Study on properties of low temperature vitrified bond modified by aluminum powder

-

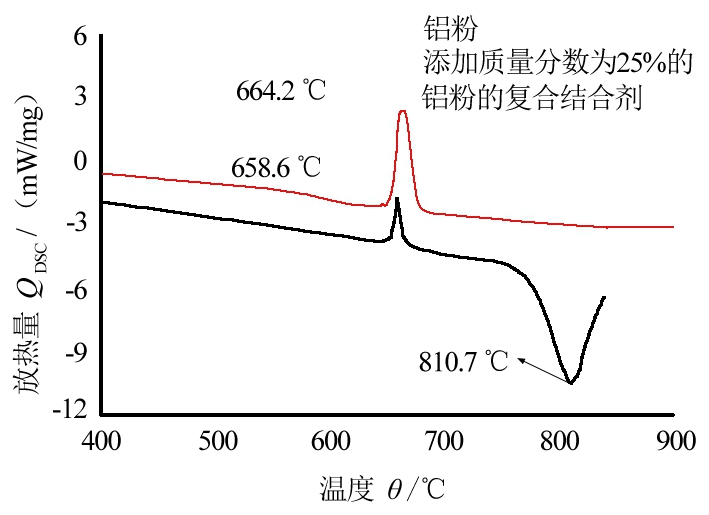

摘要: 为改善低温陶瓷结合剂的不足,采用粉末冶金的方法将铝粉添加到低温陶瓷结合剂中,使用真空热压烧结炉进行烧结,探究铝粉改性低温陶瓷结合剂的力学性能和显微结构。结果表明:当金属铝粉质量分数为20%时,结合剂的抗折强度达到116.32 MPa,比低温陶瓷结合剂抗折强度提高了42%;结合剂的平均抗冲击强度为13.01 kJ/m2,比低温陶瓷结合剂的提高了414%。铝粉的添加对结合剂的密度影响不明显,但随着铝粉质量分数的增加, 结合剂的硬度整体呈下降趋势。铝粉颗粒在低温陶瓷结合剂中均匀分散,并且以金属铝的形态存在,分散性较好,具有颗粒增韧的作用。结合剂中金属相和低温陶瓷结合剂的界面处元素扩散形成过渡带,两者互相融合,且结合情况良好。Abstract: To meliorate the properties of low temperature vitrified bond, aluminum powder was added into the vitrified bond by using powder metallurgy method and the metal-ceramic bond was sintered by vacuum hot pressing sintering furnace.The mechanical properties and microstructure of the vitrified bond modified by aluminum powder were investigated.The results show that the average flexural strength and impact strength of the vitrified bond with mass fraction of 20% aluminum powder are significantly improved to 116.32 MPa and 13.01 kJ/m2, which are 42% and 414% higher than those of low temperature vitrified bond without aluminum powder, respectively.The addition of aluminum powder has no obvious effect on the density of the vitrified bond.As the mass fraction of aluminum powder increases, the hardness of the vitrified bond generally decreases.Aluminum powder particles can exist in the form of metallic aluminum and show good dispersibility in the low temperature vitrified bond, which can improve the toughness.In the metal-ceramic bond, elements diffusion occurs at the interface between the metal phase and low-temperature vitrified bond, forming a transition zone.And the metal phase and low temperature vitrified bond are inlaid with respect to each other, and possess excellent combination.

-

表 1 原材料属性

Table 1. Properties of raw materials

-

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS