Process research on ultrasonic vibration assisted lapping of single crystal silicon carbide

-

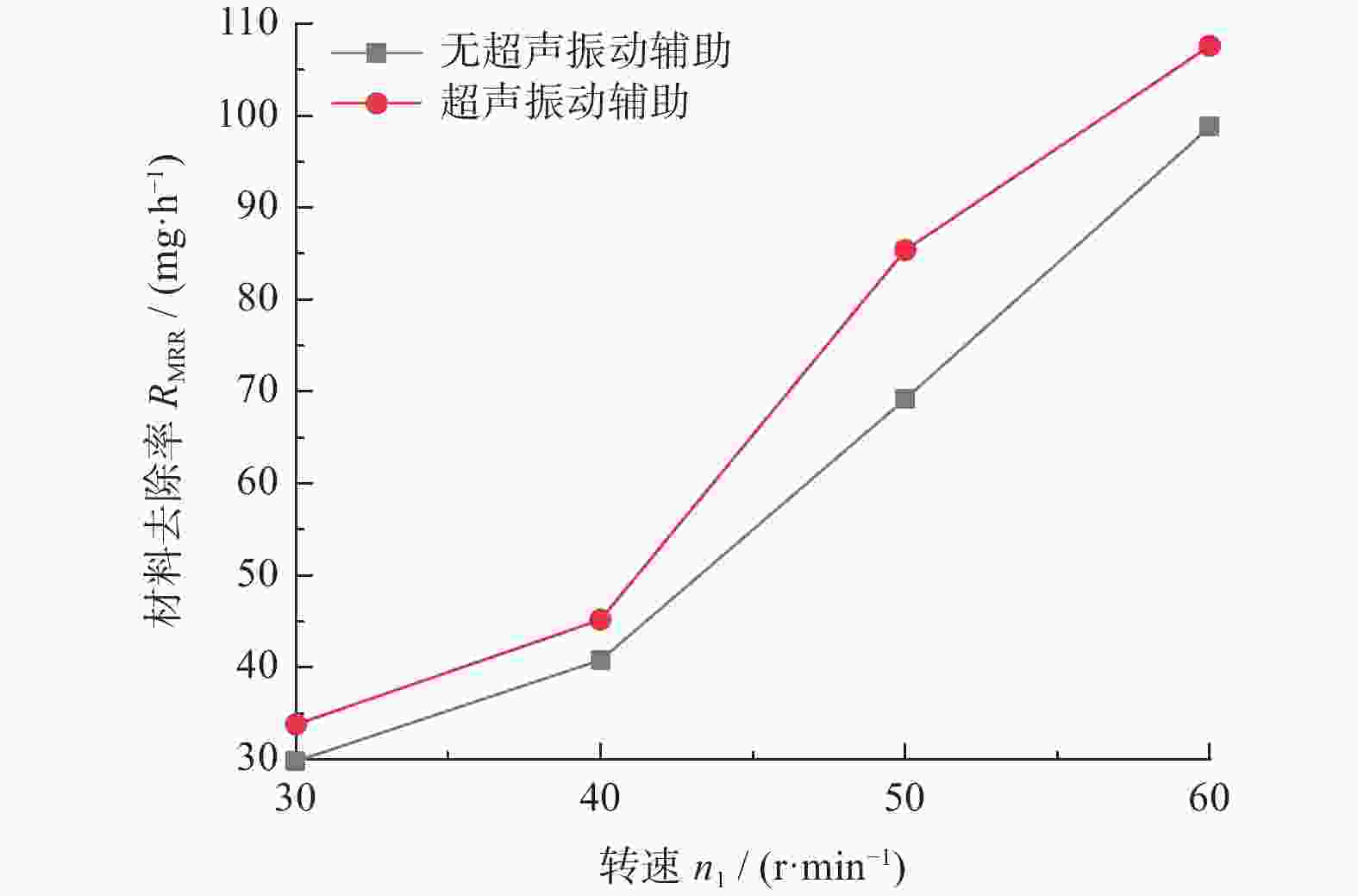

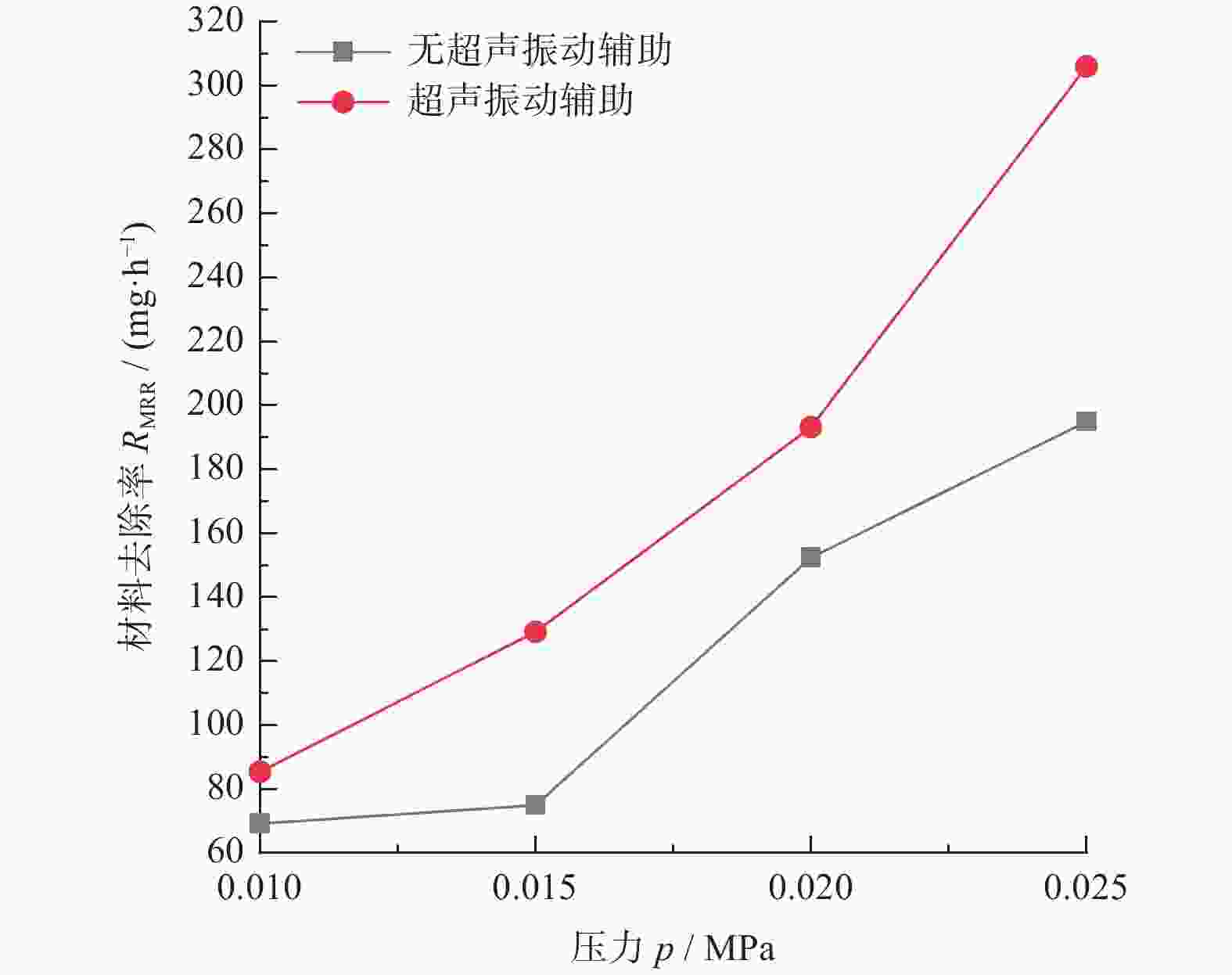

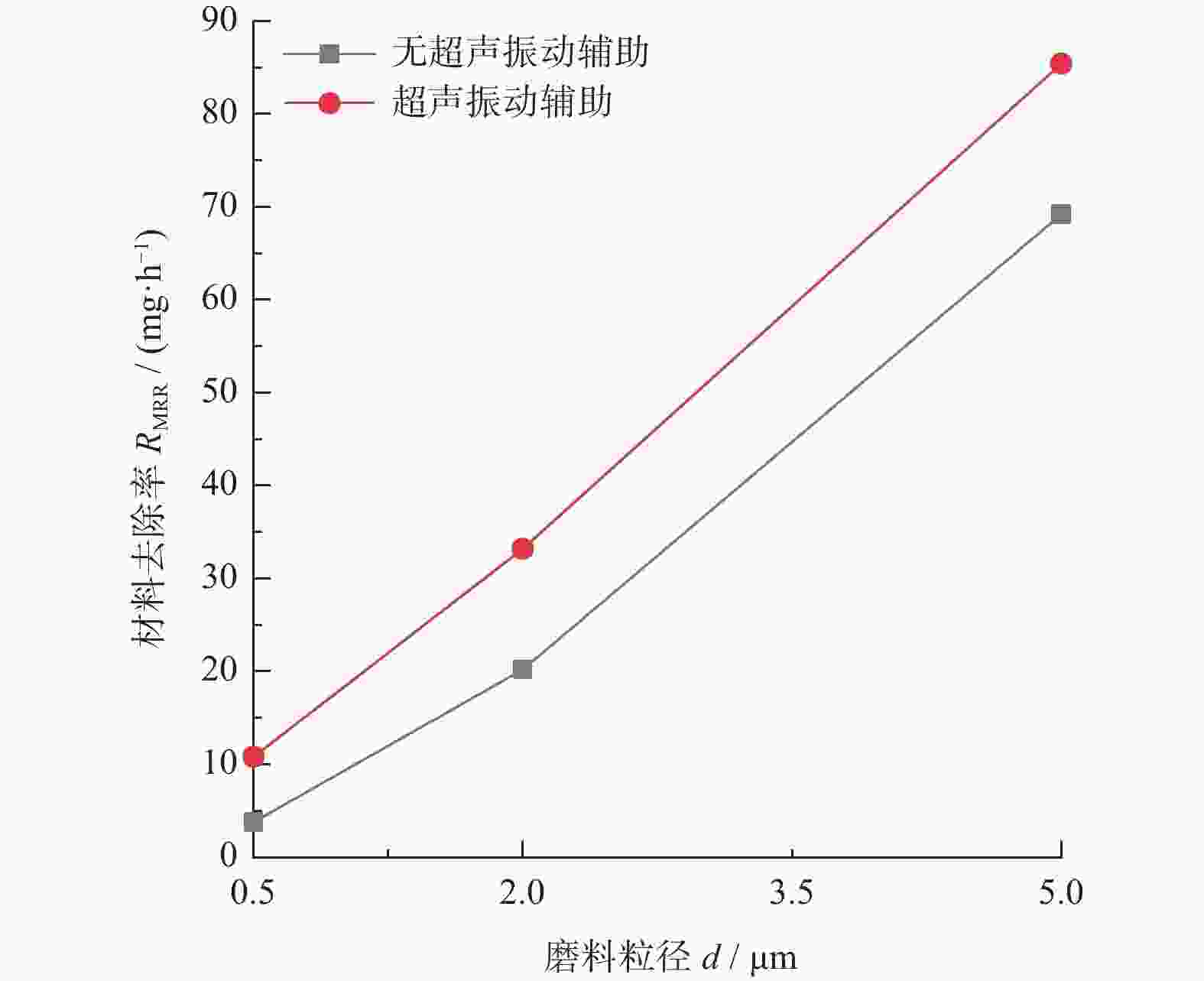

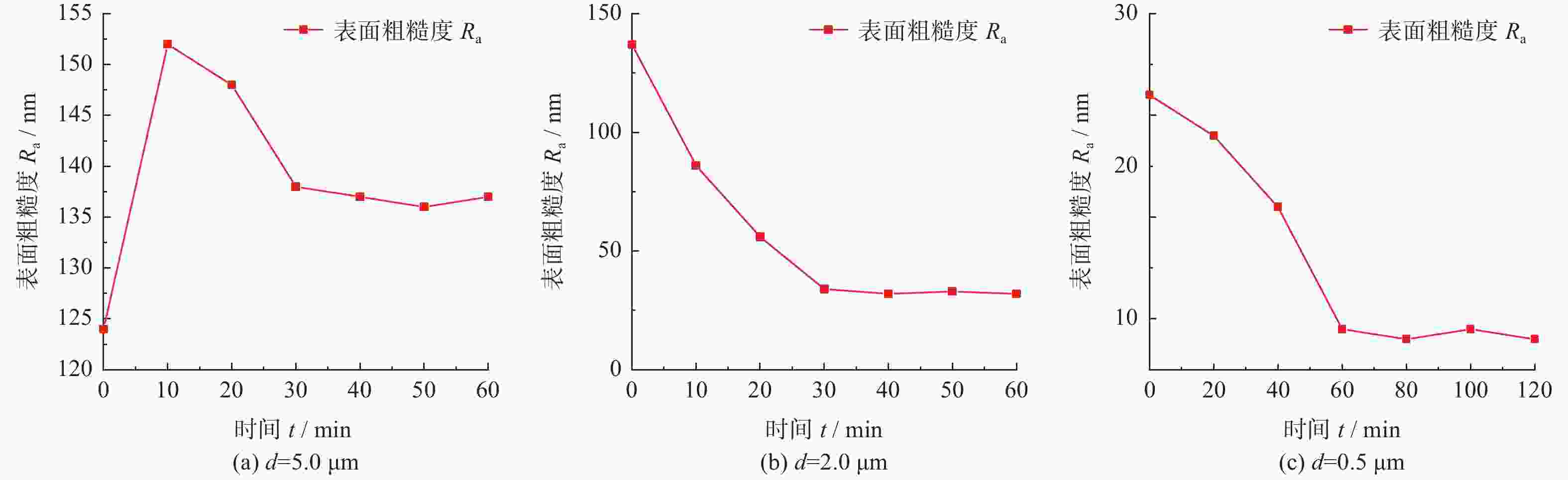

摘要: 针对传统研磨方法加工单晶碳化硅晶片存在的材料去除率低、磨料易团聚等问题,本文提出超声振动辅助研磨方法,并探究不同工艺参数(转速、磨料质量分数、抛光压力、磨料粒径)对单晶碳化硅晶片研磨效率和表面质量的影响规律。试验结果和理论分析表明:超声振动有效提高了单晶碳化硅晶片研磨的材料去除率;在研磨盘转速为50 r/min,磨料质量分数为2.5%,压力为0.015 MPa,磨料粒径为0.5 μm时超声振动对材料去除率的提升效果最明显,分别提升23.4%,33.8%,72.3%,184.2%。同时,通过对研磨过程中表面粗糙度的追踪检测,能确定不同粒径磨料超声振动辅助研磨的最佳时间。Abstract: Aimming at the problems such as low material removal rate and abrasive agglomeration when polishing single crystal silicon carbide wafers with traditional methods, this study proposed a ultrasonic vibration assisted lapping method. It studied the influence of different process parameters including speeds, abrasive concentrations, pressures and abrasive grain sizes on the lapping efficiency and lapping quality of single crystal silicon carbide wafers. The experimental results and theoretical analysis show that ultrasonic vibration effectively improves the material removal rate of single crystal silicon carbide wafer polishing. When the lapping disc speed is 50 r/min, the lapping fluid concentration is 2.5%, the pressure is 0.015 MPa and the abrasive grain size is 0.5 μm, the effect of improving the material removal rate is the most obvious, thus increased by 23.4%, 33.8%, 72.3% and 184.2% respectively. At the same time, by tracking and testing the surface roughness during the lapping process, the best time for ultrasonic vibration-assisted grinding of abrasives with different particle sizes was determined.

-

Key words:

- ultrasonic vibration /

- silicon carbide /

- polishing /

- material removal rate

-

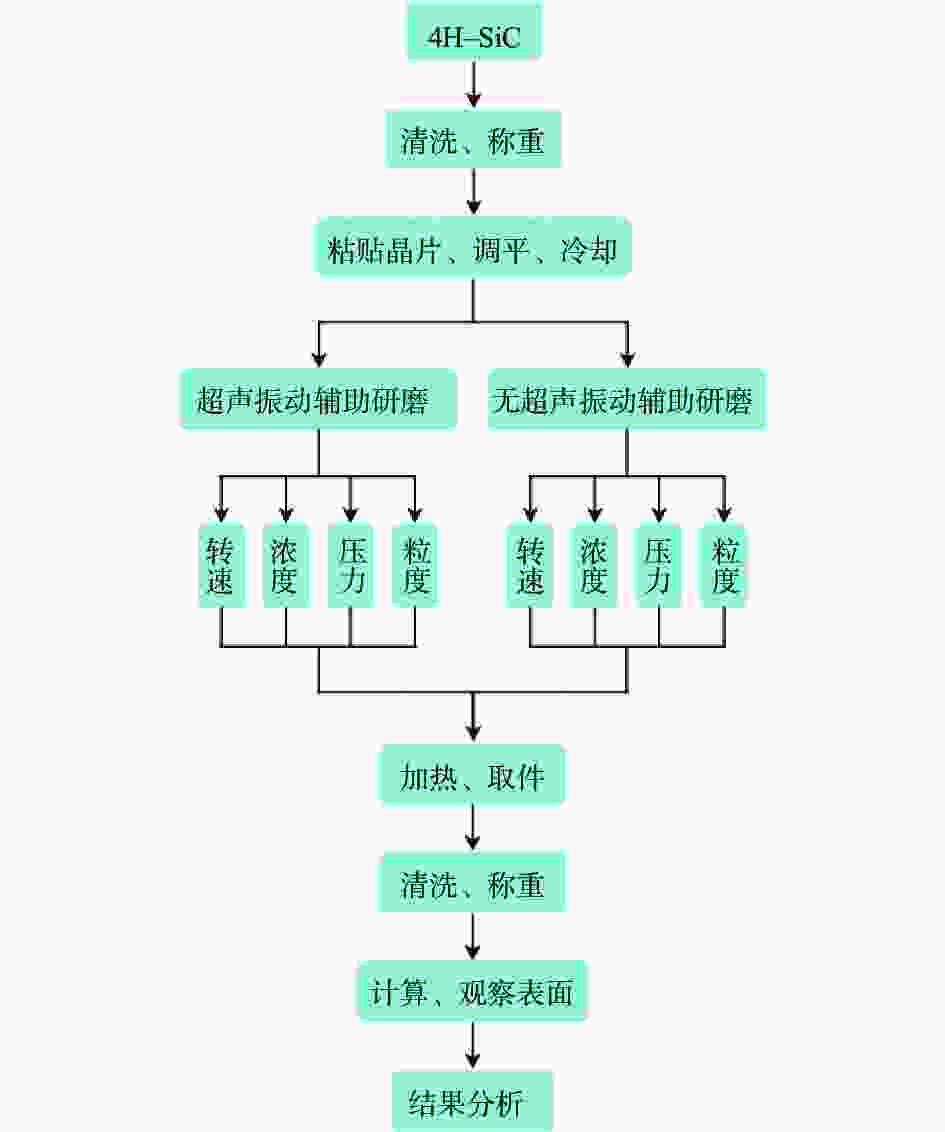

表 1 研磨试验方案

Table 1. Test program of lapping experiment

试验组别 工艺条件 研究变量 变量取值 1 d=5.0 μm,

ω=5.0%,

p=0.010 MPa研磨盘转速

n1 / (r·min−1)30,40,

50,602 d=5.0 μm,

p=0.010 MPa,

n1=50 r/min磨料质量

分数ω/ % 2.5,5.0,

7.5,10.03

ω=5.0%,

n1=50 r/min,d=5.0 μm压力 p / MPa 0.010,0.015,0.020,0.025 4 ω=5.0%,p =0.010 MPa,

n1=50 r/min磨料粒径

d / μm0.5,2.0,5.0 表 2 不同研磨转速下试件研磨前后质量

Table 2. Mass of test pieces before and after grinding at different rotational speeds

研磨盘转速

n1 / (r·min−1)研磨前试件质量

m0 / g研磨后试件质量

m1 / g无超声振

动辅助有超声振

动辅助无超声振

动辅助有超声振

动辅助30 4.563 2 4.582 5 4.548 3 4.565 6 40 4.563 0 4.582 0 4.542 6 4.559 4 50 4.562 7 4.581 7 4.528 1 4.539 0 60 4.563 0 4.582 2 4.513 6 4.528 4 表 3 不同磨料质量分数条件下试件研磨前后质量

Table 3. Mass of test pieces before and after grinding at different abrasive concentrations

磨料质量分数

ω / %研磨前试件质量

m0 / g研磨后试件质量

m1 / g无超声

振动辅助有超声

振动辅助无超声

振动辅助有超声

振动辅助2.5 4.556 7 4.583 2 4.527 1 4.543 6 5.0 4.562 7 4.581 7 4.528 1 4.539 0 7.5 4.564 2 4.582 2 4.525 4 4.534 1 10.0 4.558 3 4.582 0 4.534 5 4.550 3 表 4 不同研磨压力条件下试件研磨前后质量

Table 4. Mass of test pieces before and after grinding at different lapping pressures

压力

p / MPa研磨前试件质量

m0 / g研磨后试件质量

m1 / g无超声

振动辅助有超声

振动辅助无超声

振动辅助有超声

振动辅助0.010 4.562 7 4.5817 4.5281 4.539 0 0.015 4.559 6 4.581 1 4.522 1 4.516 5 0.020 4.558 5 4.579 8 4.482 3 4.483 2 0.025 4.561 3 4.578 3 4.463 8 4.425 3 表 5 不同磨料粒径条件下试件研磨前后质量

Table 5. Mass of test pieces before and after grinding at different grit sizes

磨料粒径

d / μm研磨前试件质量

m0 / g研磨后试件质量

m1 / g无超声

振动辅助有超声

振动辅助无超声

振动辅助有超声

振动辅助5.0 4.562 7 4.5817 4.5281 4.539 0 2.0 4.553 8 4.580 5 4.543 7 4.563 9 0.5 4.561 1 4.578 8 4.559 2 4.573 4 -

[1] 赵敏, 贺文智, 朱昊辰, 等. 碳化硅在能源领域的应用及展望 [J]. 上海节能,2017(10):578-582. doi: 10.13770/j.cnki.issn2095-705x.2017.10.004ZHAO Min, HE Wenzhi, ZHU Haochen, et al. The application and prospect of silicon carbide in the energy field [J]. Shanghai Energy Conservation,2017(10):578-582. doi: 10.13770/j.cnki.issn2095-705x.2017.10.004 [2] 刘宏勋, 徐海. 碳化硅电力电子器件及其在电力电子变压器中的应用 [J]. 科学技术与工程,2020,20(36):14777-14790. doi: 10.3969/j.issn.1671-1815.2020.36.002LIU Hongxun, XU Hai. Silicon carbide power electronic devices and their applications in power electronic transformers [J]. Science Technology and Engineering,2020,20(36):14777-14790. doi: 10.3969/j.issn.1671-1815.2020.36.002 [3] HOROWITZ K, REMO T, REESE S. A manufacturing cost and supply chain analysis of SiC power electronics applicable to medium-voltage motor drives [M]. Golden, CO: Clean Energy Manufacturing Analysis Center, 2017. [4] 朱泓达. 半导体材料在电子科学技术中的应用 [J]. 黑龙江科学,2020,11(10):80-81. doi: 10.3969/j.issn.1674-8646.2020.10.036ZHU Hongda. The application of semiconductor materials in electronic science and technology [J]. Heilongjiang Science,2020,11(10):80-81. doi: 10.3969/j.issn.1674-8646.2020.10.036 [5] SHE X, HUANG A Q, LUCIA O, et al. Review of silicon carbide power devices and their applications [J]. IEEE Transactions on Industrial Electronics,2017(10):1. [6] AIDA H, DOI T, TAKEDA H, et al. Ultraprecision CMP for sapphire, GaN, and SiC for advanced optoelectronics materials [J]. Current Applied Physics,2012,12(9):S41-S46. [7] 翟文杰, 高博. 单晶SiC的化学机械抛光及其增效技术研究进展 [J]. 哈尔滨工业大学学报,2018,50(7):1-10. doi: 10.11918/j.issn.0367-6234.201803130ZHAI Wenjie, GAO Bo. Research progress of chemical mechanical polishing of single crystal SiC and its synergistic technology [J]. Journal of Harbin Institute of Technology,2018,50(7):1-10. doi: 10.11918/j.issn.0367-6234.201803130 [8] 麦玉冰, 谢欣荣. 第三代半导体材料碳化硅(SiC)研究进展 [J]. 广东化工,2021,48(9):151-152,155.MAI Yubing, XIE Xinrong. The Research progress of the third generation semiconductor material silicon carbide (SiC) [J]. Guangdong Chemical Industry,2021,48(9):151-152,155. [9] 韩润龙. 第三代半导体材料SiC平坦化技术的研究现状 [J]. 技术应用与研究,2018(11):73-75.HAN Runlong. Research status of the third-generation semiconductor material SiC planarization technology [J]. Technology Application and Research,2018(11):73-75. [10] 李伟. SiC晶片精密研磨工艺及其表面损伤研究 [D]. 广州: 广东工业大学, 2013.LI Wei. Research on the precision grinding process and surface damage of SiC wafers [D]. Guangzhou: Guangdong University of Technology, 2013. [11] LEE T, KIM H, LEE S, et al. Self-dressing effect using a fixed abrasive platen for single-sided lapping of sapphire substrate [J]. Journal of Mechanical Science and Technology,2017,31(12):5649-5655. doi: 10.1007/s12206-017-1105-1 [12] PARK K H, KIM K T, HONG Y H, et al. Study on effect of ultrasonic vibration in machining of alumina ceramic [J]. Key Engineering Materials,2012,516:311-316. doi: 10.4028/www.scientific.net/KEM.516.311 [13] 赵明利, 赵波, 高国富. 超精密研抛及超声波研抛技术分析 [J]. 现代机械,2006(6):50-53. doi: 10.3969/j.issn.1002-6886.2006.06.021ZHAO Mingli, ZHAO Bo, GAO Guofu. Ultra-precision polishing and ultrasonic polishing technology analysis [J]. Modern Machinery,2006(6):50-53. doi: 10.3969/j.issn.1002-6886.2006.06.021 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS