Study on electrochemical mechanical polishing process of silicon carbide crystal

-

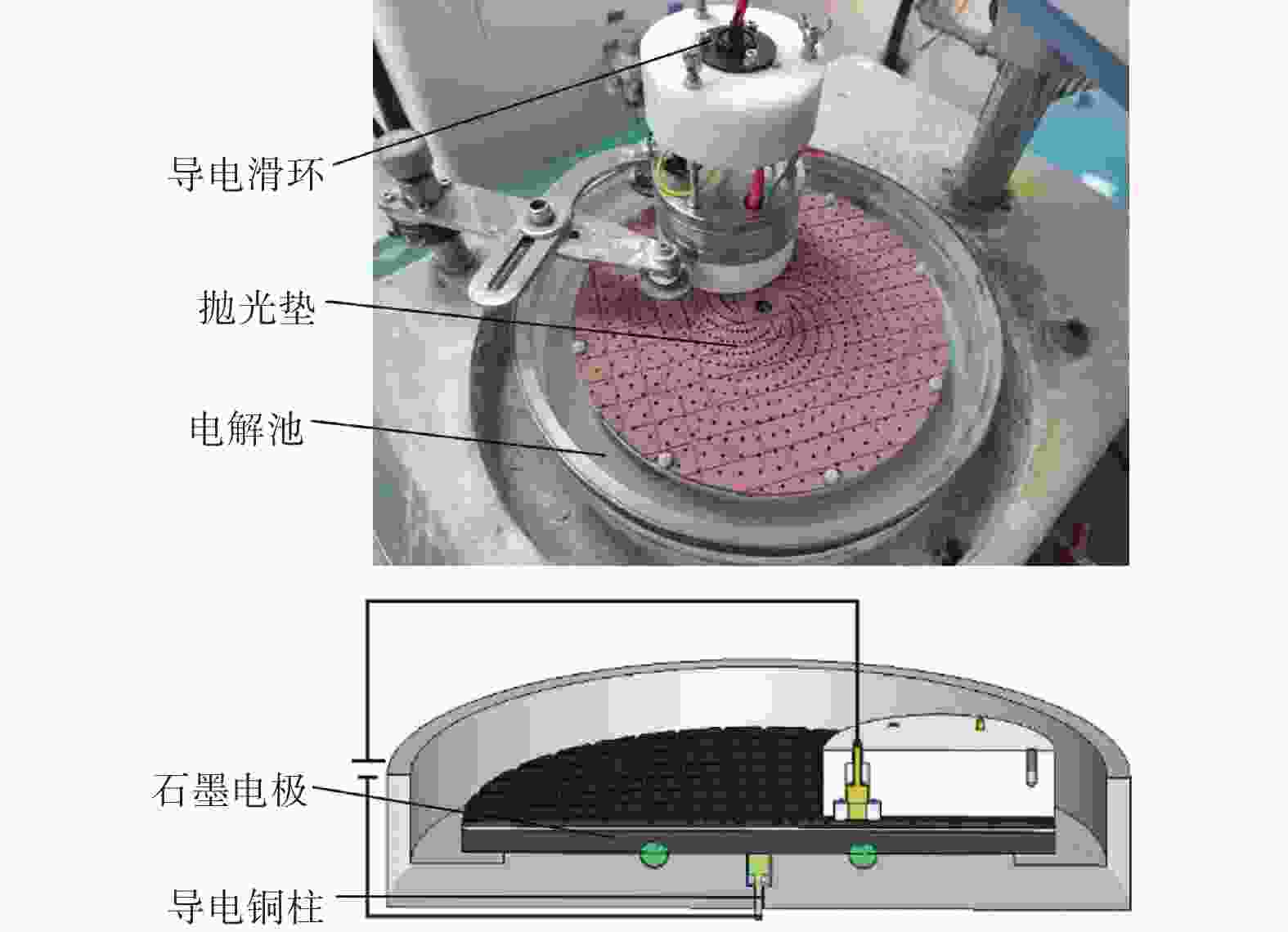

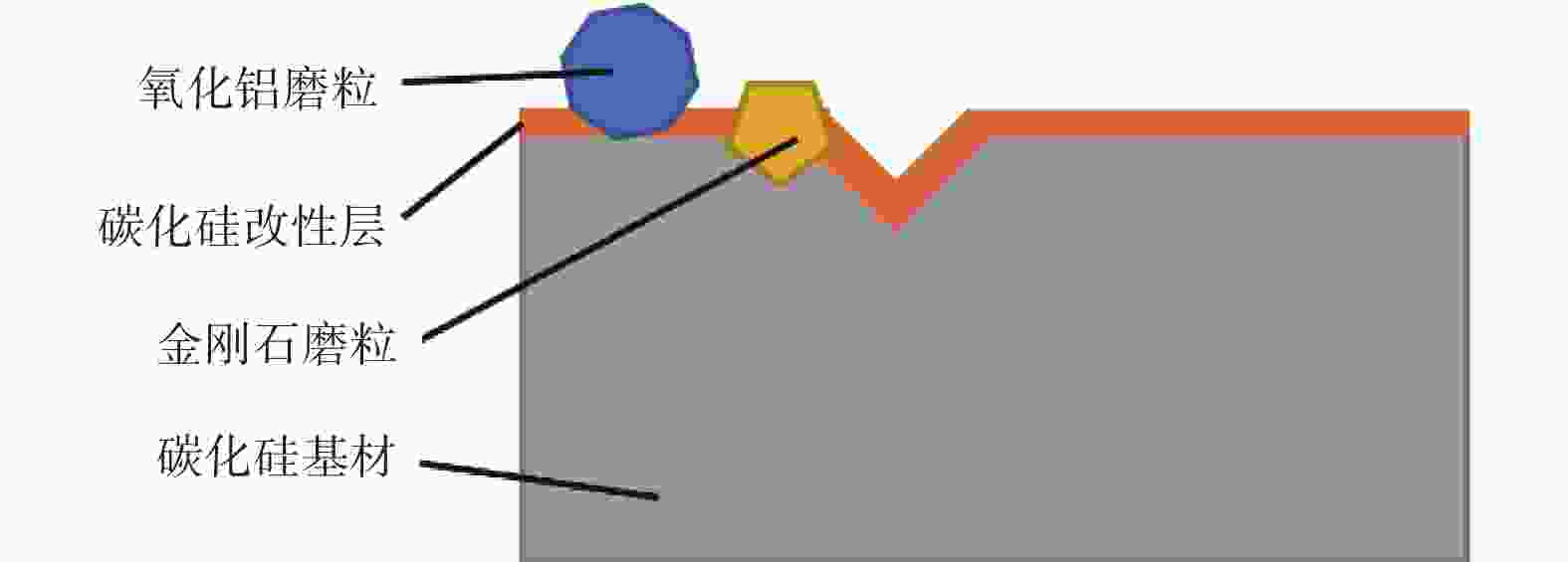

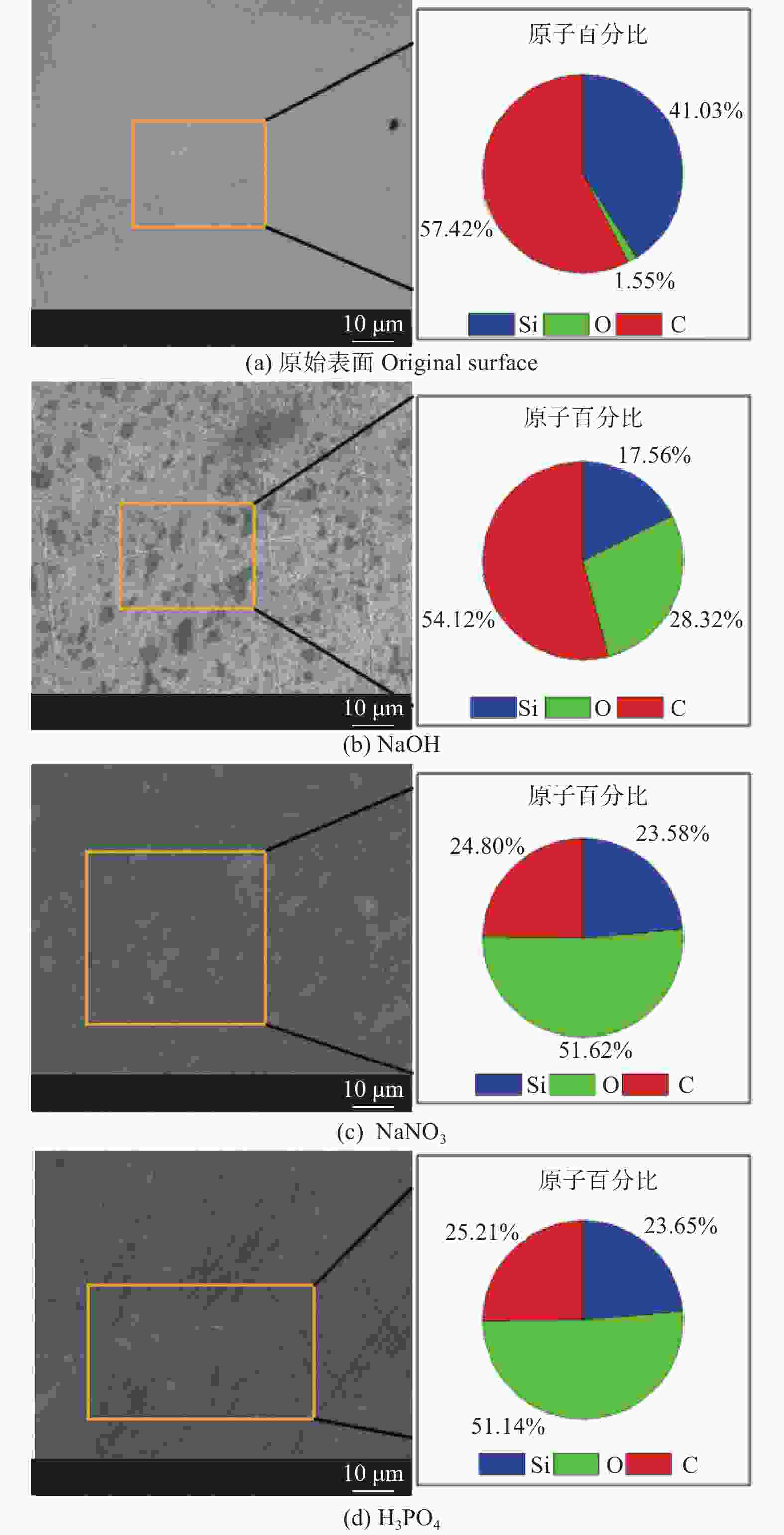

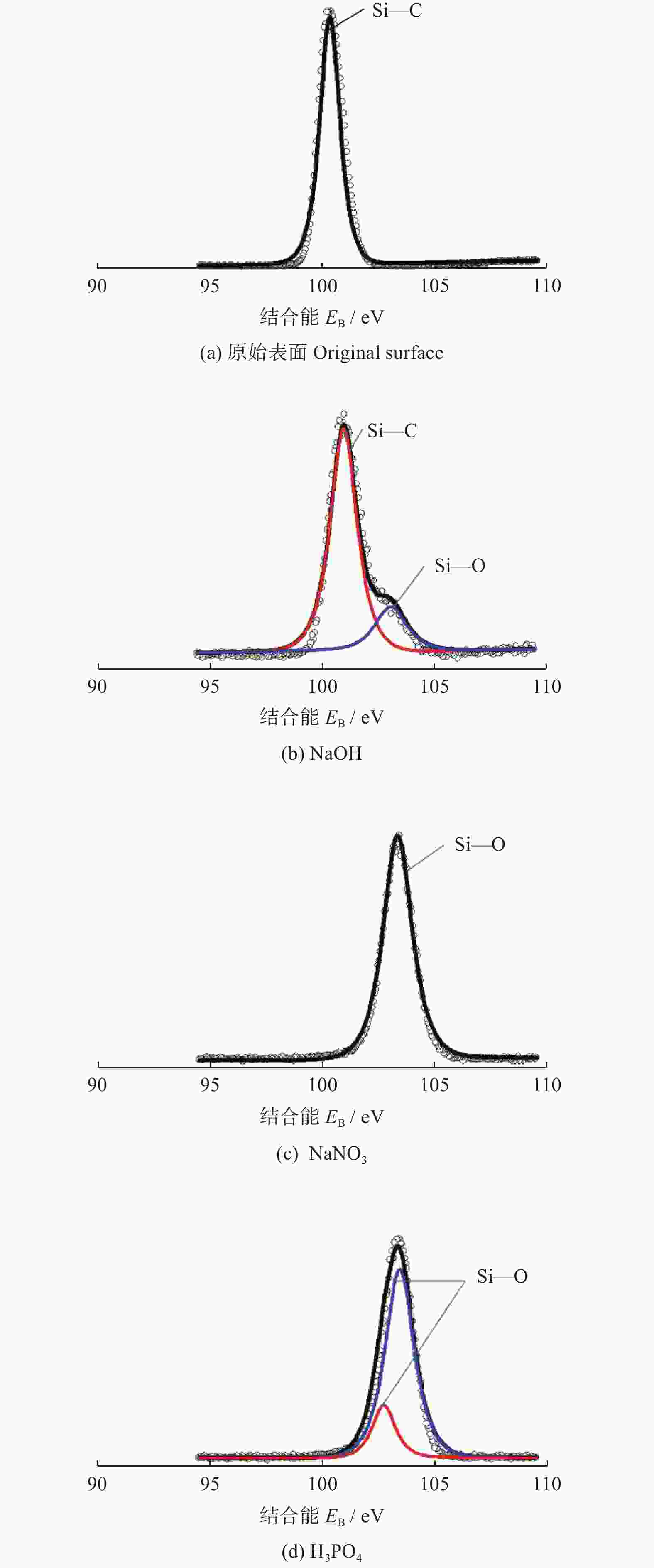

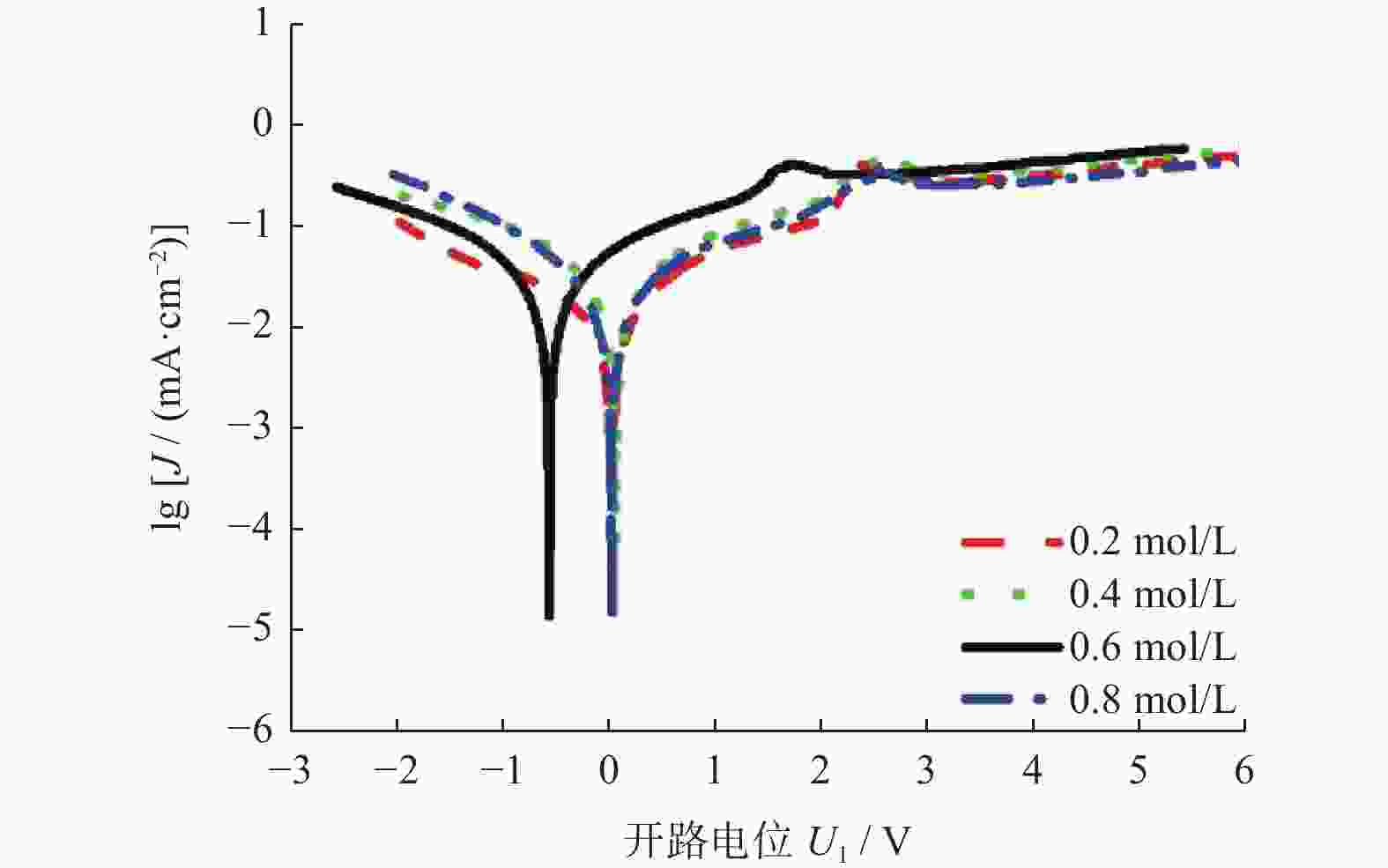

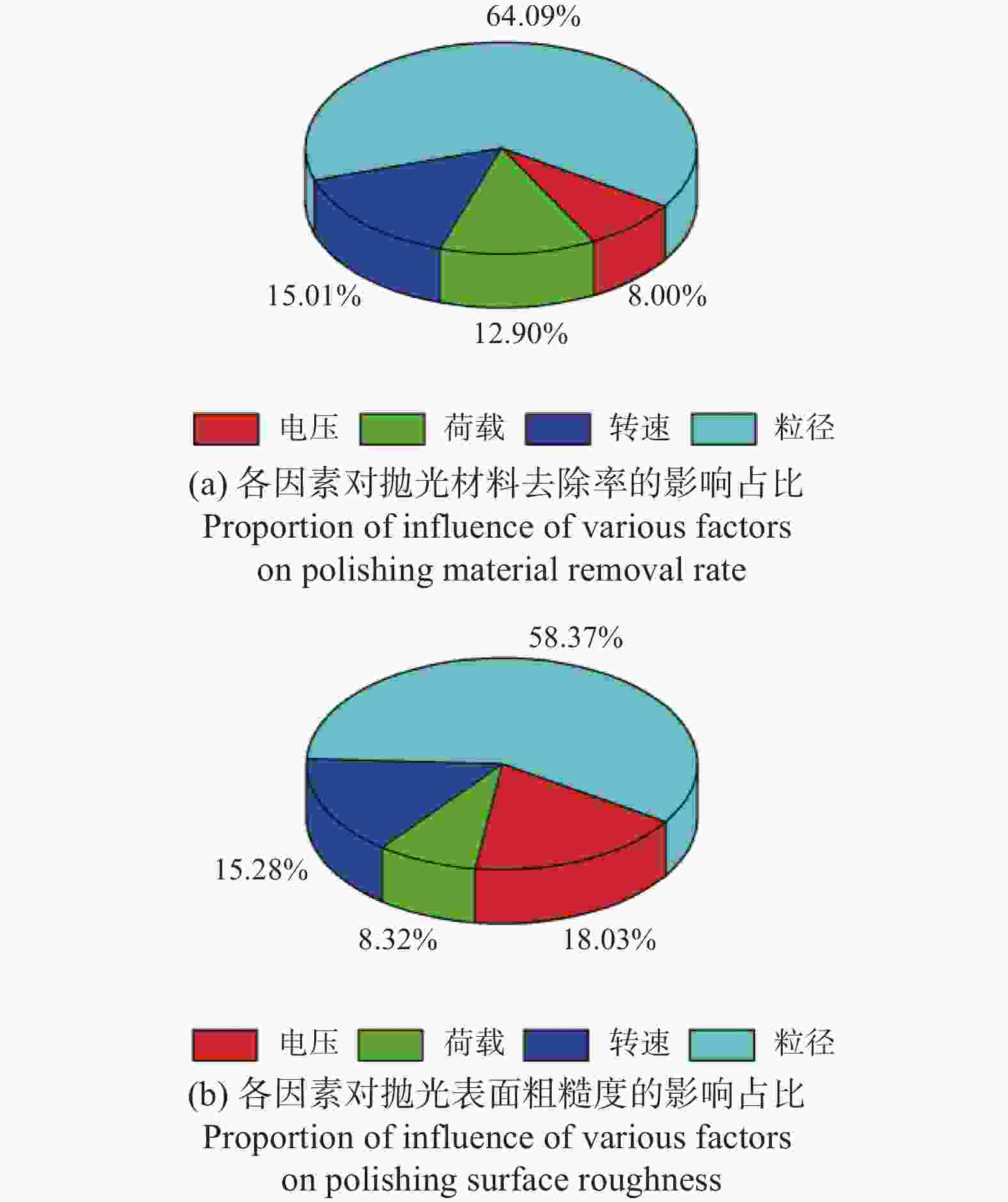

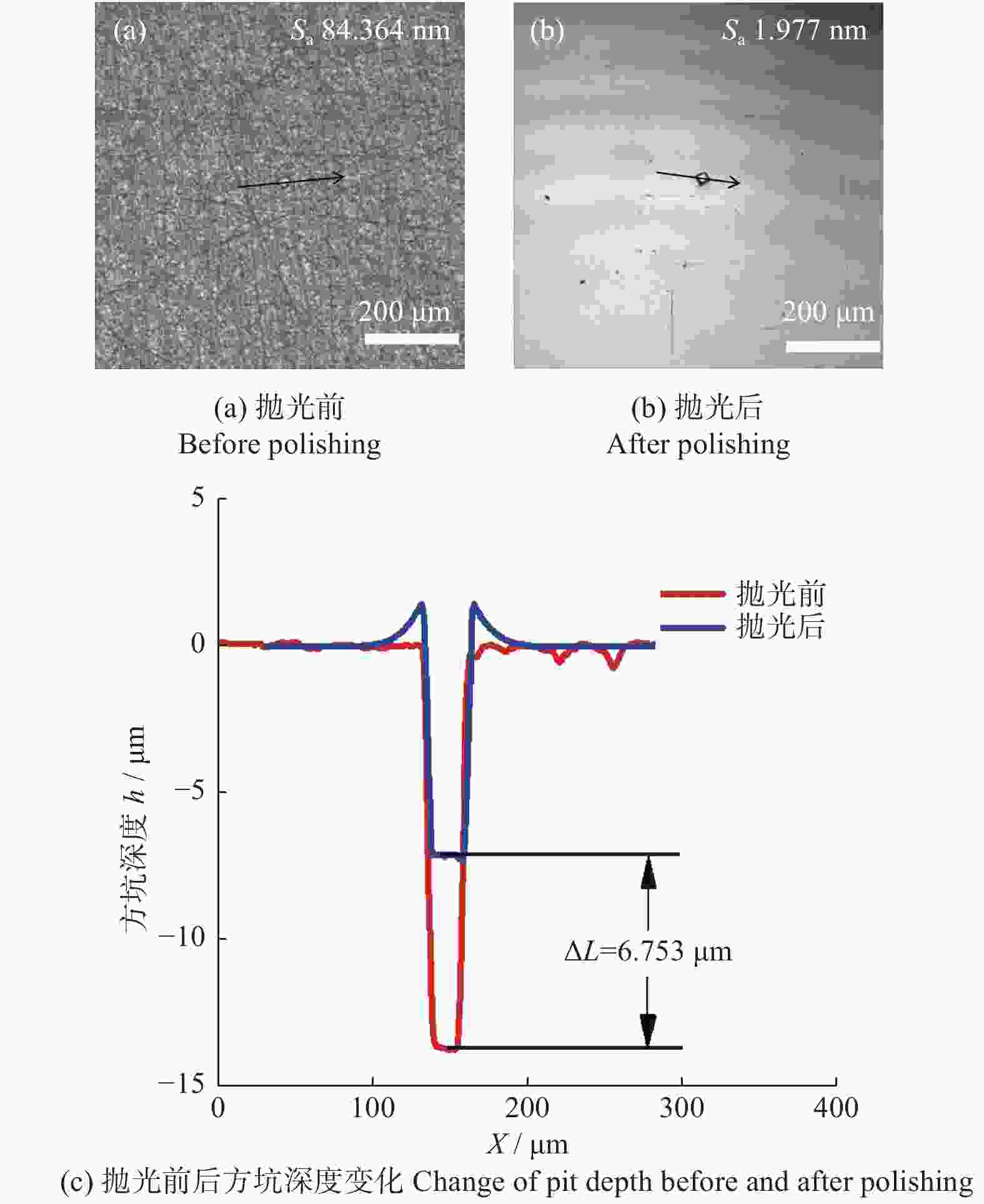

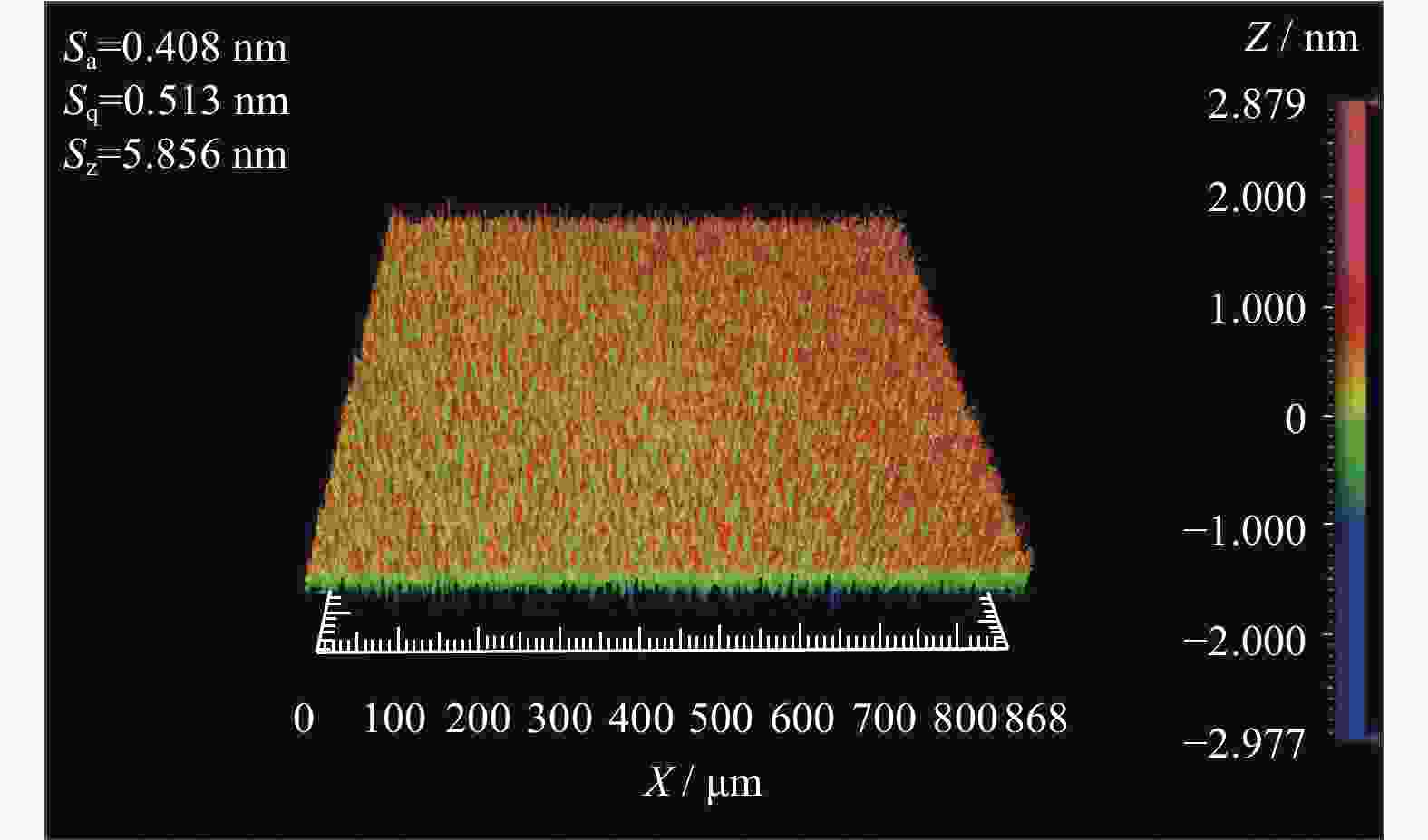

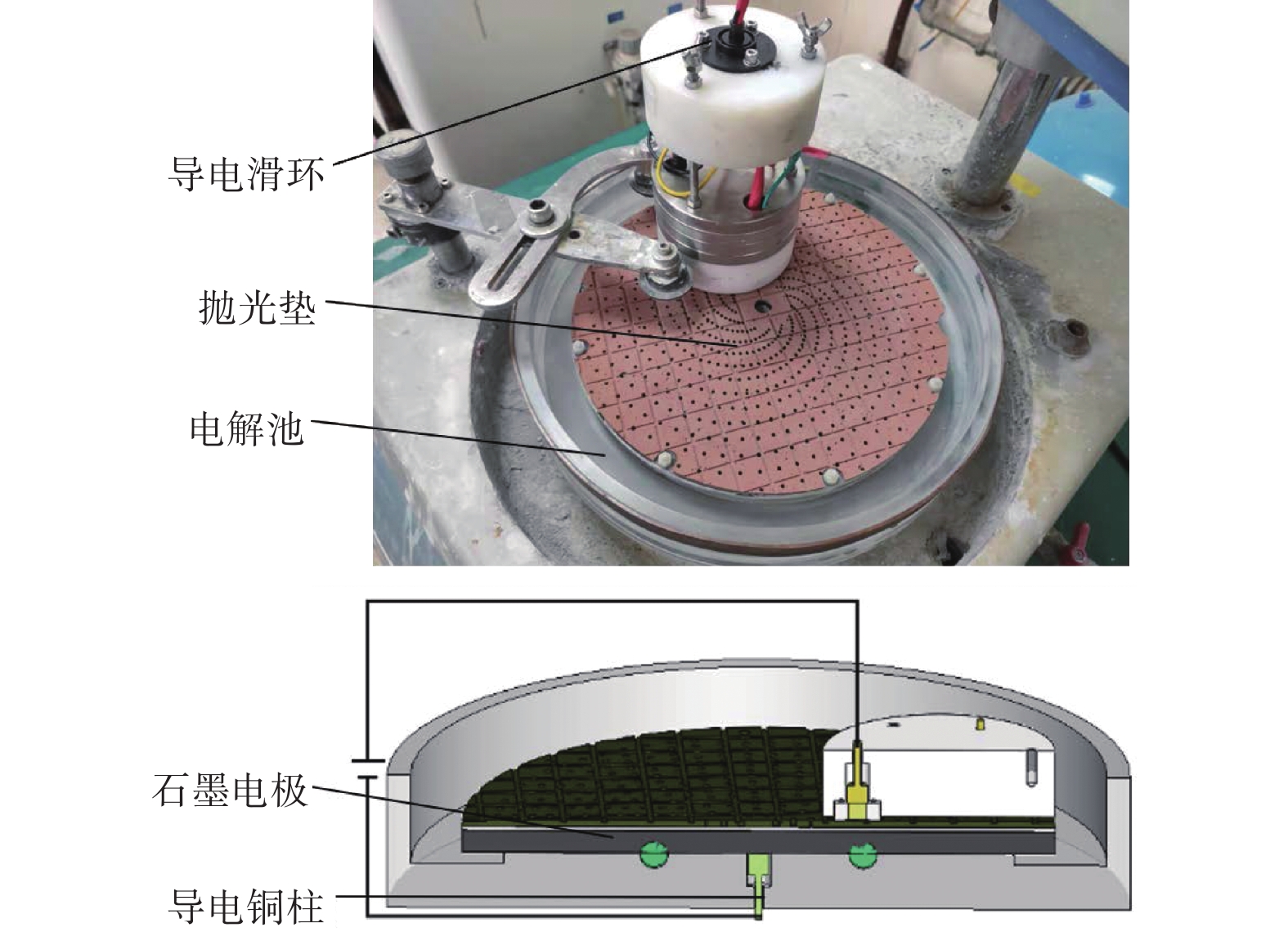

摘要: 针对碳化硅晶体抛光效率低的问题,研究碳化硅晶体的电化学机械抛光工艺,对比NaOH、NaNO3、H3PO4 3种电解液电化学氧化碳化硅晶体的效果。选用0.6 mol/L的NaNO3作为电化学机械抛光过程的电解液,使用金刚石–氧化铝混合磨粒,通过正交试验研究载荷、转速、电压、磨粒粒径对电化学机械抛光碳化硅晶体的表面质量和材料去除率的影响。采用优选的试验参数进行抛光试验,结果表明:在粗抛阶段可实现20.259 μm/h的高效材料去除,在精密抛光阶段可获得碳化硅表面粗糙度Sa为0.408 nm的光滑表面。Abstract: To solve the problem of low polishing efficiency of silicon carbide crystal, electrochemical mechanical polishing (ECMP) of silicon carbide was carried out to study the effect of NaOH, NaNO3 and H3PO4 electrolytes on electrochemical oxidation of silicon carbide. NaNO3 of 0.6 mol/L was selected as the electrolyte in the ECMP process and so were the diamond-alumina mixed abrasive particles. The influence of load, rotational speed, voltage and particle size on the surface quality and material removal rate of ECMP silicon carbide was studied by using orthogonal experiment. With the optimized processing parameters, the combined polishing experiment can achieve a high-efficiency material removal rate of 20.259 μm/h in the rough polishing stage, and finally obtain the surface roughness of Sa 0.408 nm through precision polishing.

-

表 1 正交试验参数表

Table 1. Orthogonal experiment parameter table

水平 A

电压

U / VB

载荷

F / NC

转速

ω / (r·min−1)D

磨粒组合1 5 10 20 Ⅰ 2 10 20 30 Ⅱ 3 15 30 40 Ⅲ 4 20 40 50 Ⅳ 表 2 正交试验设计表

Table 2. Orthogonal experiment design table

试验序号 A B C D 1 5 10 20 Ⅰ 2 5 20 30 Ⅱ 3 5 30 40 Ⅲ 4 5 40 50 Ⅳ 5 10 10 30 Ⅲ 6 10 20 20 Ⅳ 7 10 30 50 Ⅰ 8 10 40 40 Ⅱ 9 15 10 40 Ⅳ 10 15 20 50 Ⅲ 11 15 30 20 Ⅱ 12 15 40 30 Ⅰ 13 20 10 50 Ⅱ 14 20 20 40 Ⅰ 15 20 30 30 Ⅳ 16 20 40 20 Ⅲ 表 3 综合评分结果

Table 3. Comprehensive scoring results

试验

序号材料去除率

dMRR / (μm·h−1)粗糙度

Sa / nm材料去除率

得分Y1表面粗糙度

得分Y21 0.666 0.868 0 90 2 1.419 0.773 10 90 3 9.405 0.616 50 90 4 12.630 1.911 60 60 5 8.866 1.107 40 80 6 13.086 2.849 70 40 7 5.562 1.417 30 70 8 3.312 0.902 20 80 9 19.848 3.468 100 20 10 6.366 0.740 30 90 11 1.962 0.797 10 90 12 0.912 1.425 0 80 13 1.739 0.462 10 100 14 1.860 1.462 10 70 15 16.622 2.031 80 60 16 6.121 0.847 30 90 表 4 粗抛阶段极差分析结果

Table 4. Range analysis results during rough polishing

因素 A B C D K1 162 178 150 94 K2 182 154 166 112 K3 168 198 196 190 K4 168 150 168 284 k1 40.5 44.5 37.5 23.5 k2 45.5 38.5 41.5 28.0 k3 42.0 49.5 49.0 47.5 k4 42.0 37.5 42.0 71.0 极差R 5.0 12.0 11.5 47.5 主次顺序 4 2 3 1 最优水平 2 3 3 4 最优组合 A2B3C3D4 表 5 精抛阶段极差分析结果

Table 5. Range analysis results during precision polishing

因素 A B C D K1 309 276 290 283 K2 259 273 292 330 K3 266 296 252 329 K4 301 290 301 193 k1 77.25 69.00 72.50 70.75 k2 64.75 68.25 73.00 82.50 k3 66.50 74.00 63.00 82.25 k4 75.25 72.50 75.25 48.25 极差R 12.50 5.75 12.25 34.25 主次顺序 2 4 3 1 最优水平 1 3 4 2 最优组合 A1B3C4D2 -

[1] 王守国, 张岩. SiC材料及器件的应用发展前景 [J]. 自然杂志, 2011, 33(1): 42-45, 53.WANG Shouguo, ZHANG Yan. Application and development prospects of SiC materials and devices [J]. Chinese Journal of Nature, 2011, 33(1): 42-45, 53. [2] 何艳. 光催化辅助抛光碳化硅晶片工艺及机理研究 [D]. 沈阳: 沈阳工业大学, 2019.HE Yan. Research on the process and mechanism of photocatalytic assisted polishing of silicon carbide wafers [D]. Shenyang: Shenyang University of Technology, 2019 [3] CHEN G M, NI Z F, XU L J, et al. Performance of colloidal silica and ceria based slurries on CMP of Si-face 6H-SiC substrates [J]. Applied Surface Science, 2015, 359: 664-668. [4] 章平, 陈国美, 倪自丰等. 基于光助芬顿反应的碳化硅化学机械抛光工艺优化 [J]. 表面技术, 2022, 51(7): 253-262.ZHANG Ping, CHEN Guomei, NI Zifeng, et al. Optimization of chemical mechanical polishing of silicon carbide based on photo-assisted Fenton reaction [J]. Surface Technology, 2022, 51(7): 253-262. [5] ZHOU Y, PAN G S, SHI X L, et al. Chemical mechanical planarization (CMP) of on-axis Si-face SiC wafer using catalyst nanoparticles in slurry [J]. Surface and Coatings Technology, 2014, 251: 48-55. [6] LEE H S, KIM D I, AN J H, et al. Hybrid polishing mechanism of single crystal SiC using mixed abrasive slurry (MAS) [J]. CIRP Annals-Manufacturing Technology, 2010, 59(1): 333-336. [7] YANG X, OHKUBO Y, ENDO K, et al. AFM observation of initial oxidation stage of 4H-SiC (0001) in electrochemical mechanical polishing [J]. Procedia CIRP, 2018, 68: 735-740. [8] YANG X, YANG X Z, KAWAI K, et al. Highly efficient planarization of sliced 4H-SiC (0001) wafer by slurryless electrochemical mechanical polishing [J]. International Journal of Machine Tools and Manufacture, 2019, 144: 103431. [9] YANG X, YANG X, SUN R Y, et al. Obtaining atomically smooth 4H-SiC (0001) surface by controlling balance between anodizing and polishing in electrochemical mechanical polishing [J]. Nanomanufacturing and Metrology, 2019, 2(3): 140-147. [10] DENG H, HOSOYA K, IMANISHI Y, et al. Electro-chemical mechanical polishing of single-crystal SiC using CeO2 slurry [J]. Electrochemistry Communications, 2015, 52: 5-8. [11] 周密愉. 铜和碳化硅电化学机械抛光工艺方法研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.ZHOU Miyu. Research on electrochemical mechanical polishing process of copper and silicon carbide [D]. Harbin: Harbin Institute of Technology, 2019. [12] 倪自丰, 陈国美, 徐来军, 等. 不同氧化剂对6H-SiC化学机械抛光的影响 [J]. 机械工程学报, 2018, 54(19): 224-231.NI Zifeng, CHEN Guomei, XU Laijun, et al. Effects of different oxidizers on chemical mechanical polishing of 6H-SiC [J]. Chinese Journal of Mechanical Engineering, 2018, 54(19): 224-231. [13] 林美凤. 铝与酸、碱反应的实验探索及理论研究 [J]. 化学教育, 2001(12): 35-36.LIN Meifeng. Experimental exploration and theoretical research on the reaction of aluminum with acid and base [J]. Chemistry Education, 2001(12): 35-36. [14] 张富林. 高铬不锈钢电化学自催化预处理及切削加工性研究 [D]. 大连: 大连理工大学, 2021.ZHANG Fulin. Electrochemical autocatalytic pretreatment and machinability of high chromium stainless steel [D]. Dalian: Dalian University of Technology, 2021. [15] 贾志军, 马洪运, 吴旭冉, 等. 电化学基础(Ⅴ)——电极过程动力学及电荷传递过程 [J]. 储能科学与技术, 2013, 2(4): 402-409.JIA Zhijun, MA Hongyun, WU Xuran, et al. Fundamentals of electrochemistry (Ⅴ)—Electrochemical kinetic and charge–transfer process for electrochemical reaction [J]. Energy Storage Science and Technology, 2013, 2(4): 402-409. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS