 王子鸣, 等. 电子封装用SiCp/6063复合材料的制备与性能研究 [J]. 精密成形工程,2018,10(1):91-96. doi: 10.3969/j.issn.1674-6457.2018.01.011XIU Ziyang, ZHANG Qiang, WANG Ziming, et al. Preparation and properties of SiCp/6063 composites for electronic packaging [J]. Journal of Netshape Forming Engineering,2018,10(1):91-96. doi: 10.3969/j.issn.1674-6457.2018.01.011 [6] 刘相权. 高体积分数SiC颗粒增强Al基复合材料的制备和性能研究 [D]. 长沙: 中南大学, 2008.LIU Xiangquan. Preparation and performance study of high volume fraction SiC particles enhanced Al matrix composites [D]. Changsha: Central South University, 2008. [7] 崔岩, 李丽富, 李景林, 等. 制备空间光机结构件的高体份SiC/Al复合材料 [J]. 光学精密工程,2007(8):1175-1180. doi: 10.3321/j.issn:1004-924x.2007.08.004CUI Yan, LI Lifu, LI Jinglin, et al. High volume fraction SiC/Al composites for space-based optomechanical structures [J]. Optics and Precision Engineering,2007(8):1175-1180. doi: 10.3321/j.issn:1004-924x.2007.08.004 [8] 王丽雪, 曹丽云, 刘海鸥. 铝基复合材料研究的进展 [J]. 轻合金加工技术,2005(8):10-12, 52. doi: 10.3969/j.issn.1007-7235.2005.08.003WANG Lixue, CAO Liyun, LIU Haiou. Progress of aluminium matrix composites [J]. Light Alloy Fabrication Technology,2005(8):10-12, 52. doi: 10.3969/j.issn.1007-7235.2005.08.003 [9] 张国政, 吕栋腾, 吴治明. 碳化硅颗粒增强铝基复合材料的制备及应用的研究 [J]. 新技术新工艺,2010(11):60-62. doi: 10.3969/j.issn.1003-5311.2010.11.022ZHANG Guozheng, LYU Dongteng, WU Zhiming. Research of fabrication and application for SiCp particle reinforced aluminum matrix composites [J]. New Technology & New Process,2010(11):60-62. doi: 10.3969/j.issn.1003-5311.2010.11.022 [10] 齐云国. SiCp/Al复合材料制备及其组织与力学性能研究 [D]. 西安: 西安理工大学, 2009.QI Yunguo. Preparation of SiCp/AI composites and its microstructures and mechanical properties [D]. Xi'an: Xi'an University of Technology, 2009. [11] 崔葵馨, 常兴华, 李希鹏, 等. 高体积分数铝碳化硅复合材料研究进展 [J]. 材料导报,2012,26(S2):401-405. doi: 10.3969/j.issn.1005-023X.2012.z1.108CUI Kuixin, CHANG Xinghua, LI Xipeng, et al. Advances in research on high volume fraction aluminum silicon carbide composites [J]. Materials Reports,2012,26(S2):401-405. doi: 10.3969/j.issn.1005-023X.2012.z1.108 [12] 邹镕, 罗兵辉, 柏振海, 等. 6066Al/SiCp复合材料制备工艺与性能 [J]. 铝加工,2013(5):9-14. doi: 10.3969/j.issn.1005-4898.2013.05.02ZOU Rong, LUO Binghui, BAI Zhenhai, et al. Preparation and properties of 6066Al/SiCp composites [J]. Aluminium Fabrication,2013(5):9-14. doi: 10.3969/j.issn.1005-4898.2013.05.02 [13] 金鹏, 肖伯律, 王全兆, 等. 热压烧结温度对SiC颗粒增强铝基复合材料微观组织及力学性能的影响 [J]. 金属学报,2011,47(3):298-304.JIN Peng, XIAO Bolu, WANG Quanzhao, et al. Effect of hot pressing temperature on microstructure and mechanical properties of SiC particle reinforced aluminum matrix composites [J]. Acta Metallurgica Sinica,2011,47(3):298-304. [14] 原国森, 李明科, 王振永, 等. 烧结温度对SiCp/6061Al复合材料组织和性能的影响 [J]. 热加工工艺,2017,46(12):123-125.YUN Guosen, LI Mingke, WANG Zhenyong, et al. Effect of sintering temperature on mechanical properties and microstructure of SiCp/6061Al composite [J]. Hot Working Technology,2017,46(12):123-125. [15] 王海龙, 张锐, 刘锁兵, 等. 烧结工艺对SiC/Cu–Al复合材料的力学性能及断裂行为的影响 [J]. 硅酸盐学报,2006(11):1315-1320. doi: 10.3321/j.issn:0454-5648.2006.11.005WANG Hailong, ZHANG Rui, LIU Suobing, et al. Effects of sintering process on mechanical properties and fracture behavior of SiC/Cu-AI composites [J]. Journal of the Chinese Ceramic Society,2006(11):1315-1320. doi: 10.3321/j.issn:0454-5648.2006.11.005 [16] 王晓阳, 朱丽娟, 刘越. 粉末冶金法制备AlSiC电子封装材料及性能 [J]. 电子与封装,2007(5):9-11, 15. doi: 10.3969/j.issn.1681-1070.2007.05.003WANG Xiaoyang, ZHU Lijuan, LIU Yue. Properties of AlSiC electronic packaging composites fabricated by P/M Technology [J]. Electronics & Packaging,2007(5):9-11, 15. doi: 10.3969/j.issn.1681-1070.2007.05.003 [17] 刘兴丹, 阎峰云, 赵红娟, 等. 烧结温度对SiCp/Al复合材料组织与性能的影响 [J]. 粉末冶金材料科学与工程,2017,22(1):20-25. doi: 10.3969/j.issn.1673-0224.2017.01.004LIU Xingdan, YAN Fengyun, ZHAO Hongjuan, et al. Effect of sintering temperature on microstructure and properties of SiCpAl composites [J]. Materials Science and Engineering of Powder Metallurgy,2017,22(1):20-25. doi: 10.3969/j.issn.1673-0224.2017.01.004 [18] MAO X, HONG Y, WANG B, et al. Fabrication, microstructures and properties of 50vol.% SiCp/6061Al composites via a pressureless sintering technique [J]. Powder Metallurgy,2017:1-9. [19] 王武杰, 洪雨, 吴玉程. SiC粒径比及体积比对SiCp/Al-5Si-2.5Mg复合材料组织及性能影响 [J]. 材料热处理学报,2018,39(7):7-14. doi: 10.13289/j.issn.1009-6264.2018-0121WANG Wujie, HONG Yu, WU Yucheng. Effect of SiC particle size ratio and volume fraction ratio on microstructure and properties of SiCp/Al-5Si-2.5Mg composites [J]. Transactions of Materials and Heat Treatment,2018,39(7):7-14. doi: 10.13289/j.issn.1009-6264.2018-0121 [20] LEE H S, JEON K Y, KIM H Y, et al. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications [J]. Journal of Materials Science,2000,35(24):6231-6236. doi: 10.1023/A:1026749831726 [21] 钟鼓, 吴树森, 万里. 高SiCp或高Si含量电子封装材料研究进展 [J]. 材料导报,2008(2):13-17. doi: 10.3321/j.issn:1005-023X.2008.02.004ZHONG Gu, WU Shusen, WAN Li. Research development of electronic packaging materials with high SiCp or Si content [J]. Materials Reports,2008(2):13-17. doi: 10.3321/j.issn:1005-023X.2008.02.004 [22] 张全萍, 许伯藩, 吴新杰, 等. Mg对无压自浸渗制备SiCp/Al复合材料组织与性能的影响 [J]. 中国有色金属学报,2002(S1):147-150. doi: 10.3321/j.issn:1004-0609.2002.z1.032ZHANG Quanping, XU Bopan, WU Xinjie, et al. Effect of Mg on microstructure and properties of SiCp/ AI composite fabricated by pressureless infiltration [J]. The Chinese Journal of Nonferrous Metals,2002(S1):147-150. doi: 10.3321/j.issn:1004-0609.2002.z1.032 [23] 郭建, 沈宁福. SiC颗粒增强Al基复合材料中有害界面反应的控制 [J]. 材料科学与工程,2002(4):605-608, 600.GUO Jian, SHEN Ningfu. Control of detrimental interface reaction in SiCp/Al composite materials [J]. Materials Science and Engineering,2002(4):605-608, 600. [24] 茅学志, 洪雨, 张玉君, 等. 粉末冶金制备50%SiCp/Al复合材料的结构及性能 [J]. 中国有色金属学报,2017,27(12):2493-2500.MAO Xuezhi, HONG Yu, ZHANG Yujun, et al. Microstructures and properties of 50%SiCp/Al composites fabricated by powder metallurgy [J]. The Chinese Journal of Nonferrous Metals,2017,27(12):2493-2500. [25] 李少峰. 热压烧结制备碳化钛复合材料及其性能研究 [J]. 陶瓷学报,2022,43(1):100-106. doi: 10.13957/j.cnki.tcxb.2022.01.011LI Shaofeng. Preparation and properties of titanium carbide composites with hot pressing sintering [J]. Journal of Ceramics,2022,43(1):100-106. doi: 10.13957/j.cnki.tcxb.2022.01.011 [26] LAKSHMIPATHY J, KULENDRAN B. Reciprocating wear behaviour of 7075Al/SiC and 6061Al/Al2O3 composites: A study of effect of reinforcement, stroke and load [J]. Tribology in Industry,2014,36(2):117-126. [27] LIU Y, DAN Y, BIAN Y, et al. The thermal conductivity of a composite material with nano-sized nonmetal particles embedded in a metal matrix [J]. Journal of Alloys and Compounds,2019,801:136-141. doi: 10.1016/j.jallcom.2019.06.126 [28] 刘猛. 电子封装用高导热颗粒增强金属基复合材料制备与研究 [D]. 长沙: 国防科学技术大学, 2017.LIU Meng. Preparation and study of particle reinforced metal matrix composites with high thermal conductivity for electric packaging [D]. Changsha: National University of Defense Technology, 2017. [29] WU J, ZHANG H, YANG Z, et al. Mechanical and thermal properties of carbon nanotube/aluminum composites consolidated by spark plasma sintering [J]. Materials and Design,2012,41:344-348. doi: 10.1016/j.matdes.2012.05.014 [30] SUN J, CHEN G, WANG B, et al. Fabrication, microstructures, and properties of 50 vol.% SiCp/6061Al composites via hot pressing [J]. Journal of Materials Engineering and Performance,2019,28(5):2697-2706. [31] 黄思德. 碳化硅颗粒增强铝基复合材料的制备与性能研究 [D]. 合肥: 合肥工业大学, 2012.HUANG Side. Study on fabrication and properties of silicon carbide particle reinforced aluminum matrix composites [D]. Hefei: Hefei University of Technology, 2012. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS